Sharp DM-2000 (serv.man5) Service Manual ▷ View online

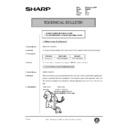

4) Loosen the set screw of the scanner drive pulley which is not in

contact with No. 2/3 mirror base unit positioning plate.

5) Without moving the scanner drive pulley shaft, manually turn the

scanner drive pulley until the positioning plate is brought into con-

tact with No. 2/3 mirror base unit, then fix the scanner drive pulley.

tact with No. 2/3 mirror base unit, then fix the scanner drive pulley.

6) Put No. 2/3 mirror base unit on the positioning plate again, push

the projections on the front frame side and the rear frame side of

the copy lamp unit to the corner frame, and tighten the wire fixing

screw.

the copy lamp unit to the corner frame, and tighten the wire fixing

screw.

(3) Main scanning direction (FR direction) distortion adjustment

This adjustment must be performed in the following cases:

● When the mirror base drive wire is replaced.

This adjustment must be performed in the following cases:

● When the mirror base drive wire is replaced.

● When the lamp unit, or No. 2/3 mirror holder is replaced.

● When a copy as shown is made.

1) Set A3 (11"

× 17") white paper on the original table as shown

below.

2) Open the original cover and make a normal (100%) copy.

3) Measure the width of the black background at the lead edge and

3) Measure the width of the black background at the lead edge and

at the rear edge.

If the width (La) of the black background at the lead edge is equal

that (Lb) at the rear edge, there is no need to execute the follow-

ing procedures of 4)

that (Lb) at the rear edge, there is no need to execute the follow-

ing procedures of 4)

∼ 7).

4) Loosen the mirror base drive pulley fixing screw on the front frame

side or on the rear frame side.

● When La < Lb

Turn the mirror base drive pulley on the front frame side in the

arrow direction A. (Do not move the mirror base drive pulley

shaft.)

arrow direction A. (Do not move the mirror base drive pulley

shaft.)

● When La > Lb

Turn the mirror base drive pulley on the front frame side in the

arrow direction A. (Do not move the mirror base drive pulley

shaft.)

arrow direction A. (Do not move the mirror base drive pulley

shaft.)

5) Tighten the mirror base drive pulley fixing screw.

Lb

La

Original

Copy

Paper exit

direction

direction

Fit the paper edge and

the glass holding plate edge.

the glass holding plate edge.

A3 (11" x 17") white paper

Glass holding plate

Allow a little space.

Paper exit direction

La: Lead edge black background width

Lb: Rear edge black background width

Lb: Rear edge black background width

A

B

Rear side

Front side

DM-2000

6 – 5

<Adjustment specification>

La = Lb

La = Lb

6) Execute the main scanning direction (FR) distartion balance ad-

justment previously described in 2) again.

(4) Sub scanning direction

(scanning direction) distortion adjustment

When there is no skew copy in the mirror base scanning direction and

there is no horizontal error (right angle to the scanning direction), the

adjustment can be made by adjusting the No. 2/3 mirror base unit rail

height.

Before performing this adjustment, be sure to perform the horizontal

image distortion adjustment in the laser scanner section.

This adjustment must be performed in the following cases:

● When the mirror base wire is replaced.

there is no horizontal error (right angle to the scanning direction), the

adjustment can be made by adjusting the No. 2/3 mirror base unit rail

height.

Before performing this adjustment, be sure to perform the horizontal

image distortion adjustment in the laser scanner section.

This adjustment must be performed in the following cases:

● When the mirror base wire is replaced.

● When the copy lamp unit or No. 2/3 mirror unit is replaced.

● When the mirror unit rail is replaced or moved.

● When a following copy is made.

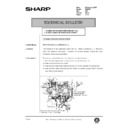

1) Making of a test sheet

Make test sheet by drawing parallel lines at 10 mm from the both

ends of A3 (11"

ends of A3 (11"

× 17") white paper as shown below. (These lines

must be correctly parallel to each other.)

2) Make a normal (100%) copy of the test sheet on A3 (11"

× 17")

paper. (Fit the paper edge with the glass holding plate edge.)

3) Measure the distances (La, Lb, Lc, Ld) at the four corners as

shown below.

