Sony DCR-TRV130 / DCR-TRV130E / DCR-TRV230 / DCR-TRV230E / DCR-TRV235E / DCR-TRV325E / DCR-TRV330 / DCR-TRV330E / DCR-TRV430E / DCR-TRV530 / DCR-TRV530E / DCR-TRV725E / DCR-TRV730 / DCR-TRV730E / DCR-TRV828 / DCR-TRV828E / DCR-TRV830 / DCR-TRV830E Service Manual ▷ View online

— 33 —

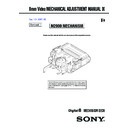

Fig. 4-20

4-20. M Slide Plate Assembly, LS Arm Assembly, Cam Gear 2, GL Arm Assembly

1. Removal procedure

Note: Identify which method of type is used by referring to the description

on page 4.

1)

Remove the LS chassis block assembly. (Refer to 4-11.)

2)

Remove the guide lock plate (S) (Refer to 4-18.)

3)

Remove the relay gear 1.

4)

Remove the M slide plate assembly 2 in the direction of the

arrow A.

arrow A.

5)

Remove the LS arm assembly 3 and LS arm roller 4.

Note: There are two types of the mechanism chassis shaft A. The

type B is the mechanism chassis shaft to which the LS guide A

roller is installed. Replace the LS guide A roller so as not to

drop it.

roller is installed. Replace the LS guide A roller so as not to

drop it.

6)

Remove the cam gear (2) 5.

7)

Remove the GL arm assembly 6 from the lower side of the

cam relay gear (1) in the direction of the arrow B.

cam relay gear (1) in the direction of the arrow B.

Note: After removing the GL arm assembly, fix the guide gear (S/T)

assembly.

2. Attachment procedure

1)

Attach the GL arm assembly 6 to the shaft so that the GL arm

assembly 6 is positioned under the cam relay gear (1) .

assembly 6 is positioned under the cam relay gear (1) .

Note: The in-phase markings of the guide gear (S/T) assembly and

GL arm assembly 6 must be aligned.

2)

While aligning the cam gear (2) 5 with the dowel of the GL

arm assembly, attach the cam gear (2) 5.

arm assembly, attach the cam gear (2) 5.

Note: The in-phase markings of the cam relay gear (1), cam gear (1)

and cam gear (2) 5 must be aligned.

3)

Attach the LS arm roller 4 to the LS arm assembly 3. While

aligning them with the cam groove on the cam gear (2) 5,

attach them.

aligning them with the cam groove on the cam gear (2) 5,

attach them.

Note: There are two types of the mechanism chassis shaft A. The

type B is the mechanism chassis shaft to which the LS guide A

roller is installed. When replacing it, apply 3 to 4 drops of

grease and then install the LS guide A roller.

roller is installed. When replacing it, apply 3 to 4 drops of

grease and then install the LS guide A roller.

4)

Attach the M slide plate assembly 2.

5)

Attach the relay gear 1.

6)

Attach the guide lock plate (S). (Refer to 4-18.)

7)

Attach the LS chassis block assembly to the mechaical chassis.

(Refer to 4-11.)

(Refer to 4-11.)

Note; Check that the in-phase marking of each gear is aligned.

Apply grease.

Apply 3-4 drops

grease.

grease.

Apply

grease.

grease.

3

LS arm

assembly

1

Relay gear

4

LS arm roller

Be careful not

to drop.

5

Cam gear

(2)

Cam relay gear (1)

Guide gear

(T) assembly

(T) assembly

Guide gear

(S) assembly

(S) assembly

Cam gear (1)

A

B

2

Remove the M slide

plate assembly in the

direction of the arrow

direction of the arrow

A

.

6

Remove the GL arm

assembly in the

direction of the

arrow

direction of the

arrow

B

.

Cam relay

gear (2)

gear (2)

Cam relay

gear (1)

gear (1)

Guide gear

(T) assembly

(T) assembly

Guide gear

(S) assembly

(S) assembly

GL arm

assembly

assembly

Cam gear (1)

M slide plate

assembly

assembly

Cam gear (2)

LS arm assembly

Hole of mechanism

chassis

chassis

SETTING THE GEAR POSITION

Rotary switch

Coat the cam groove

with grease.

with grease.

There are two types

of the mechanism

chassis shaft A.

of the mechanism

chassis shaft A.

LS guide roller A

Stop ring

(E type)

groove

(E type)

groove

Dowel

When attaching it, coat the hatched

portion with grease.

portion with grease.

