Sharp MX-C250 / MX-C250E / MX-C250F / MX-C250FE / MX-C250FR / MX-C300F / MX-C300W / MX-C300WE / MX-C300A / MX-C300WR (serv.man6) Service Manual ▷ View online

MX-C250 SIMULATION 6 – 47

Operation/Procedure

1) Set the original on the original table.

2) Select an item to be set with Arrow keys.

3) Press [OK]/[START] key

When [START] key is pressed, the adjustment value is set and

the scanned document image is outputted.

the scanned document image is outputted.

46-43

Purpose

:

Adjustment/Setup

Function (Purpose)

Used to adjust the FAX send image density.

(Super Fine)

(Super Fine)

Section

Operation/Procedure

1) Set the original on the original table.

2) Select an item to be set with Arrow keys.

3) Press [OK]/[START] key

When [START] key is pressed, the adjustment value is set and

the scanned document image is outputted.

the scanned document image is outputted.

46-51

Purpose

:

Adjustment/Setup

Function (Purpose)

Used to adjust the gamma for the copy

mode heavy paper mode and the image

process mode. (Manual adjustment)

mode heavy paper mode and the image

process mode. (Manual adjustment)

Section

Operation/Procedure

1) Select a target adjustment mode with 10keys.

2) Select an adjustment target color with [OK]/[START] key.

3) Select a target adjustment density level with Arrow keys.

4) Enter the set value with 10 keys.

5) Press [OK]/[START] key

When COPY key is pressed, the adjustment pattern is printed.

When the image density is insufficient or a background copy is

made in heavy paper copy, change this adjustment value to adjust

the image density.

made in heavy paper copy, change this adjustment value to adjust

the image density.

46-52

Purpose

:

Adjustment/Setup

Function (Purpose)

Used to reset the copy color balance

adjustment (adjustment for each dither) to

the default value.

adjustment (adjustment for each dither) to

the default value.

Section

Operation/Procedure

1) Select an item to be reset to the default (for each dither) with 10

keys.

To reset the adjustment values of all the items, select [ALL].

2) Press [OK]/[START] key

46-54

Purpose

:

Adjustment

Function (Purpose)

Used to reset the copy color balance

adjustment (auto adjustment for each

dither).

adjustment (auto adjustment for each

dither).

Section

Operation/Procedure

The color balance, the density, and the gradation are adjusted for

the monochrome mode, the heavy paper mode, the text, and the

line image edges.

This simulation is used to improve image quality in these modes

and images.

The color balance, the density, and the gradation are adjusted for

the monochrome mode, the heavy paper mode, the text, and the

line image edges.

This simulation is used to improve image quality in these modes

and images.

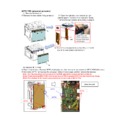

1) Press [OK]/[START] key. (A4 or 11" x 8.5" paper is automatically

selected.) The color patch image (adjustment pattern) is printed.

2) Set the color patch image (adjustment pattern) printed in the

procedure 1) on the document table so that the thin lines on the

printed color patch image (adjustment pattern) are on the left

side. Place 5 sheets of white paper on the printed color patch

image (adjustment pattern).

printed color patch image (adjustment pattern) are on the left

side. Place 5 sheets of white paper on the printed color patch

image (adjustment pattern).

3) Press [OK]/[START] key.

Item/Display

Content

Setting

range

Default

value

1

AE(PHOTO ON)

Automatic expo-

sure value (Fine/

HT)

sure value (Fine/

HT)

1 - 99

50

2

AE(PHOTP OFF)

Automatic expo-

sure value (Fine)

sure value (Fine)

1 - 99

50

3

MANUAL(PHOTO ON)

Manual exposure

value (Fine/HT)

value (Fine/HT)

1 - 99

50

4

MANUAL(PHOTO

OFF)

OFF)

Manual exposure

value (Fine)

value (Fine)

1 - 99

50

Item/Display

Content

Setting

range

Default

value

1

AE(PHOTO ON)

Automatic expo-

sure value (Super

fine/HT)

sure value (Super

fine/HT)

1 - 99

50

2

AE(PHOTP OFF)

Automatic expo-

sure value (Super

fine)

sure value (Super

fine)

1 - 99

50

3

MANUAL(PHOTO ON)

Manual exposure

value (Super fine/

HT)

value (Super fine/

HT)

1 - 99

50

4

MANUAL(PHOTO

OFF)

OFF)

Manual exposure

value (Super fine)

value (Super fine)

