Sharp MX-5500N / MX-6200N / MX-7000N (serv.man45) Service Manual ▷ View online

MX-7000N ADJUSTMENTS 6 – 1

MX-7000N

Service Manual

[6] ADJUSTMENTS

1. General

Each adjustment item in the adjustment item list is associated with

a specific Job number. Perform the adjustment procedures in the

sequence of Job numbers from the smallest to the greatest.

However, there is no need to perform all the adjustment items. Per-

form only the necessary adjustments according to the need.

a specific Job number. Perform the adjustment procedures in the

sequence of Job numbers from the smallest to the greatest.

However, there is no need to perform all the adjustment items. Per-

form only the necessary adjustments according to the need.

Unnecessary adjustments can be omitted. Even in this case, how-

ever, the sequence from the smallest to the greatest Job number

must be observed.

If the above precaution should be neglected, the adjustment would

not complete normally or trouble may occur.

ever, the sequence from the smallest to the greatest Job number

must be observed.

If the above precaution should be neglected, the adjustment would

not complete normally or trouble may occur.

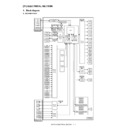

2. Adjustment item list

Job No.

Adjustment item list

Simulation

ADJ 1

Developing doctor gap adjustment (For color)

ADJ 2

Developing roller main pole position adjustment (For color)

ADJ 3

Developing doctor gap adjustment (For black)

ADJ 4

Developing roller main pole position adjustment (For black)

ADJ 5

Toner density control reference value setting

25-2

ADJ 6

High voltage adjustments

6A

Main charger grid voltage adjustment

8-2

6B

Developing bias voltage adjustment

8-1

6C

Transfer voltage adjustment

8-6

ADJ 7

Image density sensor, image

registration sensor adjustment

registration sensor adjustment

7A

Color image density sensor calibration

44-13

7B

Color image density sensor, black image density sensor, image registration sensor

adjustment

adjustment

44-2

ADJ 8

Image skew adjustment (LSU (writing) unit)

61-4

ADJ 9

OPC drum phase adjustment (Auto adjustment)

50-22

ADJ 10

Print engine image magnification ratio adjustment (BK) (Main scanning direction) (Print engine section) (Manual adjustment)

50-10

ADJ 11

Image off-center adjustment (Print engine section)

50-10

ADJ 12

Image registration adjustment

(Print engine section)

(Print engine section)

12A

Image registration adjustment (Main scanning direction, sub scanning direction)

(Auto adjustment)

(Auto adjustment)

50-22

12B

Image registration adjustment (Main scanning direction) (Manual adjustment)

50-20

12C

Image registration adjustment (Sub scanning direction) (Manual adjustment)

50-21

ADJ 13

Scan image distortion adjustment

13A

Scanner (reading) unit parallelism adjustment

13B

Scan image (sub scanning direction) distortion adjustment

13C

Scan image (main scanning direction) distortion adjustment

13D

Scan image distortion adjustment (Whole scanner)

ADJ 14

Scan image focus adjustment

(CCD unit position adjustment)

(CCD unit position adjustment)

14A

Scan image focus adjustment (Document table mode, DSPF front surface mode)

48-1

14B

Scan image focus adjustment (DSPF back surface mode)

ADJ 15

DSPF parallelism adjustment

15A

DSPF levelness adjustment

15B

DSPF skew adjustment (Front surface mode)

64-1

15C

DSPF skew adjustment (Back surface mode)

64-1

ADJ 16

Scan image magnification ratio

adjustment (Document table mode,

DSPF front surface mode)

adjustment (Document table mode,

DSPF front surface mode)

16A

Scan image magnification ratio adjustment (Main scanning direction)

(Document table mode, DSPF front surface mode)

(Document table mode, DSPF front surface mode)

48-1

16B

Scan image magnification ratio adjustment (Sub scanning direction)

(Document table mode, DSPF front surface mode)

(Document table mode, DSPF front surface mode)

