Sharp AR-C260 (serv.man11) Service Manual ▷ View online

AR-C260/C260M SETTING AND ADJUSTMENTS 8 - 1

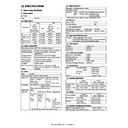

[8] SETTING AND ADJUSTMENTS

Each adjustment item in the adjustment item list is indicated with its JOB number.

Perform the adjustment procedures in the sequence of Job numbers from the smallest to the greatest.

However, there is no need to perform all the adjustment items. Perform only the necessary adjustments according to the need.

Unnecessary adjustments can be omitted. Even in this case, however, the sequence from the smallest to the greatest JOB number must be observed.

If the above precaution should be neglected, the adjustment would not complete normally or a trouble may occur.

Perform the adjustment procedures in the sequence of Job numbers from the smallest to the greatest.

However, there is no need to perform all the adjustment items. Perform only the necessary adjustments according to the need.

Unnecessary adjustments can be omitted. Even in this case, however, the sequence from the smallest to the greatest JOB number must be observed.

If the above precaution should be neglected, the adjustment would not complete normally or a trouble may occur.

*1: The simple adjustment does not use the adjustment jig. Its adjustment accuracy may be lower than that of the adjustment by using the adjustment

jig under some machine conditions.

JOB No

ADJUSTMENT ITEM LIST

SIMULATION

ADJ 1

High voltage adjustment

ADJ 1A

Main charger grid voltage adjustment

8-2

ADJ 1B

DV bias voltage adjustment

8-1

ADJ 1C

Transfer voltage adjustment

8-6

ADJ 2

Image density sensor adjustment

ADJ 2A

Color image density sensor adjustment (adjustment by the

adjustment jig)

adjustment jig)

44-13

ADJ 2B

Black image density sensor adjustment

44-2

ADJ 2C

Color image density sensor & black image density sensor

adjustment (Simple adjustment) *1

adjustment (Simple adjustment) *1

44-36

ADJ 3

Image focus, image skew adjustment (LED (writing) unit)

64-1/61-4

ADJ 4

Image registration adjustment

ADJ 4A

Image registration adjustment (Auto adjustment)

50-22

ADJ 4B

Image registration adjustment (Manual adjustment)

50-20

ADJ 5

Image position/print area adjustment

(Print engine section)

(Print engine section)

ADJ 5A

Main scanning direction image position adjustment

(Print engine section)

(Print engine section)

50-10

ADJ 5B

Sub scanning direction image position/print area adjustment

(Print engine section)

(Print engine section)

50-5

ADJ 6

Copy image distortion adjustment

ADJ 6A

Scanner (reading) unit parallelism adjustment

ADJ 6B

Copy image sub scanning direction distortion adjustment

ADJ 6C

Copy image main scanning direction distortion adjustment

ADJ 6D

Scan image distortion adjustment

ADJ 7

Copy image focus (main scanning direction copy magnification ratio) adjustment (CCD unit position adjustment)

48-1

ADJ 8

Sub scanning direction copy magnification ratio adjustment

48-1

ADJ 9

Main scanning direction copy image position adjustment (Scanner (reading) section)

50-12

ADJ 10 Copy image position/image loss/void area adjustment

50-1/50-2

ADJ 11 Copy color balance/density adjustment

ADJ 11A

63-3 (63-5)

ADJ 11B

Copy color balance adjustment (Auto adjustment)

46-24

ADJ 11C Copy color balance adjustment (Manual adjustment)

46-21

ADJ 11D Copy density adjustment in low-density area

(Normally unnecessary to adjust.)

46-1/2

ADJ 11E

Copy color balance density adjustment (each copy mode)

(Normally unnecessary to adjust.)

(Normally unnecessary to adjust.)

46-10 to 16

ADJ 11F

63-9

ADJ 11G Image edge section gamma/density adjustment

(Black text and black line reproduction adjustment) (Normally

unnecessary to adjust.)

unnecessary to adjust.)

46-27

ADJ 11H Copy color balance adjustment (Single color Copy mode)

(Normally unnecessary to adjust.)

