Sony DCR-TRV130 / DCR-TRV130E / DCR-TRV230 / DCR-TRV230E / DCR-TRV235E / DCR-TRV325E / DCR-TRV330 / DCR-TRV330E / DCR-TRV430E / DCR-TRV530 / DCR-TRV530E / DCR-TRV725E / DCR-TRV730 / DCR-TRV730E / DCR-TRV828 / DCR-TRV828E / DCR-TRV830 / DCR-TRV830E Service Manual ▷ View online

— 37 —

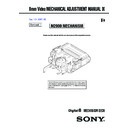

5-4. Tape Path Adjustment

Purpose:

Adjust the linearity of the head.

If the adjustment is not correct:

Noise appears on the top and bottom of the screen

when playing back the tape that is recorded by other

recorders.

when playing back the tape that is recorded by other

recorders.

5-4-1. Adjustment Preparation

1)

Clean the tape running surface (tape guides, drum, capstan shaft,

pinch roller).

pinch roller).

2)

When the drum is replaced with the new drum, perform the

check and adjustment of tape tension. When check and

adjustment are complete (refer to 5-2), run the lapping tape

(Ref. No. J-15).

Running time: 15 seconds in the FWD mode.

check and adjustment of tape tension. When check and

adjustment are complete (refer to 5-2), run the lapping tape

(Ref. No. J-15).

Running time: 15 seconds in the FWD mode.

Note: Run the lapping tape only once. When the lapping reaches its

end, replace it with the new lapping tape.

Running the lapping tape is prohibited except when a new drum

is installed.

Running the lapping tape is prohibited except when a new drum

is installed.

3)

Connect the adjustment remote commander to the remote

terminal.

terminal.

4)

Set the adjustment remote commander (Ref. No. J-8) to the

PATH mode (track shift mode)* and release the auto tracking.

PATH mode (track shift mode)* and release the auto tracking.

5)

Connect an oscilloscope as follows:

CH1: Test connector’ PB RF terminal

External trigger: Test connector’ RF SWP terminal

External trigger: Test connector’ RF SWP terminal

6)

Playback the tracking alignment tape WR5-1NP (NTSC), WR5-

1CP (PAL) (Ref. No. J-5).

1CP (PAL) (Ref. No. J-5).

7)

Confirm that the RF waveform on scope is flat both at entrance

side and exit side.

If the RF waveform is not flat, perform the adjustment by

referring to section 5-4-2.)

side and exit side.

If the RF waveform is not flat, perform the adjustment by

referring to section 5-4-2.)

8)

After the adjustment is completed, release the PATH mode

(track shift mode)*.

(track shift mode)*.

* Setting and releasing the track shift mode

In case of the DCR-TRV230

Setting

1.

Setting

1.

Select page: 0, address: 01 and set data: 01.

2.

Select page: F, address: 22 and set data: 88, and press the PAUSE

button.

button.

3.

Select page: 2, address: 2E and set data: 02. (Note)

Releasing

1.

1.

Select page: 0, address: 01 and set data: 01.

2.

Select page: F, address: 22 and set data: 80, and press the PAUSE

button.

button.

3.

Select page: 2, address: 2E and set data: 00. (Note)

4.

Select page: 0, address: 01 and set data: 00.

Note: In case of the Digital8 only, set the data of page: 2, address: 2E.

Fig. 5-4

Fig. 5-5

TG6

TG2

Capstan shaft

TG7

Pinch roller

T reel

S reel

TG1

TG3

TG4

TG5

Drum

Entrance side

Entrance side is defective

Exit side is defective

Exit side

Normal

— 38 —

5-4-2. Tracking Adjustment (Refer to Fig. 5-6)

1)

Playback the tracking alignment tape WR5-1NP (NTSC), WR5-

1CP (PAL) (Ref. No. J-5).

1CP (PAL) (Ref. No. J-5).

2)

Adjust the No.3 guide until the envelope at the entrance side

waveform becomes flat.

waveform becomes flat.

3)

Adjust the No.6 guide until the envelope at the exit side

waveform becomes flat.

waveform becomes flat.

✩ The TG-3/6 zenith adjustment screws do not need to be adjusted.

