Sharp MX-M950 / MX-MM1100 (serv.man40) Service Manual ▷ View online

MX-M1100 MAINTENANCE 9 – 5

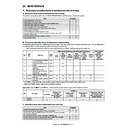

(Document scanning section)

Fusing section

(9 - 28)

(9 - 28)

20

Web guide shaft

✕

▲

▲

▲

▲

▲

▲

[PG No.: [46] - 30]

21

Web guide bearing

✕

▲

▲

▲

▲

▲

▲

[PG No.: [46] - 31]

Filter section

(9 - 35)

(9 - 35)

1

Ozone filter

▲

▲

▲

▲

▲

▲

Or 6 months

[PG No.: [72] - 26]

[PG No.: [72] - 26]

2

Suction filter

▲

▲

▲

▲

▲

▲

Or 6 months

[PG No.: [70] - 35]

[PG No.: [70] - 35]

3

Exhaust filter

▲

▲

▲

▲

▲

▲

Or 6 months

[PG No.: [72] - 10]

[PG No.: [72] - 10]

Tray paper feed

section (9 - 37)

section (9 - 37)

1

Pickup roller

✕

✕

✕

✕

✕

✕

✕

(Note 1)

2

Paper feed roller

✕

✕

✕

✕

✕

✕

✕

(Note 1)

3

Separation roller

✕

✕

✕

✕

✕

✕

✕

(Note 1)

4

Torque limiter

✕

✕

✕

✕

✕

✕

✕

(Note 1)

5

Optical reflection type sensor

{

{

{

{

{

{

{

6

Transport rollers

✕

{

{

{

{

{

▲

[PG No.: [24] - 6, [25] - 9]

Paper transport

section (9 - 44)

section (9 - 44)

1

Resist roller (Idle)

✕

{

{

{

{

{

▲

[PG No.: [32] - 28]

2

Transport rollers

✕

{

{

{

{

{

▲

[PG No.: [32] - 30]

3

Transport paper guides

{

{

{

{

{

{

{

4

Optical reflection type sensor

{

{

{

{

{

{

{

5

Paper dust cleaner

{

▲

▲

▲

▲

▲

▲

[PG No.: [32] - 1]

6

Double feed detection unit

{

Ultrasonic sensor top surface

(Air cleaning)

95/110-sheet model only.

(Air cleaning)

95/110-sheet model only.

7

PS section PWB protection

sheet

sheet

{

8

PS gears

▲

[PG No.: [31] - 36, [32] - 14,

[32] - 22, [32] - 36, [32] - 37]

[32] - 22, [32] - 36, [32] - 37]

9

CIS

{

{

10

Bearings

✕

ADU paper exit

section (9 - 55)

section (9 - 55)

1

Solenoids

✕

✕

✕

✕

✕

✕

▲

[PG No.: [52] - 34]

2

Gears

✕

✕

✕

✕

✕

✕

▲

[PG No.: [52] - 4, [52] - 10, [53] - 14,

[53] - 30, [56] - 8]

[53] - 30, [56] - 8]

3

Gates

✕

✕

✕

✕

✕

✕

▲

[PG No.: [52] - 27, [52] - 57, [54] - 40,

[54] - 43]

[54] - 43]

4

Transport rollers

✕

{

{

{

{

{

▲

[PG No.: [52] - 51, [53] - 1, [56] - 3,

[56] - 4]

[56] - 4]

5

Bearings

✕

6

Optical reflection type sensors

{

{

{

{

{

{

{

7

Discharge brush

✕

✕

✕

✕

✕

✕

✕

Drive section

(9 - 64)

(9 - 64)

1

Gears (Grease)

✕

✕

✕

✕

✕

✕

✕

(UKOG-0307FCZZ)

2

Gears (Grease)

✕

✕

✕

✕

✕

✕

✕

(UKOG-0299FCZZ)

3

Belts

✕

✕

✕

✕

✕

✕

4

Gears

✕

5

Torque limiter

✕

✕

✕

✕

✕

✕

✕

(Note 1)

6

Clutches

✕

✕

✕

✕

✕

✕

✕

(Note 2)

Image related

sections

sections

1

✕

✕

✕

✕

✕

✕

✕

Unit name

(Detailed page)

No.

Part name

When

calling

500

K

1000

K

1500

K

2000

K

2500

K

3000

K

Remark

[Refer to the Parts Guide.

Block/Item No.]

(Only the replacement parts

are described.)

Unit name

(Detailed page)

No.

Part name

When

calling

500

K

100

0K

1500

K

2000

K

2500

K

3000

K

Remark

[Refer to the Parts Guide.

Block/Item No.]

(Only the replacement parts

are described.)

