Sharp MX-1800N (serv.man28) Service Manual ▷ View online

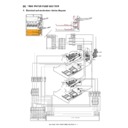

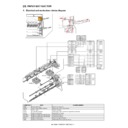

MX-1800N LSU SECTION H – 1

MX-1800N

Service Manual

[H] LSU SECTION

1. Electrical and mechanism relation diagram

CN11

B7P-PH-K-S

CN8

CN21

B4P-PH-K-R

S6B-XA

B6B-XA

CN2

B12B-PHDSS-B

CN7

CN13

CN1

B34B-PHDSS-B

S20B-PHDSS-B

B20B-PHDSS-B

CN9

CN14

S22B-PHDSS-B

B22B-PHDSS-B

CN4

B6P-PH-K-S

PS

M

2

P

R

CN10

B5P-PH-K-S

1

4

/LSUSS_B

24V3

2

19

20

21

22

12

4

V

3

1

2

D-GND

ECLK_LSU_P

ECLK_LSU_N

17

/LSUSS_B

21

22

20

15

17

18

19

4

10

5

16

11

12

13

14

15

16

VSYNC_Y_N

1

20

3

CH0_N

CH0_P

D-GND

19

1

2

14

13

D-GND

CH0_N

D-GND

D-GND

CLCLK_P

CH2_P

CH3_P

CH3_N

D-GND

ECLK_LSU_P

ECLK_LSU_N

D-GND

D-GND

HSYNC_LSU_P

HSYNC_LSU_N

D-GND

VSYNC_K_P

VSYNC_K_N

VSYNC_C_P

VSYNC_C_N

6

D-GND

3.3V

D-GND

5VN

24V1

P-GND

1

2

3

4

24V1

5

5

P-GND

6

D-GND

3

5VN

4

D-GND

1

3.3V

2

12

9

2

3

4

LSU PWB

10

11

D-GND

CLCLK_N

CH2_N

20

19

CH1_N

CH1_P

9

5

6

7

8

6

7

8

CLCLK_P

CH3_N

CH3_P

D-GND

CH2_P

D-GND

D-GND

CLCLK_N

D-GND

CH1_N

CH1_P

CH2_N

CH0_P

16

17

18

1

VSYNC_M_N

VSYNC_Y_P

VSYNC_M_P

VSYNC_Y_N

15

16

17

18

11

12

13

14

VSYNC_M_N

VSYNC_M_P

VSYNC_Y_P

2

3

4

5

6

7

8

VSYNC_K_N

VSYNC_K_P

VSYNC_C_P

VSYNC_C_N

n

TRANS_DATA

D-GND

LSUASIC_RST

n

RSV_DAT

JOBEND_INT

LSUTH1

LSUTH2

8

9

10

11

n

TRANS_RST

9

10

4

13

14

15

12

5

6

7

LSUTH2

n

RSV_DAT

n

TRANS_RST

JOBEND_INT

LSUTH1

n

SCK_LSU

n

TRANS_DATA

D-GND

LSUASIC_RST

INT5V

D-GND

D-GND

D-GND

1

2

3

D-GND

n

SCK_LSU

INT5V

D-GND

6

5

11

12

LSUTH1

D-GND

LSUTH2

1

6

/START

P-GND

24V1

/BREAK

LDCHK_Y

n

LDERR_Y

4

2

/START

P-GND

5

3

POLYCLK

/LOCK

D-GND

Vref_Y

24V1

/BREAK

6

1

POLYCLK

/LOCK

2

3

4

5

3

4

LSUTH1

D-GND

/SH_Y

/ENB_Y

DT_Y-

DT_Y+

LDCHK_M

n

LDERR_M

D-GND

INT5V

DT_M-

DT_M+

D-GND

Vref_M

D-GND

INT5V

/SH_M

/ENB_M

D-GND

Vref_C

LDCHK_C

n

LDERR_C

/SH_C

/ENB_C

DT_C-

DT_C+

26

32

34

33

29

31

30

28

22

21

27

25

18

16

14

20

15

13

17

19

2

8

10

9

5

7

6

4

4

3

2

1

8

7

6

5

D-GND

Vref_Y

LDCHK_Y

n

L

DERR_Y

/SH_Y

/ENB_Y

DT_Y-

DT_Y+

10

9

LDCHK_M

n

L

DERR_M

2

1

D-GND

INT5V

10

9

8

7

6

5

4

3

DT_M-

DT_M+

D-GND

Vref_M

D-GND

INT5V

/SH_M

/ENB_M

4

3

2

1

8

7

6

5

D-GND

Vref_C

LDCHK_C

n

L

DERR_C

/SH_C

/ENB_C

DT_C-

DT_C+

SK_K

n

LDERR_K

D-GND

INT5V

10

9

3

1

D-GND

INT5V

1

0

9

D-GND

INT5V

/SH_K

/ENB_K

DT_K-

DT_K+

D-GND

Vref_K

2

1

3

1

5

7

6

4

2

8

SK_K

n

L

DERR_K

10

9

8

7

6

5

4

3

DT_K-

DT_K+

D-GND

Vref_K

D-GND

INT5V

/SH_K

/ENB_K

5VN

D-GND

nB

D

D-GND

4

3

2

1

1

2

3

4

5VN

D-GND

nB

D

D-GND

MOTHER PWB

PCU

P

WB

D-GND

18

HSYNC_LSU_N

HSYNC_LSU_P

D-GND

PGM

1

LSUSS

2

3

4

6 7

5

14

8

9

11

13

12

9

10

10

10

10

9

MX-1800N LSU SECTION H – 2

2. Operational descriptions

A. LSU section

(1) Outline

Image data sent from the image process circuit through the mother

are converted into laser beams to be radiated onto the OPC drum

surface. The LSU unit is composed of the primary system including

optical elements such as lasers and the polygon mirror and the mir-

ror which assures the optical path and the scan system which

includes the optical elements including the polygon mirror and the

mirror which assures the optical path.

