|

|

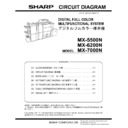

MX-5500N MX-6200N MX-7000N (serv.man41)

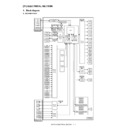

Circuit Diagram

Service Manual

|

127

|

21.31 MB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man42)

Product Outline

Service Manual

|

3

|

221.33 KB

|

|

|

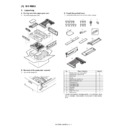

MX-5500N MX-6200N MX-7000N (serv.man43)

Consumable Parts

Service Manual

|

6

|

194.79 KB

|

|

|

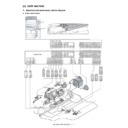

MX-5500N MX-6200N MX-7000N (serv.man44)

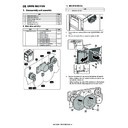

External View Internal Structure

Service Manual

|

19

|

1.97 MB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man45)

Adjustments

Service Manual

|

76

|

6.43 MB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man46)

Simulation

Service Manual

|

127

|

3.61 MB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man47)

Self diagnostics Trouble Codes

Service Manual

|

33

|

322.94 KB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man48)

Maintenance

Service Manual

|

16

|

2.12 MB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man49)

ROM Version Up

Service Manual

|

3

|

485.71 KB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man50)

Electrical Section

Service Manual

|

51

|

1.02 MB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man51)

Others

Service Manual

|

9

|

933.37 KB

|

|

|

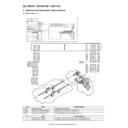

MX-5500N MX-6200N MX-7000N (serv.man52)

Paper transport Section-Detailed Section

Service Manual

|

20

|

4.83 MB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man53)

External Outfit-Detailed Section

Service Manual

|

8

|

2 MB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man54)

Operation Panel-Detailed Section

Service Manual

|

4

|

675.4 KB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man55)

DSPF Section-Detailed section

Service Manual

|

39

|

9.91 MB

|

|

|

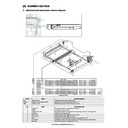

MX-5500N MX-6200N MX-7000N (serv.man56)

Scanner Section-detailed Section

Service Manual

|

10

|

1.81 MB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man57)

Manual Paper Feed Section-Detailed Section

Service Manual

|

10

|

2.53 MB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man58)

Tray Paper Feed Section-Detailed Section

Service Manual

|

23

|

6.76 MB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man59)

Duplex Section-Detailed section

Service Manual

|

17

|

6.45 MB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man60)

LSU Section-Detailed section

Service Manual

|

10

|

1.69 MB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man61)

Detailed Section

Service Manual

|

16

|

3.83 MB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man62)

Toner Supply Section-Detailed section

Service Manual

|

5

|

2.45 MB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man63)

Developing Section-Detailed Section

Service Manual

|

13

|

3.47 MB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man64)

Transfer Section-Detailed Section

Service Manual

|

18

|

6.08 MB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man65)

Process Control Sensor Reg sensor Section-Detailed Section

Service Manual

|

4

|

653.25 KB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man66)

Fusing Section-Detailed section

Service Manual

|

25

|

8.05 MB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man67)

Paper Exit Section-Detailed section

Service Manual

|

7

|

1.08 MB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man68)

Drive Section-Detailed Section

Service Manual

|

32

|

8.87 MB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man69)

Pwb Section-Detailed section

Service Manual

|

8

|

1.73 MB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man70)

Fan Filter Section-Detailed section

Service Manual

|

9

|

2.44 MB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man71)

Sensor Switch Section-Detailed section

Service Manual

|

4

|

924.7 KB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man72)

Installation Manual-Main Unit

Service Manual

|

20

|

5.46 MB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man73)

Configuration

Service Manual

|

2

|

538.55 KB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man74)

Cover Back cover-Installation Manual

Service Manual

|

4

|

1.06 MB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man75)

Whole Installation Manual

Service Manual

|

104

|

27.77 MB

|

|

MX-5500N MX-6200N MX-7000N

WHQL PCL6 32bit Printer Driver for 2k XP Vista Win7 server2003 200832 bit priNTer

Drivers

|

|

19.54 MB

|

|

MX-5500N MX-6200N MX-7000N (serv.man2)

WHQL 64bit Printer Driver for XP Vista Win7 server2003 200864 bit priNTer

Drivers

|

|

20.65 MB

|

|

MX-5500N MX-6200N MX-7000N (serv.man3)

Mac OS10.8 Driver Rquires Postscript option. Mac OS

Drivers

|

|

2.94 MB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man77)

Revised December 2011

Service Manual / Parts Guide

|

127

|

26.27 MB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man79)

Revised PWB Parts Guide.