5-4-3. No.7 Guide (TG7) Adjustment

(Refer to Fig. 5-7)

1)

Playback the tape and set the REV mode.

2)

Confirm that tape slack does not occur in between the No.6

guide (TG6) 1 and capstan 2. If any tape slack occurs, rotate

the TG7 nut 4 of the No.7 guide (TG7) 3 to remove the tape

slack.

guide (TG6) 1 and capstan 2. If any tape slack occurs, rotate

the TG7 nut 4 of the No.7 guide (TG7) 3 to remove the tape

slack.

3)

Playback the tape again and confirm that tape slack does not

occur between the capstan 2 and No.7 guide (TG7) 3. If the

tape slack occurs exceeding the specifications (specifications:

0.5 mm or less), rotate the TG7 nut 4 to make the tape slack

below the specifications (0.5 mm). When the tape slack between

the No.6 guide (TG6) 1 and capstan 2 is 0.3 mm or less in

the REV mode, it means that the adjustment is completed.

occur between the capstan 2 and No.7 guide (TG7) 3. If the

tape slack occurs exceeding the specifications (specifications:

0.5 mm or less), rotate the TG7 nut 4 to make the tape slack

below the specifications (0.5 mm). When the tape slack between

the No.6 guide (TG6) 1 and capstan 2 is 0.3 mm or less in

the REV mode, it means that the adjustment is completed.

Fig. 5-6

Fig. 5-7

Guide zenith adjustment screw

No.6 guide

(TG6)

(TG6)

No.3 guide

(TG3)

(TG3)

Tape slack

2

Capstan

1

No.6 guide

(TG6)

3

No.7 guide

(TG7)

4

TG7 nut

— 39 —

5-4-4. CUE and REV Waveform Check

(Refer to Fig. 5-8)

1)

Playback the tracking alignment tape WR5-1NP (NTSC), WR5-

1CP (PAL)(Ref. No. J-5) and enter the REV mode.

Confirm on an oscilloscope that the pitches between the peaks

of the RF waveform are equally spaced for 5 seconds or more.

If pitches between peaks of the RF waveform are not equal,

perform sections “5-4-2 Tracking Adjustment” and “5-4-3 No.

7 Guide (TG7) Adjustment”.

1CP (PAL)(Ref. No. J-5) and enter the REV mode.

Confirm on an oscilloscope that the pitches between the peaks

of the RF waveform are equally spaced for 5 seconds or more.

If pitches between peaks of the RF waveform are not equal,

perform sections “5-4-2 Tracking Adjustment” and “5-4-3 No.

7 Guide (TG7) Adjustment”.

2)

Enter the UCE mode. Confirm on an oscilloscope that the

pitches between the peaks of the RF waveform are equally

spaced for 5 seconds or more.

If pitches between peaks of the RF waveform are not equal,

perform section “5-4-2 Tracking Adjustment”.

pitches between the peaks of the RF waveform are equally

spaced for 5 seconds or more.

If pitches between peaks of the RF waveform are not equal,

perform section “5-4-2 Tracking Adjustment”.

5-4-5. Check upon Completion of Adjustment

5-4-5-1. Tracking Check

1)

Playback the tracking alignment tape in the PATH mode.

Compare the amplitude of the RF waveform in the AUTO

tracking mode and with that in the PATH mode. Confirm that

the amplitude of the RF waveform decreases to about 3/4 when

the tracking alignment tape is switched from the AUTO tracking

mode to the PATH mode. (Refer to Fig. 5-9)

Compare the amplitude of the RF waveform in the AUTO

tracking mode and with that in the PATH mode. Confirm that

the amplitude of the RF waveform decreases to about 3/4 when

the tracking alignment tape is switched from the AUTO tracking

mode to the PATH mode. (Refer to Fig. 5-9)

2)

During step 1, confirm that the minimum amplitude (E

MIN

) is

65% or more of the maximum amplitude (E

MAX

) of the RF

waveform. (Refer to Fig. 5-10)

3)

Confirm that the RF waveform does not fluctuate too

excessively.(Refer to Fig. 5-11)

excessively.(Refer to Fig. 5-11)

