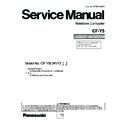

Panasonic CF-Y5LWVYZBM Service Manual ▷ View online

53

9.3.4.6. Putting Sheet

(1.0)

Puts by the standard on the left.

Affixes Palmrest Sheet (L)

Affixes KBD fixation tape

Affixes Disk angle cushion

Affixes Disk angle

cushion

cushion

Affixes Disk cover cushion

Affixes Disk shaft

fixation seat

fixation seat

Affixes Disk cover seat

Affixes the concave round type

part of a top case (four places).

part of a top case (four places).

Safety work

All are peeled off after putting

of the level peel positioning

the half and the flaking off

paper is put.

of the level peel positioning

the half and the flaking off

paper is put.

Puts within the range in the concave

happened top part.

(It is confirmed that there is not

running aground. )

happened top part.

(It is confirmed that there is not

running aground. )

Do not touch the paste side.

(garbage adhesion and down of

paste strength prevention)

(garbage adhesion and down of

paste strength prevention)

Thing without bubble generation

Thing without lattice eyes transparent

of paste confirmation

of paste confirmation

From 0.5 or less to inclination 0.2 or

less to concave bottom case part and

seat externals space difference

less to concave bottom case part and

seat externals space difference

< disk cover seat putting position >

Pressurize the

side putting part.

side putting part.

< KBD fixation tape putting position >

< disk shaft fixation seat putting position >

Along U ditch

and puts.

and puts.

< disk angle cushion putting position >

Direction of length hand of disk angle cushion

54

9.3.4.7. Assembly of the Break Lever

Affixes Disk Side Cover WP

Affixes Tape

< The Brake Lever is assembled >

sets in the rib of

the brake lever.

the brake lever.

Brake Lever

Installation in

brake spring

brake spring

Affixes Brake Pad

Do not touch

the bonding side.

the bonding side.

< installation position of brake lever >

has respect with shape up and installs.

Operativeness confirmation

of DISK brake after installation

of DISK brake after installation

Thing without Hi debt

Brake Lever installation

Affixes

Break Lever Sheet

Break Lever Sheet

Rib application putting

gap of 0.2mm or less.

the brake Lever sheet

gap of 0.2mm or less.

the brake Lever sheet

< putting position of wire rod fixation tape >

< Putting position of Disk Side Cover WP >

55

9.3.4.8. Assembly of the FAN

< Cushion putting position for cooling FAN >

Affixes Fan Cushion X3

It is a thing in the opening

which does not begin to be seen.

which does not begin to be seen.

Pressurize the frame

within this range or

neither shuttlecock in

the opening nor the

rotation axis.

within this range or

neither shuttlecock in

the opening nor the

rotation axis.

< Cable fixation seat (FAN/SP) putting position >

FAN externals

Flaking off paper ruled line

Affixes Fan/SP Cable Tape

It is a peel putting of

the half of the flaking

off paper.

the half of the flaking

off paper.

Safety work

The FAN cable confirms the thing that

beginning to see is not in the concave part.

beginning to see is not in the concave part.

FAN which has been

prepared is installed.

prepared is installed.

Pressurize neither rotation

axis nor the shuttlecock.

axis nor the shuttlecock.

Do not

transform the frame.

transform the frame.

The saliva of FAN is made

to slip into the boss of

a top case under.

to slip into the boss of

a top case under.

Screw(DXHM0057ZA)

Conclusion

Conclusion

Work notes

1. FAN must not be dropped, and do not add the impact.

< SCWER tightening torque >

Conclusion first time power : 0.16-0.18N.m {1.6-1.8kgf.cm}

At the repair : 0.10-0.12N.m {1.0-1.2kgf.cm}

At the repair : 0.10-0.12N.m {1.0-1.2kgf.cm}

After putting, the backup sheet of

the disk spring is installed.

the disk spring is installed.

Disk Cover Arm Spring installation

The point is inserted

in the hole of a top case.

in the hole of a top case.

Affixes

Disk Spring Backup Sheet

Disk Spring Backup Sheet

< putting position of disk spring backup sheet >

Rib

edge side

edge side

Do not go out of this

rib heaven side.

rib heaven side.

56

9.3.4.10. Assembly of the Disk Cover Lock / SW PCB

< Preparation for Disk Cover Lock >

There is directionality.

R shape is matched.

R shape is matched.

The insertion

order : 2

The fingernail

is multiplied.

order : 2

The fingernail

is multiplied.

The insertion order : 1

Inserts in R shape part

and the slide in

the right side.

Inserts in R shape part

and the slide in

the right side.

Disk Lock Bush installation

Safety work

The engagement fingernail is

the confirmation two places as

for there is not collapsing.

the confirmation two places as

for there is not collapsing.

Hanging fee of fingernail = (0.2)

Hole externals of

Disc Cover Lock

Disc Cover Lock

Disc Cover Lock

Convex is on both sides.

Do not crush convex

of this when detaching.

of this when detaching.

< preparation for solenoid with lead >

Flaking off

paper

paper

Solenoid Fix Tape (FAN/SP)

The same to width

of tape standard

of tape standard

Flaking off paper

leaving side

leaving side

This side of

red lead

red lead

Affixes Solen Fix Tape (FAN/SP)

The half of the

flaking off paper

is put on the

peel cable.

flaking off paper

is put on the

peel cable.

Conclusion of

Screw(DXQT2+F2FNL)

Screw(DXQT2+F2FNL)

Installation

Solenoid Angle

Solenoid Angle

Solenoid with lead

9.3.4.9. Assembly of the Disk Cover Click

Conclusion Screw(DXHM0057ZA)

Affixes Water Cap Tape

Affixes Insulation Sheet

Water Cap installation

Disk Cover Click

installation

installation

Do not hang the roller end face

in this part on the top case side.

in this part on the top case side.

Click on the first or last page to see other CF-Y5LWVYZBM service manuals if exist.