48-1

ADJ 17

Scan image magnification ratio

adjustment (DSPF back surface mode)

adjustment (DSPF back surface mode)

17A

Scan image magnification ratio adjustment (Main scanning direction)

(DSPF back surface mode)

(DSPF back surface mode)

48-1

17B

Scan image magnification ratio adjustment (Sub scanning direction)

(DSPF back surface mode)

(DSPF back surface mode)

48-1/48-5

ADJ 18

Scan image off-center adjustment

18A

Scan image off-center adjustment (Document table mode, DSPF front surface mode)

50-12

18B

Scan image off-center adjustment (DSPF back surface mode)

50-12

ADJ 19

Print area (Void area) adjustment (Print engine section)

50-10/50-1

ADJ 20

Copy image position, image loss

adjustment

adjustment

20A

Copy image position, image loss adjustment (Document table mode)

50-1 (50-2)

20B

Original scan position adjustment

53-8

20C

Copy image position, image loss adjustment (DSPF mode)

50-6 (50-7)

ADJ 21

Print lead edge image position adjustment (Printer mode) (Print engine section)

50-5

ADJ 22

Copy color balance/density adjustment

22A

63-3 (63-5)

22B

63-3

22C

Copy color balance adjustment (Auto adjustment)

46-24/44-21/

44-26

44-26

22D

Copy color balance adjustment (Manual adjustment)

46-21/44-21/

44-26/63-7/

63-8

44-26/63-7/

63-8

22E

Copy density adjustment (Each color copy mode) (Whole adjustment)

(Normally unnecessary to adjust)

(Normally unnecessary to adjust)

46-1

22F

Copy density adjustment (Each monochrome copy mode) (Whole adjustment)

(Normally unnecessary to adjust)

(Normally unnecessary to adjust)

46-2

22G

Copy color balance adjustment (Color balance adjustment at each density level in

each color copy mode) (Normally not required)

each color copy mode) (Normally not required)

46-10

22H

Monochrome copy density adjustment (Density adjustment at each density level in

each monochrome copy mode) (Normally not required)

each monochrome copy mode) (Normally not required)

46-16

MX-7000N ADJUSTMENTS 6 – 2

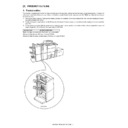

3. Details of adjustment

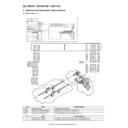

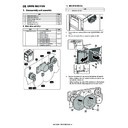

ADJ 1

Developing doctor gap

adjustment (For color)

adjustment (For color)

This adjustment must be executed in the following cases:

* When the developing unit is disassembled.

* When the print image density is low.

* When there is a blur on the print image.

* When there is unevenness in the print image density.

* There is abnormally much toner dispersion.

1)

* When the developing unit is disassembled.

* When the print image density is low.

* When there is a blur on the print image.

* When there is unevenness in the print image density.

* There is abnormally much toner dispersion.

1)

Remove the developing unit from the main unit, and remove

the developing unit upper cover and the developing doctor

cover.

the developing unit upper cover and the developing doctor

cover.

2)

Loosen the developing doctor fixing screw.

3)

Insert a thickness gauge of 0.40mm between 40mm – 70mm

from the edge of the developing doctor.

from the edge of the developing doctor.

4)

Push the developing doctor in the arrow direction, and tighten

the fixing screw of the developing doctor. (Perform the similar

procedure for the front frame and the rear frame.)

the fixing screw of the developing doctor. (Perform the similar

procedure for the front frame and the rear frame.)

