Sharp AR-M550 (serv.man14) Service Manual ▷ View online

AR-M550/M620 SETTING AND ADJUSTMENTS 7 - 4

4) Select the number that corresponds to the adjustment item using

the numeric keypad.

5) Press the Start key.

6) Press the start key to have the voltage output for 30 seconds.

The operation can be stopped with the CUSTOM SETTINGS key.

If the output voltage is not within the requirement, do the following

steps.

steps.

7) Enter the adjustment value using the numeric keypad.

8) Press the Start key

(The adjustment value is put into memory, and the corresponding

voltage is output for 30 seconds.)

voltage is output for 30 seconds.)

Repeat steps 7 to 8 until the output requirement is satisfied.

(Transfer voltage adjustment)

Transfer voltage adjustment (print operation mode)

This adjustment is needed in the following situations:

• The high voltage power PWB (MC/DV/TC) has been replaced.

• U2 trouble has occurred.

• The PCU PWB has been replaced.

• The EEPROM of the PCU PWB has been replaced.

1) Go through the modes specified in Simulation 8-6.

2) Select the number that corresponds to the adjustment item

(FRONT/BACK) using the numeric keypad.

3) Press the Start key

4) Enter the adjustment value (default) using the numeric keypad.

5) Press the Start key

(The adjustment value is put into memory, and the corresponding

voltage is output for 30 seconds.)

voltage is output for 30 seconds.)

The operation can be stopped with the CUSTOM SETTINGS key.

Note: It is not possible to determine the adjusted transfer voltage

(print operation mode) (FRONT/BACK). If the voltage seems to

be abnormal after setting the default value, therefore, the high

voltage PWB (MC/DV/TC) should be replaced.

be abnormal after setting the default value, therefore, the high

voltage PWB (MC/DV/TC) should be replaced.

Transfer voltage adjustment (transfer belt cleaning mode)

This adjustment is needed in the following situations:

• The high voltage power PWB (MC/DV/TC) has been replaced.

• U2 trouble has occurred.

• The PCU PWB has been replaced.

• The EEPROM of the PCU PWB has been replaced.

1) Remove the rear cover of the machine.

2) Apply a digital multi-meter to the connector CN2 pin (1) of the high

voltage PWB and the chassis GND.

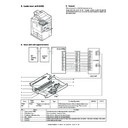

ADJ 1C

Adjust the transfer voltage

Item/operation

mode

Simulation

Adjustment voltage

(monitor voltage)

Connector

Pin #

Actual voltage/actual

current

Setting range

Default

Front print

8-6

FRONT

0 – 800

350

–

–

–

2.0 – 2.5Kv (35±1.0

µ

A)

High voltage

power PWB

(MC/DV/TC)

power PWB

(MC/DV/TC)

Back print

BACK

0 – 800

350

–

–

–

2.0 – 2.5Kv (35±1.0

µ

A)

Transfer belt

(cleaning)

(cleaning)

8-17

SHF FRONT

0 – 600

450

–

–

–

AC4.5Kv (p-p)

SHF BACK

0 – 600

450

–

–

–

AC4.5Kv (p-p)

THV-

0 – 75

10

DC -100±10v

CN2

1

DC -300±10v /

AC4.5Kv (p-p)

Transfer roller

(cleaning)

(cleaning)

8-18

CRHV PLUS

0 – 250

200

+2.0±0.1v

–

Check pin +2000±100v

High voltage

power PWB

(TC cleaning)

power PWB

(TC cleaning)

Transfer roller

(print)

(print)

CRHV MINUS

0 – 250

200

–2.0±0.1v

–

Check pin –2000±100v

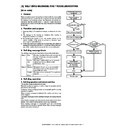

Press [START] key.

Press [CUSTOM SETTINGS] key.

Press [START] key.

Press [CUSTOM SETTINGS] key.

Or after 30sec output.

Or after 30sec output.

