Sharp MX-5500N / MX-6200N / MX-7000N (serv.man22) Peripheral ▷ View online

MX-FNX4 SELF DIAG MESSAGE AND TROUBLE CODE 10 – 1

MX-FNX4

Service Manual

[10] SELF DIAG MESSAGE AND TROUBLE CODE

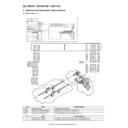

1. Self diagnosis

A. Finisher/Saddle finisher

B. Punch module (option)

Error

Condition

Timing of detection

Operation

Resetting

Stapler absent

The stapler is not set.

Monitoring at all times

Normal operation will continue; however,

operation is subject to instructions from the

host machine.

operation is subject to instructions from the

host machine.

Replace the staple cartridge;

or set it correctly.

or set it correctly.

Activated stapler

safety interlock

safety interlock

The stapler safety interlock is

activated.

activated.

When the staple

operation is started.

operation is started.

Operation of staple motor (FFSM) is

prohibited.

prohibited.

Delivery stack sheets without

stapling.

stapling.

Stack tray

overstacking

overstacking

The number of sheets deposited

on the delivery tray has exceeded

the limit imposed on the tray.

on the delivery tray has exceeded

the limit imposed on the tray.

When an extra sheet

is discharged.

is discharged.

Normal operation will continue.

Remove the sheets from the

delivery tray.

delivery tray.

Stapler jam

Staple edge cannot be aligned

correctly.

correctly.

During staple edge

aligning operation

aligning operation

Normal operation will continue; however,

operation is subject to instructions from the

host machine.

operation is subject to instructions from the

host machine.

Replace the staple cartridge,

and execute the staple edge

alignment again.

and execute the staple edge

alignment again.

Partially no stapler

in the saddle

stitcher unit

in the saddle

stitcher unit

No stapler in the stapler cartridge.

Monitoring at all times

Normal operation will continue; however,

operation is subject to instructions from the

host machine.

operation is subject to instructions from the

host machine.

Replace the staple cartridge;

or set it correctly.

or set it correctly.

Mixed sheets in

saddle stitcher unit

saddle stitcher unit

Sheets of different sizes are

deposited in the compartment.

deposited in the compartment.

When a sheet of a

different size is

placed.

different size is

placed.

Stitch operation is prohibited. Alignment is

prohibited.

prohibited.

Remove the sheets from the

compartment.

compartment.

Saddle stitcher

overstacking

overstacking

The number of sheets deposited

on the delivery tray has exceeded

the limit imposed on the tray.

on the delivery tray has exceeded

the limit imposed on the tray.

When an extra sheet

is discharged.

is discharged.

Normal operation will continue.

Remove the sheets from the

delivery tray.

delivery tray.

Excessive stitch

capacity in the

saddle stitcher unit

capacity in the

saddle stitcher unit

The number of sheets in the

compartment has exceeded 15.

compartment has exceeded 15.

When an extra sheet

is placed.

is placed.

Stitch operation is prohibited.

Remove the sheets from the

compartment.

compartment.

Error

Condition

Timing of detection

Operation

Resetting

Waste case full

The amount of waste paper in the

waste case has reached the limit.

waste case has reached the limit.

During punching

Normal operation will continue.

Remove the waste paper

from the waste case.

from the waste case.

Excess waste

The amount of waste paper in the

waste case has exceeded the

limit.

waste case has exceeded the

limit.

During punching

Punching is prohibited.

Remove the waste paper

from the waste case.

from the waste case.

MX-FNX4 SELF DIAG MESSAGE AND TROUBLE CODE 10 – 2

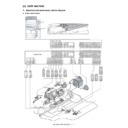

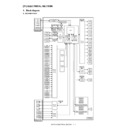

2. Trouble code

A. Outline

The CPU on the machine’s finisher control PCB is equipped with a

mechanism to check the machine condition as needed; when it

detects a fault, the machine sends the trouble contents to the host

machine in the form of a code and a detail code.

mechanism to check the machine condition as needed; when it

detects a fault, the machine sends the trouble contents to the host

machine in the form of a code and a detail code.

