|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man4)

Circuit Diagram (Revised November 2017).

Service Manual

|

127

|

18.04 MB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man5)

Service Manual (Revised November 2017).

Service Manual

|

127

|

105.17 MB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man6)

NOTE Service Manual for models with the V suffix only.

Service Manual

|

127

|

104.48 MB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man7)

NOTE Installation Manual for models with the V suffix only.

Service Manual

|

127

|

68.84 MB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man8)

NOTE Circuit Diagram for models with the V suffix only.

Service Manual

|

127

|

15.58 MB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man14)

E-manual Firmware Notes for down loading E-manual files and merging files for upload

User Manual / Operation Manual

|

1

|

278.05 KB

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man15)

Phoenix E-Manual Part 1

User Manual / Operation Manual

|

|

85.83 MB

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man16)

Phoenix E-Manual Part 2

User Manual / Operation Manual

|

|

85.85 MB

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man17)

Phoenix E-Manual Part 3

User Manual / Operation Manual

|

|

85.84 MB

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man18)

Phoenix E-Manual Part 4

User Manual / Operation Manual

|

|

85.85 MB

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man19)

Phoenix E-Manual part 5

User Manual / Operation Manual

|

|

85.84 MB

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man20)

Phoenix E-Manual part 6

User Manual / Operation Manual

|

|

85.84 MB

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man21)

Phoenix E-Manual part 7

User Manual / Operation Manual

|

|

85.84 MB

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man22)

Phoenix E-Manual part 8

User Manual / Operation Manual

|

|

85.84 MB

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man23)

Phoenix E-Manual part 9

User Manual / Operation Manual

|

|

85.84 MB

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man24)

Phoenix E-Manual part 10

User Manual / Operation Manual

|

|

85.84 MB

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man25)

Phoenix E-Manual part 11

User Manual / Operation Manual

|

|

85.84 MB

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man26)

Phoenix E-Manual part 12

User Manual / Operation Manual

|

|

85.84 MB

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man27)

Phoenix E-Manual part 13

User Manual / Operation Manual

|

|

85.85 MB

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man28)

Phoenix E-Manual part 14 inc. restoration file

User Manual / Operation Manual

|

|

14.54 MB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man29)

Quick Start Guide PDF

User Manual / Operation Manual

|

60

|

7.85 MB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man30)

User Manual PDF

User Manual / Operation Manual

|

127

|

58.19 MB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man31)

Software Setup Guide PDF

User Manual / Operation Manual

|

45

|

2.56 MB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man32)

Print release Guide PDF

User Manual / Operation Manual

|

10

|

1.11 MB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man33)

Web Page Guide PDF

User Manual / Operation Manual

|

38

|

3.25 MB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man34)

UI Customization Guide PDF

User Manual / Operation Manual

|

34

|

5.95 MB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man35)

Trouble Shooting Guide PDF

User Manual / Operation Manual

|

58

|

1.57 MB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man10)

PWB Parts Guide for models with the V suffix.

Service Manual / Parts Guide

|

57

|

2.67 MB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man11)

NOTE Parts Guide for models with the V suffix only.

Service Manual / Parts Guide

|

127

|

157.23 MB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man12)

Parts Guide (Revised September 2017).

Service Manual / Parts Guide

|

127

|

93.12 MB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man13)

PWB Parts Guide (Revised June 2016).

Service Manual / Parts Guide

|

40

|

2.3 MB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man56)

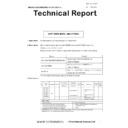

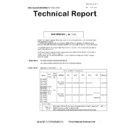

Fuser temperature relating to paper type. Offsetting.

Service Manual / Technical Bulletin

|

1

|

21.65 KB

|

|

|

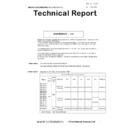

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man57)

CCE 1847 PARTS MODIFICATION FOR PRODUCTIVITY IMPROVEMENT

Service Manual / Technical Bulletin

|

3

|

278.75 KB

|

|

|

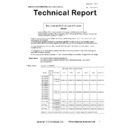

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man58)