ADJ 22

Copy color balance/density adjustment

22I

Gamma/density adjustment in the text image edge section (Normally not required)

46-27

22J

Copy color balance adjustment (Single color copy mode) (Normally not required)

46-25

22K

Auto color balance adjustment by the user (Copy color balance auto adjustment

ENABLE setting and adjustment)

ENABLE setting and adjustment)

26-53

22L

Background process condition setting in the color auto copy mode

46-33

22M

Color document identification level (ACS operation) setting

46-33

ADJ 23

Printer color balance/density

adjustment

adjustment

23A

Printer color balance adjustment (Auto adjustment)

67-24/44-26

23B

Printer color balance adjustment (Manual adjustment)

67-25/44-26/

67-27/67-28

67-27/67-28

23C

Auto color balance adjustment by the user (Printer color balance auto adjustment

ENABLE setting and adjustment)

ENABLE setting and adjustment)

26-54

ADJ 24

Fusing paper guide position adjustment

ADJ 25

Document size sensor adjustment

25A

Document size sensor detection point adjustment

41-1

25B

Document size sensor sensitivity adjustment

41-2

ADJ 26

Manual paper feed tray paper size (width) sensor adjustment

40-2

ADJ 27

DSPF paper feed tray paper size (width) sensor adjustment

53-6

ADJ 28

Touch panel coordinate setting

65-1

ADJ 29

Image loss, void area, image off-

center, image magnification ratio auto

adjustment with SIM50-28

center, image magnification ratio auto

adjustment with SIM50-28

29A

Print image main scanning direction image magnification ratio automatic adjustment

50-28

29B

Image off-center automatic adjustment

50-28

29C

Copy lead edge image reference position adjustment, image off-center, sub scanning

direction image magnification ratio automatic adjustment

direction image magnification ratio automatic adjustment

50-28

29D

DSPF mode auto void adjustment (Service installation adjustment)

50-28

ADJ 30

Shading adjustment

63-2

Job No.

Adjustment item list

Simulation

40mm

70mm

40mm

70mm

MX-7000N ADJUSTMENTS 6 – 3

5)

Check that the doctor gaps at two positions in 40mm – 70mm

from the both sides of the developing doctor are in the range of

0.40

from the both sides of the developing doctor are in the range of

0.40

± 0.05mm.

* When inserting a thickness gauge, be careful not to scratch the

developing doctor and the developing roller.

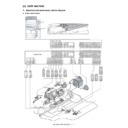

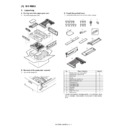

ADJ 2

Developing roller main pole

position adjustment (For color)

position adjustment (For color)

This adjustment must be executed in the following cases:

* When the developing unit is disassembled.

* When the print image density is low.

* When there is a blur on the print image.

* When there is unevenness in the print image density.

* There is abnormally much toner dispersion.

1)

* When the developing unit is disassembled.

* When the print image density is low.

* When there is a blur on the print image.

* When there is unevenness in the print image density.

* There is abnormally much toner dispersion.

1)

Remove the developing doctor cover, and place the develop-

ing unit on a flat surface.

ing unit on a flat surface.

2)

Attach a thread to a needle or a pin.

3)

Hold the thread and bring the needle near the developing

roller. (Do not use a paper clip because it will not provide a cor-

rect position.)

roller. (Do not use a paper clip because it will not provide a cor-

rect position.)

4)

Mark the developing roller surface on the extension line of the

needle with the needle at 2 – 3mm from the developing roller

surface. (Never touch the needle tip with the developing roller.)

needle with the needle at 2 – 3mm from the developing roller

surface. (Never touch the needle tip with the developing roller.)

5)

Measure the distance between the marking position and posi-

tion A of the developing unit frame, and check that it is 37.8

tion A of the developing unit frame, and check that it is 37.8

±

0.5mm.

If the distance is not within the above range, adjust the devel-

oping roller main pole position in the following procedures.

If the distance is not within the above range, adjust the devel-

oping roller main pole position in the following procedures.

6)

Remove the developing unit front cover, loosen the fixing

screw of the developing roller main pole adjustment plate, and

move the adjustment plate in the arrow direction to adjust.

screw of the developing roller main pole adjustment plate, and

move the adjustment plate in the arrow direction to adjust.

Repeat procedures 3) – 6) until the developing roller main pole

position comes to the specified range.

position comes to the specified range.

7)

After completion of the adjustment of the developing roller

main pole position, fix the developing roller main pole adjust-

ment plate with the fixing screw.

main pole position, fix the developing roller main pole adjust-

ment plate with the fixing screw.

