Sharp AR-M550 (serv.man14) Service Manual ▷ View online

AR-M550/M620 SETTING AND ADJUSTMENTS 7 - 41

2) Open the manual paper feed guide to the maximum width position.

3) Select MAX. POSITION using the numeric keypad.

4) Press the Start key.

The maximum width detection level is recognized.

5) Press the CUSTOM SETTINGS key.

6) Set the manual paper feed guide to the width for the A4R size.

7) Select POSITION 1 using the numeric keypad.

8) Press the Start key

The A4R width detection level is recognized.

9) Press the CUSTOM SETTINGS key.

10) Set the manual paper feed guide to the width for the A5R size.

11) Select POSITION 2 using the numeric keypad.

12) Press the Start key.

The A5R width detection level is recognized.

13) Press the CUSTOM SETTINGS key.

14) Open the manual paper feed guide to the minimum width position.

15) Select MIN. POSITION using the numeric keypad.

16) Press the Start key

The minimum width detection level is recognized.

Note: When each of the above operations has been completed, the

"COMPLETE" message appears; when any of the operations

has failed, the "ERROR" message appears.

has failed, the "ERROR" message appears.

This adjustment is needed in the following situations:

• The paper feed tray section has been disassembled.

• The paper feed tray unit has been replaced.

• U2 trouble has occurred.

• The PCU PWB has been replaced.

• The EEPROM on the PCU PWB has been replaced.

1) Go through the modes specified in Simulation 40-12.

2) Open the paper feed guide to the maximum width position.

3) Select MAX. POSITION using the numeric keypad.

4) Press the Start key.

The maximum width detection level is recognized.

5) Press the CUSTOM SETTINGS key.

6) Open the paper feed guide to the minimum width position.

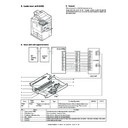

5

11

1

2

A5

A4

B4 B5

A3

A4

B5

7

1

2

8

1

2

ADJ 14B

Adjust the paper width sensor for paper

feed tray 3

feed tray 3

Select 2 and press [START] key.

Press [CUSTOM SETTINGS] key.

SIMULATION 40-12

TRAY3 ADJUSTMENT. SELECT 1-2, AND PRESS START.

1. MAX. POSITION

2. MIN. POSITION

1

SIMULATION 40-12

TRAY3 ADJUSTMENT.

MAX. POSITION ··· COMPLETE (or "ERROR")

Press [CUSTOM SETTINGS] key.

Select 1 and press [START] key.

SIMULATION 40-12

TRAY3 ADJUSTMENT.

MIN. POSITION ··· COMPLETE (or "ERROR")

AR-M550/M620 SETTING AND ADJUSTMENTS 7 - 42

7) Select MIN. POSITION using the numeric keypad.

8) Press the Start key.

The minimum width detection level is recognized.

Note: When each of the above operations has been completed, the

"COMPLETE" message appears; when any of the operations

has failed, the "ERROR" message appears.

has failed, the "ERROR" message appears.

This adjustment is needed in the following situations:

• The paper feed tray section has been disassembled.

• The paper feed tray unit has been replaced.

• U2 trouble has occurred.

• The scanner PWB has been replaced.

• The EEPROM on the scanner PWB has been replaced.

1) Go through the modes specified in Simulation 53-6.

2) Open the SPF paper feed guide to the maximum width position.

3) Select MAX. POSITION using the numeric keypad.

4) Press the Start key.

The maximum width detection level is recognized.

5) Press the CUSTOM SETTINGS key.

6) Open the SPF paper feed guide to the width for the A4R size.

7) Select POSITION 1 using the numeric keypad.

8) Press the Start key

The A4R width detection level is recognized.

9) Press the CUSTOM SETTINGS key.

10) Open the SPF paper feed guide to the width for the A5R size.

11) Select POSITION 2 using the numeric keypad.

12) Press the Start key.

The A5R width detection level is recognized.

13) Press the CUSTOM SETTINGS key.

14) Open the SPF paper feed guide to the minimum width position.

15) Select MIN. POSITION using the numeric keypad.

16) Press the Start key

The minimum width detection level is recognized.

Note: When each of the above operations has been completed, the

"COMPLETE" message appears; when any of the operations

has failed, the "ERROR" message appears.

has failed, the "ERROR" message appears.

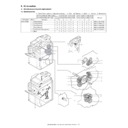

ADJ 14C

Adjust the paper width sensor for the

SPF paper feed tray

SPF paper feed tray

Select 4, and press [START] key.

Press [CUSTOM SETTINGS]

key.

key.

1

Select 2, and press [START] key.

Select 3, and press [START] key.

Press [CUSTOM SETTINGS] key.

Press [CUSTOM SETTINGS] key.

Press [CUSTOM SETTINGS] key.

SIMULATION 53-6

SPF TRAY ADJUSTMENT. SELECT 1-4, AND PRESS START.

1.MAX.POSITION

2.POSITION 1

3.POSITION 2

4.MIN.POSITION

SIMULATION 53-6

SPF TRAY ADJUSTMENT.

MAX.POSITION ... COMPLETE (or “ERROR”)

SIMULATION 53-6

SPF TRAY ADJUSTMENT.

POSITION 1 ... COMPLETE (or “ERROR”)

SIMULATION 53-6

SPF TRAY ADJUSTMENT.

POSITION 2 ... COMPLETE (or “ERROR”)

Select 1, and

press [START] key.

press [START] key.