Service Manual / Parts Guide

|

34

|

396.78 KB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man40)

Specification

Service Manual / Specification

|

16

|

314.08 KB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man92)

Parts change for productivity improvement.

Service Manual / Technical Bulletin

|

3

|

184.15 KB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man93)

Design change of MF Tray 2 Upper.

Service Manual / Technical Bulletin

|

2

|

216.35 KB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man94)

Change of Photo Sensor and Harness

Service Manual / Technical Bulletin

|

3

|

962.43 KB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man96)

CCE 1508 IMPROVEMENT OF PERFORMANCE WHEN OPENING CLOSING DSPF LOWER DOOR

Service Manual / Technical Bulletin

|

3

|

235.02 KB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man96)

CCE 1508 IMPROVEMENT OF PERFORMANCE WHEN OPENING CLOSING DSPF LOWER DOOR

Service Manual / Technical Bulletin

|

3

|

235.02 KB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man97)

Design change of delivery paper guide.

Service Manual / Technical Bulletin

|

2

|

91.45 KB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man97)

Design change of delivery paper guide.

Service Manual / Technical Bulletin

|

2

|

91.45 KB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man98)

CHANGE IN COLOUR OF PIPE CUSHION

Service Manual / Technical Bulletin

|

2

|

60.2 KB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man98)

CHANGE IN COLOUR OF PIPE CUSHION

Service Manual / Technical Bulletin

|

2

|

60.2 KB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man99)

Starting Powder List (This list takes priority over information in Service Manuals).

Service Manual / Technical Bulletin

|

4

|

66.25 KB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man99)

Starting Powder List (This list takes priority over information in Service Manuals).

Service Manual / Technical Bulletin

|

4

|

66.25 KB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man100)

Recommended shutdown procedure and Power Cycling of MFD

Service Manual / Technical Bulletin

|

1

|

186.43 KB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man100)

Recommended shutdown procedure and Power Cycling of MFD

Service Manual / Technical Bulletin

|

1

|

186.43 KB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man101)

IMPORTANT Handling of EEPROM's.

Service Manual / Technical Bulletin

|

5

|

203.32 KB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man102)

MODIFICATION OF NOISE GENERATED BY CONTACT BETWEEN TENSION PLATE AND DRIVE TRANSPORT FRAME.

Service Manual / Technical Bulletin

|

2

|

208.65 KB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man103)

CCE-1306 A REMINDER TO INSERT CONNECTORS TO DRIVER PWB COMPLETELY

Service Manual / Technical Bulletin

|

2

|

237.57 KB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man104)

IMPROVEMENT OF DETECTION ACCURACY FOR DSPF TRANSPORT UPPER ACTUATOR.

Service Manual / Technical Bulletin

|

2

|

198.78 KB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man105)

ENHANCEMENT TO PREVENT DETACHMENT OF PAPER FEED GUIDE TRANSPORT TOP ACTUATOR

Service Manual / Technical Bulletin

|

2

|

66.52 KB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man106)

CCE-1076 WHITE STREAK S DUE TO THE DOCTOR COVER SEAL OR INNER BLADE WEAR.

Service Manual / Technical Bulletin

|

3

|

280.8 KB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man107)

CCE-1067 Shape of the waste toner pipe D has been changed to improve operation.

Service Manual / Technical Bulletin

|

2

|

189.02 KB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man108)

CCE 950 COUNTERMESURE NOISE FROM DSPF UPPER AND LOWER TRANSPORT UNITS

Service Manual / Technical Bulletin

|

2

|

304.1 KB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man109)

FALSE DELIVERY PAPER FULL DETECTION DURING PAPER DELVERY.

Service Manual / Technical Bulletin

|

1

|

289.4 KB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man110)

F2-02 AND F2-64 ERROR CODE OCCURRING FROM EXCESSIVE LOAD ON THE TN ROLLER OF THE (BK) DV UNIT.

Service Manual / Technical Bulletin

|

2

|

150.3 KB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man111)

CCE-905 Noise from the lower HR bearing modification.

Service Manual / Technical Bulletin

|

2

|

342.83 KB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man112)

REF CCE837 ELIMINATING CHARGING IRREGULARITIES, IMPROVING CQ.

Service Manual / Technical Bulletin

|

2

|

366.93 KB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man113)

Ref CCE821 L4-04 OCCURRING FROM THE PEELING MG SIDE SHEET F OF THE DV UNIT (BK).