When La = Lb and Lc = Ld, no need to perform the procedures

4) and 5).

4) and 5).

4) Move the mirror base B rail position up and down (in the arrow

direction) to adjust.

● When La Lb

Shift the mirror base B rail upward by the half of the difference

of La – Lb.

of La – Lb.

● When La Lb

Shift the mirror base B rail downward by the half of the difference

of Lb – La.

of Lb – La.

Example:

When La = 12 mm and Lb = 9 mm, shift the

mirror base B rail upward by 1.5 mm.

mirror base B rail upward by 1.5 mm.

● When Lc Ld

Shift the mirror base B rail downward by the half of the difference

of Lc – Ld.

of Lc – Ld.

● When Lc Ld

Shift the mirror base B rail downward by the half of the difference

of Ld – Lc.

of Ld – Lc.

∗ When moving the mirror base rail, hold the mirror base rail with

your hand.

<Adjustment specification>

La = Lb, Lc = Ld

La = Lb, Lc = Ld

5) After completion of adjustment, manually turn the mirror base

drive pulley, scan the mirror base A and mirror base B fully, and

check that the mirror bases are not in contact with each other.

∗ If the mirror base rail is moved extremely, the mirror base may

check that the mirror bases are not in contact with each other.

∗ If the mirror base rail is moved extremely, the mirror base may

be in contact with the frame or the original glass. Be careful to

avoid this.

avoid this.

(5) Main scanning direction (FR direction) magnification ratio ad-

justment (SIM 48-1)

Note: Before performing this adjustment, be sure to check that the

CCD unit is properly installed.

1) Put a scale on the original table as shown below.

2) Execute SIM 48-1.

3) After warmup, shading is performed and the current set value of

3) After warmup, shading is performed and the current set value of

the main scanning direction magnification ratio is displayed on the

display section in 2 digits.

display section in 2 digits.

4) Select the mode and press the start key again.

Original

Copy A

Copy B

10mm

10mm

10mm

10mm

Parallel line

White paper

Parallel line

La

Lb

Ld

Lc

Paper exit

direction

direction

DM-2000

6 – 6

5) Auto correction mode (AE lamp ON)

The mirror unit moves to the shading position, and the reference

width of the reference white plate is scanned, and the correction

value is automatically calculated from that scanned value.

The correction value is displayed and a copy is made.

width of the reference white plate is scanned, and the correction

value is automatically calculated from that scanned value.

The correction value is displayed and a copy is made.

6) Compare the scale image and the actual scale.

If a fine adjustment is required, switch to the manual correction

mode with the magnification ratio display key and perform fine ad-

justment.

mode with the magnification ratio display key and perform fine ad-

justment.

7) Manual correction mode (TEXT lamp ON)

Enter the set value and press the start key.

The set value is stored and a copy is made.

The set value is stored and a copy is made.

<Adjustment specification>

Note: A judgement must be made with 200mm width, and must not be

Note: A judgement must be made with 200mm width, and must not be

made with 100mm width.

Mode

Specification

SIM

Set value

Set range

Main

scanning

direction

magnification

ratio

scanning

direction

magnification

ratio

At normal:

±1.0%

SIM

48-1

Add 1:

0.1% increase

Reduce 1:

0.1% decrease

0.1% increase

Reduce 1:

0.1% decrease

1

∼ 99

● Error in the auto correction mode

Display

Content

Major cause

Copy

quantity

display “– –”

quantity

display “– –”

The correction

value

calculated is

over 5%.

value

calculated is

over 5%.

Improper position of reference

width line of the reference

white plate

width line of the reference

white plate

Improper installation of CCD

unit

unit

Paper jam

lamp ON

lamp ON

Reference line

scanning error

scanning error

Defective CCD

No reference white plate

∗ When SIM 48-01 (AE) is executed, the main scanning direction mag-

nification ratio is automatically set. Therefore, the main scanning

direction magnification ratio adjustment previously described in 5)

must be made again.

direction magnification ratio adjustment previously described in 5)

must be made again.

(6) Sub scanning direction (scanning direction) magnification

ratio adjustment (SIM 48-2, SIM 48-5)

a. OC mode in copying

Note:

Note:

● Before performing this adjustment, be sure to check that the

CCD unit is properly installed.