Fig. 5-8

Fig. 5-9

Fig. 5-10

Fig. 5-11

3/4 A

A

E

MIN

E

MIN

E

MAX

E

MAX

65 (%)

A

C

C

C 1/6 A

a

b

c

d

— 40 —

Fig. 5-12

Fig. 5-13

Tape slack

Capstan

No.6 guide

(TG6)

(TG6)

No.7 guide

(TG7)

(TG7)

Capstan

Drum

Pinch roller

No.7 guide

(TG7)

(TG7)

No.6 guide

(TG6)

(TG6)

No.3 guide

(TG3)

(TG3)

No.1 guide

(TG1)

(TG1)

5-4-5-2. Rise-up Check (Refer to Fig. 5-12)

1)

Playback the tracking alignment tape WR5-1NP (NTSC), WR5-

1CP (PAL)(Ref. No. J-5).

1CP (PAL)(Ref. No. J-5).

2)

Turn OFF the Track Shift mode.

3)

Eject the cassette tape once. Then insert the cassette tape for

loading again.

loading again.

4)

Confirm that the RF waveform rises up to the flat envelope

within 3 seconds after the machine enters the PLAY mode.

Check also that the tape slack does not occur at around the

pinch roller.

within 3 seconds after the machine enters the PLAY mode.

Check also that the tape slack does not occur at around the

pinch roller.

5)

Run the tape in the CUE/REV and the FF/REW mode. Then

playback the tracking alignment tape and confirm the RF

waveform rises up to the flat envelope within 3 seconds after

the machine enters the PLAY mode. Check also that the tape

slack does not occur at around the pinch roller.

playback the tracking alignment tape and confirm the RF

waveform rises up to the flat envelope within 3 seconds after

the machine enters the PLAY mode. Check also that the tape

slack does not occur at around the pinch roller.

6)

Repeat the above steps 3) to 5) once again for re-check.

5-4-5-3. Tape Run Check (Refer to Fig. 5-13)

1)

Play back a thin tape such as P6-120MP.

Check if tape floats or not, and check if tape curl occurs or not

as follows.

No. 3 (TG3) tape guide’s top flange side,

No. 6 (TG6) tape guide’s top flange side,

No. 7 (TG7) tape guide’s top and bottom flange sides

Check if tape floats or not, and check if tape curl occurs or not

as follows.

No. 3 (TG3) tape guide’s top flange side,

No. 6 (TG6) tape guide’s top flange side,

No. 7 (TG7) tape guide’s top and bottom flange sides

Specified value:

• Floating of tape from the flange: There must be no floating

• Floating of tape from the flange: There must be no floating

of tape from the flange.

• Tape curl:

No. 3 (TG3) and No. 7 (TG7)

t Less than 0.8 mm

No. 6 (TG6)

t Less than 1.3 mm

2)

Press the REW button to enter the REV mode.

Check if tape floats or not, and check if tape curl occurs or not

as follows.

No. 3 (TG3) tape guide’s top flange side,

No. 6 (TG6) tape guide’s top flange side,

No. 7 (TG7) tape guide’s top and bottom flange sides

Check if tape floats or not, and check if tape curl occurs or not

as follows.

No. 3 (TG3) tape guide’s top flange side,

No. 6 (TG6) tape guide’s top flange side,

No. 7 (TG7) tape guide’s top and bottom flange sides

Specified value:

• Floating of tape from the flange: There must be no floating

• Floating of tape from the flange: There must be no floating

of tape from the flange.

• Tape curl:

No. 3 (TG3) and No. 7 (TG7)

t Less than 0.8 mm

No. 6 (TG6)

t Less than 1.3 mm

Click on the first or last page to see other DCR-TRV130 / DCR-TRV130E / DCR-TRV230 / DCR-TRV230E / DCR-TRV235E / DCR-TRV325E / DCR-TRV330 / DCR-TRV330E / DCR-TRV430E / DCR-TRV530 / DCR-TRV530E / DCR-TRV725E / DCR-TRV730 / DCR-TRV730E / DCR-TRV828 / DCR-TRV828E / DCR-TRV830 / DCR-TRV830E service manuals if exist.