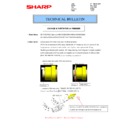

CCE 1847 ADDITION OF HL EDGE PROTECT SHEET

Service Manual / Technical Bulletin

|

2

|

212.95 KB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man59)

CCE 1793 ADDITION OF HL EDGE PROTECT SHEET

Service Manual / Technical Bulletin

|

2

|

212.69 KB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man60)

CCE 1732 COUNTERMEASURE FOR RE-TRANSPORT OF MX-FN27

Service Manual / Technical Bulletin

|

4

|

566.57 KB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man61)

CCE 1714 FIELD ACTION FOR TRAY JAM

Service Manual / Technical Bulletin

|

4

|

389.96 KB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man62)

CCE 1839 PARTS CHANGE FOR PRODUCTIVITY IMPROVEMENT

Service Manual / Technical Bulletin

|

2

|

169.03 KB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man63)

CCE 1831 IMPORTANT NOTE WHEN INSTALLING OPTIONS to MX2630 and MX30XX series

Service Manual / Technical Bulletin

|

6

|

611.78 KB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man64)

CCE 1835 ROM Upgrade (3) DSK V07.00.()1.00 FR51U FR52U Bulletin Only

Service Manual / Technical Bulletin

|

6

|

261.04 KB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man65)

CCE 1835 ROM Upgrade (13) V07.00.()1.00 Bulletin Only

Service Manual / Technical Bulletin

|

7

|

292.51 KB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man66)

CCE 1835 PARTS MODIFICATION FOR COMMON USE WITH OTHER MODELS

Service Manual / Technical Bulletin

|

2

|

236.61 KB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man67)

Box Connector (TLS 1.2) Special Firmware release (Revision)

Service Manual / Technical Bulletin

|

2

|

144.51 KB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man68)

CCE 1830 Supply of Lamp Unit

Service Manual / Technical Bulletin

|

1

|

175.19 KB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man69)

CCE-1829 MODIFICATION OF PARTS DESIGN

Service Manual / Technical Bulletin

|

2

|

305 KB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man70)

CCE-1827 MODIFICATION OF PARTS DESIGN

Service Manual / Technical Bulletin

|

3

|

311 KB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man71)

CCE-1823 NOTES FOR INSTALLATION OF SCANNER HEATER

Service Manual / Technical Bulletin

|

2

|

214.44 KB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man72)

CCE 1819 CHANGE OF OPTICAL WEB GUIDE PLATE SEAL

Service Manual / Technical Bulletin

|

2

|

219.59 KB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man73)

CCE 1818 CHANGES IN FINISHER

Service Manual / Technical Bulletin

|

5

|

392.45 KB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man74)

CCE 1817 CHANGE OF PAPER FIXING PLATE for TR20

Service Manual / Technical Bulletin

|

2

|

210.05 KB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man75)

CCE 1678 DISUSE OF LVDS PWB CONNECTOR

Service Manual / Technical Bulletin

|

1

|

249.26 KB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man76)

CCE 1822 Service parts set up for CL roller kit

Service Manual / Technical Bulletin

|

1

|

155.87 KB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man77)

CCE 1800 Rom Upgrade (1 2) for DSK ONLY MX-FR51U MX-FR52U Bulletin only

Service Manual / Technical Bulletin

|

10

|

365.34 KB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man78)

CCE 1802 PARTS CHANGE FOR PRODUCTIVITY IMPROVEMENT

Service Manual / Technical Bulletin

|

3

|

276.26 KB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man79)

CCE 1799 SUPPLIED HARNESSES TO INSTALL OPTION (PERIPHERALS) N VERSION

Service Manual / Technical Bulletin

|

2

|

129.8 KB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man80)

CCE 1795 CHANGE OF FUSING BELT UNIT FOR PRODUCTIVITY IMPROVEMENT

Service Manual / Technical Bulletin

|

3

|

230.16 KB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man81)

CCE 1738 SERVICE PARTS SETUP OF CORRECTIVE PARTS FOR PRINT CONTAMINATION FROM FUSER ROLLER

Service Manual / Technical Bulletin

|

6

|

794.01 KB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man82)

CCE 1803 ROM UPGRADE 12 PHOENIX, GRIFFIN AND SPHINX BULLETIN ONLY

Service Manual / Technical Bulletin

|

3

|

236.05 KB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man83)

CCE 1790 CHANGE OF WAVEGUIDE STICK CLEANING METHOD (Optics)

Service Manual / Technical Bulletin

|

4

|

272.05 KB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man84)

CCE 1798 CHANGE OF PARTS FOR FINISHER FN30 31

Service Manual / Technical Bulletin

|

5

|

427.27 KB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man85)

CCE 1801 ADDITIONAL SUPPLY TO TONER COLLECTING CONTAINER (MX-607HB)

Service Manual / Technical Bulletin

|

1

|

106.71 KB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man86)

CCE 1787 CHANGE OF USB CONNECTOR PWB UNIT for MX-EB18 Wireless option

Service Manual / Technical Bulletin

|

3

|

271.4 KB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man87)

CCE 1784 CHANGE OF CONNECTOR and HARNESS for MX-FX15

Service Manual / Technical Bulletin

|

5

|

334.47 KB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man88)

CCE 1791 ROM UPGRADE. (11) V06.50.K1 Z1 Bulletin Only for both models Phoenix and Griffin