B. Trouble code

(1) Finisher unit

F1-00

Finisher communication trouble

(Machine side detection)

F1-03

Finisher oscillation motor trouble

F1-08

Finisher stapler shift motor trouble

F1-10

Finisher staple motor abnormality

F1-15

Finisher tray lift motor abnormality

F1-19

Finisher pre-alignment motor abnor-

mality

mality

F1-20

Finisher after-alignment motor abnor-

mality

mality

F1-21

Finisher interface fan motor abnormal-

ity

ity

F1-22

Finisher rear edge assist motor trou-

ble

ble

F1-23

Shutter trouble

Trouble content

Communication line test error when turning on the

power or after canceling an exclusion simulation.

Communication error with the finisher

power or after canceling an exclusion simulation.

Communication error with the finisher

Section

PCU

Case 1

Cause

Malfunction due to electrical noises

Check

and

Remedy

and

Remedy

Turn OFF/ON the power to cancel.

Case 2

Cause

PCU finisher connector or harness connection error

or disconnection

or disconnection

Check

and

Remedy

and

Remedy

Check the connector and harness in the

communication line.

communication line.

Case 3

Cause

Finisher control PWB trouble

Check

and

Remedy

and

Remedy

Replace the finisher control PWB.

Case 4

Cause

Control (PCU) PWB trouble

Check

and

Remedy

and

Remedy

Replace the PCU PWB.

Trouble content

Oscillation motor operation abnormality

Section

PCU

Case 1

Cause

Motor lock, motor RPM abnormality, motor

overvoltage, finisher control PWB trouble

overvoltage, finisher control PWB trouble

Check

and

Remedy

and

Remedy

Use SIM3-3 to check the operation of the motor

(FSWM).

Replace the finisher control PWB.

(FSWM).

Replace the finisher control PWB.

Trouble content

Stapler shift motor operation abnormality

Section

PCU

Case 1

Cause

Motor lock, motor RPM abnormality, motor

overvoltage, finisher control PWB trouble

overvoltage, finisher control PWB trouble

Check

and

Remedy

and

Remedy

Use SIM3-3 to check the operation of the staple

motor (FSM).

Replace the finisher control PWB.

motor (FSM).

Replace the finisher control PWB.

Trouble content

Staple operation trouble

Section

PCU

Case 1

Cause

Motor lock, motor RPM abnormality, motor

overvoltage, finisher control PWB trouble

overvoltage, finisher control PWB trouble

Check

and

Remedy

and

Remedy

Use SIM3-3 to check the operation of the staple

motor (FFSM).

Replace the finisher control PWB.

motor (FFSM).

Replace the finisher control PWB.

Trouble content

Lift motor trouble

Section

PCU

Case 1

Cause

Motor lock, motor RPM abnormality, motor

overvoltage, finisher control PWB trouble

overvoltage, finisher control PWB trouble

Check

and

Remedy

and

Remedy

Use SIM3-3 to check the operation of the tray lift

motor (FTLM).

Replace the finisher control PWB.

motor (FTLM).

Replace the finisher control PWB.

Case 2

Cause

Interlock switch (black bar-shape switch under the

upper tray) operation

upper tray) operation

Check

and

Remedy

and

Remedy

Check that there is nothing on the interlock switch.

If there is, remove it.

If there is, remove it.

Trouble content

Pre-alignment motor trouble

Section

PCU

Case 1

Cause

Motor lock, motor RPM abnormality, motor

overvoltage, finisher control PWB trouble

overvoltage, finisher control PWB trouble

Check

and

Remedy

and

Remedy

Use SIM3-3 to check the operation of the

prealignment motor (FFJM).

Replace the finisher control PWB.

prealignment motor (FFJM).

Replace the finisher control PWB.