SIMULATION 8-6

1

THV+ SETTING. SELECT 1-2, AND PRESS START.

1.FRONT

350

2.BACK

350

SIMULATION 8-6

THV+ SETTING. INPUT VALUE, AND PRESS START.

1.FRONT(0-800)

350

SIMULATION 8-6

THV+ SETTING. EXECUTING···.

1.FRONT

350

CN2

1

AR-M550/M620 SETTING AND ADJUSTMENTS 7 - 5

3) Go through the modes specified in Simulation 8-17.

4) Select the number that corresponds to the adjustment item (SHF

FRONT / SHF BACK) using the numeric keypad.

5) Press the Start key.

6) Set each adjustment item to the default value (enter the adjust-

ment value and then press the Start key).

Note: The adjustment items (SHF FRONT / SHF BACK) correspond

to the AC component of the 'transfer belt cleaning mode voltage'

applied to the transfer roller, but this voltage component cannot

be determined. If the voltage seems to be abnormal after setting

the default adjustment value, therefore, the high voltage PWB

(MC/DV/TC) should be replaced.

applied to the transfer roller, but this voltage component cannot

be determined. If the voltage seems to be abnormal after setting

the default adjustment value, therefore, the high voltage PWB

(MC/DV/TC) should be replaced.

7) Select the number that corresponds to cleaning operation mode

(THV-) using the numeric keypad.

Note: The adjustment items (THV-) corresponds to the DC component

of the 'transfer belt cleaning mode voltage' applied to the trans-

fer roller.

fer roller.

8) Press the Start key.

9) Press the Start key to have the voltage output for 30 seconds.

If the output voltage is not within the requirement, do the following

steps.

steps.

The operation can be stopped with the CUSTOM SETTINGS key.

10) Enter the adjustment value using the numeric keypad.

11) Press the Start key.

(The adjustment value is put into memory, and the corresponding

voltage is output for 30 seconds.)

voltage is output for 30 seconds.)

Repeat steps 10 to 11 until the output requirement is satisfied.

Transfer voltage adjustment (transfer roller cleaning/

transfer roller print modes)

transfer roller print modes)

This adjustment is needed in the following situations:

• The high voltage power PWB (TC cleaning) has been replaced.

• U2 trouble has occurred.

• The PCU PWB has been replaced.

• The EEPROM of the PCU PWB has been replaced.

1) Connect the transfer section to the main body side using the trans-

fer extension harness (DHAi-3629FCZZ).

2) Remove the front frame cover of the duplex section, and remove

the rear frame cover of the transfer section.

3) Apply a digital multi-meter to the check pin of the high voltage

PWB (TC cleaning) and the chassis GND.

Press [START] key.

Press [CUSTOM SETTINGS] key.

Press [START] key.

Press [CUSTOM SETTINGS] key.

Or after 30sec output.

Or after 30sec output.

SIMULATION 8-17

1

TRANSFER ROLLER SETTING. SELECT 1-3, AND PRESS START.

1.SHV FRONT

450

2.SHV BACK

450

3.THV-

30

SIMULATION 8-17

TRANSFER ROLLER SETTING. INPUT VALUE, AND PRESS START.

1.FRONT (0-600)

450

SIMULATION 8-17

TRANSFER ROLLER SETTING. EXECUTING···.

1.FRONT(0-600)

450

AR-M550/M620 SETTING AND ADJUSTMENTS 7 - 6

4) Go through the modes specified in Simulation 8-18.

5) Select the number that corresponds to the adjustment item (CRHV

PLUS / CRHV MINUS) using the numeric keypad.

6) Press the Start key

7) Press the Start key to have the voltage output for 30 seconds.

The operation can be stopped with the CUSTOM SETTINGS key.

If the output voltage is not within the requirement, do the following

steps.

steps.

8) Enter the adjustment value using the numeric keypad.

9) Press the Start key.

