Sharp AR-C260 (serv.man14) Service Manual ▷ View online

AR-C260/C260M TROUBLESHOOTING 11 - 1

[11] TROUBLESHOOTING

1. Outline

In case of a trouble in the machine, or when a consumable part has

nearly reached or already reach the lifetime, the machine detects it,

analyze it, and displays it on the display section and notifies the user

and the serviceman by a voice message.

nearly reached or already reach the lifetime, the machine detects it,

analyze it, and displays it on the display section and notifies the user

and the serviceman by a voice message.

The user and the serviceman are bale to perform the proper counter-

measures according to a voice message. In case of a trouble, the

machine is stopped to restrict damage to a minimum in addition to a

voice message.

measures according to a voice message. In case of a trouble, the

machine is stopped to restrict damage to a minimum in addition to a

voice message.

2. Functions and purposes

1) Assures safety. (The machine is stopped when a trouble is

detected.)

2) Restricts damage to a minimum. (The machine is stopped when a

trouble is detected.)

3) By displaying the trouble content, the trouble position can be iden-

tified immediately and accurately. (An accurate repair work can be

performed, improving the repair efficiency.)

performed, improving the repair efficiency.)

4) By providing a preparatory warning when the lifetime of a consum-

able part is nearly reached, arrangement of the consumable part

can be made in advance. (Stopping the machine by exhaustion of

a consumable part is avoidable.)

can be made in advance. (Stopping the machine by exhaustion of

a consumable part is avoidable.)

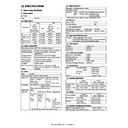

3. Kinds of self diagnostic messages

The self diagnostic messages are classified as follows:

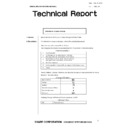

4. Self diagnostic operation

A. Self diagnostic operation and work flow

The machine always monitors its own status.

When the machine detects a trouble, it stops operations and displays a

trouble message.

trouble message.

A warning message is provided mainly when a consumable part is

nearly or completely exhausted.

nearly or completely exhausted.

When a warning message is provided, the machine may be stopped or

may not be stopped depending on the message.

may not be stopped depending on the message.

The trouble and warning messages are indicated with the LCD and

lamps.

lamps.

Some trouble messages may be automatically cleared after removing

the trouble, and some must be cleared with the simulation.

the trouble, and some must be cleared with the simulation.

Some warning messages of consumable parts are automatically

cleared when the trouble is repaired. Some other warning messages

must be cleared by a simulation.

cleared when the trouble is repaired. Some other warning messages

must be cleared by a simulation.

Class 1

User

Troubles and warning messages (paper jam,

consumable part life expiration, etc.) which

can be processed by the user

consumable part life expiration, etc.) which

can be processed by the user

Service

Troubles and warning messages (motor

trouble, maintenance, etc.) which can be

processed only by a serviceman

trouble, maintenance, etc.) which can be

processed only by a serviceman

Other

—

Class 2

Warning

Warning messages (consumable part life

expiration, etc.) for the user, which are not

directly related to any machine trouble.

expiration, etc.) for the user, which are not

directly related to any machine trouble.

Trouble

Related to a machine trouble. The machine is

stopped.

stopped.

Other

—

Troubleshoot the cause.

YES

NO

Detects/analyzes

the content.

Trouble/Warning

Warning

Trouble

The machine is stopped.

The content is displayed.

Trouble/Warning

Warning

A consumable

part has reached

its lifetime.

Trouble

Replace or supply

the consumable part.

Cancel the self-

diagnostic message with

the diagnostics

(test commands).

Reset

Standby state

Monitors the machine

conditions.

Repair

AR-C260/C260M TROUBLESHOOTING 11 - 2

5. List

Model

Main

code

code

Sub

code

Content

AR-C260

AR-C260M

AR-C260M

C2

10

Image density sensor error/Transfer

charger error (Black)

charger error (Black)

E7

01

Image data memory trouble

10

Shading trouble (Black correction)

11

Shading trouble (White correction)

20

LED controller initial trouble (Black)

21

LED controller initial trouble (Cyan)

22

LED controller initial trouble (Magenta)

23

LED controller initial trouble (Yellow)

24

LED controller output trouble (Black)

25

LED controller output trouble (Cyan)

26

LED controller output trouble (Magenta)

27

LED controller output trouble (Yellow)

28

LED control ASIC connection

abnormality

abnormality

40

Color correction data writing abnormality

41

Color correction data transfer

abnormality

abnormality

80

ICU-SCN communication trouble (ICU

detection)

detection)

