Sony DCR-TRV130 / DCR-TRV130E / DCR-TRV230 / DCR-TRV230E / DCR-TRV235E / DCR-TRV325E / DCR-TRV330 / DCR-TRV330E / DCR-TRV430E / DCR-TRV530 / DCR-TRV530E / DCR-TRV725E / DCR-TRV730 / DCR-TRV730E / DCR-TRV828 / DCR-TRV828E / DCR-TRV830 / DCR-TRV830E Service Manual ▷ View online

— 29 —

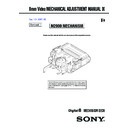

4-16. LS Guide Roller, Guide Lock Plate (T), Pinch Pusher Assembly, Eject Arm

1. Removal procedure

1)

Remove the LS chassis block assembly. (Refer to 4-11.)

2)

Remove the LS guide roller 1.

3)

Remove the P pressure plate spring 2.

4)

Remove the HLW cut (0.98

×

3

×

0.25) 3.

5)

Remove the pitch pressure plate assembly 4 in the direction

of the arrow A.

of the arrow A.

6)

Remove the relay gear 5.

7)

Remove the screw (camera pan2 M1.4

×

1.6) 6.

8)

Remove the guide lock plate (T) 7 in the direction of the arrow

B

B

.

9)

Remove the eject arm spring 8 and HLW cut (0.98

×

3

×

0.25) 9.

Note: Do not reuse the HLW cut.

10) Remove the eject arm 0.

2. Attachment procedure

1)

Attach the eject arm spring 8 to the eject arm 0.

2)

Hook one end of the eject arm spring 8 on the protrusion of

the main chassis block assembly and attach the eject arm to the

shaft.

the main chassis block assembly and attach the eject arm to the

shaft.

3)

Attach the HLW cut (0.98

×

3

×

0.25) 9.

Do not reuse the HLW cut.

4)

Attach the guide lock plate T 7 while aligning it with the

notches C and D.

notches C and D.

5)

Attach the screw (camera pan2 M1.4

×

1.6) 6.

Tightening torque: 0.078

±

0.01 N•m (0.8

±

0.1 kgf•cm)

6)

Attach the relay gear 5.

7)

Attach the pinch pusher plate 4 with the HLW cut (0.98

×

3

×

0.25) 3.

8)

Attach the P pressure plate spring 2.

Insert the concave side of the LS guide roller 1 into the shaft

to attach the LS guide roller.

Insert the concave side of the LS guide roller 1 into the shaft

to attach the LS guide roller.

Note: Insert the roller completely.

9)

Attach the LS chassis block assembly to the mechanical chassis.

(Refer to 4-11.)

(Refer to 4-11.)

Fig. 4-16

When attaching it, coat the hatched

portion with grease.

portion with grease.

6

Screw

(camera pan 2 main M1.4

×

1.6)

7

Remove the guide lock

plate (T) in the direction

of the arrow B.

of the arrow B.

4

Remove the pinch pressure

plate assembly in the direction

of the arrow A.

of the arrow A.

5

Relay gear

3

HLW cut

(0.98

×

3

×

0.25)

2

P pressure

plate spring

Coat inside with grease too.

Coat inside with grease too.

Concave side

Pinch the rotary switch.

9

HLW cut (Do not reuse)

(0.98

×

3

×

0.25)

8

Eject arm spring

0

Eject arm

1

LS guide roller

Notch C

Notch D

B

A

— 30 —

Fig. 4-17

4-17. Rotary Switch, Cam Relay Gear, Change Gear Assembly, Timing Belt

Before replacing the timing belt, remove the guide rail T2 and capstan motor. (Refer to 4-4.)

1. Removal procedure

1)

Remove the LS chassis block assembly. (Refer to 4-11.)

2)

Remove the guide lock plate (T), pinch pressure assembly and

eject arm. (Refer to 4-16.)

eject arm. (Refer to 4-16.)

3)

Remove the cam relay gear 1.

4)

Remove the timing belt 2.

5)

Remove the HLW cut (0.98

×

3

×

0.25) 3 and change gear

assembly 4.

6)

Remove the four solderings 5 and remove the FP-299/375

flexible wiring board 6.

flexible wiring board 6.