1) Put a scale on the original table as shown below, and make a nor-

mal (100%) copy.

2) Compare the scale image and the actual image. If necessary, per-

form the following adjustment procedures.

3) Execute SIM 48-2.

4) After warmup, shading is performed and the current set value of

4) After warmup, shading is performed and the current set value of

the sub scanning direction magnification ratio is displayed on the

display section in 2 digits.

display section in 2 digits.

5) Enter the set value and press the start key.

The set value is stored and a copy is made.

<Adjustment specification>

Mode

Specification

SIM

Set value

Set range

Sub scanning

direction

magnification

ratio

(OC mode)

direction

magnification

ratio

(OC mode)

Normal

±1.0%

SIM

48-2

Add 1:

0.1% increase

Reduce 1:

0.1% decrease

0.1% increase

Reduce 1:

0.1% decrease

1

∼ 99

b. SPF mode in copying

Note:

Note:

● Before performing this adjustment, be sure to check that the

CCD unit is properly installed.

● Before performing this adjustment, the OC mode adjustment

in copying must be completed.

1) Put a scale on the original table as shown below, and make a nor-

mal (100%) copy to make a test chart.

Note: Since the printed copy is used as a test chart, put the scale in

parallel with the edge lines.

2) Set the test chart on the SPF and make a normal (100%) copy.

3) Compare the scale image and the actual image. If necessary, per-

3) Compare the scale image and the actual image. If necessary, per-

form the following adjustment procedures.

4) Execute SIM 48-5.

5) After warmup, shading is performed and the current set value of

5) After warmup, shading is performed and the current set value of

the sub scanning direction magnification ratio is displayed on the

display section in 2 digits.

display section in 2 digits.

6) Enter the set value and press the start key.

The set value is stored and a copy is made.

<Adjustment specification>

Mode

Specification

SIM

Set value

Set range

Sub scanning

direction

magnification

ratio

(SPF mode)

direction

magnification

ratio

(SPF mode)

Normal

±1.0%

SIM

48-5

Add 1:

0.1% increase

Reduce 1:

0.1% decrease

0.1% increase

Reduce 1:

0.1% decrease

1

∼ 99

(7) Off center adjustment (SIM 50-13, SIM 50-16)

a. OC mode

Note:

a. OC mode

Note:

● The operation of SIM 50-13 is the same as that of SIM 48-01

(Photo LED ON)

1) Make a test chart as shown below and set it so that its center line

is fit with the original guide center mark.

∗ To make a test chart, draw a line on A3 or 11" × 17" paper at

∗ To make a test chart, draw a line on A3 or 11" × 17" paper at

the center in the paper transport direction.

2) Make a normal copy from the manual paper feed tray, and com-

pare the copy and the test chart.

If necessary, perform the following adjustment procedures.

If necessary, perform the following adjustment procedures.

3) Execute SIM 50-13.

4) After warmup, shading is performed and the current set value of

4) After warmup, shading is performed and the current set value of

the off center adjustment is displayed on the display section in 2

digits.

digits.

5) Enter the set value and press the start key.

The set value is stored and a copy is made.

Center

Original guide

Copy paper

(A3 or 17" x 11")

(A3 or 17" x 11")

DM-2000

6 – 7

<Adjustment specification>

Mode

Specification

SIM

Set value

Set range

Original off

center mode

(OC mode)

center mode

(OC mode)

Single:

Center

Center

±

2.0 mm

SIM

50-13

Add 1:

0.1 mm shift

to R side

Reduce 1:

0.1 mm shift

to L side

0.1 mm shift

to R side

Reduce 1:

0.1 mm shift

to L side

1

∼ 99

Duplex:

Center

Center

±2.5

mm

b. SPF mode

Note:

Note:

● Before performing this adjustment, be sure to check that the

paper off center is properly adjusted.

1) Make a test chart for the center position adjustment and set it on

the SPF.

<Adjustment specification>

Draw a line on a paper in the scanning direction.

Draw a line on a paper in the scanning direction.

2) Make a normal copy from the manual paper feed tray, and com-

pare the copy and the original test chart.

If necessary, perform the following adjustment procedures.