Trouble content

After-alignment motor trouble

Section

PCU

Case 1

Cause

Motor lock, motor RPM abnormality, motor

overvoltage, finisher control PWB trouble

overvoltage, finisher control PWB trouble

Check

and

Remedy

and

Remedy

Use SIM3-3 to check the operation of the

afteralignment motor (FRJM).

Replace the finisher control PWB.

afteralignment motor (FRJM).

Replace the finisher control PWB.

Trouble content

Interface transport fan motor trouble

Section

PCU

Case 1

Cause

Motor lock, motor RPM abnormality, motor

overvoltage, finisher control PWB trouble

overvoltage, finisher control PWB trouble

Check

and

Remedy

and

Remedy

Use SIM3-3 to check the operation of the fan motor

(FJFM).

Replace the finisher control PWB.

(FJFM).

Replace the finisher control PWB.

Trouble content

Rear edge assist motor operation trouble

Section

PCU

Case 1

Cause

Motor trouble, HP sensor trouble, harness

disconnection, finisher control PWB trouble

disconnection, finisher control PWB trouble

Check

and

Remedy

and

Remedy

Use SIM3-3 to check the operation of the rear edge

assist motor.

Replace the finisher control PWB.

assist motor.

Replace the finisher control PWB.

Trouble content

Shutter operation trouble

Section

PCU

Case 1

Cause

Motor trouble, HP sensor trouble, harness

disconnection, finisher control PWB trouble

disconnection, finisher control PWB trouble

Check

and

Remedy

and

Remedy

Use SIM3-3 to check the operation of the bundle

paper exit motor.

Replace the finisher control PWB.

paper exit motor.

Replace the finisher control PWB.

MX-FNX4 SELF DIAG MESSAGE AND TROUBLE CODE 10 – 3

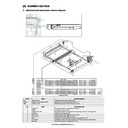

F1-30

Communication trouble between the

finisher and the saddle

finisher and the saddle

F1-31

Finisher folding motor trouble

F1-41

Positioning plate motor trouble

F1-42

Guide motor trouble

F1-43

Side alignment motor trouble

F1-44

Stitch motor rear trouble

F1-45

Stitch motor front trouble

F1-46

Paper pushing motor trouble

F1-50

Finisher incompatibility trouble

F1-51

Sensor connector connection trouble

F1-52

Micro SW trouble

F1-60

Communication trouble between the

finisher and the inserter

finisher and the inserter

Trouble content

Communication error between the finisher and the

saddle unit

saddle unit

Section

PCU

Case 1

Cause

Malfunction due to electrical noises.

Check

and

Remedy

and

Remedy

Turn ON/OFF the power to cancel the error.

Case 2

Cause

Connection trouble or disconnection of the connector

and the harness between the finisher and the saddle

unit.

and the harness between the finisher and the saddle

unit.

Check

and

Remedy

and

Remedy

Check the connector and harness in the

communication line.

communication line.

Case 3

Cause

Finisher control PWB trouble. Saddle control PWB

trouble.

trouble.

Check

and

Remedy

and

Remedy

Replace the finisher control PWB. Replace the

saddle control PWB.

saddle control PWB.

Trouble content

Sensor input value abnormality

Section

PCU

Case 1

Cause

Sensor breakage, harness disconnection, finisher

control PWB trouble

control PWB trouble

Check

and

Remedy

and

Remedy

Use SIM3-2 to check the operation of the

bookbinding position sensor (FFPD).

Replace the finisher control PWB.

bookbinding position sensor (FFPD).

Replace the finisher control PWB.

Trouble content

Positioning plate motor operation trouble

Section

PCU

Case 1

Cause

Motor trouble, HP sensor trouble, harness

disconnection, finisher control PWB trouble

disconnection, finisher control PWB trouble

Check

and

Remedy

and

Remedy

Use SIM3-3 to check the operation of the paper

positioning plate motor.