Mechanism type B

— 34 —

5. Adjustment

5-1. Check and Adjustment of TG1 Back-tension Position

1. Check Procedure

1)

Assemble the mechanism deck into the main unit.

2)

Thread a normal tape and let the machine enter the PB (or REC)

mode.

mode.

3)

Check that the distance between the upper flange of the TG1

guide and the side surface of the LS chassis block is 12.0

guide and the side surface of the LS chassis block is 12.0

±

0.4

mm (range of fluctuation: 0.5 mm or less).

2. Adjustment Procedure

1)

Remove the cassette compartment and the blind plate.

2)

Adjust the position of the TG1 guide by changing the tilt of the

rising metal sheet of the LS chassis block assembly.

rising metal sheet of the LS chassis block assembly.

Fig. 5-1

Loading motor

Drum

S reel

TG1

BT band

Right

Left

Left

Right

12.0

±

0.4 mm

(range of fluctuation:

0.5 mm or less).

Rising metal sheet

— 35 —

5-2. Check and Adjustment of FWD/RVS Back-tension

1. Check Procedure

1)

1)

Install the mechanism deck in the main unit and set the take-up

torque cassette (Ref. No. J-6).

torque cassette (Ref. No. J-6).

2)

Enter the PLAY mode.

3)

Check the FWD torque as follows.

• Check the FWD torque of the T reel side in the PLAY mode.

• Check the FWD torque of the T reel side in the PLAY mode.

Specified value: 5 gf•cm or higher.

4)

Check the FWD back tension as follows.

• Check the FWD back tension by measuring the torque of

• Check the FWD back tension by measuring the torque of

the S reel side.

Specified value: 7.5 to 9.5 gf•cm

Specified value: 7.5 to 9.5 gf•cm

• Adjustment procedure

If the value of the FWD back tension does not satisfy the

specifications, change the position where the TG1 arm spring

is hooked.

If the value is larger than the specifications:

Change the spring hook position in the direction of the arrow

A

specifications, change the position where the TG1 arm spring

is hooked.

If the value is larger than the specifications:

Change the spring hook position in the direction of the arrow

A

.

If the value is smaller than the specifications:

Change the spring hook position in the direction of the arrow

B

Change the spring hook position in the direction of the arrow

B

.

Fig. 5-2

BT band

assembly

assembly

RVS arm

spring

spring

TG1 arm

spring

spring

TG1 arm

Reel table

(T) assembly

(T) assembly

A

B

5)

Enter the RVS mode.

6)

Check the RVS torque as follows.

• Check the RVS torque of the S reel side in the RVS mode.

• Check the RVS torque of the S reel side in the RVS mode.

Specified value: 17 to 35 gf•cm

7)

Check the RVS brake torque as follows.

• Check the RVS brake torque by measuring the torque of the

• Check the RVS brake torque by measuring the torque of the

T reel side.

Specified value: 8 to 16 gf•cm

Specified value: 8 to 16 gf•cm

— 36 —

Fig. 5-3

5-3. Capstan Motor Azimuth Position Adjustment

1. Check Procedure

1)

Insert the thickness gauge (Ref. No. J-14) of 0.75 mm between

the protrusion of the mechanism chassis and the capstan motor,

and check the azimuth position.

the protrusion of the mechanism chassis and the capstan motor,

and check the azimuth position.

2. Adjustment Procedure

1)

Loosen the capstan azimuth adjustment screw (SANG camera

pan 2 M1.4

pan 2 M1.4

×

4.5) 1, and insert the thickness gauge (0.75

mm)(Ref. No. J-14) between the protrusion of the mechanism

chassis and the capstan motor.

chassis and the capstan motor.

2)

Slowly tighten the capstan azimuth adjustment screw until it

slightly contacts the thickness gauge, and remove the thickness

gauge.

slightly contacts the thickness gauge, and remove the thickness

gauge.

Capstan

motor

motor

1

Capstan azimuth adjustment screw

(SANG camera pan 2 M1.4

×

4.5)

2

Thickness gauge

t = 0.75 mm

FP-300 flexible

board

board

Mechanism

chassis

chassis

Protrusion of the mechanism chassis

Click on the first or last page to see other DCR-TRV130 / DCR-TRV130E / DCR-TRV230 / DCR-TRV230E / DCR-TRV235E / DCR-TRV325E / DCR-TRV330 / DCR-TRV330E / DCR-TRV430E / DCR-TRV530 / DCR-TRV530E / DCR-TRV725E / DCR-TRV730 / DCR-TRV730E / DCR-TRV828 / DCR-TRV828E / DCR-TRV830 / DCR-TRV830E service manuals if exist.