90

ICU-PCU communication trouble (ICU

detection)

detection)

F1

00

Finisher communication trouble (PCU

detection)

detection)

02

Finisher transport motor trouble

(Finisher detection)

(Finisher detection)

03

Finisher paddle motor trouble

06

Finisher slide motor trouble

10

Finisher staple motor abnormality

(Finisher detection)

(Finisher detection)

11

Finisher bundle process motor

abnormality (Finisher detection)

abnormality (Finisher detection)

15

Finisher tray lift motor abnormality

(Finisher detection)

(Finisher detection)

19

Finisher front alignment motor

abnormality (Finisher detection)

abnormality (Finisher detection)

20

Finisher rear alignment motor

abnormality (Finisher detection)

abnormality (Finisher detection)

31

Finisher fold sensor trouble

32

Finisher punch unit communication

trouble

trouble

33

Finisher punch side registration motor

trouble

trouble

34

Finisher punch motor trouble

35

Finisher punch side registration sensor

trouble

trouble

36

Finisher punch registration sensor

trouble

trouble

37

Finisher/sorter backup RAM trouble

38

Finisher punch backup RAM trouble

39

Finisher punch dust sensor trouble

40

Finisher punch power disconnection

trouble

trouble

83

Sorter guide bar oscillation motor (M3)

lock

lock

89

Sorter bin shift motor lock (M1)

91

Sorter bin paper sensor automatic

adjustment trouble

adjustment trouble

AR-C260

AR-C260M

AR-C260M

F2

15

Drum unit initial detection trouble (Black)

16

Drum unit initial detection trouble (Cyan)

17

Drum unit initial detection trouble

(Magenta)

(Magenta)

18

Drum unit initial detection trouble

(Yellow)

(Yellow)

19

Transfer unit initial detection trouble

39

Process thermistor breakdown

40

Toner empty sensor abnormality (Black)

41

Toner empty sensor abnormality (Cyan)

42

Toner empty sensor abnormality

(Magenta)

(Magenta)

43

Toner empty sensor abnormality

(Yellow)

(Yellow)

44

Black image density sensor trouble

(Transfer belt surface reflection ratio

abnormality)

(Transfer belt surface reflection ratio

abnormality)

45

Color image density sensor trouble

(Calibration plate surface reflection ratio

abnormality)

(Calibration plate surface reflection ratio

abnormality)

58

Process humidity sensor breakdown

70

Developing unit improper cartridge

detection (Black)

detection (Black)

71

Developing unit improper cartridge

detection (Cyan)

detection (Cyan)

72

Developing unit improper cartridge

detection (Magenta)

detection (Magenta)

73

Developing unit improper cartridge

detection (Yellow)

detection (Yellow)

74

Developing unit CRUM trouble (Black)

75

Developing unit CRUM trouble (Cyan)

76

Developing unit CRUM trouble

(Magenta)

(Magenta)

77

Developing unit CRUM trouble (Yellow)

78

Trouble of image density sensor for

registration (Transfer belt surface

reflection ratio abnormality)

registration (Transfer belt surface

reflection ratio abnormality)

80

Half-tone process control 1st batch error

(Black)

(Black)

81

Half-tone process control 1st batch error

(Cyan)

(Cyan)

82

Half-tone process control 1st batch error

(Magenta)

(Magenta)

83

Half-tone process control 1st batch error

(Yellow)

(Yellow)

84

Half-tone process control 2nd batch

error (Black)

error (Black)

85

Half-tone process control 2nd batch

error (Cyan)

error (Cyan)

86

Half-tone process control 2nd batch

error (Magenta)

error (Magenta)

87

Half-tone process control 2nd batch

error (Yellow)

error (Yellow)

90

Half-tone process control limit error

F3

12

Cassette 1 lift up trouble

F9

00

ICU-PRT communication trouble (ICU

detection)

detection)

01

PRT DRAM trouble

02

NIC port check error

20

HDD trouble (PRT controller detection)

H2

00

Thermistor open (HL1)

01

Thermistor open (HL2)

H3

00

Fusing section high temperature trouble

(HL1)

(HL1)

01

Fusing section high temperature trouble

(HL2)

(HL2)

Model

Main

code

code

Sub

code

Content

AR-C260/C260M TROUBLESHOOTING 11 - 3

6. Details

AR-C260

AR-C260M

AR-C260M

H4

00

Fusing section low temperature trouble

(HL1)

(HL1)