Replace the finisher control PWB.

positioning plate motor.

Replace the finisher control PWB.

Trouble content

Guide motor operation trouble

Section

PCU

Case 1

Cause

Motor trouble, HP sensor trouble, harness

disconnection, finisher control PWB trouble

disconnection, finisher control PWB trouble

Check

and

Remedy

and

Remedy

Use SIM3-3 to check the operation of the guide

motor.

Replace the finisher control PWB.

motor.

Replace the finisher control PWB.

Trouble content

Side alignment motor operation trouble

Section

PCU

Case 1

Cause

Motor trouble, HP sensor trouble, harness

disconnection, finisher control PWB trouble

disconnection, finisher control PWB trouble

Check

and

Remedy

and

Remedy

Use SIM3-3 to check the operation of the alignment

motor.

Replace the finisher control PWB.

motor.

Replace the finisher control PWB.

Trouble content

Rear stitch motor operation trouble

Section

PCU

Case 1

Cause

Motor trouble, HP sensor trouble, harness

disconnection, finisher control PWB trouble

disconnection, finisher control PWB trouble

Check

and

Remedy

and

Remedy

Use SIM3-3 to check the operation of the rear stitch

motor.

Replace the finisher control PWB.

motor.

Replace the finisher control PWB.

Trouble content

Front stitch motor operation trouble

Section

PCU

Case 1

Cause

Motor trouble, HP sensor trouble, harness

disconnection, finisher control PWB trouble

disconnection, finisher control PWB trouble

Check

and

Remedy

and

Remedy

Use SIM3-3 to check the operation of the front stitch

motor.

Replace the finisher control PWB.

motor.

Replace the finisher control PWB.

Trouble content

Paper pushing motor operation trouble

Section

PCU

Case 1

Cause

Motor trouble, HP sensor trouble, harness

disconnection, finisher control PWB trouble

disconnection, finisher control PWB trouble

Check

and

Remedy

and

Remedy

Use SIM3-3 to check the operation of the paper

pushing motor.

Replace the finisher control PWB.

pushing motor.

Replace the finisher control PWB.

Trouble content

Detection of finisher incompatible with MX-5500N/

6200N/7000N

6200N/7000N

Section

PCU

Case 1

Cause

Connection of the AR-F13, etc. which is incompatible

with MX-5500N/6200N/7000N is detected.

with MX-5500N/6200N/7000N is detected.

Check

and

Remedy

and

Remedy

Connect the MX-FNX3/MX-FNX4.

Trouble content

Sensor operation trouble

Section

PCU

Case 1

Cause

Sensor trouble, harness disconnection, finisher

control PWB trouble

control PWB trouble

Check

and

Remedy

and

Remedy

Use SIM3-2 to check the operation of the guide HP

sensor, the paper pushing plate HP sensor, and the

paper pushing plate lead edge sensor.

Replace the finisher control PWB.

sensor, the paper pushing plate HP sensor, and the

paper pushing plate lead edge sensor.

Replace the finisher control PWB.

Trouble content

Micro SW operation trouble

Section

PCU

Case 1

Cause

Sensor trouble, harness disconnection, finisher

control PWB trouble

control PWB trouble

Check

and

Remedy

and

Remedy

Use SIM3-2 to check the operation of the inlet port

cover open/close sensor and the paper exit cover

open/close sensor.

Replace the finisher control PWB.

cover open/close sensor and the paper exit cover

open/close sensor.

Replace the finisher control PWB.

Trouble content

Communication error between the finisher and the

inserter

inserter

Section

PCU

Case 1

Cause

Malfunction due to electrical noises.

Check

and

Remedy

and

Remedy

Turn ON/OFF the power to cancel the error.