Scanner section

(9 - 73)

(9 - 73)

1

Lens

{

{

{

{

{

{

2

CCD

{

{

{

{

{

{

3

Mirror

{

{

{

{

{

{

4

Table glass

{

{

{

{

{

{

{

5

SPF glass

{

{

{

{

{

{

{

6

Reflector

{

{

{

{

{

{

7

Scanner lamp

{

{

{

{

{

{

8

Rail (Grease)

✩

✩

✩

✩

✩

✩

9

Drive belt

✕

✕

✕

✕

✕

✕

10

Drive wire

✕

✕

✕

✕

✕

✕

11

Sensor

✕

✕

✕

✕

✕

✕

12

Dust cover

✕

✕

✕

✕

✕

✕

MX-M1100 MAINTENANCE 9 – 6

(Note 1) Replacement reference: Use the paper feed, DSPF counters values for replacement reference.

• Paper pickup roller, paper feed roller, separation roller: 200K or 1 year

• Torque limiter: 800K

* Paper feed section roller life

• Paper pickup roller, paper feed roller, separation roller: 200K or 1 year

• Torque limiter: 800K

* Paper feed section roller life

Each roller life is 200K. When, therefore, a certain unit is used intensively, the life will be expired before the maintenance cycle.

Since, however, sheets of different sizes are used with different paper feed trays actually, it is quite rare that the roller replacement is

required before the maintenance cycle.

If a certain size of paper is intensively used, explain the user to use different paper feed trays for that size as far as possible.

When servicing, always check the use frequency of each paper feed tray, and replace the roller according to necessity.

When cleaning the roller, it is recommendable to use wet cloth.

The wear level is greater in the sequence of the separation roller, the paper feed roller, and the paper pickup roller.

Since, however, sheets of different sizes are used with different paper feed trays actually, it is quite rare that the roller replacement is

required before the maintenance cycle.

If a certain size of paper is intensively used, explain the user to use different paper feed trays for that size as far as possible.

When servicing, always check the use frequency of each paper feed tray, and replace the roller according to necessity.

When cleaning the roller, it is recommendable to use wet cloth.

The wear level is greater in the sequence of the separation roller, the paper feed roller, and the paper pickup roller.

(Note 2) The conditions of the clutches differ depending on the paper pass conditions from the paper tray. Refer to the table below for

replacement of the clutches.

replacement of the clutches.

(Note 3) Optical reflection sensor cleaning

* Optical reflection sensor which allows cleaning when opening/closing the jam cancel door: 200K

* Optical reflection sensor which allows cleaning when opening/closing the jam cancel door: 200K

DSPF

section

(9 - 77)

section

(9 - 77)

Paper

feed,

Transport

section

feed,

Transport

section

1

Paper feed roller

✕

✕

✕

✕

✕

✕

✕

(Note 1)

2

Paper pickup roller

✕

✕

✕

✕

✕

✕

✕

(Note 1)

3

Separation roller

✕

✕

✕

✕

✕

✕

✕

(Note 1)

4

No. 1 resist roller

{

{

{

{

{

{

{

5

Torque limiter

✕

✕

✕

✕

✕

✕

(Note 1)

6

Double feed detection unit

{

Ultrasonic sensor top surface

(Air cleaning)

95/110-sheet model only.

(Air cleaning)

95/110-sheet model only.

7

Transport roller 1

{

{

{

{

{

{

{

8

Transport roller 2

{

{

{

{

{

{

{

9

Second resist roller

{

{

{

{

{

{

{

10

Platen roller

{

{

{

{

{

{

{

11

Transport roller 3

{

{

{

{

{

{

{

12

Transport roller 4

{

{

{

{

{

{

{

Scanning

section

section

13

Lens

✕

{

{

{

{

{

{

14

CCD

✕

{

{

{

{

{

{

15

Mirror

✕

{

{

{

{

{

{

16

Reflector

✕

{

{

{

{

{

{

17

Scanner lamp

✕

{

{

{

{

{

{

18

Back surface scanning section

glass Upper, Lower

glass Upper, Lower

{

{

{

{

{

{

{

Paper exit

section

section

19

Transport roller 5

{

{

{

{

{

{

{

20

Paper exit roller

{

{

{

{

{

{

{

Drive

section

section

21

Gears (Grease)

✕

✕

✕

✕

✕

✕

✕

(UKOG-0299FCZZ)

22

Belts

✕

✕

✕

✕

✕

✕

Others

23

Document mat

{

{

{

{

{

{

{

24

Scanning section paper guide

(White Mylar)

(White Mylar)

{

{

{

{

{

{

{

25

Discharge brush

✕

✕

✕

✕

✕

✕

✕

26

Optical reflection type sensors

{

{

{

{

{

{

{

(Note 3)

27

Optical reflection type sensors

{

{

{

{

{

{

{

28

Paper guides

✕

{

{

{

{

{

{

UN

Tandem drive

Multi-stage drive B

Transport drive

Tandem drive

Multi-stage

drive B

Signal name

C1PFC

C1PTC

C2PFC

C3PFC

C4PFC

MPTFC

LCCPTC

VPTC3

VPTC2

VPTC1

P/N

PCLC-

0355FCZZ

PCLC-

0354FCZZ

PCLC-

0355FCZZ

PCLC-0356FCZZ

PCLC-

0355FCZZ

PCLC-

0354FCZZ

PCLC-0354FCZZ

PCLC-

0357FCZZ

No. 1 tray

3000K

3000K

No. 2 tray

3000K

Total

3000K

No. 3 tray

3000K

Total

3000K

Total

1500K

No. 4 tray

3000K

Manual paper feed

3000K

LCC paper feed

3000K

Unit name

(Detailed page)

No.