01

Fusing section low temperature trouble

(HL2)

(HL2)

H5

01

Five continuous detections of POD1 not-

reached jam

reached jam

H8

01

Fusing unit initial detection trouble

L1

00

Mirror feed trouble

L3

00

Mirror return trouble

L4

02

Paper feed motor lock trouble

06

Transfer belt lift motor trouble

07

Transfer belt motor trouble

11

Shift motor trouble

L8

01

Full wave signal not provided

02

Full wave signal width abnormality

04

Main power switch abnormality

detection

detection

PF

00

RIC copy inhibit signal reception

U0

00

ICU-OPE communication trouble (ICU/

OPE detection)

OPE detection)

U1

02

RTC read trouble

U2

00

EEPROM read/write error (ICU

detection)

detection)

11

EEPROM check sum error (ICU

detection)

detection)

30

Production No. data discrepancy

(ICU

(ICU

⇔

ICU)

80

EEPROM read/write error (SCN

detection)

detection)

81

EEPROM check sum error (SCN

detection)

detection)

90

EEPROM read/write error (PCU

detection)

detection)

91

EEPROM check sum error (PCU

detection)

detection)

U4

02

ADU alignment plate operation

abnormality

abnormality

U5

00

ADF communication trouble

01

ADF resist sensor defect

02

ADF repulsion sensor defect

03

ADF timing sensor defect

11

Paper feed motor operation abnormality

U6

00

Desk communication trouble

01

Desk tray 1 lift motor trouble

02

Desk tray 2 lift motor trouble

03

Desk tray 3 lift motor trouble

10

Desk transport motor trouble

U7

00

RIC communication trouble

Model

Main

code

code

Sub

code

Content

Main

code

code

Sub

code

Title

Image density sensor error/

Transfer charger error (Black)

Transfer charger error (Black)

C2

10

Display

Lamp/Message

Phenomenon

Detail

Black image density

sensor trouble /Transfer

trouble (Black) /The

deference between the

transfer belt surface

detection level and the

black toner patch density

detection level is normal.

(Judged in black image

density sensor calibration)

sensor trouble /Transfer

trouble (Black) /The

deference between the

transfer belt surface

detection level and the

black toner patch density

detection level is normal.

(Judged in black image

density sensor calibration)

Section

Transfer

Case 1

Cause

Black image density

sensor trouble

sensor trouble

Check &

Remedy

Remedy

Black density image

sensor cleaning,

replacement

sensor cleaning,

replacement

Case 2

Cause

Transfer voltage trouble

Check &

Remedy

Remedy

Check and adjust the

transfer voltage.

transfer voltage.

Case 3

Cause

High voltage PWB trouble

Check &

Remedy

Remedy

Replace the high voltage

PWB.

PWB.

Case 4

Cause

Transfer unit trouble

Check &

Remedy

Remedy

Check the transfer belt

surface for dirt and

scratches.

Replace the transfer belt,

replace the cleaning blade,

replace the transfer unit.

surface for dirt and

scratches.

Replace the transfer belt,

replace the cleaning blade,

replace the transfer unit.

Case 5

Cause

PCU PWB trouble

Check &

Remedy

Remedy

PCU PWB replacement

Case 6

Cause

Photoconductor unit

trouble

trouble

Check &

Remedy

Remedy

Replace the

photoconductor unit.

photoconductor unit.

Case 7

Cause

Developing unit trouble

Check &

Remedy

Remedy

Replace the developing

unit

unit

Case 8

Cause

Connector, harness

trouble (PCU PWB, high

voltage PWB, image

density sensor,

photoconductor unit,

transfer unit, developing

unit)

trouble (PCU PWB, high

voltage PWB, image

density sensor,

photoconductor unit,

transfer unit, developing

unit)

Check &

Remedy

Remedy

Check contact. Replace

the harness. Replace the

PWB.

the harness. Replace the

PWB.

AR-C260/C260M TROUBLESHOOTING 11 - 4

Main

code

code

Sub

code

Title

Image data memory trouble

E7

01

Display

Lamp/Message

Phenomenon

Detail

The ICU image data

memory (SDRAM) cannot

be detected as 256MB or

more. The required

SDRAM capacity for the

model is not provided.

memory (SDRAM) cannot

be detected as 256MB or

more. The required

SDRAM capacity for the

model is not provided.

Section

ICU PWB

Case 1

Cause

The SDRAM of ICU PWB

is not installed. The

SDRAM of ICU PWB is

improperly installed.

is not installed. The

SDRAM of ICU PWB is

improperly installed.