(The adjustment value is put into memory, and the corresponding

voltage is output for 30 seconds.)

voltage is output for 30 seconds.)

Repeat steps 8 to 9 until the output requirement is satisfied.

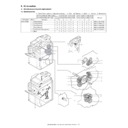

This adjustment is needed in the following situations:

• The developing unit has been disassembled.

• The print density is low.

• The toner is excessively dispersed.

1) Remove the developing unit of the machine.

2) Remove the developing unit cover and blade cover.

3) Loosen the DV doctor fixing screws.

4) Manually turn the DV roller to align the marking on the DV roller

surface with the DV doctor position.

5) Insert a 0.525mm clearance gauge in between the DV roller and

DV doctor so that the gauge is positioned at a distance of 40 mm to

70 mm from the DV doctor end face.

70 mm from the DV doctor end face.

6) Tighten the DV doctor fixing screws while pressing the DV doctor

in the arrow direction.

(This should be done for both front and rear frames.)

(This should be done for both front and rear frames.)

Press [START] key.

Press [CUSTOM SETTINGS] key.

Press [START] key.

Press [CUSTOM SETTINGS] key.

Or after 30sec output.

Or after 30sec output.

ADJ 2

Adjusting the developing unit

ADJ 2A

Adjust the developing doctor gap

SIMULATION 8-18

1

TRANSFER CLEANING ROLLER SETTING. SELECT 1-2, AND

PRESS START.

1.CRHV PLUS

50

2.CRHV MINUS

50

SIMULATION 8-18

TRANSFER CLEANING ROLLER SETTING. INPUT VALUE, AND

PRESS START.

1.CRHV PLUS (0-250)

200

SIMULATION 8-18

TRANSFER CLEANING ROLLER SETTING. EXECUTING···.

1.CRHV PLUS(0-250)

200

AR-M550/M620 SETTING AND ADJUSTMENTS 7 - 7

7) On both sides of the DV doctor and at its center, make sure that

the DV doctor gap is 0.525 ±0.03.

Note: When inserting a clearance gauge, take care not to damage the

DV doctor or MG roller.

Repeat steps 2 to 6 until the DV doctor gap meets the requirement.

This adjustment is needed in the following situations:

• The developing unit has been disassembled.

• The print density is low.

• The toner is excessively dispersed.

1) Remove the dveloping unit

.

2) Remove the developing unit cover and blade cover, and then place

the developing unit on a level surface.

3) Attach a piece of string to a sewing needle or pin.

4) With the string in hand, bring the needle closer to the DV roller

while keeping the needle parallel with the roller. (Do not use a clip,

which does not accurately indicate the position.)

which does not accurately indicate the position.)

5) Keeping the needle 2 to 3 mm off the DV roller surface, mark the

DV roller surface at an extension of the needle tip. (Do not let the

needle tip contact the DV roller.)

needle tip contact the DV roller.)

6) Measure the distance between the marking on the DV roller and

leading edge of the DV doctor, and make sure that it is 19±0.5mm.

If this requirement is not met, do the following steps.

7) Remove the front cover.

8) Loosen the fixing screws of the developing roller main pole adjust-

ing plate, and make adjustments by moving the adjusting plate in

the arrow direction.

the arrow direction.

Repeat steps 3 to 6 until the developing roller main pole meets the

positional requirement.

positional requirement.

This adjustment is needed in the following situations:

• The LSU has been replaced or removed.

• Print images are distorted.

This adjustment should be followed by:

"ADJ 7 / ADJ A: Adjust the print image off-center (print engine section)"

1) Set A4 (11 x 8.5) paper to Tray 1.

2) Set A3 (11 x 17) paper to Tray 1.

3) Go through the modes specified in Simulation 64-1.

ADJ 2B

Adjust the developing roller main pole

ADJ 3

Adjusting image distortions

ADJ 3A

Adjust print image distortions (LSU

parallelism adjustment)

parallelism adjustment)

19 0.5 mm