Service Manual / Technical Bulletin

|

3

|

217.77 KB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man89)

CCE 1776 PARTS CHANGE FOR COMMON USE WITH OTHER MODELS

Service Manual / Technical Bulletin

|

5

|

447.33 KB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man90)

CCE 1785 DISCONTINUATION OF SUPPLY OF LAMP BASE

Service Manual / Technical Bulletin

|

4

|

400.71 KB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man91)

CCE 1783 DESIGN CHANGE OF UPPER SENSOR HARNESS HOLDER (H4-02 Mod)

Service Manual / Technical Bulletin

|

2

|

256.26 KB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man92)

CCE 1782 DESIGN CHANGE OF LIFT COUPLING

Service Manual / Technical Bulletin

|

2

|

196.01 KB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man93)

CCE 1781 DESIGN CHANGE OF USB PWB HOLDER

Service Manual / Technical Bulletin

|

2

|

228.25 KB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man94)

CCE 1772 CHANGE OF MHPS SENSOR HARNESS PROTECT SHEET

Service Manual / Technical Bulletin

|

3

|

262.56 KB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man95)

CCE 1771 PARTS CHANGE FOR COMMON USE WITH OTHER DESTINATIONS (MFP PROGRAM ROM AND MFP PROGRAM MSATA)

Service Manual / Technical Bulletin

|

2

|

157.25 KB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man96)

CCE 1769 MODIFICATION OF ORIGINAL GUIDE AND WIDTH DETECT RACK ON DSPF (MX-XX70 only)

Service Manual / Technical Bulletin

|

2

|

308.7 KB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man97)

CCE 1767 DESIGN CHANGE OF ADU FRAME AND RIGHT DOOR BASE PLATE

Service Manual / Technical Bulletin

|

3

|

323.25 KB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man98)

CCE 1764R Rom Upgrade 9 10 additional info.

Service Manual / Technical Bulletin

|

9

|

297.67 KB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man99)

END OF LIFE CONNECTORS

Service Manual / Technical Bulletin

|

2

|

135.9 KB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man100)

CCE-1764 Rom Upgrade 9 10 V6 Phoenix and Griffin. Bulletin Only.