If necessary, perform the following adjustment procedures.

3) Execute SIM 50-16.

4) After warmup, shading is performed and the current set value of

4) After warmup, shading is performed and the current set value of

the off center adjustment at each paper feed port is displayed on

the display section in 2 digits.

the display section in 2 digits.

5) Enter the set value and press the start key.

<Adjustment specification>

Mode

Specification

SIM

Set value

Set range

Original off

center mode

(SPF mode)

center mode

(SPF mode)

Single:

Center

Center

±

3.0 mm

SIM

50-16

Add 1:

0.1 mm shift

to R side

Reduce 1:

0.1 mm shift

to L side

0.1 mm shift

to R side

Reduce 1:

0.1 mm shift

to L side

1

∼ 99

Duplex:

Center

Center

±3.5

mm

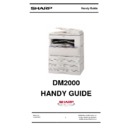

(8) OC (SPF) open/close detection position adjustment

1) Set A4 or 8 1/2"

× 11" paper on the OC table.

Check that the document size display on the operation panel in-

dicates the correct size of the set paper.

dicates the correct size of the set paper.

2) Close the OC (SPF) with a small clearance for insertion of your

hand left, and remove the paper from the OC table.

The document size display does not change from the display in 1).

The document size display does not change from the display in 1).

3) Open the OC (SPF) slowly until the display on the operation panel

changes (all the document size display lamps are turned off), and

measure dimension A shown below under that state.

measure dimension A shown below under that state.

<Spec value>

OC (SPF) open/close position A: 207

OC (SPF) open/close position A: 207

∼ 302mm

4) If the OC (SPF) open/close position A is not 207

∼ 302mm, adjust

the open/close sensor mounting plate position as shown below.

(9) Original sensor adjustment (SIM 43-3)

1) Execute SIM 41-2.

2) Set A3 (11"

2) Set A3 (11"

× 17") paper on the OC table.

3) Press the start key again.

4) The sensor level of the original sensor is automatically checked

4) The sensor level of the original sensor is automatically checked

and the value with an original - 40 is made as the threshold value

for scanning. (Automatic setting)

for scanning. (Automatic setting)

5) Execute SIM 43-3.

6) The light reception level of the original sensor is displayed.

6) The light reception level of the original sensor is displayed.

The first digit of the copy quantity display shows “A”: Light recep-

tion level display

The first digit of the copy quantity display shows “b”: Original

judgement level display

(The mode selection is made with the magnification ratio display

key.)

tion level display

The first digit of the copy quantity display shows “b”: Original

judgement level display

(The mode selection is made with the magnification ratio display

key.)

7) By changing the paper set on the original table, the original size

LED sensed by the sensor is lighted.

C. Image density adjustment

(1) Copy mode (SIM 46-1)

1) Set a test chart (UKOG-0162FCZZ) on the OC table as shown

below.

2) Put several sheets of A3 or 11"

× 17" white paper on the test

chart.

3) Execute SIM 46-1.

4) After warmup, shading is performed and the current set value of

4) After warmup, shading is performed and the current set value of

the density level is displayed on the display section in 2 digits.

For mode selection, use the density select key.

For mode selection, use the density select key.

5) Change the set value with the 10-key to adjust the copy image

density.

6) Make a copy and check that the specification below is satisfied.

<Adjustment specification>

Den-

sity

mode

Dis-

play

play

lamp

Ex-

posure

level

Sharp Gray

Chart output

Set value

Set

range

Auto

Auto

—

“3” is slightly

copied.

copied.

The greater

the set value

is, the

greater the

density is.

The smaller

the set value

is, the

smaller the

density is.

the set value

is, the

greater the

density is.

The smaller

the set value

is, the

smaller the

density is.

1

∼

99

Manual

Manual

3

“3” is slightly

copied.

copied.

Photo

Photo

3

“3” is slightly

copied.

copied.

Toner

save

Manual

/

Photo

3

“3” is slightly

copied.

copied.

Open

A

Distance A = Table glass top - OC (SPF) knob 117"

Check the position where the display checked in

procedure 1) is changed.

procedure 1) is changed.

(A)

(B)

Open/close sensor mounting plate

Factory setting : second from the top

DM-2000

6 – 8