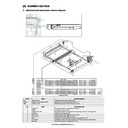

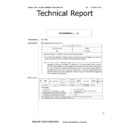

ADJ 3

Developing doctor gap

adjustment (For black)

adjustment (For black)

This adjustment must be executed in the following cases:

* When the developing unit is disassembled.

* When the print image density is low.

* When there is a blur on the print image.

* When there is unevenness in the print image density.

* There is abnormally much toner dispersion.

1)

* When the developing unit is disassembled.

* When the print image density is low.

* When there is a blur on the print image.

* When there is unevenness in the print image density.

* There is abnormally much toner dispersion.

1)

Remove the developing unit from the main unit, and remove

the developing unit upper cover and the developing doctor

cover.

the developing unit upper cover and the developing doctor

cover.

2)

Loosen the developing doctor fixing screw.

40mm

70mm

40mm

70mm

2㨪3mm

37.8+0.5mm

A

37.8+0.5mm

MX-7000N ADJUSTMENTS 6 – 4

3)

Insert a thickness gauge of 0.45mm between 40mm – 70mm

from the edge of the developing doctor.

from the edge of the developing doctor.

4)

Push the developing doctor in the arrow direction, and tighten

the fixing screw of the developing doctor. (Perform the similar

procedure for the front frame and the rear frame.)

the fixing screw of the developing doctor. (Perform the similar

procedure for the front frame and the rear frame.)

5)

Check that the doctor gaps at two positions in 40mm – 70mm

from the both sides of the developing doctor are in the range of

0.45

from the both sides of the developing doctor are in the range of

0.45

± 0.05mm.

* When inserting a thickness gauge, be careful not to scratch the

developing doctor and the developing roller.

ADJ 4

Developing roller main pole

position adjustment (For black)

position adjustment (For black)

This adjustment must be executed in the following cases:

* When the developing unit is disassembled.

* When the print image density is low.

* When there is a blur on the print image.

* When the developing unit is disassembled.

* When the print image density is low.

* When there is a blur on the print image.

* When there is unevenness in the print image density.

* There is abnormally much toner dispersion.

1)

* There is abnormally much toner dispersion.

1)

Remove the developing doctor cover, and place the develop-

ing unit on a flat surface.

ing unit on a flat surface.

2)

Attach a thread to a needle or a pin.

3)

Hold the thread and bring the needle near the developing

roller. (Do not use a paper clip because it will not provide a cor-

rect position.)

roller. (Do not use a paper clip because it will not provide a cor-

rect position.)

4)

Mark the developing roller surface on the extension line of the

needle with the needle at 2 – 3mm from the developing roller

surface. (Never touch the needle tip with the developing roller.)

needle with the needle at 2 – 3mm from the developing roller

surface. (Never touch the needle tip with the developing roller.)

5)

Measure the distance between the marking position and posi-

tion A of the developing unit frame, and check that it is 62.1

tion A of the developing unit frame, and check that it is 62.1

±

0.5mm.

If the distance is not within the above range, adjust the devel-

oping roller main pole position in the following procedures.

If the distance is not within the above range, adjust the devel-

oping roller main pole position in the following procedures.

6)

Remove the developing unit front cover, loosen the fixing

screw of the developing roller main pole adjustment plate, and

move the adjustment plate in the arrow direction to adjust.

screw of the developing roller main pole adjustment plate, and

move the adjustment plate in the arrow direction to adjust.

Repeat procedures 3) – 6) until the developing roller main pole

position comes to the specified range.

position comes to the specified range.

7)

After completion of the adjustment of the developing roller

main pole position, fix the developing roller main pole adjust-

ment plate with the fixing screw.

main pole position, fix the developing roller main pole adjust-

ment plate with the fixing screw.

40mm

70mm

70mm

40mm

40mm

70mm

70mm

40mm

2

㨪3mm

62.1 0.5mm

+

62.1 0.5mm

+

A