Sharp MX-5500N / MX-6200N / MX-7000N (serv.man21) Peripheral ▷ View online

MX-FNX4 ADJUSTMENTS 8 – 1

MX-FNX4

Service Manual

[8] ADJUSTMENTS

1. Finisher, saddle stitcher section

A. Basic adjustments

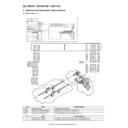

(1) Upper curl mode

a. Outline

Paper may not be stacked properly depending on the paper state.

(Refer to the figure below.)

Paper may not be stacked properly depending on the paper state.

(Refer to the figure below.)

In such a case:

1) Turn back and set the paper in the paper feed cassette.

1) Turn back and set the paper in the paper feed cassette.

If the upper curl is greater than that before resetting the paper,

turn back the paper again to set in the previous state.

turn back the paper again to set in the previous state.

B. Adjustments when replacing parts

(1) Adjustment of alignment position

This adjustment is required when the finisher controller PCB is

replaced or when it is required to change the alignment position for

some reason.

1)

replaced or when it is required to change the alignment position for

some reason.

1)

Remove the rear cover in the finisher.

2)

Check to confirm that the power of the host machine is turned

OFF, and set SW104 on the finisher controller PCB as shown

below, according to the paper used for the adjustment.

OFF, and set SW104 on the finisher controller PCB as shown

below, according to the paper used for the adjustment.

3)

Turn ON the power of the host machine.

4)

Press the SW103 on the finisher controller PCB once.

* When the SW103 is pressed, the swing guide is opened to

* When the SW103 is pressed, the swing guide is opened to

shift the alignment plates to the specified position.

5)

Insert ten sheets of A4/LTR paper between the alignment

plates, and push the paper so that it is in contact with the stop-

per.

plates, and push the paper so that it is in contact with the stop-

per.

6)

Press the SW101 or SW102 on the finisher controller PCB

until the alignment plates come in contact with paper.

* When the SW101 is pressed, the alignment plate is shifted

until the alignment plates come in contact with paper.

* When the SW101 is pressed, the alignment plate is shifted

to the front side by 0.42mm.

* When the SW102 is pressed, the alignment plate is shifted

to the rear side by 0.42mm.

7)

After the adjustment is completed, remove the paper, and

press the SW103 on the finisher controller PCB once to save

the adjustment value.

press the SW103 on the finisher controller PCB once to save

the adjustment value.

8)

Set all the bits of the SW104 on the finisher controller PCB to

OFF.

OFF.

9)

Turn OFF the power of the host machine, and install the rear

cover of the finisher.

cover of the finisher.

(2) Adjustment of staple position

This adjustment is performed when the finisher controller PCB is

replaced or when it is required to change the staple position for

some reason. If the paper used for the adjustment is of AB series,

front/back stapling adjustments are performed for A4/A4R, respec-

tively. When the paper used for the adjustment is of inch series,

front/back binding adjustments are performed for LTR/LTRR,

respectively.

1)

replaced or when it is required to change the staple position for

some reason. If the paper used for the adjustment is of AB series,

front/back stapling adjustments are performed for A4/A4R, respec-

tively. When the paper used for the adjustment is of inch series,

front/back binding adjustments are performed for LTR/LTRR,

respectively.

1)

Remove the rear cover of the finisher.

2)

Check to confirm that the power of the host machine is turned

OFF, and set the SW104 on the finisher controller PCB as

shown below, according to the paper used for the adjustment

and the stapling position.

OFF, and set the SW104 on the finisher controller PCB as

shown below, according to the paper used for the adjustment

and the stapling position.

When A4 is used

When LTR is used

A4/staple in the front

A4R/staple in the front

LTR/staple in the front

LTRR/staple in the front

A4/staple at the back

A4R/staple at the back

LTR/staple at the back

LTRR/staple at the back

MX-FNX4 ADJUSTMENTS 8 – 2

3) Turn ON the power of the host machine.

4) Press the SW103 on the finisher controller PCB once.

4) Press the SW103 on the finisher controller PCB once.

