Sharp MX-1800N (serv.man17) Service Manual ▷ View online

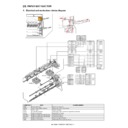

MX-1800N MAINTENANCE 9 – 1

MX-1800N

Service Manual

[9] MAINTENANCE

1. Maintenance system table

: Check (Clean, replace, or adjust according to necessity.) {: Clean : Replace

: Adjust ✩: Lubricate : Shift the position.

(Color supply)

(Monochrome supply/Mechanical parts)

Unit name

Part name

When

calling

40

K

80

K

120

K

160

K

200

K

240

K

280

K

320

K

360

K

400

K

~

1200

K

Remark/Refer to

the Parts Guide.

the Parts Guide.

Block/Item No.

(Only the

replacement parts

are described.)

Drum

peripheral

(Color)

peripheral

(Color)

Drum

Cleaning blade

Cleaning blade

(P/G No.: [24]-14)

Main charger unit

(P/G No.: [24]-2)

Toner stirring sheet

(P/G No.: [24]-42)

Toner stirring plate

(P/G No.: [24]-45)

Side seal F/R

Toner reception seal

Toner reception seal

Developing

section

section

Developer (C/M/Y)

DV blade N kit

(C/M/Y)

DV blade N kit

(C/M/Y)

(P/G No.: [22]-22)

DV side seal F/R

(C/M/Y)

(C/M/Y)

(P/G No.: [23]-26,

[23]-15)

[23]-15)

Toner filter unit

(P/G No.: [22]-37)

Toner cartridge

(C/M/Y)

(C/M/Y)

User replacement for every toner empty (or the specified traveling distance).

Bias pin/Connector

Unit name

Part name

When

calling

80

K

160

K

240

K

320

K

400

K

480

K

560

K

640

K

720

K

800

K

~

1200

K

Remark/Refer to

the Parts Guide.

Block/Item No.

(Only the

replacement parts

are described.)

Drum

peripheral

peripheral

Drum

Cleaning blade

Cleaning blade

(P/G No.: [24]-14)

Main charger unit

(P/G No.: [24]-2)

Toner stirring sheet

(P/G No.: [24]-42)

Toner stirring plate

(P/G No.: [24]-45)

Side seal F/R

Toner reception seal

Waste toner box

Toner reception seal

Waste toner box

Each color 5%

coverage,

color ratios 25%

coverage,

color ratios 25%

LSU

Dust proof glass

{

{

{

{

{

{

{

{

{

{

{

{

{

Cleaning base

Developing

section

section

Developer

DV blade N kit

DV blade N kit

(P/G No.: [22]-22)

DV side seal F/R

(P/G No.: [23]-15,

[23]-26)

[23]-26)

Toner filter unit

(P/G No.: [22]-37)

Toner cartridge

User replacement for every toner empty (or the specified traveling distance).

Bias pin/Connector

Transfer

section

section

Intermediate transfer

belt

belt

(P/G No.: [26]-3)

Primary transfer coat

roller

roller

{

{

{

{

{

{

{

{

/

(P/G No.: [27]-9,

[28]-27)

[28]-27)

Primary transfer blade

(P/G No.: [25]-19)

Belt drive gear

/

(P/G No.: [27]-13)

Primary transfer

conduction collar

conduction collar

(P/G No.: [27]-8,

[28]-25)

[28]-25)

TC roller bearing

(P/G No.: [27]-39)

Transfer drive roller

{

{

{

{

{

{

{

{

{

{

{

{

Transfer follower

roller

roller

{

{

{

{

{

{

{

{

{

{

{

{

Tension roller

{

{

{

{

{

{

{

{

{

{

{

{

Roller CL brush

Y auxiliary roller

Y auxiliary roller

{

{

{

{

{

{

{

{

{

{

{

{

Resist backup roller

Cleaner seal

Cleaner seal R

Cleaner seal

Cleaner seal R

MX-1800N MAINTENANCE 9 – 2

Transfer

section

section

Transfer toner

reception seal

Secondary transfer

belt

reception seal

Secondary transfer

belt

/

(P/G No.: [30]-21)