Part name

When

calling

500

K

100

0K

1500

K

2000

K

2500

K

3000

K

Remark

[Refer to the Parts Guide.

Block/Item No.]

(Only the replacement parts

are described.)

MX-M1100 MAINTENANCE 9 – 7

5. Photoconductor section

A. Maintenance table

✕: Check (Clean, replace, or adjust as necessary.) {: Clean ▲: Replace U: Adjust ✩: Lubricate : Shift the position

No.

Part name

When

calling

500

K

1000

K

1500

K

2000

K

2500

K

3000

K

Remark

[Refer to the Parts Guide. Block/Item No.]

(Only the replacement parts are described.)

1

OPC drum

✕

✕

▲

✕

▲

✕

▲

2

Cleaning blade

✕

▲

▲

▲

▲

▲

▲

[PG No.: [36] - 35]

When replacing, apply stearic acid. (UKOG-0312FCZZ)

When replacing, apply stearic acid. (UKOG-0312FCZZ)

3

Sub blade

✕

▲

▲

▲

▲

▲

▲

[PG No.: [36] - 54]

4

Side seal F, R

✕

▲

▲

▲

▲

▲

▲

[PG No.: [36] - 20, [36] - 66]

5

Drum separation pawl

✕

▲

▲

▲

▲

▲

▲

When replacing, shift the separation pawl mounting

position.

[PG No.: [37] - 2]

position.

[PG No.: [37] - 2]

6

Discharge lamp

✕

{

{

{

{

{

{

7

Procon sensor

✕

{

{

{

{

{

{

8

Surface potential sensor

✕

{

{

{

{

{

{

Hold the sensor so that no foreign material enters the

port of the sensor. Wipe it with waste cloth. Use alcohol if

it is dirtied with oil.

port of the sensor. Wipe it with waste cloth. Use alcohol if

it is dirtied with oil.

9

Cleaning brush roller

✕

{

{

{

{

{

▲

[PG No.: [36] - 61]

10

Charger wire

{

▲

▲

▲

▲

▲

▲

[PG No.: [38] - 25]

11

Screen grid

✕

▲

▲

▲

▲

▲

▲

[PG No.: [38] - 26]

12

Charger cleaner

▲

▲

▲

▲

▲

▲

[PG No.: [38] - 6]

13

Charger cushion

▲

▲

▲

▲

▲

▲

[PG No.: [38] - 6]

14

Duct sheet

▲

▲

▲

▲

▲

▲

[PG No.: [74] - 61]

15

Blade side seal F, R

✕

✕

✕

✕

✕

✕

▲

[PG No.: [36] - 24, [36] - 58]

16

Cleaning brush bearing

✕

17

Cleaning brush drive bearing

✕

18

Separation pawl oscillation bearing

✕

19

Auxiliary cleaning brush bearing

✕

20

Bearing

✕

21

Separation pawl oscillation arm

✕

22

Separation pawl oscillation shaft

✕

23

Ball bearings

✕

24

Gears

✕

25

Cleaner base guide

▲

▲

▲

▲

▲

▲

[PG No.: [38] - 3]

26

Sub blade seal F, R

✕

✕

✕

✕

✕

✕

27

Main charger case

{

{

{

{

{

▲

[PG No.: [38] - 9]

1

5

5

5

5

6

8

19

9

16

20

11

27

2

15

15

21

19

17

24

23

4

26

10

13

7

3

18

22

12

25

13

26

4

14

MX-M1100 MAINTENANCE 9 – 8

B. Details

1)

Open the front cover (a), and pull out the toner tray (b) a little.

2)

Remove the screw (a), and remove the cover (b).

3)

Remove the blue screw (a), and remove the plate (b).

4)

Slide the developing unit (a) to the right, and pull it out until the

grip (b) can be held.

grip (b) can be held.

5)

Hold the handle (a) of the developing unit, and lift it up to

remove completely.

* When placing the developing unit, use the stand (b) and

remove completely.

* When placing the developing unit, use the stand (b) and

place the unit on it.

6)

Disconnect the connector (a) and the blue screw (b), and pull

out the Main charger unit (c).

out the Main charger unit (c).

a

b

a

a

b

a

a

a

b

a

b

b

a

b

c

a

Click on the first or last page to see other MX-M950 / MX-MM1100 (serv.man40) service manuals if exist.