* When SW103 is pressed, the swing guide is opened, and

the alignment plates are shifted to the specified positions.

5) Insert a sheet between the alignment plates, and push it so

that it is in contact with the stopper. Push the paper so that the

rear edge is in contact with the rear alignment plate.

* If there is a clearance of 1mm or more between the front

rear edge is in contact with the rear alignment plate.

* If there is a clearance of 1mm or more between the front

alignment plate and the front edge of paper, stop the adjust-

ment of staple position, and adjust the alignment position.

Then, perform adjustment of the staple position again.

ment of staple position, and adjust the alignment position.

Then, perform adjustment of the staple position again.

6) Press the SW103 on the finisher controller PCB once to per-

form stapling. Since, however, paper is not discharged, the

stapled paper must be manually removed and the stapling

position must be checked.

stapled paper must be manually removed and the stapling

position must be checked.

7) Press the SW103 on the finisher controller PCB once.

8) If the stapling position is proper, insert a sheet of paper

8) If the stapling position is proper, insert a sheet of paper

between the alignment plates, and push it so that it is in con-

tact with the stopper. Push the paper so that the rear edge is in

contact with the rear alignment plate. Press the SW103 once

(stapling/adjustment value saving), and go to the step 11).

tact with the stopper. Push the paper so that the rear edge is in

contact with the rear alignment plate. Press the SW103 once

(stapling/adjustment value saving), and go to the step 11).

9) To adjust the stapling position, press the SW101 or SW102 on

the finisher controller PCB.

* When the SW101 is pressed, the stapling position is shifted

* When the SW101 is pressed, the stapling position is shifted

to the front side by 0.49mm.

* When the SW102 is pressed, the stapling position is shifted

to the rear side by 0.49mm.

10) Repeat the steps 5) and 6) to check that the stapling position is

properly adjusted.

11) Set all the bits of the SW104 on the finisher controller PCB to

OFF.

12) Turn OFF the power of the host machine, and install the rear

cover of the finisher.

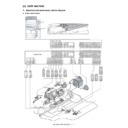

(3) Adjustment of folding position (MX-FNX4)

To adjust the folding position, change the setting of bits from 6 to 8

of the DIPSW1 on the saddle stitcher controller PCB, and adjust

the folding position to the stitch position. (Adjust the paper position-

ing plate shift amount from the stitch position to the folding posi-

tion.)

If the saddle stitcher controller PCB is replaced, shift the setting of

the DIPSW1 on the old PCB to the new PCB. If the folding position

must be changed for some reason, this adjustment should be per-

formed.

1) Check to confirm that the power of the host machine is turned

of the DIPSW1 on the saddle stitcher controller PCB, and adjust

the folding position to the stitch position. (Adjust the paper position-

ing plate shift amount from the stitch position to the folding posi-

tion.)

If the saddle stitcher controller PCB is replaced, shift the setting of

the DIPSW1 on the old PCB to the new PCB. If the folding position

must be changed for some reason, this adjustment should be per-

formed.

1) Check to confirm that the power of the host machine is turned

OFF, and separate the finisher from the host machine. If the

optional punch module is installed, remove it from the finisher.

optional punch module is installed, remove it from the finisher.

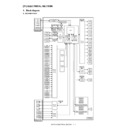

2) Remove the PCB cover, and set the bits from 1 to 4 of the

SW504 on the saddle stitcher controller PCB as shown below:

3) Remove the rear cover, and open the inlet cover of the saddle

stitcher. Then, fix the inlet cover sensor (FSINDD) and the inlet

door switch (FSINDSW) actuator with tape.

door switch (FSINDSW) actuator with tape.

4)

Put a mark on the top of the paper before paper feeding. Use

two sheets of A3 or LDR paper.

two sheets of A3 or LDR paper.

5)

Turn ON the power of the host machine.

6)

Press the SW1 of the saddle stitcher controller PCB. (When

LDR is used, keep pressing for 3 sec or more.) Then, the feed

motor (FSFM) starts running.

LDR is used, keep pressing for 3 sec or more.) Then, the feed

motor (FSFM) starts running.