Service Manual / Technical Bulletin

|

1

|

30.24 KB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man114)

CCE817 MX-FNX4 ROM Upgrade 2. When paper is rolled over the folding roller, there has been cases where the paper has slipped.

Service Manual / Technical Bulletin

|

1

|

29.41 KB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man115)

CCE803 IMPROVEMENTS TO DUST RESISTANCE OF THE DSPF REDUCTION OPTICAL UNIT

Service Manual / Technical Bulletin

|

2

|

854.47 KB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man116)

REF CCE 794 2ND TRANSFER BELT BEAD STRENGTH INCREASED.

Service Manual / Technical Bulletin

|

2

|

470.85 KB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man117)

Ref CCE779 MX-CFX1 COUNTERMEASURES FOR JAM (HI_SEN_S, ETC.)RESULTING FROM MISALIGNED SPRING HOOK SECTION OF DELIVERY SENSOR LEVER.

Service Manual / Technical Bulletin

|

2

|

342.03 KB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man118)

Ref CCE773 MX-FN3 FN4 HOW TO REMOVE THE F1-37 ERROR WHEN REPLACING THE FINISHER PWB

Service Manual / Technical Bulletin

|

1

|

18.65 KB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man119)

Ref CCE788 E7-20 When printing in thick paper mode, FIRMWARE CHANGE.

Service Manual / Technical Bulletin

|

1

|

21.91 KB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man120)

CCE-744 MX-FRX3U DSK FIRMWARE ROM UPGRADE ICU VERSION 01.15.Dm Production Run Date December 2009

Service Manual / Technical Bulletin

|

5

|

43.47 KB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man121)

ARE-963 MX-LCX3N FIRMWARE UPGRADE V01.01. Production Run Date Febuary 2010

Service Manual / Technical Bulletin

|

2

|

28.95 KB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man122)

CCE770 COUNTERMEASURES AGAINST THE MIDDLE TRANSFER BELT BEAD DETERIORATION

Service Manual / Technical Bulletin

|

1

|

326.19 KB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man123)

CCE-768 LCD BACK LIGHT LAMP CHANGED

Service Manual / Technical Bulletin

|

1

|

27.14 KB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man124)

ARE-962 F1-46 TROUBLE CODE OCCURRENCE AFTER JAM PROCESSING.

Service Manual / Technical Bulletin

|

2

|

290.02 KB

|

|

MX-5500N MX-6200N MX-7000N (serv.man125)

REF ARE963 MX-LCX3N FIRMWARE UPGRADE.

Service Manual / Technical Bulletin

|

|

93.86 KB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man126)

CCE-752 COUNTERMEASURES TO PREVENT TRANSFER BELT SLIPPING DUE TO A COLLAR MISSING ON THE 1ST TRANSFER FOLLOWER ROLLER

Service Manual / Technical Bulletin

|

2

|

490.79 KB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man127)

CEE-750 PRECAUTIONS WHEN REPLACING THE WEB ROLLER

Service Manual / Technical Bulletin

|

2

|

617.5 KB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man128)

ARE-957 PREVENTION OF THE COOLING FAN MOTOR BEARING FIXING FROM BEING STRIPPED

Service Manual / Technical Bulletin

|

2

|

195.25 KB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man129)

ARE-958 PRECAUTIONS WHEN INSERTING A TONER CARTRIDGE

Service Manual / Technical Bulletin

|

1

|

15.47 KB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man130)

REF CCE722R POD1 JAM PROBLEM AND OTHERS, CAUSED BY TONER ADHERING TO POST-FUSING UPPER PG ON FUSING UNIT REVISED

Service Manual / Technical Bulletin

|

3

|

1.24 MB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man131)

REF CCE-730 PREVENTION OF THE DRUM SCUFFING AGAINST THE DV UNIT WHEN PULLED OUT

Service Manual / Technical Bulletin

|

2

|

768.82 KB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man132)

Operations Required for Machine Movement

Service Manual / Technical Bulletin

|

1

|

14.68 KB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man133)

CCE727 DAMAGE ON DRUM SURFACE CAUSED WHEN DV UNIT IS PULLED OUT.

Service Manual / Technical Bulletin

|

2

|

1.1 MB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man134)

ISSUING EXPLANATORY MATERIAL OF JOB LOG CODES.

Service Manual / Technical Bulletin

|

13

|

160.14 KB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man135)

REF. CCE-703 LFR CHANGES TO PERVENT SCRATCHES TO THE UFR.