Check &

Remedy

Remedy

Check installation of the

SDRAM of ICU ASIC PWB.

SDRAM of ICU ASIC PWB.

Case 2

Cause

The SDRAM of ICU PWB

does not operate properly.

does not operate properly.

Check &

Remedy

Remedy

Use SIM 60-01 to check

the capacity of the

SDRAM. Replace the

SDRAM of ICU PWB.

the capacity of the

SDRAM. Replace the

SDRAM of ICU PWB.

Case 3

Cause

ICU PWB abnormality

Check &

Remedy

Remedy

Replace the ICU PWB.

Main

code

code

Sub

code

Title

Shading trouble (Black correction)

E7

10

Display

Lamp/Message

Phenomenon

Detail

CCD black reading level

abnormality when the copy

lamp is off.

abnormality when the copy

lamp is off.

Section

CCD unit

Case 1

Cause

Improper installation of the

flat cable to the CCD unit.

flat cable to the CCD unit.

Check &

Remedy

Remedy

Check installation of the

flat cable to the CCD unit.

flat cable to the CCD unit.

Case 2

Cause

CCD unit abnormality

Check &

Remedy

Remedy

Check the CCD unit.

Case 3

Cause

MFP PWB abnormality

Check &

Remedy

Remedy

Check the MFP PWB.

Main

code

code

Sub

code

Title

Shading trouble (White correction)

E7

11

Display

Lamp/Message

Phenomenon

Detail

CCD white reading level

abnormality when the copy

lamp is off.

abnormality when the copy

lamp is off.

Section

CCD unit

Case 1

Cause

Improper installation of the

flat cable to the CCD unit.

flat cable to the CCD unit.

Check &

Remedy

Remedy

Check installation of the

flat cable to the CCD unit.

flat cable to the CCD unit.

Case 2

Cause

Dirt on the mirror, the lens,

or the reference white plate.

or the reference white plate.

Check &

Remedy

Remedy

Clean the mirror, the lens,

or the reference white

plate.

or the reference white

plate.

Case 3

Cause

CCD unit abnormality

Check &

Remedy

Remedy

Check the CCD unit.

Case 4

Cause

MFP PWB abnormality

Check &

Remedy

Remedy

Check the MFP PWB.

Main

code

code

Sub

code

Title

LED controller initial trouble

(Black)

(Black)

E7

20

Display

Lamp/Message

Phenomenon

Detail

The initial process of the

LED controller cannot be

completed properly.

LED controller cannot be

completed properly.

Section

LED/ICU PWB

Case 1

Cause

Disconnection of the LED

head connector.

head connector.

Check &

Remedy

Remedy

Check connection of the

LED head connector.

LED head connector.

Case 2

Cause

Disconnection of the

harness inside the LED

head.

harness inside the LED

head.

Check &

Remedy

Remedy

Replace the LED head

unit.

unit.

Case 3

Cause

ICU PWB abnormality

Check &

Remedy

Remedy

Replace the ICU PWB.

Main

code

code

Sub

code

Title

LED controller initial trouble (Cyan)

E7

21

Display

Lamp/Message

Phenomenon

Detail

The initial process of the

LED controller cannot be

completed properly.

LED controller cannot be

completed properly.

Section

LED/ICU PWB

Case 1

Cause

Disconnection of the LED

head connector.

head connector.

Check &

Remedy

Remedy

Check connection of the

LED head connector

LED head connector

Case 2

Cause

Disconnection of the

harness inside the LED

head.

harness inside the LED

head.

Check &

Remedy

Remedy

Replace the LED head

unit.

unit.

Case 3

Cause

ICU PWB abnormality

Check &

Remedy

Remedy

Replace the ICU PWB.

Main

code

code

Sub

code

Title

LED controller initial trouble

(Magenta)

(Magenta)

E7

22

Display

Lamp/Message

Phenomenon

Detail

The initial process of the

LED controller cannot be

completed properly.

LED controller cannot be

completed properly.

Section

LED/ICU PWB

Case 1

Cause

Disconnection of the LED

head connector.

head connector.

Check &

Remedy

Remedy

Check connection of the

LED head connector

LED head connector

Case 2

Cause

Disconnection of the

harness inside the LED

head.

harness inside the LED

head.

Check &

Remedy

Remedy

Replace the LED head

unit.

unit.

Case 3

Cause

ICU PWB abnormality

Check &

Remedy

Remedy

Replace the ICU PWB.