7)

Feed two sheets of paper from the saddle inlet cover section.

Feed paper until the paper lead edge is in contact with the

paper positioning plate.

Feed paper until the paper lead edge is in contact with the

paper positioning plate.

8)

Close the inlet cover.

9)

Press the SW1 of the saddle stitcher controller PCB.

* The saddle stitcher section stitches, folds, and discharges

* The saddle stitcher section stitches, folds, and discharges

paper automatically,

10) Measure the distance (L) between the stitch position and the

folding position. There are a "positive adjustment width" and a

"negative adjustment width" depending on the relations of the

stitch position and the folding position.

* If the stitch position is lower than the folding position, the

"negative adjustment width" depending on the relations of the

stitch position and the folding position.

* If the stitch position is lower than the folding position, the

width is the "positive adjustment width."

* If the stitch position is higher than the folding position, the

width is the "negative adjustment width."

Do not change the

setting of bits from 5 to 8.

Mark

A3/LDR paper

Paper feed direction

Mark

Example of a positive

adjustment value

Unit: mm

Ex.) If L is 1mm, the width is "+1mm".

Folding position

Example of a negative

adjustment value

Mark

Stitch position

Folding position

Stitch position

Unit: mm

Ex.) If L is 0.5mm, the width is "-0.5mm".

MX-FNX4 ADJUSTMENTS 8 – 3

11) Change the setting of bits from 6 to 8 of the SW504 depending

on the clearance. Refer to the table below.

* When the adjustment width is 0:

* When the adjustment width is 0:

Since the stitch position is aligned with the folding position,

the setting is not changed.

the setting is not changed.

* In the case of a "positive adjustment width":

Subtract the distance from the value on the above figure,

and set the obtained value to SW504.

Example) If the current set value of the SW504 is +2 and the

clearance is +1mm newly, set the SW504 to -2.

and set the obtained value to SW504.

Example) If the current set value of the SW504 is +2 and the

clearance is +1mm newly, set the SW504 to -2.

* In the case of a "negative adjustment value":

Add the distance to the value on the above figure, and set

the obtained value to SW504.

Example) When the current set value of the SW504 is -1 and

the distance is -0.5mm, newly set the SW504 to +1.

the obtained value to SW504.

Example) When the current set value of the SW504 is -1 and

the distance is -0.5mm, newly set the SW504 to +1.

The following bits must not be set.

12) Set bits from 1 to 4 of the SW504 to OFF.

(4) Stitch position (Center stapling adjustment)

(MX-FNX4)

Use the user mode of the host machine for this adjustment.

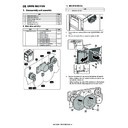

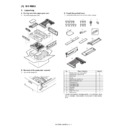

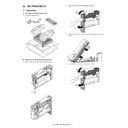

(5) Adjustment of stitcher unit (MX-FNX4)

1) Open the front cover.

2) Pull out the stitcher base unit to the front, and pull the stitcher

2) Pull out the stitcher base unit to the front, and pull the stitcher

handle [1] once and raise the stitcher.

3) Remove the three screws [2], and remove the stitcher cover

[3].

4)

Remove the positioning tool [4] attached to the back of the

cover.

cover.

5)

For adjustment of the stitcher in the front side, remove the front

guide plate [5] and the center guide plate [6]. For adjustment of

the stitch in the rear side, remove the center guide plate [6]

and the rear guide plate [7]. (one screw, each)

guide plate [5] and the center guide plate [6]. For adjustment of

the stitch in the rear side, remove the center guide plate [6]

and the rear guide plate [7]. (one screw, each)

6)

For adjustment of the stitcher in the front side, loosen the two

screws [9] of the stitcher base [8]. For adjusting of the stitcher

in the rear side, loosen the two screws [10] of the stitcher base

[8].

screws [9] of the stitcher base [8]. For adjusting of the stitcher

in the rear side, loosen the two screws [10] of the stitcher base

[8].

7)

Insert the tool [12] into the staple slot of the stitcher [11].