46-25

ADJ 11I

Auto color balance adjustment by user (Copy color balance

auto adjustment enable setting and adjustment)

auto adjustment enable setting and adjustment)

26-53

ADJ 11J

Background process conditions setting in the color auto copy

mode, image auto recognition conditions setting, text-on-dot

recognition conditions setting

mode, image auto recognition conditions setting, text-on-dot

recognition conditions setting

46-33

ADJ 12 Fusing pressure adjustment

ADJ 13 Fusing paper guide position adjustment

ADJ 14 Document size sensor adjustment

ADJ 14A

Original size sensor detection point adjustment

41-2

ADJ 14B

Original size sensor sensitivity adjustment

41-2

ADJ 15 Manual paper feed tray paper size sensor adjustment

40-2

ADJ 16 Touch panel coordinates setting

65-1

ADJ 17 Power voltage adjustment

ADJ 17A

3.4 V power voltage adjustment

ADJ 17B

5.0 V power voltage adjustment

ADJ 18 FAX/scanner mode image loss adjustment

50-27

AR-C260/C260M SETTING AND ADJUSTMENTS 8 - 2

Since the output voltage cannot be checked directly due to the

machine structure, the adjustment value of the simulation is set to the

default (specified value) to perform the adjustment.

machine structure, the adjustment value of the simulation is set to the

default (specified value) to perform the adjustment.

This adjustment must be performed in the following cases:

• When the high voltage power PWB is replaced.

• When a U2 trouble occurs.

• When the PCU PWB is replaced.

• When the EEPROM of the PCU PWB is replaced.

1) Enter the SIM 8-2 mode.

SIM 8-2

2) Select the output mode to be adjusted with the color key and scroll

key.

3) Enter the adjustment value (specified value), and press the [OK]

key.

By entering the default value (specified value), the specified volt-

age is outputted.

age is outputted.

Remark: When the default value is set, the specified voltage is output-

ted.

There is, therefore, no need to check the output voltage

unless there is a doubt for any abnormality in the output volt-

age.

If there is a need to check that the normal voltage is output-

ted or to adjust by referring to the output voltage, use the

method below.

There is, therefore, no need to check the output voltage

unless there is a doubt for any abnormality in the output volt-

age.

If there is a need to check that the normal voltage is output-

ted or to adjust by referring to the output voltage, use the

method below.

1) Remove the rear cover of the machine.

2) Remove the image process fan motor and the duct.

3) Connect the high voltage adjustment harnesses (DHAi-3471FCZZ/

DHAi-3472FCZZ) with the connectors CNMON and CNMONK on

the high voltage PWB.

the high voltage PWB.

4) Enter the SIM8-2 mode.

5) Select the output mode to be adjusted with the color key and the

scroll key.

6) Check that the pin numbers of the connectors CNMON and

CNMONK are properly assigned to the connector pin numbers of

the high voltage adjustment harness.

the high voltage adjustment harness.

7) Apply a digital multi-meter to the connector pins of the high voltage

adjustment harness corresponding to the output mode to be

adjusted.

adjusted.

ADJ 1

High voltage adjustment

ADJ 1A

Main charger grid voltage adjustment

Color

Item Operation

mode

Adjustment value

Main charger grid voltage

Monitor (High voltage PWB)

Pin

No.

Actual

voltage

Adjustment

range

Specified

value

(Default)

Monitor voltage

(Specified value)

Connector

K

A: HIGH SPEED

High speed (140mm/s) (B & W)

180 – 700

620

53.5 ± 0.2v

CNMONK

1

–620v

B: MIDDLE SPEED

Middle speed (117mm/s) (Color) (B & W)

180 – 700

620

53.5 ± 0.2v

CNMONK

1

–620v

C: LOW SPEED

Low speed (58.5mm/s) (Color) (B & W)

(Special paper)

(Special paper)

180 – 700

590

50.6 ± 0.2v

CNMONK

1

–590v

C

A: MIDDLE SPEED

Middle speed (117mm/s) (Color) (B & W)

180 – 700

620

53.5 ± 0.2v

CNMON

3

–620v

B: LOW SPEED

Low speed (58.5mm/s) (Color) (B & W)

(Special paper)

(Special paper)

180 – 700

590

50.6 ± 0.2v

CNMON

3

–590v

M

A: MIDDLE SPEED

Middle speed (117mm/s) (Color) (B & W)

180 – 700

620

53.5 ± 0.2v

CNMON

7

–620v

B: LOW SPEED

Low speed (58.5mm/s) (Color) (B & W)

(Special paper)

(Special paper)

180 – 700

590

50.6 ± 0.2v

CNMON

7

–590v

Y

A: MIDDLE SPEED

Middle speed (117mm/s) (Color) (B & W)

180 – 700

620

53.5 ± 0.2v

CNMON

11

–620v

B: LOW SPEED

Low speed (58.5mm/s) (Color) (B & W)

(Special paper)

(Special paper)

180 – 700

590

50.6 ± 0.2v

CNMON

11

–590v

A

B

AR-C260/C260M SETTING AND ADJUSTMENTS 8 - 3

8) Press the [EXECUTE] key.

The main charger grid voltage is outputted for 30sec.

If this operation is performed for a long time, the OPC drum and

the developing roller may be damaged. Be careful to perform this

operation in a short time.

the developing roller may be damaged. Be careful to perform this

operation in a short time.