are converted into laser beams to be radiated onto the OPC drum

surface. The LSU unit is composed of the primary system including

optical elements such as lasers and the polygon mirror and the mir-

ror which assures the optical path and the scan system which

includes the optical elements including the polygon mirror and the

mirror which assures the optical path.

(2) Composition

(Primary system)

(Scan system)

(On the polygon mirror)

(3) Outline of LSU specifications

Signal name

Name

Function/Operation

PGM

Polygon motor

Laser beam is reflected at the constant speed rotation.

No.

Name

Function/Operation

1

LD PWB (K)

Controls laser beam flashing and the output value.

2

LD PWB (C)

3

LD PWB (M)

4

LD PWB (Y)

5

Cylindrical lens

Converges laser beams and focus.

6

f

θ lens 1

Laser beams are refracted so that the laser scan speed on the OPC drum is even in both ends and at the center.

7

f

θ lens 2

8

Reflection mirror

Secures the path for laser beams.

9

Cylindrical lens

Converges laser beams, and focus on the OPC drum.

10

OPC drum

Forms electrostatic latent images according to laser beams.

11

Convergence lens for BD

Converges laser beams to the BD PWB.

12

BD PWB

Detects the timing for starting laser scanning.

13

LSU CNT PWB

Laser beams are controlled and the polygon motor control signal is generated according to the PCU PWB control

signal and image data.

signal and image data.

14

LSU therminstor

Measures the temperature in LSU.

Model

Number of

mirror

surfaces

Rotating

speed

Bearing

Remark

MX-1800N

7 surfaces

25106rpm

OIL

Effective scan width:

307mm

Resolution:

600dpi

Beam diameter:

Main scan = 50 to 65µm, Sub scan = 60 to 75µm

Laser power:

Max. 0.65mW

LD wavelength:

770 to 795nm

MX-1800N LSU SECTION H – 3

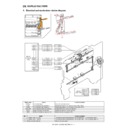

3. Disassembly and assembly

A. LSU section

(1) LSU

1) Remove the left cabinet rear lower and the left cabinet. (Refer

to Left Cabinet Rear Lower and Left Cabinet in External Outfit

Section.)

Section.)

2) Remove the waste toner box.

3) Remove the LSU left plate PA.

4)

Remove the LSU slant adjustment plate screw (A), and loosen

the screw (B).

Remove the LSU shaft fixing plate. Remove the screws.

the screw (B).

Remove the LSU shaft fixing plate. Remove the screws.

5)

Shift the front side of the LSU shaft from (A) to (B), and remove

the LSU shaft.

the LSU shaft.

6)

Disconnect the connector, and remove the LSU.

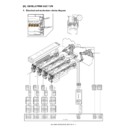

a. Dust-proof glass

1)

1)

Remove the waste toner box.

2)

Remove the LSU cleaning stick from the front cover.

Unit

Parts

Maintenance

(1)

LSU

a

Dust-proof glass

{

b

Polygon motor

(2)

Others

a

LSU shutter solenoid

b

Cleaning base

(1)

(1)-b

(2)-a

(2)-b

(1)-a

1

2

1

2

1

2

A

B

B

A

2

3

1

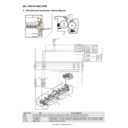

MX-1800N LSU SECTION H – 4

3) Insert the LSU cleaning rod and slide it back and forth a few

times to clean the dust-proof glass.

b. Polygon motor

1) Remove the LSU.

2) Remove the screws, and remove the LSU CNT PWB cover R.

1) Remove the LSU.

2) Remove the screws, and remove the LSU CNT PWB cover R.

3) Remove the screws, then lift up the LSU CNT PWB cover F

(A).

Remove the screws, and lift up the polygon motor unit (B).

Remove the screws, and lift up the polygon motor unit (B).

4) Remove the connector and the screws, then remove the poly-

gon motor.

* When installing, do not touch the moving section of the poly-

* When installing, do not touch the moving section of the poly-

gon mirror and the mirror surface.

(2) Others

a. LSU shutter solenoid 1

1)

1)

Remove the LSU.

2)

Remove the connector and the screws, then remove the LSU

shutter solenoid unit.

* When installing, the shutter U-groove is engaged with the

shutter solenoid unit.

* When installing, the shutter U-groove is engaged with the

shutter lever arm shaft section (A).

3)

Remove the screws, and remove the LSU shutter solenoid 1.

* When installing, engage the solenoid pin with the shutter

* When installing, engage the solenoid pin with the shutter

lever arm.

b. Cleaning base

1)

1)

Remove the waste toner box.

2)

Remove the LSU cleaning stick from the front cover.

3)

Remove the cleaning base from the LSU cleaning rod.

A

B

1

2

A

Display