7)

Push up the dowel of the rotary switch 7 from the bottom of

the mechanism chassis assembly and remove the rotary switch

in the direction of the arrow.

the mechanism chassis assembly and remove the rotary switch

in the direction of the arrow.

2. Attachment procedure

1)

Insert the dowel of the rotary switch 7 into the hole on the

mechanism chassis assembly and attach the rotary switch

clockwise.

mechanism chassis assembly and attach the rotary switch

clockwise.

Note: If any oil has attached on the surface of the rotary switch, wipe

the oil off with a clean cotton cloth before starting installation.

2)

Align the FP-299/375 flexible wiring board 6 with the

reference hole on the mechanism chassis and solder the flexible

wiring board to the rotary switch 7 (at four locations).

reference hole on the mechanism chassis and solder the flexible

wiring board to the rotary switch 7 (at four locations).

3)

Attach the change gear assembly 4 with the HLC cut (0.98

×

3

×

0.25)3.

4)

Attach the timing belt 2.

Note: There must be a clearance between the rotary switch 7 and

timing belt 2.

5)

Attach the cam relay gear 1.

The in-phase markings of the rotary switch 7, cam relay gear

(2) and cam relay gear (1) must be aligned.

The in-phase markings of the rotary switch 7, cam relay gear

(2) and cam relay gear (1) must be aligned.

6)

Attach the guide lock plate (T), pinch pressure assembly and

eject arm. (Refer to 4-16.)

eject arm. (Refer to 4-16.)

7)

Attach the LS chassis block assembly to the mechanical chassis.

(Refer to 4-11.)

(Refer to 4-11.)

8)

Clean the shaft of the capstan motor. (Refer to 2-2.)

1

Cam relay gear (2)

2

Timing

belt

4

Change gear

assembly

5

Remove the

four solderings

6

FP-299/375 flexible

board

3

HLW cut

(0.98

×

3

×

0.25)

Rotary switch

Cam relay gear (2)

Cam relay gear (1)

Cam relay

gear (1)

gear (1)

7

Remove the rotary switch

in the direction of the arrow.

Dowel

When attaching it, coat the hatched

portion with grease.

portion with grease.

Belt must be completely

free from twist or stain

when it is installed

free from twist or stain

when it is installed

Clearance must exist between

the claw of the rotary switch and

the belt.

the claw of the rotary switch and

the belt.

Bend here at right angles.

Align the holes.

Attachment direction

The ribs must be facing upward.

The ribs must be facing upward.

Hole of mechanism chassis

Phase adjustment of gears

— 31 —

Fig. 4-18

4-18. Guide Gear (S) Assembly, Guide Gear (T) Assembly, Cam Relay Gear 1,

Guide Lock Plate (S)

1. Removal procedure

1)

Remove the LS chassis block assembly. (Refer to 4-11.)

2)

Remove the screw (camera pan2 main M1.4

×

1.6) 1.

3)

Remove the guide lock plate (S) 2 in the direction of the arrow

A

A

.

4)

Remove the two stop ring 1.2 (E type) 3.

5)

Remove the guide gear (S) assembly 4 and guide gear (T)

assembly 5.

assembly 5.

6)

Remove the HLW cut (0.98

×

3

×

0.25) 6.

7)

Remove the cam relay gear (1) 7.

2. Attachment procedure

1)

Attach the cam relay gear (1) 7 with the HLW cut (0.98

×

3

×

0.25) 6.

Note: The in-phase markings of the cam relay gear (1) 7, cam gear

(2) and cam relay gear must be aligned.

2)

Attach the guide gear (T) assembly 5 and guide gear (S)

assembly 4 to the shaft in this order and adjust the positions.

Then, attach them with the two stop ring 1.2 (E type) 3.

assembly 4 to the shaft in this order and adjust the positions.

Then, attach them with the two stop ring 1.2 (E type) 3.

Note1:The in-phase markings of the GL arm assembly, guide gear

(S) 4 and guide gear (T) 5 must be aligned.

Note2:The guide gear assembly (S/T) has a different shape

respectively. Pay attention to the shapes.