Bit setting of DIPSW1

Set value

(Unit:0.5 mm)

Bit 6

Bit 7

Bit 8

OFF

ON

ON

+3

OFF

ON

OFF

+2

OFF

OFF

ON

+1

OFF

OFF

OFF

0

ON

OFF

ON

-1

ON

ON

OFF

-2

ON

ON

ON

-3

Bit 6

Bit 7

Bit 8

ON

OFF

OFF

[2]

[3]

[1]

[4]

[7]

[6]

[5]

[10]

[9]

[8]

[11]

[12]

MX-FNX4 ADJUSTMENTS 8 – 4

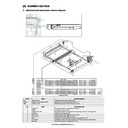

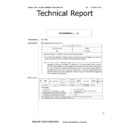

8) Tilt the stitcher. Then, rotate the stitch gear [13], fit the tool [14]

and the concave section of the base [15], and tighten the

screw of the base [15] to fix.

screw of the base [15] to fix.

2. Punch module (MX-PNX2A/B/C/D)

A. Adjusting the punch hole position (feed

direction)

To enter the service mode, turn ON the power supply while the

dipswitch1 of FIN is ON.

dipswitch1 of FIN is ON.

B. Adjusting the sensor output

Perform the following when the punch control PCB, transmission

sensor (photosensor PCB/LED PCB), or reflection sensor (waste

full photosensor PCB unit) has been replaced.

1) Remove the rear cover of the puncher after ensuring that the

sensor (photosensor PCB/LED PCB), or reflection sensor (waste

full photosensor PCB unit) has been replaced.

1) Remove the rear cover of the puncher after ensuring that the

power supply of the host machine is OFF.

2) Set the SW601 of the punch control PCB as shown below.

3) Turn ON the host machine.

4) Press the SW602 on the punch control PCB. The sensor out-

4) Press the SW602 on the punch control PCB. The sensor out-

put is automatically adjusted.

* The adjustment is complete when the LED 601 and LED 602

* The adjustment is complete when the LED 601 and LED 602

on the punch control PCB blink alternately.

5) Press the SW602 or SW603 on the punch control PCB to end

the adjustment mode. Then, set all the bits of the SW601 to

OFF.

OFF.

6) Turn OFF the host machine.

C. Registering the number of punch holes

Perform the following to register the type of punch module (number

of holes) used to the IC on the punch control PCB for identification

by the finisher. Be sure to register the type whenever you have

replaced the punch control PCB.

1) Remove the rear cover of the puncher after ensuring that the

of holes) used to the IC on the punch control PCB for identification

by the finisher. Be sure to register the type whenever you have

replaced the punch control PCB.

1) Remove the rear cover of the puncher after ensuring that the

power supply to the host machine is turned OFF.

2) Set the SW601 of the punch control PCB as shown below.

3) Turn ON the host machine.

4) Press the SW602 on the punch control PCB to select your

4) Press the SW602 on the punch control PCB to select your

desired number of punch holes.

* Each press on SW602 moves the selection through the fol-

* Each press on SW602 moves the selection through the fol-

lowing (repeatedly from top to bottom).

5)

Press the SW603 on the punch control PCB. Then, the num-

ber of punch holes is registered into the punch control PCB.

* The registration is complete when the LED 601 and LED

ber of punch holes is registered into the punch control PCB.

* The registration is complete when the LED 601 and LED

602 on the punch control PCB blink alternately.

6)

Press the SW602 or SW603 on the punch control PCB to end

the adjustment mode. Then, shift all the bits of the SW601 to

OFF.

the adjustment mode. Then, shift all the bits of the SW601 to

OFF.

7)

Turn OFF the host machine.

[15]

[14]

[13]

ON

1

2

3

4

ON

1

2

3

4

Number of punch holes

LED601/602

2 holes (punch module L1)

Blinks once in a cycle

2/3 holes (punch module M1)

Blinks twice in a cycle

4 holes (punch module N1 (FRA))

Blinks thrice in a cycle

4 holes (punch module P1 (SWD))

Blinks four times in a cycle

Display