Service Manual / Technical Bulletin

|

9

|

294.45 KB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man101)

CCE 1737 QTY CHANGE OF FUSING DRAWER HOLDER FIXING SCREW

Service Manual / Technical Bulletin

|

2

|

219.63 KB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man102)

CCE 1736 ENHANCEMENT OF GROUNDING CAPABILITY ON DELIVERY UNIT

Service Manual / Technical Bulletin

|

2

|

210.27 KB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man103)

CCE 1733 CHANGE OF PARTS FOR PRODUCTIVITY IMPROVEMENT

Service Manual / Technical Bulletin

|

2

|

354.25 KB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man104)

CCE 1731 CHANGE OF FUSING JOINT SHAFT

Service Manual / Technical Bulletin

|

2

|

307.17 KB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man105)

CCE 1729 CHANGE OF LCD HARNESS

Service Manual / Technical Bulletin

|

2

|

242.78 KB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man106)

CCE 1728 REMEDY FOR SHIFT IN THE PRINT POSITION

Service Manual / Technical Bulletin

|

2

|

363.47 KB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man107)

CCE 1727 CHANGE IN THERMOSTAT

Service Manual / Technical Bulletin

|

2

|

320.68 KB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man108)

CCE 1726 CHANGE OF MC PWB FIXING COVER

Service Manual / Technical Bulletin

|

2

|

231.89 KB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man109)

CCE 1723 DESIGN CHANGE OF TRANSFER ARM HOLDER

Service Manual / Technical Bulletin

|

2

|

331.47 KB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man110)

CCE 1722 NOISE REDUCTION OF OPERATING SOUND OF FUSING DRIVE UNIT GEAR

Service Manual / Technical Bulletin

|

2

|

260.51 KB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man111)

CCE 1721 CHANGE OF DC POWER SUPPLY UNIT FOR COMMON USE WITH OTHER MODELS

Service Manual / Technical Bulletin

|

2

|

288.91 KB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man112)

CCE 1716 DESIGN CHANGE OF OPERATION BASE PLATE

Service Manual / Technical Bulletin

|

2

|

157.48 KB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man113)

CCE 1715 ADDITION OF FERRITE CORE FIXING PARTS FOR DSPF UNIT

Service Manual / Technical Bulletin

|

2

|

234.86 KB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man114)

CCE 1711 CHANGE OF PARTS ON PAPER PASS UNIT

Service Manual / Technical Bulletin

|

3

|

317.9 KB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man115)

CCE 1710 CHANGE OF MAIN SWITCH HARNESS

Service Manual / Technical Bulletin

|

2

|

141.48 KB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man116)

CCE 1709 PARTS CHANGE FOR COMMON USE WITH OTHER MODELS

Service Manual / Technical Bulletin

|

5

|

624.48 KB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man117)

CCE 1708 ADDITION OF PAPER FEED BASE EDGE PROTECT SHEET

Service Manual / Technical Bulletin

|

2

|

134.34 KB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man118)

CCE 1707 NOTES WHEN REPLACING LED PWB UNIT

Service Manual / Technical Bulletin

|

2

|

311.19 KB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man119)

CCE 1702 DESIGN CHANGE OF WASTE TONER BOX UNIT

Service Manual / Technical Bulletin

|

2

|

176.12 KB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man120)

CCE 1699 CHANGE IN PARTS FOR 3K FINISHER FN30 31

Service Manual / Technical Bulletin

|

8

|

764.49 KB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man121)

CCE 1697 Rom Upgrade (8) V 05.12.K Z1 Bulletin only

Service Manual / Technical Bulletin

|

3

|

179.61 KB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man122)

CCE 1698 REMOVAL OF CORE AND EARTH SHEET FOR DSPF UNIT

Service Manual / Technical Bulletin

|

2

|

108.63 KB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man123)

CCE 1696 ENHANCEMENT FOR NOISE AT DELIVERY SECTION

Service Manual / Technical Bulletin

|

2

|

258.72 KB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man124)

CCE 1686 ADDITION OF MAIN UNIT EXIT SHEET (prevention of POD2 jams)