It is advisable to install an unnecessary developing unit and unnec-

essary OPC drums to the machine for this adjustment.

essary OPC drums to the machine for this adjustment.

9) Check the monitor voltage with the digital multi-meter.

If the monitor voltage is not in the above specified range, change

the adjustment value and adjust again. If the specified voltage is

not obtained even by changing the adjustment value, the following

parts may be judged as defective.

the adjustment value and adjust again. If the specified voltage is

not obtained even by changing the adjustment value, the following

parts may be judged as defective.

High voltage PWB

PCU PWB

Developing unit

Photoconductor unit

High voltage circuit electrode

This adjustment must be performed in the following cases:

• When the high voltage power PWB is replaced.

• When a U2 trouble occurs.

• When the PCU PWB is replaced.

• When the EEPROM of the PCU PWB is replaced.

1) Enter the SIM 8-1 mode.

SIM 8-1

2) Select the output mode to be adjusted with the color key and the

scroll key.

3) Enter the adjustment value (specified value), and press the [OK]

key.

By entering the default value (specified value), the specified volt-

age is outputted.

age is outputted.

Remark: When the default value is set, the specified voltage is output-

ted.

There is, therefore, no need to check the output voltage

unless there is a doubt for any abnormality in the output volt-

age.

If there is a need to check that the normal voltage is output-

ted or to adjust by referring to the output voltage, use the

method below.

There is, therefore, no need to check the output voltage

unless there is a doubt for any abnormality in the output volt-

age.

If there is a need to check that the normal voltage is output-

ted or to adjust by referring to the output voltage, use the

method below.

1) Remove the rear cover of the machine.

2) Remove the image process fan motor and the duct.

3) Connect the high voltage adjustment harnesses (DHAi-3471FCZZ/

DHAi-3472FCZZ) with the connectors CNMON and CNMONK on

the high voltage PWB.

the high voltage PWB.

4) Enter the SIM8-2 mode.

5) Select the output mode to be adjusted with the color key and the

scroll key.

6) Check that the pin numbers of the connectors CNMON and

CNMONK are properly assigned to the connector pin numbers of

the high voltage adjustment harness.

the high voltage adjustment harness.

ADJ 1B

DV bias voltage adjustment

Color

Item

Operation mode

Adjustment value

Developing bias voltage

Monitor (High voltage PWB)

Pin

No.

Actual

voltage

Adjustment

range

Specified

value

(Default)

Monitor voltage

(Specified value)

Connector

K

A: HIGH SPEED

High speed (140mm/s) (B & W)

180 – 700

315

7.43 ± 0.1V

CNMONK

3

–315v

B: MIDDLE SPEED

Middle speed (117mm/s) (Color) (B & W)

180 – 700

315

7.43 ± 0.1V

CNMONK

3

–315v

C: LOW SPEED

Low speed (58.5mm/s) (Color) (B & W)

(Special paper)

(Special paper)

180 – 700

285

6.45 ± 0.1V

CNMONK

3

–285v

C

A: MIDDLE SPEED

Middle speed (117mm/s) (Color) (B & W)

180 – 700

265

5.76 ± 0.1V

CNMON

1

–265v

B: LOW SPEED

Low speed (58.5mm/s) (Color) (B & W)

(Special paper)

(Special paper)

180 – 700

235

4.75 ± 0.1V

CNMON

1

–235v

M

A: MIDDLE SPEED

Middle speed (117mm/s) (Color) (B & W)

180 – 700

265

5.76 ± 0.1V

CNMON

5

–265v

B: LOW SPEED

Low speed (58.5mm/s) (Color) (B & W)

(Special paper)

(Special paper)

180 – 700

235

4.75 ± 0.1V

CNMON

5

–235v

Y

A: MIDDLE SPEED

Middle speed (117mm/s) (Color) (B & W)

180 – 700

240

4.75 ± 0.1V

CNMON

9

–240v

B: LOW SPEED

Low speed (58.5mm/s) (Color) (B & W)

(Special paper)

(Special paper)

180 – 700

210

3.78 ± 0.1V

CNMON

9

–210v

A

B

AR-C260/C260M SETTING AND ADJUSTMENTS 8 - 4

7) Apply a digital multi-meter to the connector pins of the high voltage

adjustment harness corresponding to the output mode to be

adjusted.

adjusted.

8) Press the [EXECUTE] key.

The developing bias voltage is outputted for 30sec.

If this operation is performed for a long time, the OPC drum and

the developing roller may be damaged. Be careful to perform this

operation in a short time.

the developing roller may be damaged. Be careful to perform this

operation in a short time.

It is advisable to install an unnecessary developing unit and unnec-

essary OPC drums to the machine for this adjustment.

essary OPC drums to the machine for this adjustment.