Secondary transfer

roller

roller

/

(P/G No.: [30]-6)

Secondary belt drive

roller

roller

{

{

{

/{

Secondary belt

tension roller

tension roller

{

{

{

/{

Secondary belt

follower roller

follower roller

{

{

{

/{

Secondary transfer

idle gear

idle gear

/

(P/G No.: [29]-6)

Sensors (Process

control resist sensor)

control resist sensor)

{

{

{

{

{

{

{

{

{

{

{

{

Fusing section

Upper heat roller unit

/

(P/G No.: [32]-32)

Lower heat roller unit

/

(P/G No.: [33]-15)

Upper separation

pawl

pawl

/

(P/G No.: [32]-11)

Lower separation

pawl

pawl

/

(P/G No.: [33]-100)

Upper thermistor

(Non-contact type)

(Non-contact type)

/

(P/G No.: [32]-37)

Upper thermistor

(Contact type)

(Contact type)

/

(P/G No.: [32]-18)

Lower thermistor

/

(P/G No.: [33]-20)

Gears

✩

✩

✩

✩

✩

✩

✩

✩

✩

✩

✩

✩

Paper guides

{

{

{

{

{

{

{

{

{

{

{

{

{

Filters

Ozone filter PA

(P/G No.: [47]-40)

Paper exit filter

(P/G No.: [37]-100)

Paper feed

section

section

Pickup roller

{

{

{

{

{

{

{

{

{

{

{

{

Replacement

reference: Replace

every 100K counts

for each paper feed.

reference: Replace

every 100K counts

for each paper feed.

Paper feed roller

{

{

{

{

{

{

{

{

{

{

{

{

Separation roller

{

{

{

{

{

{

{

{

{

{

{

{

Torque limiter

Replacement

reference: Replace

every 100K counts

for each paper feed.

reference: Replace

every 100K counts

for each paper feed.

Transport

section/

Paper exit

reverse section

section/

Paper exit

reverse section

PS follower roller

{

{

{

{

{

{

{

{

{

{

{

{

Transport rollers

{

{

{

{

{

{

{

{

{

{

{

{

Transport paper

guides

guides

{

{

{

{

{

{

{

{

{

{

{

{

{

Discharge brush

Gears

Gears

When checking,

apply to the

necessary positions

(specified positions).

apply to the

necessary positions

(specified positions).

PS paper dust

removal unit

removal unit

(P/G No.: [26]-100)

Drive section

Gears (Grease)

When checking,

apply to the

necessary positions

(specified positions).

apply to the

necessary positions

(specified positions).

Shaft earth sections

(Conduction grease)

(Conduction grease)

When checking,

apply to the

necessary positions

(specified positions).

apply to the

necessary positions

(specified positions).

Belts

Sensors

Sensors

Optical section

Mirror/Lens/Reflector/

CCD

CCD

{

{

{

{

{

{

{

{

{

{

{

{

{

Table glass/SPF glass

{

{

{

{

{

{

{

{

{

{

{

{

{

Scanner lamp

{

{

{

{

{

{

{

{

{

{

{

{

{

Rails

✩

✩

✩

✩

✩

✩

✩

✩

✩

✩

✩

✩

✩

Drive belt/Drive wire

Unit name

Part name

When

calling

80

K

160

K

240

K

320

K

400

K

480

K

560

K

640

K

720

K

800

K

~

1200

K

Remark/Refer to

the Parts Guide.

Block/Item No.

(Only the

replacement parts

are described.)

MX-1800N MAINTENANCE 9 – 3

2. Details of maintenance

A. Drum peripheral

: Check (Clean, replace, or adjust according to necessity.) {: Clean : Replace

: Adjust ✩: Lubricate : Shift the position.

No.

Part name

Monochrome

supply/

Mechanical

parts

When

calling

80

K

160

K

240

K

320

K

400

K

480

K

560

K

640

K

720

K

800

K

~

1200

K

Remark/Refer to

the Parts Guide.

Block/Item No.

(Only the

replacement parts

are described.)