Service Manual / Technical Bulletin

|

2

|

232.98 KB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man125)

CCE 1684 REGISTRATION OF ASM_RETURN_PADDLE_PLATE_MOT AS SERVICE PART

Service Manual / Technical Bulletin

|

2

|

154.42 KB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man126)

CCE 1681 ENHANCEMENT AGAINST STATIC ELECTRICITY MX-PN15

Service Manual / Technical Bulletin

|

2

|

181.22 KB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man127)

CCE 1682 ADDITION OF ENTRANCE UPPER MYLAR

Service Manual / Technical Bulletin

|

4

|

338.5 KB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man128)

CCE 1676 CHANGE DISUSE OF HARNESS FIXING BAND QTY CHANGE OF MINI CLAMP

Service Manual / Technical Bulletin

|

2

|

461.42 KB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man129)

CCE-1670 CHANGE IN LENGTH OF MOUNTING SCREW FOR FRONT CABINET UPPER RIGHT

Service Manual / Technical Bulletin

|

2

|

175.71 KB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man130)

IMPROVEMENT IN ENDURANCE AGAINST STATIC ELECTRICITY

Service Manual / Technical Bulletin

|

3

|

332.46 KB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man131)

CCE-1668 PREVENTION OF PINCHED LVDS-FFC

Service Manual / Technical Bulletin

|

1

|

214.2 KB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man132)

CCE-1667 REGISTRATION OF CLEANER FRAME B SUB UNIT AS SERVICE PARTS

Service Manual / Technical Bulletin

|

2

|

171.81 KB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man133)

CCE 1666R Rom Upgrade 5 6 V5 Combined Firmware Bulletin Only

Service Manual / Technical Bulletin

|

7

|

500.8 KB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man134)

CCE-1665 FIELD ACTION FOR NOISE FROM FUSING PRESSURE RELEASE SYSTEM

Service Manual / Technical Bulletin

|

1

|

189.2 KB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man135)

CCE-1664 CHANGE OF OSCILLATOR ON CCD PWB

Service Manual / Technical Bulletin

|

2

|

134.98 KB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man136)

CCE-1663 CHANGE OF CRUM HARNESS AND LCD HARNESS

Service Manual / Technical Bulletin

|

2

|

208.51 KB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man137)

CCE-1661 DESIGN CHANGE OF 3K FINISHER

Service Manual / Technical Bulletin

|

2

|

309.02 KB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man138)

CCE-1658 NOISE PREVENTION FOR FUSING UNIT

Service Manual / Technical Bulletin

|

2

|

188.69 KB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man139)

CCE 1657 NOISE PREVENTION FOR PAPER FEED OPTIONS

Service Manual / Technical Bulletin

|

2

|

279.24 KB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man140)

CCE 1659 NOISE PREVENTION FOR TRANSPORT FOLLOWER ROLLER SHAFT 1 ON DSPF UNIT

Service Manual / Technical Bulletin

|

1

|

183.31 KB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man141)

CCE 1656 DESIGN CHANGE OF INNER FINISHER FRONT LOWER COVER

Service Manual / Technical Bulletin

|

2

|

202.54 KB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man142)

CCE 1655 REMOVAL OF LCC FIXING PLATE FROM PACKAGE

Service Manual / Technical Bulletin

|

1

|

139.37 KB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man143)

CCE-XXXX FK3 on Machine set up

Service Manual / Technical Bulletin

|

1

|

68.55 KB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man144)

CCE 1653 CHANGE OF RIGHT DOOR PWB

Service Manual / Technical Bulletin

|

2

|

125.64 KB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man145)

CCE 1649 CHANGE OF FAX MAIN PWB

Service Manual / Technical Bulletin

|

2

|

137.46 KB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man146)

CCE 1647 CHANGE IN SHAPE OF FUSING REAR GATE PAPER GUIDE

Service Manual / Technical Bulletin

|

2

|

182.11 KB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man147)

CCE 1644 DESIGN CHANGE OF REGULATION PLATE SUPPORT BLOCK

Service Manual / Technical Bulletin

|

2

|

228.66 KB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man148)

CCE 1645 CHANGE OF TRANSPORT FOLLOWER ROLLER

Service Manual / Technical Bulletin

|

2

|

179.18 KB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man149)

CCE 1643 CHANGE OF TIGHTENING DIRECTION OF RSPF SCREW

Service Manual / Technical Bulletin

|

2

|

382.12 KB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man150)

CCE 1642 CHANGE IN PARTS FOR 3K FINISHER

Service Manual / Technical Bulletin

|

4

|

535.84 KB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man151)

CCE 1641 MODIFICATION OF INLET UNIT HARNESS AND INLET FIXING PLATE DUE TO CHANGE OF INLET

Service Manual / Technical Bulletin

|

2

|

107.81 KB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man152)

CCE 1633 DESIGN CHANGE OF UPPER DELIVERY TRAY

Service Manual / Technical Bulletin

|

2

|

168.36 KB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man153)

CCE 1629 IMPROVEMENT OF NOISE DUE TO ABRASION OF BLADE FACE ROLLER

Service Manual / Technical Bulletin

|

2

|

191 KB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man154)

CCE 1630 CHANGE OF PTC UNIT FOR COMMON USE WITH OTHER MODELS

Service Manual / Technical Bulletin

|

1

|

82.21 KB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man155)

CCE 1628 DESIGN CHANGE OF SOLENOID FIXING PLATE

Service Manual / Technical Bulletin

|

2

|

188.71 KB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man156)

CCE 1627 DESIGN CHANGE OF TN COUPLING

Service Manual / Technical Bulletin

|

2

|

217.58 KB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man157)

CCE 1625 COUNTERMEASURE FOR L4-12 TROUBLE

Service Manual / Technical Bulletin

|

2

|

235.68 KB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man158)

CCE 1624 COUNTERMEASURE FOR NOISE FROM DELIVERY SECTION

Service Manual / Technical Bulletin

|

3

|

492.54 KB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man159)

CCE 1623 DESIGN CHANGE FOR COMMON USE WITH OTHER MODELS

Service Manual / Technical Bulletin

|

4

|

421.23 KB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man160)

CCE 1620 CHANGE IN SHAPE OF DISCHARGE BRUSH

Service Manual / Technical Bulletin

|

2

|

113.81 KB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man161)

CCE 1618 DESIGN CHANGE OF UPPER CABINET RIGHT UPPER CABINET FRONT RIGHT LOWER R

Service Manual / Technical Bulletin

|

2

|

280.05 KB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man162)

CCE 1617 NOISE REDUCTION OF DELIVERY DRIVE UNIT

Service Manual / Technical Bulletin

|

2

|

155.9 KB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man163)

CCE 1616 ADDITION OF PACKING MATERIALS FOR PUNCH UNIT

Service Manual / Technical Bulletin

|

2

|

274.74 KB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man164)

CCE 1612 CHANGE OF FOLLOWER COLLAR PRESSURE SPRING AT UPPER DELIVERY SECTION

Service Manual / Technical Bulletin

|

2

|

270.72 KB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man165)

CCE 1611 DESIGN CHANGE OF MFPC COVER

Service Manual / Technical Bulletin

|

2

|

232.89 KB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man166)

CCE 1610 ENHANCEMENT FOR MEANDERING OF FUSING BELT

Service Manual / Technical Bulletin

|

2

|

260.64 KB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man167)

CCE 1609 ENHANCEMENT OF SEALING WASTE TONER

Service Manual / Technical Bulletin

|

3

|

211.2 KB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man168)

CCE 1608 DESIGN CHANGE OF MULTI TRAY

Service Manual / Technical Bulletin

|

2

|

278.01 KB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man169)

CCE 1606 REGISTRATION OF NEW MHPS HARNESS FOR DSPF MODEL

Service Manual / Technical Bulletin

|

2

|

196.08 KB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man170)

CCE 1605 Rom Upgrade 3 V4 for Phoenix and Griffin. Please read instructions prior to Upgrade.

