Sharp MX-M950 / MX-MM1100 (serv.man40) Service Manual ▷ View online

MX-M1100 MAINTENANCE 9 – 29

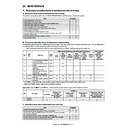

B. Details

1)

Open the front cover (a), and pull out the intermediate frame

(b).

(b).

2)

While pushing the lever (a), slide the ADU paper exit unit (b).

3)

Remove the screw (a), and remove the upper heat roller sepa-

ration pawl unit 1 (b).

ration pawl unit 1 (b).

4)

Remove the screw (a), and remove the upper heat roller sepa-

ration pawl unit 2 (b).

ration pawl unit 2 (b).

5)

Remove the spring (a), and replace the upper heat roller sepa-

ration pawl (b).

ration pawl (b).

6)

Clean the paper guide (a) at every 500K.

7)

Remove the screw (a), and remove the cover (b) and the knob

(c).

(c).

8)

Remove the screw (a), and remove the rail (b).

a

b

a

b

a

b

a

a

b

a

b

a

a

a

b

c

a

b

MX-M1100 MAINTENANCE 9 – 30

9)

Remove the screw (a), and remove the fusing unit (b).

* Be careful to handling of the fusing unit heated to a high

* Be careful to handling of the fusing unit heated to a high

temperature. When removing it, hold the resin sections on

both sides of the fusing unit.

both sides of the fusing unit.

10) Insert a screwdriver into the pressure release shaft (a) to

release the pressure.

* When the pressure is released, the arrow on the pressure

* When the pressure is released, the arrow on the pressure

release shaft faces diagonally (b). When the pressure is

applied, the arrow faces upward (c).

applied, the arrow faces upward (c).

11) Remove the screw (a) on the side of “W” mark from the fusing

upper unit, and remove the web unit (b).

12) Remove the screw (a), and remove the web guide shaft unit

(b). Replace the web guide shart (c) and the web guide bear-

ing (d).

ing (d).

13) Remove the screw (a), and slide and remove the WEB roller

(b), and replace the WEB roller.

* After replacement, rotate the gear (a) and manually wind the

web roller until the red line (b) of the web roller is covered.

* After completion of maintenance, execute SIM. 24-4 (Fusing

web cleaning feed counter clear).

* When the web unit is not installed, the FK3 code is dis-

played. In this case, set the web unit and cancel it with

Sim.14. (The FK3 code is deleted, but the web feed counter

continues the operation.)

Sim.14. (The FK3 code is deleted, but the web feed counter

continues the operation.)

a

a

b

a

c

b

a

a

b

W

W

a

d

c

d

b

a

b

a

b

MX-M1100 MAINTENANCE 9 – 31

14) Remove the screw (a), and remove the metal fixture (b).

Replace the WEB backup roller (c) and the WEB backup roller

bearing (d).

* When installing, be careful to the hang the spring (e) prop-

bearing (d).

* When installing, be careful to the hang the spring (e) prop-

erly.

15) Remove the screw (a), and separate the fusing upper unit (b)

and the fusing lower unit (c).

16) Disconnect the connector (a), and remove the screw (b), and

remove the sub thermistor (c). Check or the sub thermistor (c)

at every 500K, or replace it at every 3000K.

* When handling the thermistor, be careful not to deform it.

at every 500K, or replace it at every 3000K.

* When handling the thermistor, be careful not to deform it.

17) Turn the fusing upper unit upside down. Remove the screw (a),

and remove the cover (b).

18) Open the clamp (a). Disconnect the connector (b) of the upper

heater lamp.

* When assembling, store the white clamp (a) at the bottom of

the clamp (b), and store the black connector (c) to the clamp

(b). (Europe 95/110-sheet model only)

(b). (Europe 95/110-sheet model only)

* Check to confirm that the black connector (c) does not

extend from the reference line.

* When storing each connector, be careful not to pinch it.

a

b

d

c

d

e

a

a

b

c

a

b

c

a

b

b

a

b

b

b

a

c

MX-M1100 MAINTENANCE 9 – 32

19) Remove the screw (a), and remove the lamp holder (b).

* When installing, engage the positioning (c) of the upper

heater lamp with the notch of the lamp holder.

20) Remove the upper heater lamp (a), and check it at every 500K,

or replace it at every 3000K.

* Insert the positioning (b) into the upper heater lamp so that

* Insert the positioning (b) into the upper heater lamp so that

the positioning (b) is on the front side.

21) Remove the fixing fin (a), and remove the upper heat roller unit

(b).

* When installing, assemble the fixing fin (a) inside the bear-

* When installing, assemble the fixing fin (a) inside the bear-

ing flange (c).

22) Remove the C-ring (a), and remove the upper heat roller gear

(b), the upper heat roller insulation bush (c), and the upper

heat roller ball bearing (d) from the upper heat roller (e).

Check the upper heat roller gear (b), the upper heat roller insu-

lation bush (c), the upper heat roller ball bearing (d), and the

upper heat roller (e) at every 500K, or replace them at every

1000K.

heat roller ball bearing (d) from the upper heat roller (e).

Check the upper heat roller gear (b), the upper heat roller insu-

lation bush (c), the upper heat roller ball bearing (d), and the

upper heat roller (e) at every 500K, or replace them at every

1000K.

* When replacing, apply grease (UKOG-0235FCZZ) to the

upper heat roller insulation bush and the upper heat roller

section (a).

section (a).

23) Check the non-contact thermistor (a) at every 500K.

a

b

b

a

F

c

F

c

Other model

EU 95/110-

sheet model

sheet model

Other model

EU 95/110-

sheet model

sheet model

R

R

Other model

EU 95/110-

sheet model

sheet model

a

b

Other model

EU 95/110-

sheet model

sheet model

a

a

b

a

c

a

c

a

b

c

d

d

c

a

e

a

a

a

a

a

Click on the first or last page to see other MX-M950 / MX-MM1100 (serv.man40) service manuals if exist.