Panasonic KV-S2087 (serv.man2) Service Manual ▷ View online

77

11 Troubleshooting

11.1. Troubleshooting-1 (when no error message is displayed on PC)

Symptom

Possible Cause

Check Point

Remarks

LED does not light

up.

up.

1. Power cord is not inserted correctly

Insert the power cord correctly.

2. Cables in the scanner are not connected

properly. (especially around Power Supply)

Insert the cables properly.

3. Power circuit (including a safety circuit) does

not work, properly.

1.Check the power supply.

(1) CN3-1pin:+12V

(2) CN3-4, 6, 7pin:+24V

(2) CN3-4, 6, 7pin:+24V

2.Check the connection between the Main Board

and Power Supply.

3.Replace Power Supply.

4. FAN does not rotate.

1.Try to rotate the FAN, manually.

2.Check the power supply to the FAN.

2.Check the power supply to the FAN.

(1) CN14-1pin:+24V

3.Replace the FAN.

5. PANEL Board does not work properly.

1. Check the following connection.

(1) between CN5001(Panel SW Board) and

CN11 (Main Board)

2. Monitor the following signals on the CN5001.

(1) CN5001 pin12 : 0V during Power SW ON

(2) IC5001-5pin:+3.3V

(2) IC5001-5pin:+3.3V

3. Check the soldering condition of the following

parts on the PANEL Board.

(1) CN5001

(2) IC5000

(1) CN5001

(2) IC5000

4. Replace faulty parts or PANEL Board.

6. DC ON/OFF circuit on Main Board does not

work correctly.

1. Monitor the following signals on Main Board.

(1) Q31-C Typ. 10 V (when turning on the power)

(2) Q32-B Typ. 0.6 V

(when turning on the power)

(3) C838 of IC59 Typ. 3.3 V

(2) Q32-B Typ. 0.6 V

(when turning on the power)

(3) C838 of IC59 Typ. 3.3 V

(when turning on the power)

2.Check the soldering condition of the following

parts and of their surrounding circuits on the

Main Board.

Main Board.

Q31,Q32,IC59

3. Replace faulty parts on Main Board.

7. Main Board does not work properly.

1. Check whether all connections (all connectors on

the Main Board and cables to the Main Board)

are normal.

are normal.

2. Check the soldering condition of the following

parts and of their surrounding circuits on the

Main Board.

(1) 3.3VCPU Typ. 3.3V (IC59)

(2) 1.2VCPU Typ. 1.2V (IC62)

(3) 3.3VSLP Typ. 3.3V (IC58)

(4) IC5 (CPU)

(5) IC1 (Reset IC)

Main Board.

(1) 3.3VCPU Typ. 3.3V (IC59)

(2) 1.2VCPU Typ. 1.2V (IC62)

(3) 3.3VSLP Typ. 3.3V (IC58)

(4) IC5 (CPU)

(5) IC1 (Reset IC)

3.Check the soldering condition of the following

parts on the Main Board.

(1) CN11

(1) CN11

4. Monitor the following signals on CN11.

(1) CN11-1pin:+12V typ.

5. Replace faulty parts or Main Board.

Scanne

r does not

recognize USB connection.

1. USB cable is not connected normally.

1.Check the device (USB) condition of PC with

Device Manager.

2.Re-attach the USB cable, and then restart the

scanner and PC.

3.Replace the USB cable

4.Check if the USB connector (JK1) has any

4.Check if the USB connector (JK1) has any

damage.

2. USB interface circuit does not work.

1. Check the soldering condition of the following

parts and of their surrounding circuits on the

MAIN Board, and then repair it.

(1) JK1 (USB IF connector)

(2) LF1, LF3 (Common mode filter)

(3) IC42 (Common mode filter)

MAIN Board, and then repair it.

(1) JK1 (USB IF connector)

(2) LF1, LF3 (Common mode filter)

(3) IC42 (Common mode filter)

2. Replace the MAIN Board.

78

START/STOP Button, Skip

Button, or Cursor Button

don't work properly.

Button, or Cursor Button

don't work properly.

1. Mechanical problem with ON/OFF switch.

1. Perform the “Key/Sensor” test in the

Sec.10.3.7. to check the button's ON/OFF status.

2. Check the contact between the button cover and

switch

(RM5000 [Start/Stop] on PANEL SW Board)

(RM5001 [Skip] on PANEL SW Board)

(RM5002 [Up] on PANEL SW Board)

(RM5003 [Down] on PANEL SW Board)

(RM5004 [Left] on PANEL SW Board)

(RM5005 [Right] on PANEL SW Board)

(RM5006 [

(RM5000 [Start/Stop] on PANEL SW Board)

(RM5001 [Skip] on PANEL SW Board)

(RM5002 [Up] on PANEL SW Board)

(RM5003 [Down] on PANEL SW Board)

(RM5004 [Left] on PANEL SW Board)

(RM5005 [Right] on PANEL SW Board)

(RM5006 [

OK] on PANEL SW Board)

3.Check the button's ON/OFF mechanical condi-

tion.