Service Manual / Technical Bulletin

|

14

|

629.51 KB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man171)

CCE 1604 CHANGE IN SHAPE OF PUNCH SLIDE ASSEMBLY

Service Manual / Technical Bulletin

|

2

|

122.83 KB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man172)

CCE 1603 DESIGN CHANGE OF WEB ROLLER FIXING HOLDER

Service Manual / Technical Bulletin

|

2

|

264.74 KB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man173)

CCE 1602 DESIGN CHANGE OF WASTE TONER DRIVE COVER

Service Manual / Technical Bulletin

|

2

|

200.43 KB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man174)

CCE 1599 CHANGE IN SHAPE OF PARTS FOR TONER DRIVE UNIT

Service Manual / Technical Bulletin

|

3

|

283.57 KB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man175)

CCE 1598 ADDITION OF PARTS FOR COMMON USE WITH OTHER MODELS

Service Manual / Technical Bulletin

|

3

|

395.2 KB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man176)

CCE 1597 CHANGE IN SHAPE OF PLASTIC BEARING

Service Manual / Technical Bulletin

|

2

|

123.12 KB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man177)

CCE 1595 MODIFICATION OF OPTIONAL DESK AND TANDEM DESK

Service Manual / Technical Bulletin

|

4

|

626.3 KB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man178)

CCE 1593 CHANGE IN SHAPE OF MC PWB FIXING COVER AND MC ELECTRODE PLATE HOLDER

Service Manual / Technical Bulletin

|

2

|

127.09 KB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man179)

CCE 1591 ATTACHMENT OF PROTECTION SHEET FOR FUSING UNIT

Service Manual / Technical Bulletin

|

2

|

184.74 KB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man180)

CCE 1587 IMPROVEMENT IN RETURN MOVEMENT OF PAPER FEED ACTUATOR ON INTERFACE UNIT for PDPPD jams

Service Manual / Technical Bulletin

|

2

|

144.4 KB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man181)

CCE 1586 DESIGN CHANGE OF FR JOINT FRAME

Service Manual / Technical Bulletin

|

2

|

215.27 KB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man182)

CCE 1584 FINISHER UPGRADE ..... (1)

Service Manual / Technical Bulletin

|

2

|

59.16 KB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man183)

CCE 1578 MOUNTING EARTH HARNESS ON FUSING REAR PAPER GUIDE UNIT (L4-11 Error Code)

Service Manual / Technical Bulletin

|

4

|

518.31 KB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man184)

CCE 1582 Design Change of Process Frame.

Service Manual / Technical Bulletin

|

2

|

247.31 KB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man185)

CCE 1579 Countermeasure for Paper Jam at RSPF Paper Feed Section

Service Manual / Technical Bulletin

|

2

|

165.96 KB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man186)

CCE 1577 Change of PCU pwb For productivity improvement

Service Manual / Technical Bulletin

|

3

|

416.49 KB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man187)

CCE 1513 Careful handling must be used when installing the main unit providing service and during transportation

Service Manual / Technical Bulletin

|

2

|

166.4 KB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man188)

CCE 1573 Changes to Inner finisher MX-FN27

Service Manual / Technical Bulletin

|

3

|

515.98 KB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man189)

CCE 1570 SHIPMENT STYLE OF DEVELOPER (DV already installed before shipping)

Service Manual / Technical Bulletin

|

2

|

56.67 KB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man190)

CCE 1566 CHANGE IN SHAPE OF PLATE TRANSPORT MIDDLE

Service Manual / Technical Bulletin

|

5

|

467.25 KB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man191)

CCE 1531 MODIFICATION OF FRAME UNIT

Service Manual / Technical Bulletin

|

3

|

253.63 KB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man192)

Notification of CPO (License Manager) and support for SHA-2.

Service Manual / Technical Bulletin

|

3

|

38.6 KB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man193)

CCE 1565 COUNTERMEASURE FOR NOISE FROM THE DSPF HINGE

Service Manual / Technical Bulletin

|

2

|

103.27 KB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man194)

CCE 1561 CHANGE OF 1ST TRANSFER BELT

Service Manual / Technical Bulletin

|

2

|

190.29 KB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man195)

CCE 1560 MODIFICATION OF DESK LCC

Service Manual / Technical Bulletin

|

3

|

388.46 KB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man196)

CCE 1549 COUNTERMEASURE FOR NOISE FROM RSPF

Service Manual / Technical Bulletin

|

2

|

235.86 KB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man197)

CCE 1508 IMPROVEMENT OF PERFORMANCE WHEN OPENING CLOSING DSPF LOWER DOOR

Service Manual / Technical Bulletin

|

3

|

235.02 KB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man198)

Design change of delivery paper guide.