3)

Fit the guide lock plate (S) 2 in the groove on the shaft and

insert the portion B into the notch. Then, attach the plate with

the screw (camera pan2 main M1.4

insert the portion B into the notch. Then, attach the plate with

the screw (camera pan2 main M1.4

×

1.6) 1.

Tightening torque: 0.078

±

0.01 N•m (0.8

±

0.1 kgf•cm)

4)

Attach the LS chassis block assembly to the mechanical chassis.

(Refer to 4-11.)

(Refer to 4-11.)

Rotary switch

7

Cam relay gear (1)

Cam gear (2)

Cam

gear (2)

gear (2)

GL arm

assembly

assembly

4

Guide gear (S) assembly

5

Guide gear

(T) assembly

3

Two stop ring 1.2 (E type)

1

Screw

(camera pan 2 main

M1.4

M1.4

×

1.6)

6

HLW cut

(0.98

×

3

×

0.25)

Cam relay gear (2) Cam relay gear (1)

Guide gear

(T) assembly

(T) assembly

Guide gear

(S) assembly

(S) assembly

GL arm

assembly

assembly

2

Remove the guide lock plate (S)

in the direction of the arrow A.

When attaching it, coat the hatched

portion with grease.

portion with grease.

The pattern-printed side

must be facing upward.

must be facing upward.

Pay attention

to the shapes.

to the shapes.

Hole of mechanism chassis

SETTING THE GEAR POSITION

A

B

— 32 —

Fig. 4-19

4-19. LD Gear 4, Cam Gear 1, HC Drive Arm

Remove in advance the HCL arm assembly and loading motor assembly beforehand. (Refer to 4-2.)

1. Removal procedure

1)

Remove the LS chassis block assembly. (Refer to 4-11.)

2)

Remove the guide lock plate (S). (Refer to 4-18.)

3)

Remove the cover sheet 1 and LD gear (4) 2.

4)

Remove the T1 limiter arm 3 and cam gear (1) 4.

5)

Remove the HC drive arm 5 in the direction of the arrow.

2. Attachment procedure

1)

Attach the HC drive arm 5 under the drive base assembly.

2)

Attach the cam gear (1) 4.

The dowel of the HC drive arm 5 must be inserted into the

groove on the lower side of the cam gear (1) 4.

The in-phase markings of the cam gear (1) 4, cam gear (2)

and cam relay gear (1) must be aligned.

The dowel of the HC drive arm 5 must be inserted into the

groove on the lower side of the cam gear (1) 4.

The in-phase markings of the cam gear (1) 4, cam gear (2)

and cam relay gear (1) must be aligned.

3)

Attach the LD gear (4) 2 with the cover sheet 1.

4)

Attach the guide plate (S).

5)

Attach the LS chassis block assembly to the mechanical chassis.

(Refer to 4-11.)

(Refer to 4-11.)

6)

Clean the tape running path. (Refer to 2-2.)

When attaching it, coat the hatched

portion with grease.

portion with grease.

Cam gear (2)

Cam relay

gear (1)

gear (1)

3

T1 limitter

arm

4

Cam

gear (1)

2

LD gear (4)

1

Cover

sheet

5

Remove the HC

drive arm in the

direction of the

arrow.

direction of the

arrow.

Cam relay

gear (1)

gear (1)

Hole of mechanism chassis

M slide plate

assembly

assembly

LS arm assembly

Cam gear (2)

Cam gear (1)

HC drive arm

SETTING THE GEAR POSITION

Coat more than half round

of the grooves on both the

inner and outer sides of

the cam with grease.

of the grooves on both the

inner and outer sides of

the cam with grease.

Attachment direction

The larger gear must be

facing upward.

The larger gear must be

facing upward.

T1 limitter

arm

arm

Cover sheet

Loading motor

assembly

assembly

Cam relay

gear (2)

gear (2)

Click on the first or last page to see other DCR-TRV130 / DCR-TRV130E / DCR-TRV230 / DCR-TRV230E / DCR-TRV235E / DCR-TRV325E / DCR-TRV330 / DCR-TRV330E / DCR-TRV430E / DCR-TRV530 / DCR-TRV530E / DCR-TRV725E / DCR-TRV730 / DCR-TRV730E / DCR-TRV828 / DCR-TRV828E / DCR-TRV830 / DCR-TRV830E service manuals if exist.