Service Manual / Technical Bulletin

|

2

|

191.95 KB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man136)

CCE696 COUNTERMEASURES FOR ABNORMAL SOUND (PATTER)FROM BEARING SECTIONS OF UPPER AND LOWER HEAT ROLLERS OF FUSING UNIT.

Service Manual / Technical Bulletin

|

2

|

541.15 KB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man137)

CCE695 MX-FNX4 ROM UPGRADE ... (1).

Service Manual / Technical Bulletin

|

1

|

27.93 KB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man138)

CCE694 CHANGE OF INITIAL VALUES OF PREHEAT MODE AND AUTO POWER SHUT-OFF MODE INVOLVED IN SUPPORT OF ENERGY STAR VER1.1 (TIER II).

Service Manual / Technical Bulletin

|

1

|

22.91 KB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man139)

WEB IDLE GEAR MATERIAL CHANGED TO IMPROVE HEAT FRICTION RESISTANCE

Service Manual / Technical Bulletin

|

1

|

195.17 KB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man140)

CCE686 CHANGE OF SHAPE OF PROCESS F COVER.

Service Manual / Technical Bulletin

|

2

|

198.81 KB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man141)

CCE617 MODIFICATION TO FUSER UNIT, PREVENTING TONER ADHERTION TO UPPER HEAT ROLLER AND SEP PAWS

Service Manual / Technical Bulletin

|

4

|

1.65 MB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man142)

CCE591 COUNTERMEASURES FOR BK FOG.

Service Manual / Technical Bulletin

|

6

|

990.59 KB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man143)

MEASURE TO PREVENT WASTE TONER CLOGGING

Service Manual / Technical Bulletin

|

2

|

240.5 KB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man144)

IMPROVING HEAT- AND FRICTION-RESISTANCE MARGINS

Service Manual / Technical Bulletin

|

2

|

351.88 KB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man145)

PAPER FEED JAM (DPFD1_N4, ETC.) RESULTING FROM CONTACT BETWEEN SEPARATE CRIMPING SP OF CASSETTE PAPER FEED UNIT SECTION AND PF LOWER PG REINFORCE PLATE.

Service Manual / Technical Bulletin

|

2

|

282.83 KB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man146)

SOLUTION TO FAULT OF SLACKENED SCREWS SECURING OUTSIDE HL HOLDERS AND OUTSIDE HAENESS HOLDERS IN FUSING UNIT

Service Manual / Technical Bulletin

|

2

|

351.88 KB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man147)

COUNTERMEASURES FOR F2-40 TROUBLE RESULTING FROM LEAK IN MC UNIT SECTION.

Service Manual / Technical Bulletin

|

2

|

85.83 KB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man148)

POINTS TO KEEP IN MIND WHEN ADJUSTING

Service Manual / Technical Bulletin

|

1

|

22.07 KB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man149)

REINFORCEMENT OF DSPF GUIDES.

Service Manual / Technical Bulletin

|

2

|

75.83 KB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man150)

COMPATIBILITY OF LWR THERMOSTAT PART CHANGE.

Service Manual / Technical Bulletin

|

2

|

56.51 KB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man151)

REMEDY FOR MARKS IN REVERSE OF PAPER WHEN DOUBLE SIDING

Service Manual / Technical Bulletin

|

2

|

130.22 KB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man152)

PROCEDURE FOR REPLACING MFP PWB

Service Manual / Technical Bulletin

|

2

|

206.24 KB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man153)

COUNTERMEASURE TO IMPROVE UNEVEN SHADING OF IMAGE.

Service Manual / Technical Bulletin

|

1

|

31.16 KB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man154)

REDUCING UNEVEN CHARGE(IMAGE STREAKING)IMPROVEMENT OF MC UNIT CLEANING PERFORMANCE.

Service Manual / Technical Bulletin

|

2

|

48.71 KB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man155)

MX 55-7000 DRIVE UNIT CHANGES FOR BLACK DRUM DRIVE MXFNX3 4 RETURN ROLLER SHAFT PARTS CHANGES

Service Manual / Technical Bulletin

|

2

|

169.32 KB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man156)

COUNTERMEASURE FOR TRANSFER MISALIGNMENT 95MM FROM LEAD EDGE OF PAPER

Service Manual / Technical Bulletin

|

2

|

73.13 KB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man157)

PREVENTION OF TONER BOTTLE COUPLING DISENGAGEMENT.

