Sharp MX-M950 / MX-MM1100 (serv.man40) Service Manual ▷ View online

MX-M1100 MAINTENANCE 9 – 9

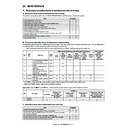

7)

Remove the blue screw (a), and remove the bearing (b) and

bearing (c).

* When installing the bearing, fit the D-cut direction and

bearing (c).

* When installing the bearing, fit the D-cut direction and

engage it properly.

8)

Hold the handle (a), and pull out the process unit (b) until it

stops.

stops.

9)

Hold the green label section (a) of the process unit frame, and

lift it up and remove it completely.

lift it up and remove it completely.

10) Check the OPC drum (a) at every 500K.

* Place the cleaner unit on the lower side.

11) Remove the blue screw (a), and open the frame (b).

12) Remove the OPC drum unit (a).

* Use a great care not to damage the OPC drum.

c

b

a

a

a

d

d

a

b

a

a

a

a

a

b

a

MX-M1100 MAINTENANCE 9 – 10

13) Rotate the bearing (a) and remove it.

* While performing the procedure, turn back the cover (a) that

have been removed in step 2), and put the OPC drum unit

on the cover.

When putting the OPC drum unit on the cover, in advance

remove the bearing, place it according to "F" and "R"

marked on the cover (a).

Cover the OPC drum unit with paper to prevent exposure.

on the cover.

When putting the OPC drum unit on the cover, in advance

remove the bearing, place it according to "F" and "R"

marked on the cover (a).

Cover the OPC drum unit with paper to prevent exposure.

14) Remove the blue screw (a), and remove the flange (b).

Replace the OPC drum (c) at every 1000K.

* When installing the OPC drum, check to confirm that the

label (a) inside the OPC drum comes on the rear side.

* When handling the OPC drum, be careful not to touch the

photoconductor surface (b). Put your hand inside the OPC

drum to install it.

drum to install it.

* After replacement, apply stearic acid (UKOG-0312FCZZ) (a)

to the whole surface of the OPC drum

* After installing the OPC drum to the unit, rotate it one revolu-

tion in the normal direction.

* Never apply powder other than stearic acid.

15) Clean the procon sensor (a) every 500K.

a

R

F

a

a

c

b

a

b

a

a

a

MX-M1100 MAINTENANCE 9 – 11

16) Clean the front surface potential sensor (a) at every 500K.

* When cleaning, be careful not to drop a foreign material into

the small window (b) of the surface potential sensor.

17) Remove the blue screw (a), and replace the cleaning blade

(b).

* Do not touch the urethane edge of the cleaning blade.

* Tighten the blue screw (a) in the sequence of (1), (2), and

* Do not touch the urethane edge of the cleaning blade.

* Tighten the blue screw (a) in the sequence of (1), (2), and

(3).

18) Replace the side seal F (a) and the side seal R (b). Check the

sub blade seal F (c) and the sub blade seal R (d).

* Slide the cleaning blade (a) in the arrow direction, and

attach the side seal F (b), the side seal R (c), the sub blade

seal F (d), and the sub blade seal R (e) according to the ref-

erences.

seal F (d), and the sub blade seal R (e) according to the ref-

erences.

* When attaching the seal, check to confirm that the side seal

is not covered with the cleaning blade.

* The cleaning blade can be shifted to the front side or the

rear side by turning the knob (a) on the front side clockwise

or counterclockwise.

or counterclockwise.

b

a

a

a

a

b

1

2

3

a

b

c

d

a

b

d

a

c

e

a

MX-M1100 MAINTENANCE 9 – 12

* After attachment, apply side seal powder (UKOG-0309FC

ZZ) to the whole surfaces of the side seal F and side seal R

evenly by using Patel (UKOG-0311FCZZ) .

evenly by using Patel (UKOG-0311FCZZ) .

19) Check the blade side seal F (a) and the blade side seal R (b)

at every 500K, and replace them at every 300K.

* When attaching them, attach according to the reference.

* When attaching them, attach according to the reference.

20) Remove the blue screw (a), and replace the sub blade (b).

* Tighten the blue screw (a) in the sequence of (1), (2), and

(3).

21) Clean the cleaning brush roller (a) at every 500K.

22) Remove the screw (a). Remove the brush bearing (b), and

check at every 3000K.

23) Replace the cleaning brush roller (a).

* When attaching, the cleaning brush roller, engage the slit (b)

at the lead edge with the pin (c) in the shaft.

a

b

a

a

a

b

1

2

3

a

a

a

b

c

Click on the first or last page to see other MX-M950 / MX-MM1100 (serv.man40) service manuals if exist.