1 - 99

50

Item/Display

Content

1

HEAVYPAPER K

Copier heavy paper K

2

HEAVYPAPER C

Copier heavy paper C

3

HEAVYPAPER M

Copier heavy paper M

4

HEAVYPAPER Y

Copier heavy paper Y

5

DITHER1 K

Color error diffusion K

6

DITHER1 C

Color error diffusion C

7

DITHER1 M

Color error diffusion M

8

DITHER1 Y

Color error diffusion Y

9

DITHER2

Monochrome error diffusion

10

DITHER3

Monochrome dither (600dpi)

Item/Display

Density level

(Point)

Setting range

Default

value

1

POINT1

Point 1

1 - 255

128

2

POINT2

Point 2

1 - 255

128

3

POINT3

Point 3

1 - 255

128

4

POINT4

Point 4

1 - 255

128

5

POINT5

Point 5

1 - 255

128

6

POINT6

Point 6

1 - 255

128

7

POINT7

Point 7

1 - 255

128

8

POINT8

Point 8

1 - 255

128

9

POINT9

Point 9

1 - 255

128

10

POINT10

Point 10

1 - 255

128

11

POINT11

Point 11

1 - 255

128

12

POINT12

Point 12

1 - 255

128

13

POINT13

Point 13

1 - 255

128

14

POINT14

Point 14

1 - 255

128

15

POINT15

Point 15

1 - 255

128

16

POINT16

Point 16

1 - 255

128

17

POINT17

Point 17

1 - 255

128

Select item (Mode/Image)

Content

Dither

ALL

All dither values

Heavy Paper

Dither values for heavy paper

Color ED

Dither values for color mode

B/W ED

Dither values for the monochrome mode

B/W 600dpi

Dither values for the monochrome 600dpi

mode

mode

Item/Display

Content

MX-C250 SIMULATION 6 – 48

The color balance adjustment is automatically performed.

The adjustment pattern is printed out. Check it for any abnor-

mality.

The adjustment pattern is printed out. Check it for any abnor-

mality.

4) Press [OK]/[START] key.

The list of the adjustment items (for each dither) is displayed.

5) Select an adjustment item (for each dither).

6) Press [OK]/[START] key. (A4 or 11" x 8.5" paper is automatically

selected.)

The color patch image (adjustment pattern) is printed out.

7) Set the color patch image (adjustment pattern) printed in the

procedure 6) on the document table so that the thin lines on the

printed color patch image (adjustment pattern) are on the left

side. Place 5 sheets of white paper on the printed color patch

image (adjustment pattern).

printed color patch image (adjustment pattern) are on the left

side. Place 5 sheets of white paper on the printed color patch

image (adjustment pattern).

8) Press [OK]/[START] key.

The color balance adjustment is automatically performed.

The adjustment pattern is printed out. Check it for any abnor-

mality.

The adjustment pattern is printed out. Check it for any abnor-

mality.

9) When [OK]/[START] key is pressed, the adjustment result is

registered and the adjustment mode is terminated. When [EXE-

CUTE] key is pressed, the adjustment result is registered and

the screen is shifted to the other item (Mode/Image) select

menu.

CUTE] key is pressed, the adjustment result is registered and

the screen is shifted to the other item (Mode/Image) select

menu.

To execute the adjustment of the other item (Mode/Image),

press [EXECUTE] key.

After completion of all the adjustments of the items (Mode/

Image), press [OK]/[START] key, and the adjustment results

are registered.

press [EXECUTE] key.

After completion of all the adjustments of the items (Mode/

Image), press [OK]/[START] key, and the adjustment results

are registered.

10)Make a copy, and check the copy image quality.

48

48-1

Purpose

:

Adjustment

Function (Purpose)

Used to adjust the scan image magnifica-

tion ratio (in the main scanning direction

and the sub scanning direction).

tion ratio (in the main scanning direction

and the sub scanning direction).

Section

Operation/Procedure

1) Enter the set value with 10 keys.

2) Press [OK]/[START] key.

The set value in step 1) is saved.

When the adjustment value is increased, the image magnification

ratio is increased.

A change of "1" in the adjustment value of item 1, 3, or 5 corre-

sponds to a change of about 0.02% in the copy magnification ratio.

A change of "1" in the adjustment value of item 2, 4, or 6 corre-

sponds to a change of about 0.1% in the copy magnification ratio.

ratio is increased.