Service Manual / Technical Bulletin

|

2

|

68.86 KB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man158)

RELEASE OF MXFNX1 3 4 STAPLE UNIT COMPLETE.

Service Manual / Technical Bulletin

|

1

|

65.53 KB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man159)

CCE 545- MX FNX3 4 CHANGES TO TIMING BELT MYLAR.

Service Manual / Technical Bulletin

|

2

|

85.08 KB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man160)

CCE 541- MX CFX1 ROM CHANGE BULLETIN ONLY TO COUNTERACT HI_SEN STATUS (A02 0103D0)

Service Manual / Technical Bulletin

|

1

|

59.02 KB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man161)

CCE 534- L4-35 DUE TO ELECTRICAL NOISE FROM DELIVERY MOTOR.

Service Manual / Technical Bulletin

|

3

|

101.03 KB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man162)

CCE 528- PREVENTION OF FUSER NOISE.

Service Manual / Technical Bulletin

|

2

|

66.69 KB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man163)

CCE 519- PREVENTION OF DAMAGE TO AC-DC HARNESS COATING.

Service Manual / Technical Bulletin

|

2

|

85.66 KB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man164)

CCE 524- LSU HEATER PARTS AVAILABLE AS SERVICE PARTS.

Service Manual / Technical Bulletin

|

5

|

251.27 KB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man165)

CCE 515- IMPROVEMENT IN WASTE TONER SCATTER FROM WASTE TONER SHUTTER.

Service Manual / Technical Bulletin

|

2

|

79 KB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man166)

CCE 514- IMPROVEMENT TO DEV GEAR PITCH TO COUNTERACT BANDING.

Service Manual / Technical Bulletin

|

2

|

67.55 KB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man167)

CCE 511-STRENGTH IMPROVEMENT OF CASSETTE LIFT MOTOR A.

Service Manual / Technical Bulletin

|

2

|

81.85 KB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man168)

CCE 510- INFORMATION OF PARTS CHANGE TO FUSER ASSEMBLY

Service Manual / Technical Bulletin

|

2

|

91.87 KB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man169)

PME 487-PARTS CHANGE TO MX LCX2 LCC

Service Manual / Technical Bulletin

|

1

|

43.3 KB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man170)

CCE 508- REDUCTION OF WEB OIL TO IMPROVE PAPER SEPERATION FROM UFR

Service Manual / Technical Bulletin

|

1

|

65.21 KB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man171)

CCE 489-NEW SET OF SERVICE PARTS THAT COMBINES THE FILTER COVER WITH TONER FILTER.

Service Manual / Technical Bulletin

|

1

|

64.73 KB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man172)

CCE 499-PRIMARY TRANSFER CHARGE ROLLER PARTS CHANGE TO IMPROVE PRODUCTIVITY

Service Manual / Technical Bulletin

|

1

|

73.71 KB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man173)

DV COVER MOUNTING INSTRUCTIONS TO PREVENT DAMAGE

Service Manual / Technical Bulletin

|

2

|

98.61 KB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man174)

NEW SET OF SERVICE PARTS THAT COMBINES THE FILTER COVER WITH TONER FILTER.

Service Manual / Technical Bulletin

|

1

|

59.68 KB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man175)

CONTACT PREVENTION BETWEEN THE LOWER MAIN HARNESS AND THE CENTRAL VENTILATION FAN MOTOR INSIDE THE MACHINE.

Service Manual / Technical Bulletin

|

2

|

94.05 KB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man176)

IMPROVED ACCESS TO TANDEM TRAYS 1 2 WHEN REPLENISHING PAPER

Service Manual / Technical Bulletin

|

7

|

309.05 KB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man177)

STRENGTHENED FUSER FRONT COVER

Service Manual / Technical Bulletin

|

2

|

73.86 KB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man178)

IMPROVED PACKING TO PREVENT SLIT GLASS BREAKAGE

Service Manual / Technical Bulletin

|

2

|

80.07 KB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man179)

IMPROVEMENT OF CONTACT AREA OF THERMISTOR TO FUSER ROLLER

Service Manual / Technical Bulletin

|

2

|

88.22 KB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man180)

STRENGHTHENING OF MF TRAY HARNESS

Service Manual / Technical Bulletin

|

2

|

79.49 KB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man181)

SCORE LINES ON COPIES FROM DELIVERY ROLLERS

Service Manual / Technical Bulletin

|

2

|

69.65 KB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man182)

CCE 434-PAPER FEEDS IN A BUNDLE OWING TO THE STOPPER THAT DESCENDS WHEN LOADING PAPER TO THE BYPASS TRAY.