Case 2

Cause

Connection trouble or disconnection of the connector

and the harness between the finisher and the

inserter. Finisher control PWB trouble, inserter

control PWB trouble

and the harness between the finisher and the

inserter. Finisher control PWB trouble, inserter

control PWB trouble

Check

and

Remedy

and

Remedy

Check the connector and the harness in the

communication line. Replace the finisher control

PWB. Replace the inserter control PWB.

communication line. Replace the finisher control

PWB. Replace the inserter control PWB.

MX-FNX4 SELF DIAG MESSAGE AND TROUBLE CODE 10 – 4

F1-61

Inserter EEPROM trouble

F1-62

Inserter reverse sensor trouble

(2) Punch module

F1-32

Communication trouble between the

finisher and the punch unit

finisher and the punch unit

F1-33

Finisher punch shift motor trouble

F1-34

Finisher punch motor trouble

F1-37

Finisher backup RAM trouble

F1-38

Finisher punch backup RAM trouble

Trouble content

EEPROM trouble

Section

PCU

Case 1

Cause

EEPROM trouble, finisher control PWB trouble,

inserter control PWB trouble

inserter control PWB trouble

Check

and

Remedy

and

Remedy

Replace the finisher control PWB.

Replace the inserter control PWB.

Replace the inserter control PWB.

Trouble content

Sensor adjustment failure

Section

PCU

Case 1

Cause

Sensor trouble, harness disconnection, finisher

control PWB trouble, inserter control PWB trouble

control PWB trouble, inserter control PWB trouble

Check

and

Remedy

and

Remedy

Use SIM3-2 to check the operation of the inlet port

cover open/close sensor and the paper exit cover

open/close sensor.

Replace the finisher control PWB.

Replace the inserter control PWB.

cover open/close sensor and the paper exit cover

open/close sensor.

Replace the finisher control PWB.

Replace the inserter control PWB.

Trouble content

Finisher and punch unit communication error

Section

PCU

Case 1

Cause

Malfunction due to electrical noises

Check

and

Remedy

and

Remedy

Cancel by turning OFF/ON the power.

Case 2

Cause

Connector/harness connection error or disconnection

between the finisher and the punch unit

between the finisher and the punch unit

Check

and

Remedy

and

Remedy

Check the connector and the harness in the

communication line.

communication line.

Case 3

Cause

Finisher control PWB trouble

Check

and

Remedy

and

Remedy

Replace the finisher control PWB.

Case 4

Cause

Control (PCU) PWB trouble

Check

and

Remedy

and

Remedy

Replace the control (PCU) PWB

Trouble content

Punch shift motor operation abnormality

Section

PCU

Case 1

Cause

Motor lock, motor RPM abnormality, motor

overvoltage, finisher control PWB trouble, punch

control PWB trouble

overvoltage, finisher control PWB trouble, punch

control PWB trouble

Check

and

Remedy

and

Remedy

Use SIM3-3 to check the operation of the punch shift

motor (FPSM).

Replace the finisher punch unit (Replace the punch

control PWB.).

motor (FPSM).

Replace the finisher punch unit (Replace the punch

control PWB.).

Trouble content

Punch motor operation abnormality

Section

PCU

Case 1

Cause

Motor lock, motor RPM abnormality, motor

overvoltage, finisher control PWB trouble, punch

control PWB trouble

overvoltage, finisher control PWB trouble, punch

control PWB trouble

Check

and

Remedy

and

Remedy

Use SIM3-3 to check the operation of the punch

motor (FPNW).

Replace the finisher punch unit (Replace the punch

control PWB.).

motor (FPNW).

Replace the finisher punch unit (Replace the punch

control PWB.).

Trouble content

Backup RAM data garbled

Section

PCU

Case 1

Cause

Finisher control PWB trouble, malfunction due to

electrical noises

electrical noises

Check

and

Remedy

and

Remedy

Replace the finisher control PWB.

Trouble content

Punch unit backup RAM data garbled

Section

PCU

Case 1

Cause

Punch control PWB trouble, malfunction due to

electrical noises

electrical noises

Check

and

Remedy

and

Remedy

Replace the punch control PWB.

Display