A change of "1" in the adjustment value of item 1, 3, or 5 corre-

sponds to a change of about 0.02% in the copy magnification ratio.

A change of "1" in the adjustment value of item 2, 4, or 6 corre-

sponds to a change of about 0.1% in the copy magnification ratio.

48-6

Purpose

:

Adjustment

Function (Purpose)

Used to adjust the rotation speed of each

motor.

motor.

Section

Operation/Procedure

1) Select an item to be set with Arrow keys.

2) Enter the set value with 10 keys.

3) Press [OK]/[START] key.

The set value in step 2) is saved.

When the adjustment value is increased, the speed is increased,

and vice versa. A change of 1 in the adjustment value corresponds

to a change of about 0.1% in the speed.

and vice versa. A change of 1 in the adjustment value corresponds

to a change of about 0.1% in the speed.

49

49-1

Purpose

:

Function (Purpose)

Used to perform the firmware update.

Section

Operation/Procedure

1) Save the firmware to the USB flash drive.

2) Insert the USB flash drive into the main unit.

3) Select a target firmware file for update.

Press Arrow key to select all the Firmware collectively.

4) Press [OK]/[START] key.

5) Press [OK]/[START] key.

The selected firmware is updated.

When the operation normally completed, "COMPLETE" is dis-

played. When terminated abnormally, "ERROR" is displayed.

When the operation normally completed, "COMPLETE" is dis-

played. When terminated abnormally, "ERROR" is displayed.

Item/Display

Content

Set-

ting

ting

range

Default

value

1

CCD (MAIN)

SCAN main scanning mag-

nification ratio adjustment

(CCD)

nification ratio adjustment

(CCD)

1 - 99

50

2

CCD (SUB)

SCAN sub scanning magni-

fication ratio adjustment

(CCD)

fication ratio adjustment

(CCD)

1 - 99

50

3

SPF (MAIN)

RSPF document front sur-

face magnification ratio

(Main scan)

face magnification ratio

(Main scan)

1 - 99

50

4

SPF (SUB)

RSPF document front sur-

face magnification ratio

(Sub scan)

face magnification ratio

(Sub scan)

1 - 99

50

5

SPFB (MAIN)

RSPF document back sur-

face magnification ratio

(Main scan)

face magnification ratio

(Main scan)

1 - 99

50

6

SPFB (SUB)

RSPF document back sur-

face magnification ratio

(Sub scan)

face magnification ratio

(Sub scan)

1 - 99

50

Item/Display

Content

Min

Max

Defa

ult

COLOR

FUM

Drum motor correction value

1

99

56

DVM

Drum motor correction value

1

99

56

DM

Drum motor correction value

1

99

56

C2MM

2CStransport motor correction value

1

99

56

MONO

FUM

Fusing motor correction value

1

99

56

DM

Drum motor correction value

1

99

56

HEAVY

FUM

Drum motor correction value

1

99

54

DVM

Drum motor correction value

1

99

56

DM

Drum motor correction value

1

99

56

Item/Display

Content

Set-

ting

ting

range

Default

value

MX-C250 SIMULATION 6 – 49

49-2

Purpose

:

Function (Purpose)

Used to perform the FPGA update.

Section

Operation/Procedure

1) Save the FPGA file to the USB flash drive.

2) Insert the USB flash drive into the main unit.

3) Select a target FPGA file for update.

Press Arrow key to select all the FPGA collectively.

4) Press [OK]/[START] key.

Right after pressing the button, the selected firmware is started

to be updated.

to be updated.

5) Turn OFF and ON the power of the machine. .

When the operation normally completed, "COMPLETE" is dis-

played. When terminated abnormally, "ERROR" is displayed.

played. When terminated abnormally, "ERROR" is displayed.

50

50-1

Purpose

:

Adjustment

Function (Purpose)

Copy image position, image loss adjust-

ment

ment

Section

Operation/Procedure

1) Select an item to be set with Arrow keys.

2) Enter the set value with 10 keys.

Set the items other than RRCA, LEAD, and SIDE to the

default.

RRCA: Image lead edge reference position adjustment

LEAD: Lead edge image loss adjustment

SIDE: Side image loss adjustment

default.

RRCA: Image lead edge reference position adjustment

LEAD: Lead edge image loss adjustment

SIDE: Side image loss adjustment

3) Press [OK]/[START] key. The set value in step 2) is saved.