Color supply

40

K

80

K

120

K

160

K

200

K

240

K

280

K

320

K

360

K

400

K

~

1200

K

1

Drum (BK)

Monochrome

supply

supply

2

Cleaning blade (BK)

(P/G No.: [24]-14)

3

Main charger unit (BK)

(P/G No.: [24]-2)

4

Drum (C)

Color supply

5

Cleaning blade (C)

(P/G No.: [24]-14)

6

Main charger unit (C)

(P/G No.: [24]-2)

7

Side seal F/R (BK)

Mechanical

parts

parts

8

Toner reception seal

(BK)

(BK)

9

Side seal F/R (C)

10

Toner reception seal (C)

11

Waste toner box

Each color 5%

coverage,

color ratios 25%

coverage,

color ratios 25%

3,6

7,9

8,10

2,5

7,9

1,4

11

MX-1800N MAINTENANCE 9 – 4

The PM cycle means the replacement timing of periodic replace-

ment consumable parts which are required for maintaining the per-

formance.

The PM cycle is specified only for B/W output. For color output, it is

used as a reference value.

[Reason] Since the ratio of B/W to color differs depending on the

user's operation scene which varies every day, the PM cycle can-

not be specified in a certain cycle for color output.

Replacement of a PM item at the recommended life is performed

by the dealer's judgment or at PM call or at EM call.

Life end definition of a drum

When the drum counter exceeds the specified level of 100% black

output or 100% full color output, it is judged as life end.

However in practice, the number of rotations specifies quality

assurance policy of the tandem engine, where its wear cannot be

solely defined by the number of sheets but other operating condi-

tions including increased slip rotations depending on the ratio of B/

W to color and/or B/W printing in the color mode using the ACS.

The guaranteed number of rotations for the MX-1800 series drum

is 840K.

ment consumable parts which are required for maintaining the per-

formance.

The PM cycle is specified only for B/W output. For color output, it is

used as a reference value.

[Reason] Since the ratio of B/W to color differs depending on the

user's operation scene which varies every day, the PM cycle can-

not be specified in a certain cycle for color output.

Replacement of a PM item at the recommended life is performed

by the dealer's judgment or at PM call or at EM call.

Life end definition of a drum

When the drum counter exceeds the specified level of 100% black

output or 100% full color output, it is judged as life end.

However in practice, the number of rotations specifies quality

assurance policy of the tandem engine, where its wear cannot be

solely defined by the number of sheets but other operating condi-

tions including increased slip rotations depending on the ratio of B/

W to color and/or B/W printing in the color mode using the ACS.

The guaranteed number of rotations for the MX-1800 series drum

is 840K.

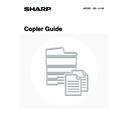

The drum life is affected by the number of sheets of one print job.

This is because the actual life is determined by rotations of the

drum. If the number of sheets of one print job is less than 2 sheets,

the number of rotations for page is increased. As shown in the fig-

ure below, therefore, the number of sheets of drum life varies

depending on the number of sheets of one print job.

As a reference of the drum life, "Life meter" can be checked with

SIM22-1 from the accumulated number of rotations of each drum.

"Life meter" indicates the remained life (%) of the drum with the

entire drum life as 100%.

(Example) If the used number of rotations is 588K:

This is because the actual life is determined by rotations of the

drum. If the number of sheets of one print job is less than 2 sheets,

the number of rotations for page is increased. As shown in the fig-

ure below, therefore, the number of sheets of drum life varies

depending on the number of sheets of one print job.

As a reference of the drum life, "Life meter" can be checked with

SIM22-1 from the accumulated number of rotations of each drum.

"Life meter" indicates the remained life (%) of the drum with the

entire drum life as 100%.

(Example) If the used number of rotations is 588K:

588 (K rotations) / 840 (K rotations) x 100 = 070 (%)

* For 100% full color output by the user, the life of the black drum

is 40K similarly to the life of the color drums.

Drum counter

Number of rotations of drum

B/W

Full color

B/W

Full color

Drum

80K

40K

840K rotations

840K rotations

Drum Life

0

50

100

150

200

0

1

2

Number of sheets of one print job

Drum

L

ife

(

-

K

p

ages)

Black Drum

Color Drum