Service Manual / Technical Bulletin

|

2

|

91.45 KB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man199)

CCE 1557 CHANGE OF SILENCE MOQUETTE ON RSPF

Service Manual / Technical Bulletin

|

2

|

203.99 KB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man200)

CCE 1537 MODIFICATION OF THE SHAPE OF COUPLING ON TN MOTOR UNIT

Service Manual / Technical Bulletin

|

2

|

169.73 KB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man201)

CCE 1544 ADDITION OF RIGHT UPPER PANEL HARNESS PROTECT SHEET

Service Manual / Technical Bulletin

|

2

|

211.33 KB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man202)

CCE 1517 REMEDY FOR MALFUNCTION OF PICK UP ARM ON MANUAL PAPER FEED UNIT

Service Manual / Technical Bulletin

|

2

|

201.19 KB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man203)

CCE 1543 DESIGN CHANGE OF FUSING REAR LOWER PAPER GUIDE

Service Manual / Technical Bulletin

|

2

|

375.63 KB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man204)

CCE 1542 ENHANCEMENT FOR WASTE TONER DROP

Service Manual / Technical Bulletin

|

2

|

255.37 KB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man205)

CCE 1540 MODIFICATION OF THE SHAPE OF FUSING REAR GATE LINK ARM

Service Manual / Technical Bulletin

|

2

|

168.84 KB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man206)

CCE 1538 ENHANCEMENT OF STRENGTH OF TENSION ROLLER BEARING

Service Manual / Technical Bulletin

|

2

|

333.42 KB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man207)

CCE 1539 CHANGE IN SHAPE OF TRANSPORT DRIVE HOLDER

Service Manual / Technical Bulletin

|

2

|

83.16 KB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man208)

CCE 1536 IMPROVEMENT OF NOISE-REDUCTION OF FUSING REAR UNIT

Service Manual / Technical Bulletin

|

1

|

255.4 KB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man209)

CCE 1535 ENHANCEMENT OF RIB ON TR SHUTTER FOR DV UNIT

Service Manual / Technical Bulletin

|

1

|

67.94 KB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man210)

CCE 1532 ADDITION OF REVERSE GATE TRAY ON MX-RB25

Service Manual / Technical Bulletin

|

3

|

279.67 KB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man211)

CCE 1528 ADDITION OF DISCHARGING BRUSH

Service Manual / Technical Bulletin

|

2

|

266.73 KB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man212)

CCE 1527 APPLICATION OF HANARL GREASE ON TONER MOTOR UNIT

Service Manual / Technical Bulletin

|

1

|

173.01 KB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man213)

CCE 1526 COUNTERMEASURE FOR DOG EAR ON SMALL SIZE PAPER

Service Manual / Technical Bulletin

|

2

|

123.97 KB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man214)

CCE 1525 DESIGN CHANGE OF MF PICK UP ARM SPRING

Service Manual / Technical Bulletin

|

2

|

129.14 KB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man215)

CCE 1524 DESIGN CHANGE OF MULTI REGULATION PLATE

Service Manual / Technical Bulletin

|

2

|

236.18 KB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man216)

CCE 1522 COUNTERMEASURE FOR PAPER FEED UNIT DRIVE BELT ACCIDENTALLY DETACHED

Service Manual / Technical Bulletin

|

2

|

269.25 KB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man217)

CCE 1520 ADDITION OF CABLE TIE FOR PROCESS FAN

Service Manual / Technical Bulletin

|

2

|

174.12 KB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man218)

CCE 1518 CHANGE IN SHAPE OF WASTE TONER DRIVE COVER

Service Manual / Technical Bulletin

|

2

|

107.52 KB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man219)

CCE 1516 COUNTERMEASURE FOR MEANDERING OF FUSING BELT

Service Manual / Technical Bulletin

|

2

|

304.18 KB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man220)

CCE 1514 COUNTERMEASURE FOR NOISE FROM RIGHT LOWER DOOR

Service Manual / Technical Bulletin

|

3

|

476.76 KB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man221)

CCE 1515 ROM UPGRADE (2) V02.01.Z1.00 Bulletin Only

Service Manual / Technical Bulletin

|

2

|

93.17 KB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man222)

CCE 1512 REMEDY FOR NOISE FROM MANUAL PAPER FEED UNIT

Service Manual / Technical Bulletin

|

2

|

191.75 KB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man223)

CCE 1511 CHANGE IN SHAPE OF PAPER FEED UPPER PAPER GUIDE

Service Manual / Technical Bulletin

|

2

|

248.58 KB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man224)

CCE 1509 CHANGE IN SHAPE OF FUSING REAR PAPER GUIDE LOWER

Service Manual / Technical Bulletin

|

2

|

117.03 KB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man225)

CCE 1507 ROM UPGRADE ..... (1). 02.00.Z1.00 Bulletin Only

Service Manual / Technical Bulletin

|

3

|

203.38 KB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man226)

CCE 1504 REDUCTION OF OPERATING SOUND OF FUSER

Service Manual / Technical Bulletin

|

2

|

269.43 KB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man227)

Counter Measure to overcome L4-11 Error when MX-TU16 is not fitted

Service Manual / Technical Bulletin

|

1

|

18.14 KB

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man42)