1. (RRC-A) Timing from starting document scanning to specifying

the image lead edge reference is adjusted. (01.mm/step)

the image lead edge reference is adjusted. (01.mm/step)

* When the value is decreased, the timing is advanced. When

the value is increased, the timing is delayed.

2 - 5. (RRC-B) Timing of paper (resist roller ON) for the image posi-

tion on the transfer belt is adjusted. (0.1mm/step)

tion on the transfer belt is adjusted. (0.1mm/step)

* When the value is decreased, the timing is delayed. When

the value is increased, the timing is advanced.

6. (LEAD) The lead edge image loss amount is adjusted. (0.1mm/

step)

step)

* When the value is increased, the image loss is increased.

7. (SIDE) The side image loss amount is adjusted.

* When the value is increased, the image loss is increased.

(0.1mm/step)

8. (DEN-A) The paper lead edge void amount is adjusted. (0.1mm/

step)

step)

* When the value is increased, the void is increased.

9 (DEN-B) The paper rear edge void amount is adjusted. (0.1mm/

step)

step)

* When the value is increased, the void is increased.

10. (FRONT/REAR) The void amount on the right and left edges of

paper is adjusted. (0.1mm/step)

paper is adjusted. (0.1mm/step)

Item/Display

Content

Set-

ting

ting

range

Default

value

1

Lead edge

adjustment

value

adjustment

value

RRCA

Document lead edge

reference position

(OC)

reference position

(OC)

0 - 99

50

2

RRCB-

CS1

CS1

Resist

motor

ON tim-

ing

adjust-

ment

motor

ON tim-

ing

adjust-

ment

Stan-

dard

Tray

dard

Tray

1 - 99

40

3

RRCB-

DSK

DSK

Desk

1 - 99

42

4

RRCB-

MFT

MFT

Manual

paper

feed

paper

feed

1 - 99

50

5

RRCB-

ADU

ADU

ADU

1 - 99

50

6

Image loss

area setting

value

area setting

value

LEAD

Lead edge image

loss area setting

loss area setting

0 - 99

10

7

SIDE

Side image loss

area adjustment

area adjustment

0 - 99

10

8

Void area

adjustment

adjustment

DENA

Lead edge void area

adjustment

adjustment

1 - 99

40

9

DENB

Rear edge void area

adjustment

adjustment

1 - 99

35

10

FRONT/

REAR

REAR

FRONT/REAR void

area adjustment

area adjustment

1 - 99

35

11

Off-center

adjustment

adjustment

OFSET_

OC

OC

OC document off-

center adjustment

center adjustment

1 - 99

50

12

Magnifica-

tion ratio cor-

rec-tion

tion ratio cor-

rec-tion

SCAN_

SPEED_

OC

SPEED_

OC

SCAN sub scanning

magnification ratio

adjustment (CCD)

magnification ratio

adjustment (CCD)

1 - 99

50

13

Sub scan-

ning direction

print area

correction

value

ning direction

print area

correction

value

DENB-

MFT

MFT

Manual feed correc-

tion value

tion value

1 - 99

50

14

DENB-

CS1

CS1

Tray 1 correction

value

value

1 - 99

50

15

DENB-

CS2

CS2

Tray 2 correction

value

value

1 - 99

50

16

DENB-

ADU

ADU

ADU correction

value

value

1 - 99

50

Item/Display

Content

Set-

ting

ting

range

Default

value

MX-C250 SIMULATION 6 – 50

50-5

Purpose

:

Adjustment

Function (Purpose)

Used to adjust the print lead edge image

position. (PRINTER MODE)

position. (PRINTER MODE)

Section

Operation/Procedure

1) Select a target adjustment item (DEN-C) with Arrow key.

2) Enter the adjustment value using the 10 keys.

3) Press [OK]/[START] key.

The set value is saved, and the adjustment check pattern is

printed.

printed.

4) Measure the distance from the paper lead edge the adjustment

pattern to the image lead edge, and check to confirm that it is in

the standard adjustment value range.

the standard adjustment value range.

Standard reference value: 4.0 +/- 2.0mm

When the adjustment value is increased, the distance from the

paper lead edge to the image lead edge is increased. When the

adjustment value is decreased, the distanced is decreased.

When the set value is changed by 1, the distance is changed by

about 0.1mm.

paper lead edge to the image lead edge is increased. When the

adjustment value is decreased, the distanced is decreased.

When the set value is changed by 1, the distance is changed by

about 0.1mm.

When the adjustment value is increased, the distance from the paper lead edge to the image lead edge is increased. When the adjustment

value is decreased, the distance from the paper lead edge to the image lead edge is decreased.