9) Check the monitor voltage with the digital multi-meter.

If the monitor voltage is not in the above specified range, change

the adjustment value and adjust again. If the specified voltage is

not obtained even by changing the adjustment value, the following

parts may be judged as defective.

the adjustment value and adjust again. If the specified voltage is

not obtained even by changing the adjustment value, the following

parts may be judged as defective.

High voltage PWB

PCU PWB

Developing unit

Photoconductor unit

High voltage circuit electrode

This adjustment must be performed in the following cases:

• When the high voltage power PWB is replaced.

• When a U2 trouble occurs.

• When the PCU PWB is replaced.

• When the EEPROM of the PCU PWB is replaced.

1) Enter the SIM 8-6 mode.

SIM 8-6

2) Select the mode to be adjusted with the color key and scroll key.

3) Enter the adjustment value (specified value), and press the [OK]

key.

By entering the default value (specified value), the specified volt-

age is outputted.

age is outputted.

Press the [EXECUTE] key to output the transfer voltage.

The image density sensor sections are of uneven quality in parts and

assembly. This causes variations in the absolute detection level

between machines. This adjustment (calibration) is performed to cor-

rect the variations.

assembly. This causes variations in the absolute detection level

between machines. This adjustment (calibration) is performed to cor-

rect the variations.

This adjustment is required in the following cases:

• When the image density sensor is replaced.

• When the transfer unit is replaced.

• When maintenance is performed.

• When U2 trouble occurs.

• When the PCU PWB is replaced.

• When the EEPROM on the PCU PWB is repalced.

The targets of the adjustment are the color image density sensor and

the black image density sensor. There are following adjustment meth-

ods:

the black image density sensor. There are following adjustment meth-

ods:

• Color image density sensor adjustment (adjustment by the adjust-

ment jig) SIM44-13

• Black image sensity sensor adjustment SIM44-2

• Image density sensor adjustment (The color image density sensor

and the black image density sensor are adjusted at the same time.)

(Simple adjustment) SIM44-36

(Simple adjustment) SIM44-36

Normally the following adjustments are executed:

• ADJ 2A Color image density sensor adjustment (adjustment by the

adjustment jig) (SIM44-13)

• ADJ 2B Black image density sensor adjustment (SIM44-2)

ADJ 1C

Transfer voltage adjustment

Item

Print mode

Standard setting value

(Default)

Adjustment

range

Output voltage (Kv)

K

C

M

Y

K

C

M

Y

A

PLAIN_SPX_CL

Color

Normal paper

117mm/s

173

159

132

132

51 - 255

2.4

2.4

2.4

2.4

B

PLAIN_DPX_CL

Color

Normal paper(Duplex mode)

117mm/s

188

173

142

142

2.7

2.7

2.7

2.7

C

OHP1_CL

Color

Transparency film 1

117mm/s

204

187

153

153

3

3

3

3

D

OHP2_CL

Color

Transparency film 2

58.5mm/s

137

150

153

163

1.7

2.2

3

3.3

E

HEAVY P1_SPX_CL

Color

Thick paper 1

58.5mm/s

158

146

122

122

2.1

2.1

2.1

2.1

F

HEAVY_P1_DPX_CL

Color

Thick paper 1(Duplex mode)

58.5mm/s

188

173

142

142

2.7

2.7

2.7

2.7

G

HEAVY_P2_CL

Color

Thick paper 2

58.5mm/s

173

159

132

132

2.2

2.2

2.2

2.2

H

ENV_CL

Color

Envelope

117mm/s

163

150

125

125

2.2

2.2

2.2

2.2

I

PLAIN_SPX_BW

B & W

Normal paper

140mm/s

168

2.3

J

PLAIN_DPX_BW

B & W

Normal paper(Duplex mode)

140mm/s

178

2.5

K

OHP1_BW

B & W

Transparency film 1

117mm/s

204

3

L

OHP2_BW

B & W

Transparency film 2

58.5mm/s

137

1.7

M

HEAVY_P1_SPX_BW

B & W

Thick paper 1

58.5mm/s

147

1.9

N

HEAVY_P1_DPX_BW

B & W

Thick paper 1(Duplex mode)

58.5mm/s

178

2.5

O

HEAVY_P2_BW

B & W

Thick paper 2

58.5mm/s

163

2.2

P

ENV_BW

B & W

Envelope

140mm/s

168

2.3

Color

Actual output variable range

Voltage change/Adjustment value (1) (Varying amount when the adjustment value is changed by 1)

K

0 to 4000V

About 19.6V

C

0 to 4500V

About 22.1V

M

0 to 6000V

About 29.4V

Y

0 to 6000V

About 29.4V

ADJ 2

Image density sensor adjustment