Service Manual / Technical Bulletin

|

2

|

78.31 KB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man183)

BARRIETA GREASE SPRAY FOR FUSING UNIT

Service Manual / Technical Bulletin

|

2

|

77.64 KB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man184)

MXFNX3 4 PARTS CHANGE-STAPLE UNIT,COVERS HANDLE

Service Manual / Technical Bulletin

|

1

|

46.98 KB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man185)

CCE 448 MX FNX3 4 JAM (FED_S) CAUSED BY ENTRANCE SENSOR LEVER STICKING HOLDER.

Service Manual / Technical Bulletin

|

1

|

65.16 KB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man186)

PARTS CHANGE MAIN CHARGE COVER WASTE TONER PANEL

Service Manual / Technical Bulletin

|

2

|

82.89 KB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man187)

CCE 424-H4 02 DAMAGED SUB HEATER LAMP (200V)

Service Manual / Technical Bulletin

|

1

|

77.73 KB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man188)

CCE 395-LOCK PREVENTION OF SHAFT-WASTE TONER TRANSPORT SECTION

Service Manual / Technical Bulletin

|

2

|

87.03 KB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man189)

CCE 408-MX IMPROVEMENT OF THERMOSTAT OFF TEMPERATURE-FUSER UNIT

Service Manual / Technical Bulletin

|

1

|

78.36 KB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man190)

CCE 401- MXCFX1 IMPROVEMENT IN SENSOR LEVER TO ELIMINATE HI_SEN MISFEED

Service Manual / Technical Bulletin

|

1

|

63.91 KB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man191)

CCE 392- MX FNX3 4 PAPER DETECTION FLAG ERRORS OUTPUT TRAY SYNCHRONISATION FAULT

Service Manual / Technical Bulletin

|

2

|

80.52 KB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man192)

CCE 340-MX CFX1 INSERTER ROM UPGRADE

Service Manual / Technical Bulletin

|

1

|

62.58 KB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man193)

CCE 335-CHANGE OF FULL WEIGHT OF WASTE TONER BOTTLE

Service Manual / Technical Bulletin

|

2

|

85.42 KB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man194)

CCE 324-NOTE ON MX-FXX1 INSTALLATION

Service Manual / Technical Bulletin

|

1

|

67.95 KB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man195)

GENERAL PROCEDURE FOR COLOUR CALIBRATION SET-UP

Service Manual / Technical Bulletin

|

2

|

83.06 KB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man196)

CCE 301-CAUTIONS ON HDD REPLACEMENT AND PROCEDURE FOR UPDATING INSTRUCTION MANUAL.

Service Manual / Technical Bulletin

|

5

|

135.85 KB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man197)

CCE 380-IMPROVEMENT IN CLEANING BY PREVENTING THE DEFORMATION OF THE TONER STIRRING SHEET OF THE PROCESS UNIT.

Service Manual / Technical Bulletin

|

2

|

118.15 KB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man198)

MX PNX2A-D ADJUSTMENTS AFTER REPLACING HOLE PUNCH UNIT CONTROL PCB PREVENTING F1-38 ERROR

Service Manual / Technical Bulletin

|

2

|

107.61 KB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man199)

CCE 417-JAM OWING TO DEFECTIVE RETURN OF RIGHT HAND PAPER DISCHARGING GATE

Service Manual / Technical Bulletin

|

1

|

68.79 KB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man200)

CHANGES TO TRANSFER HVT PCB

Service Manual / Technical Bulletin

|

2

|

112.31 KB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man201)

MX PNX2A-D ROM UPGRADE(CONTROL No A01 VERSION 0103DO) WITH FIRMWARE PCU 0104DO 0105DO

Service Manual / Technical Bulletin

|

1

|

59.7 KB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man202)

MX FNX3 4 ROM UPGRADE(CONTROL No A02 FINISHER VERSION 0103DO)WITH PCU 01.04.DO 01.05.DO

Service Manual / Technical Bulletin

|

1

|

59.7 KB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man203)

REVISED TEMP TABLE ADJUSTMENTS FOR PCU 01.04 AND PCU 01.05

Service Manual / Technical Bulletin

|

3

|

328.84 KB

|

|

MX-5500N MX-6200N MX-7000N (serv.man204)

FIRMWARE FOR MX5500 6200 ONLY TO OVERCOME FUSER OFFSET (PCU 01.04.0D)