When the set value is changed by 1, the distance is changed by about 0.1mm.

value is decreased, the distance from the paper lead edge to the image lead edge is decreased.

When the set value is changed by 1, the distance is changed by about 0.1mm.

50-6

Purpose

:

Adjustment

Function (Purpose)

Used to adjust the copy image position and

the image loss. (RSPF mode)

the image loss. (RSPF mode)

Section

RSPF

Operation/Procedure

1) Select an item to be set with 10 keys.

2) Enter the set value with 10 keys.

3) Press [OK]/[START] key.

The set value in step 2) is saved.

Item 1, 2: When the adjustment value is increased, the scan timing

is delayed.

Item 3 - 8: When the adjustment value is increased, the image loss

is increased.

Item 1 - 8: 1 step = 0.1mm change

is delayed.

Item 3 - 8: When the adjustment value is increased, the image loss

is increased.

Item 1 - 8: 1 step = 0.1mm change

Item/Display

Content

Setting

range

Default

value

NOTE

1

DEN-C

Used to adjust the print

lead edge image posi-

tion.

(PRINTER MODE)

lead edge image posi-

tion.

(PRINTER MODE)

1 - 99

50

Adjustment value too align the print lead edge for the printer. When the

adjustment value of this item is decreased by 1, the printer print start position

in the paper transport direction is shifted to the lead edge by 0.1mm.

adjustment value of this item is decreased by 1, the printer print start position

in the paper transport direction is shifted to the lead edge by 0.1mm.

2

DEN-B

Rear edge void area

adjustment

adjustment

1 - 99

40

Void amount generated at the paper rear edge. When the adjustment value

of item B (DEN-B) is decreased by 1, the print area adjustment value in the

sub scanning direction for the paper transport direction is decreased by

0.1mm.

of item B (DEN-B) is decreased by 1, the print area adjustment value in the

sub scanning direction for the paper transport direction is decreased by

0.1mm.

3

FRONT/REAR

FRONT/REAR void area

adjustment

adjustment

1 - 99

35

Adjustment of the void amount generated on the left and right edges of

paper. When the adjustment value is increased, the void amount is

increased.

paper. When the adjustment value is increased, the void amount is

increased.

4

DENB-MFT

Manual feed rear edge

void area adjustment

correction value

void area adjustment

correction value

1 - 99

50

Fine adjustment value of each paper feed source for the adjustment value of

DEN-B

DEN-B

5

DENB-CS1

Tray 1 rear edge void

area adjustment correc-

tion value

area adjustment correc-

tion value

1 - 99

50

6

DENB-CS2

Tray 2 rear edge void

area adjustment correc-

tion value

area adjustment correc-

tion value

1 - 99

50

7

DENB-ADU

ADU rear edge void aria

adjustment correction

value

adjustment correction

value

1 - 99

50

Item/Display

Content

Setting

range

Default

value

1

SIDE1

Front surface

document scan

position adjust-

ment (CIS)

document scan

position adjust-

ment (CIS)

1 - 99

50

2

SIDE2

Back surface doc-

ument scan posi-

tion adjustment

(CIS)

ument scan posi-

tion adjustment

(CIS)

1 - 99

50

3

Image

loss

amount

setting

SIDE1

loss

amount

setting

SIDE1

LEAD_EDGE

(SIDE1)

(SIDE1)

Front surface

lead edge image

loss amount set-

ting

lead edge image

loss amount set-

ting

0 - 99

10

4

FRONT_REAR

(SIDE1)

(SIDE1)

Front surface side

image loss

amount setting

image loss

amount setting

0 - 99

10

5

TRAIL_EDGE

(SIDE1)

(SIDE1)

Front surface rear

edge image loss

amount setting

edge image loss

amount setting

0 - 99

35

6

Image

loss

amount

setting

SIDE2

loss

amount

setting

SIDE2

LEAD_EDGE

(SIDE2)

(SIDE2)

Back surface lead

edge image loss

amount setting

edge image loss

amount setting

0 - 99

10

7

FRONT_REAR

(SIDE2)

(SIDE2)

Back surface side

image loss

amount setting

image loss

amount setting

0 - 99

10

8

TRAIL_EDGE

(SIDE2)

(SIDE2)

Back surface rear

edge image loss

amount setting

edge image loss

amount setting

0 - 99

35

Item/Display

Content

Setting

range

Default

value