V7 DSK ONLY Box connector (TLS 1.2)firmware release 07.00.Zca0. Phoenix Model MXxx60 and MXxx70 Inc. Box connector enablement. Bulletin Embedded PLEASE READ INSTRUCTIONS PRIOR TO UPGRADE

Driver / Update

|

|

290.81 MB

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man43)

V7 DSK ONLY Box connector (TLS 1.2)firmware release 07.00.Kca0. Griffin Model MXxx50 Inc. Box connector enablement. Bulletin Embedded PLEASE READ INSTRUCTIONS PRIOR TO UPGRADE

Driver / Update

|

|

290.19 MB

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man44)

Box connector (TLS 1.2) firmware release 07.00.K1a0. Griffin Model MXxx50 Inc. Box connector enablement. Bulletin Embedded PLEASE READ INSTRUCTIONS PRIOR TO UPGRADE

Driver / Update

|

|

290.18 MB

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man45)

Box connector (TLS 1.2)firmware release 07.00.K1a0. Phoenix Model MXxx60 and MXxx70 Inc. Box connector enablement. Bulletin Embedded PLEASE READ INSTRUCTIONS PRIOR TO UPGRADE

Driver / Update

|

|

290.81 MB

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man46)

ROM UPGRADE 13 V 07.00.Z100 Phoenix Model MXxx60 and MXxx70 Bulletin Embedded PLEASE READ INSTRUCTIONS PRIOR TO UPGRADE

Driver / Update

|

|

290.7 MB

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man47)

ROM UPGRADE 13 V 07.00.K100 Griffin Model MXxx50 Bulletin Embedded PLEASE READ INSTRUCTIONS PRIOR TO UPGRADE

Driver / Update

|

|

290.16 MB

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man48)

ROM UPGRADE 12 V 06.50.Kc.00 Griffin Model MXxx50 DSK ONLY Bulletin Embedded PLEASE READ INSTRUCTIONS PRIOR TO UPGRADE

Driver / Update

|

|

286.61 MB

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man49)

ROM UPGRADE 12 V 06.50.Zc.00 Phoenix Model MXxx60 and MXxx70 DSK ONLY Bulletin Embedded PLEASE READ INSTRUCTIONS PRIOR TO UPGRADE

Driver / Update

|

|

287.15 MB

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man50)

ROM UPGRADE 12 V 06.50.Z1.00 Phoenix Model MXxx60 and MXxx70 Bundle 06.51.Z1 Bulletin Embedded PLEASE READ INSTRUCTIONS PRIOR TO UPGRADE

Driver / Update

|

|

287.04 MB

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man51)

ROM UPGRADE 12 V 06.50.K1.00 Griffin Model MXxx50 Bundle 06.51.K1 Bulletin Embedded PLEASE READ INSTRUCTIONS PRIOR TO UPGRADE

Driver / Update

|

|

286.5 MB

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man52)

Griffin DSK special Firmware MX-FR51U PLEASE TURN MACHINE OFF AND ON AGAIN PRIOR TO UPGRADING

Driver / Update

|

|

279.66 MB

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man53)

Phoenix DSK special Firmware MX-FR52U PLEASE TURN MACHINE OFF AND ON AGAIN PRIOR TO UPGRADING

Driver / Update

|

|

276.87 MB

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man54)

OCR Dictionary Firmware V2 (Updated)

Driver / Update

|

|

57.78 MB

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man55)

Watermark Firmware

Driver / Update

|

|

8.07 MB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N

Griffin Handy Guide MX-XX50 Updated Dec 16 Note Handy Guides are not a Substitute for the Service Manual

Handy Guide

|

82

|

5.03 MB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man2)

Phoenix Handy Guide MX-XX60 MX-XX70 Updated Dec 16 Note Handy Guides are not a Substitute for the Service Manual

Handy Guide

|

82

|

5.22 MB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man3)

MX3050-4070 Full Sales Brochure

Handy Guide

|

8

|

3.81 MB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man36)

How to update firmware via FTP

FAQ

|

2

|

650.37 KB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man37)

Updated EEPROM Programming Procedure

FAQ

|

4

|

592.71 KB

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man38)

MX3050-MX4070 Pantone LUT, How to Guide and application Support files. For use with Sharp Driver

FAQ

|

|

26.31 MB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man39)

Procedure to reset the Admin or Service Password. Please download relevant Request to reset Form below

FAQ

|

5

|

311.14 KB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man40)

Request to Reset Service Password Form Please fill in all sections of this form

FAQ

|

1

|

147.81 KB

|

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man41)

Request to Reset Admin Password Form Please fill in all sections of this form

FAQ

|

1

|

147.88 KB

|

|

MX-3050N MX-3060N MX-3070N MX-3550N MX-3560N MX-3570N MX-4050N MX-4060N MX-4070N (serv.man228)

MSDS for Phoenix and Griffin Toner and Developer. Zipped file containing all.

Regulatory Data

|

|

933.93 KB

|