Service Manual / Technical Bulletin

|

|

27.66 MB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man205)

Adjustment to system settings to overcome fusing offset

Service Manual / Technical Bulletin

|

2

|

46.04 KB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man206)

CCE 414- CORRECTION OF FUSER OFFSET PROBLEMS MX 7000 ONLY SEE UPDATES PCU 01.05.0D

Service Manual / Technical Bulletin

|

2

|

329.56 KB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man207)

SCANNER DRYING HEATER AS SERVICE PART

Service Manual / Technical Bulletin

|

5

|

244.94 KB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man208)

CCE 419- MXFNX3 FNX4 PARTS CORRECTION

Service Manual / Technical Bulletin

|

1

|

63.49 KB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man209)

SERV PARTS SETTING OF MAIN UNIT CASSETTE TANDEM HEATER

Service Manual / Technical Bulletin

|

12

|

517.94 KB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man210)

SERVICE PARTS OF ELECTRICAL HEATER COMPONENTS

Service Manual / Technical Bulletin

|

7

|

2.28 MB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man211)

CCE 371-REMINDER TO UNLOCK PAPER CASSETTE

Service Manual / Technical Bulletin

|

2

|

80.67 KB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man212)

IC Failure causing scan copy issues

Service Manual / Technical Bulletin

|

4

|

116.08 KB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man213)

CCE 360-COLOUR TONER NEAR END 26-69 IMPROVEMENT OF TONER SCATTER 44-4,61-3.

Service Manual / Technical Bulletin

|

1

|

60.05 KB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man214)

CCE 331- SETTING OF DSPF DEDICATED CHART

Service Manual / Technical Bulletin

|

2

|

113.85 KB

|

|

MX-5500N MX-6200N MX-7000N (serv.man86)

SAP Device Types for MX Colour devices.

Driver / Update

|

|

3.18 MB

|

|

MX-5500N MX-6200N MX-7000N (serv.man87)

ROM control No.A15 ROM Version 0103D0 SEE BULLETIN CCE817

Driver / Update

|

|

150.09 KB

|

|

MX-5500N MX-6200N MX-7000N (serv.man88)

ROM control No.C02 ICU 01.15.D0,PCU 01.11.D0 1. SEE BULLETIN CCE788

Driver / Update

|

|

27.86 MB

|

|

MX-5500N MX-6200N MX-7000N (serv.man89)

PPD2_PRI Jam When Using Citrix Universal Printer

Driver / Update

|

|

6.41 MB

|

|

MX-5500N MX-6200N MX-7000N (serv.man90)

PPD2_PRI Jam When Using Citrix Universal Printer

Driver / Update

|

|

6.12 MB

|

|

MX-5500N MX-6200N MX-7000N (serv.man91)

Safecom Special Firmware PCU Version 01.14.D0b0

Driver / Update

|

|

27.85 MB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man4)

GENERAL PROCEDURE FOR COLOUR CALIBRATION SET-UP

Handy Guide

|

2

|

83.06 KB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man5)

VERSION 1A

Handy Guide

|

54

|

1.04 MB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man6)

HANDYGUIDE VERSION 1.1

Handy Guide

|

52

|

942.82 KB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man80)

How To Read A Main Machine Serial Number

FAQ

|

1

|

16.5 KB

|

|

MX-5500N MX-6200N MX-7000N (serv.man81)

UPDATED PJL PCL PS Command Lists

FAQ

|

|

128.84 KB

|

|

MX-5500N MX-6200N MX-7000N (serv.man82)

Firmware Combi_0112D0c0_B RIPFIX

FAQ

|

|

27.89 MB

|

|

MX-5500N MX-6200N MX-7000N (serv.man83)

0112 F w version B11 DEC07

FAQ

|

|

27.96 MB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man84)

How to connect MX colour product to Linux UNIX systems using CUPS

FAQ

|

9

|

1.45 MB

|

|

MX-5500N MX-6200N MX-7000N (serv.man85)