4. Re-attach the button cover after checking

whether it is broken.

5. Replace faulty parts.

2. ON/OFF monitor circuit does not function.

1. Check the soldering condition of the following

parts and of their surrounding circuits on the

PANEL SW Board.

(1) RM5000,R5006

(2) RM5001,R5007

(3) RM5002,R5008

(4) RM5003,R5009

(5) RM5004,R5010

(6) RM5005,R5011

(7) RM5006,R5012

PANEL SW Board.

(1) RM5000,R5006

(2) RM5001,R5007

(3) RM5002,R5008

(4) RM5003,R5009

(5) RM5004,R5010

(6) RM5005,R5011

(7) RM5006,R5012

2. Check the following connection.

(1) Between CN5001 ( PANEL SW Board) and

CN11 (Main Board)

(2) FFC Cable

(3) Between CN5000 ( PANEL SW Board) and

CN5002 (PANEL LCD Board)

CN11 (Main Board)

(2) FFC Cable

(3) Between CN5000 ( PANEL SW Board) and

CN5002 (PANEL LCD Board)

3.Check the soldering condition of the following

parts and their surrounding circuits on the Main

Board.

(1) CN11

Board.

(1) CN11

4. Check the following signals on the PANEL

Board.

(1) IC5000

(1) IC5000

5. Replace faulty parts or boards.

Scanning position is

shifted.

shifted.

1. After replacing or re-assembling the CIS

assembly and/or mechanical parts related to

conveying documents, re-adjustment of

scanning position has not been done.

conveying documents, re-adjustment of

scanning position has not been done.

1. Perform the “All Position” and/or “Individual

Position” in the Sec. 10.3.8. so that the scan-

ning position can be adjusted properly.

ning position can be adjusted properly.

2. The CIS assembly is not installed properly.

1. Re-assemble the CIS Assembly. (See Disassem-

bly and Assembly Instructions (P.39 and P.47)

The document skews when

scanned

scanned

1. Document Guides are not set properly

according to the size of documents on the

Feed Tray.

Feed Tray.

1.Slide and set the Document Guides according to

the document size.

2. ADF Door is not closed tightly.

1.Close the door until it clicks into place, after open-

ing it.

3. Rollers are dirty.

1. Clean the rollers with the roller cleaning paper.

2. After cleaning the Paper Feed Roller and DFP

2. After cleaning the Paper Feed Roller and DFP

Roller, perform the “Clear Counter (After Clean

Roller)” in the Sec.10.3.6. to clear the cleaning

roller counter.

Roller)” in the Sec.10.3.6. to clear the cleaning

roller counter.

4. Rollers are not properly installed into their

default positions when re-assembling.

1. Check the roller attachments to the scanner

(whether a gap between roller and conveyor is

secured equally)

secured equally)

2. Re-attach the rollers to their default positions.

5. Rollers have reached their life expectancy.

1. After checking the configuration, replace the roll-

ers

2. After replacing the Paper Feed Roller and Dou-

ble-feed Prevention Roller, perform the “Clear

Counter (After Replace Roller)” in the

Sec.10.3.6. to clear the roller replacement coun-

ter.

Counter (After Replace Roller)” in the

Sec.10.3.6. to clear the roller replacement coun-

ter.

Symptom

Possible Cause

Check Point

Remarks

79

Scanned image data have

black lines, white lines, or

darker image than the orig-

inal

black lines, white lines, or

darker image than the orig-

inal

1. The dust exists on the Scanning Glass ((F)

or (B)) or its surrounding (Reference area or

others).

others).

1.Wipe off the dust with soft and dry cloth.

2.Perform the "Focus" in the Sec. 10.3.7. to

2.Perform the "Focus" in the Sec. 10.3.7. to

monitor the CIS's output level.

2. Shading data stored in Main board is not

proper to perform an image process.

1. Perform the "Shading" in the Sec.10.3.8. to

over-write new data.

3. Problem with Pixel data from CIS (F) or from

image processing circuit.

1.Check the connection and soldering condition of

the following parts.

(1) between CIS (F) and CN2100

(CIS Relay Board)

(2) between CN2101(CIS Relay Board) and CN4

(Main Board)

(1) between CIS (F) and CN2100

(CIS Relay Board)

(2) between CN2101(CIS Relay Board) and CN4

(Main Board)

2. Check the soldering condition of the following

parts and their surrounding circuits on the Main

Board.