SIMULATION 53-6

SPF TRAY ADJUSTMENT.

MIN.POSITION ... COMPLETE (or “ERROR”)

AR-M550/M620 SETTING AND ADJUSTMENTS 7 - 43

This adjustment is needed in the following situations:

• The original size sensor section has been disassembled.

• The original size sensor section has been replaced.

• U2 trouble has occurred.

• The scanner control PWB has been replaced.

• The EEPROM on the scanner control PWB has been replaced.

1) Go through the modes specified in Simulation 41-1.

2) Gradually turn over the original detection arm unit in the arrow

direction, and loosen the original cover switch actuator adjusting

screw so that the OCSW indicator changes from inverse video to

normal video when the arm unit top reaches a height of 32±0.5mm

from the table glass. Then move the actuator to adjust its position.

(If the original cover switch turns on in improper timing, the original

detection mechanism mail fail to operate correctly.)

screw so that the OCSW indicator changes from inverse video to

normal video when the arm unit top reaches a height of 32±0.5mm

from the table glass. Then move the actuator to adjust its position.

(If the original cover switch turns on in improper timing, the original

detection mechanism mail fail to operate correctly.)

1) Go through the modes specified in Simulation 41-2.

2) Open the original cover. With nothing placed on the original table,

select NO ORIGINAL using the numeric keypad.

3) Press the Start key

This sets the sensor level with no original detected.

4) Set A3 (11" x 17") paper on the original table, and select A3 ORIG-

INAL using the numeric keypad.

5) Press the Start key

This sets the sensor level with an original detected.

When each of the above operations has been completed, the "COM-

PLETE" message appears; when any of the operations has failed, the

"ERROR" message appears.

PLETE" message appears; when any of the operations has failed, the

"ERROR" message appears.

This adjustment is needed in the following situations:

• The operation panel has been replaced.

• U2 trouble has occurred.

• The MFP control PWB has been replaced.

• The EEPROM on the MFP control PWB has been replaced.

1) Go through the modes specified in Simulation 65-1.

2) Press the four cross mark points.

Pressing the cross mark points correctly results in gray display. When

the touch panel adjustment is complete with the four points pressed,

the sub-number entry screen for simulation reappears.

the touch panel adjustment is complete with the four points pressed,

the sub-number entry screen for simulation reappears.

If any error is detected, the touch panel returns to adjustment mode.

Note: Never use something with a sharp tip (such as a needle or pin)

to press the touch panel.

ADJ 15

Adjusting the original size

detection (in original table mode)

detection (in original table mode)

ADJ 15A

Adjust the detection point of the original

size sensor (in original table mode)

size sensor (in original table mode)

SIMULATION 41-1

PD SENSOR CHECK..

OCSW

PD1

PD2

PD3

PD4 PD5 PD6 PD7

32 5mm

+

-

Original detection

arm unit

arm unit

Table glass

Original cover switch actuator

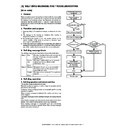

ADJ 15B

Adjust the sensitivity of the original size

sensor

sensor

Select 2 and press [START] key.

(Error)

(Error)

Press [CUSTOM SETTINGS]

key.

key.

ADJ 16

Adjusting the touch panel

coordinates

coordinates

SIMULATION 41-2

PD SENSOR ADJUSTMENT. SELECT1-2, AND PRESS START.

(PLEASE OPEN THE ORIGINAL COVER.)

1. NO ORIGINAL

2. A3 ORIGINAL

1

SIMULATION 41-2

Press [CUSTOM SETTINGS] key.

Select 1 and

press [START] key.

press [START] key.

PD SENSOR ADJUSTMENT.

NO ORIGINAL ··· COMPLETE (or "ERROR at

PD1 PD2

...")

A3 ORIGINAL ··· INCOMPLETE

SIMULATION 41-2

PD SENSOR ADJUSTMENT.

NO ORIGINAL ··· COMPLETE

A3 ORIGINAL ··· COMPLETE (or "ERROR at

PD1 PD2

...")

SIMULATION 65-1

AR-M550/M620 SETTING AND ADJUSTMENTS 7 - 44

This adjustment is needed in the following situations:

• One or more parts of the DC main power supply unit have been

replaced.

• One or more parts of the DC sub power supply unit have been

replaced.

(24 V supply voltage adjustment)

1) Apply a digital multi-meter to the DC main PWB 24 V line (CN3, 1

pin) and GND (CN3, 4 pin).

2) Turn RV202 on the DC main power supply PWB so that the volt-

age is 24 V.

(38 V supply voltage adjustment)

3) Apply a digital multi-meter to the DC main PWB 38 V line (CN8, 1

pin) and GND (CN8, 4 pin).

4) Turn RV201 on the DC main power supply PWB so that the volt-

age is 38 V.

(12 V supply voltage adjustment)

5) Apply a digital multi-meter to the DC sub PWB 12 V line (CN4, 1

pin) and GND (CN4, 6 pin).

6) Turn RV102 on the DC sub power supply PWB so that the voltage

is 12 V.

ADJ 17

Adjusting the supply voltage

RV202

(CN3, 4pin) (CN3, 1pin)

GND

+24V

RV201

(CN8, 4pin) (CN8, 1pin)

GND

+38V

RV102

(CN4, 6pin) (CN4, 1pin)

GND

+12V