PCL PJL COMMANDS FOR MX SERIES

FAQ

|

|

69.87 KB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man215)

MAGENTA DEV

Regulatory Data

|

4

|

32.74 KB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man216)

YELLOW TONER

Regulatory Data

|

4

|

32.34 KB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man217)

YELLOW DEV

Regulatory Data

|

4

|

32 KB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man218)

CYAN DEV

Regulatory Data

|

4

|

32.73 KB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man219)

BLACK DEV

Regulatory Data

|

4

|

34.84 KB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man220)

MAGENTA TONER

Regulatory Data

|

4

|

32.33 KB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man221)

CYAN TONER

Regulatory Data

|

4

|

32.31 KB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man222)

BLACK TONER

Regulatory Data

|

4

|

34.43 KB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man7)

Updated December 2011

Peripheral

|

17

|

1.41 MB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man8)

Updated Jan 08

Peripheral

|

20

|

2.34 MB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man9)

FULL CIRCUIT DIAGRAM 55 62 7000 LCX2 3 FNX3 4 PNX2A-D RBX2 CFX1 FXX1

Peripheral

|

127

|

21.31 MB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man10)

MX-LCX2 SERVICE MANUAL COMPLETE

Peripheral

|

30

|

2.2 MB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man11)

MX-LCX3 SERVICE MANUAL COMPLETE

Peripheral

|

34

|

3.59 MB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man12)

MX- PEX2 PARTS GUIDE

Peripheral

|

8

|

475.38 KB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man13)

WHOLE PARTS GUIDE MXFNX3 4 MXPNX2-4 MXRBX2

Peripheral

|

76

|

8.86 MB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man14)

MX-FNX3 4 MX-RBX2 MXPNX2A-D SERVICE MANUAL-Product Outline

Peripheral

|

2

|

339.95 KB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man15)

MX-FNX3 4 MX-RBX2 MXPNX2A-D SERVICE MANUAL-Specifications

Peripheral

|

3

|

117.74 KB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man16)

MX-FNX3 4 MX-RBX2 MXPNX2A-D SERVICE MANUAL-External Views Internal Structures

Peripheral

|

8

|

610.96 KB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man17)

MX-FNX3 4 MX-RBX2 MXPNX2A-D SERVICE MANUAL-Operational Description

Peripheral

|

28

|

3.26 MB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man18)

MX-FNX3 4 MX-RBX2 MXPNX2A-D SERVICE MANUAL-Disassembly Assembly-1

Peripheral

|

39

|

12.88 MB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man19)

MX-FNX3 4 MX-RBX2 MXPNX2A-D SERVICE MANUAL-Disassembly Assembly-2

Peripheral

|

30

|

11.13 MB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man21)

MX-FNX3 4 MX-RBX2 MX-PNX2A-D SERVICE MANUAL-Adjustments

Peripheral

|

4

|

195.33 KB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man22)

MX-FNX3 4 MX-RBX2 MX-PNX2A-D SERVICE MANUAL-Self Diag Message Trouble code

Peripheral

|

4

|

102.18 KB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man23)

MX-FNX3 4 MX-RBX2 MX-PNX2A-D SERVICE MANUAL-Electrical Section

Peripheral

|

13

|

541.47 KB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man24)

MX CFX1 SERVICE MANUAL COMPLETE

Peripheral

|

39

|

4.64 MB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man25)

MX- PEX2 SERVICE MANUAL

Peripheral

|

99

|

2.87 MB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man26)

MX PEX2 INSTALLATION MANUAL

Peripheral

|

12

|

2.19 MB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man27)

MX-RBX2 Paper Pass Unit-Installation Manual

Peripheral

|

5

|

2.18 MB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man28)

MX-FNX3 4K Finisher-Installation Manual

Peripheral

|

8

|

2.55 MB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man29)

MX-FNX4 4K Saddle Stitch Finisher-Installation Manual

Peripheral

|

9

|

3.08 MB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man30)

MX-PNX2A-D Punch Module-Installation Manual

Peripheral

|

6

|

2.09 MB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man31)

MX-CFX1 Inserter-Installation Manual

Peripheral

|

10

|

3.06 MB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man32)

MX-LCX2 LCT A4-Installation Manual

Peripheral

|

9

|

1.84 MB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man33)

MX-LCX3 LCT A3-Installation Manual

Peripheral

|

13

|

3.72 MB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man34)

MX-PKX1 PS3 Expansion Kit-Installation Manual

Peripheral

|

1

|

90.1 KB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man35)

MX-FRX3 FRX3U Data security Kit-Installation Manual

Peripheral

|

5

|

1.03 MB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man36)

MX-FXX1-Fax Expansion Kit-Installation Manual

Peripheral

|

6

|

1.07 MB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man37)

AR-PF1-Barcode Font kit-Installation Manual

Peripheral

|

4

|

920.53 KB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man38)

MX-FWX1-Internet Expansion kit-Installation Manual

Peripheral

|

1

|

87.18 KB

|

|

|

MX-5500N MX-6200N MX-7000N (serv.man39)

MX-AMX1 Application INtergration module-Installation Manual

Peripheral

|

1

|

84.72 KB

|