(1) IC16 (AFE)

(2) R138, R139, R140, R141, R142, R143

Board.

(1) IC16 (AFE)

(2) R138, R139, R140, R141, R142, R143

3. Monitor the following CIS Timing signals on the

CN4.

(1) FCLK: 10MHz

(2) FSP:52.8

(1) FCLK: 10MHz

(2) FSP:52.8

s period (300dpi)

96.6

s period (600dpi)

4. Replace faulty parts or boards.

4. Problem with Pixel data from CIS (B) or from

the image processing circuit.

1.Check the connection and soldering condition of

the following parts.

(1) between CIS (B) and CN6 (Main Board)

(1) between CIS (B) and CN6 (Main Board)

2. Check the soldering condition of the following

parts and their surrounding circuits on the Main

Board.

(1) IC22 (AFE)

(2) R314, R315, R316, R317, R318, R319

Board.

(1) IC22 (AFE)

(2) R314, R315, R316, R317, R318, R319

3. Monitor the following CIS Timing signals on the

CN6.

(1) FCLK: 10MHz

(2) FSP:52.8

(1) FCLK: 10MHz

(2) FSP:52.8

s period (300dpi)

96.6

s period (600dpi)

4. Replace faulty parts or boards.

Noise

1. Problem with the Paper Feed Motor

1. Perform the "Feed Motor" test in the Sec.

10.3.7.to check the sound.

2. Replace faulty parts.

2. Problem with the Conveyor Motor

1. Perform the "Conveyor Motor" test in the Sec.

10.3.7. to check the sound.

2. Replace faulty parts.

3. Problem with the Exit Motor

1. Perform the "Exit Motor" test in the Sec. 10.3.7.

to check the sound.

2. Replace faulty parts.

4. Problem with the Platen Motor

1. Perform the "Platen Motor" test in the Sec.

10.3.7. to check the sound.

2. Replace faulty parts.

Symptom

Possible Cause

Check Point

Remarks

80

11.2. Troubleshooting-2 (with an error message on PC)

Error Code

ST1 ST2 ST3 ST4

Possible Cause

Check Point

Remarks

U1X(Paper Jam)

Hold the document before opening the ADF Door when a paper jam error occurred,

to get the stop position of the document.

to get the stop position of the document.

U11(Paper feed jam:

Paper did not reach the

Waiting Sensor)

Paper did not reach the

Waiting Sensor)

11

00

00

00 1. Paper Feed Roller module or

DFP Roller is not assembled

properly.

properly.

1. Reassemble the rollers.

2. Check the paper feed mechanism from the

Paper Feed Motor's gear to Paper Feed

Roller's gear.

2. Check the paper feed mechanism from the

Paper Feed Motor's gear to Paper Feed

Roller's gear.

2. Rollers (Paper Feed,

Separation, DFP) are dirty.

1. Clean the rollers in the Sec.9.2.

2. Clear counter for cleaning roller to zero with

the service utility's operation in the Sec.

2. Clear counter for cleaning roller to zero with

the service utility's operation in the Sec.

10.3.6.

3. Rollers have reached their life

expectancy.

1. Replace the Paper Feed, Separation, and

DFP Rollers after checking each roller

configuration and Scanner Counter of

Service Utility software.

2. Clear counter for replacing roller to zero with

the above service utility.

DFP Rollers after checking each roller

configuration and Scanner Counter of

Service Utility software.

2. Clear counter for replacing roller to zero with

the above service utility.

4. Paper dust exists on or around

the Waiting Sensor.

1. Clean up the dirt with cleaning paper or

cotton swab or soft and dry cloth in the Sec.

9.2.

9.2.

2. Execute Key / Sensor and Sensor

Sensitive Level tests in the Sec. 10.3.7. to

check the sensor condition.

check the sensor condition.

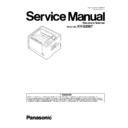

Paper Feed

Roller

Roller

Drive Roller 3

Drive

Roller 2

Roller 2

Conveyor Motor

Paper

Sensor

Sensor

Drive Roller 1

Starting

Sensor

Sensor

Paper Feed

Motor

Motor

Exit Roller

Exit Motor

U-Turn Path

Waiting

Sensor

Sensor

CIS [B]

CIS [F]

Double Feed

Detector[G]

Detector[G]

Gate

DFP Roller

Separation

Roller

Roller

Straight Path

Jam Sensor

Ending Sensor

U11

U12

U13

U14

U16

U16

Click on the first or last page to see other KV-S2087 (serv.man2) service manuals if exist.