Panasonic CF-Y5LWVYZBM Service Manual ▷ View online

49

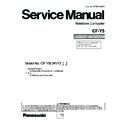

9.4.3.4. Assembly of the LCD Knob / Putting Cushion

(L)

(R)

Confirms the operation about the LCD knob

after building in

after building in

<Position where Pad Button cushion (L),(R) is affixed>

A

LCD Knob Cushion

A

A-A SEC

Top Case Rib

<Position where cushion for LCD knob is affixed>

Affixes in a central aim of the top

case rib and folds to the rib side

case rib and folds to the rib side

The gap on the edge

side is 1.0 or less by

return

side is 1.0 or less by

return

Pad Button Cushion (L) affixation

Pad Button Cushion (R) affixation

LCD Knob

The convex part is made to slip into the Top

Case under (right and left)

Case under (right and left)

The hook is put from the upper part on the top case

hole in the LCD Latch Spring.When expanding or

transforming, it is not possible to recycle

hole in the LCD Latch Spring.When expanding or

transforming, it is not possible to recycle

LCD Konb Spring

After the hook in the LCD

Latch Spring is hooked,

installs in a Top Case

Latch Spring is hooked,

installs in a Top Case

Directionality attention

A hither hook is upward.

A hither hook is upward.

LCD Knob WP Cushin

Division attention of LCD Knob

<0075YA-0>

0075YA-0Goods

This outside (R) is

expanded.

This outside (R) is

expanded.

(Inside R and a concentric circle R)

Safety work

<Position where LED LENZ BATT is installed>

2 places on the inside are

the reserves for the second

fixation.

the reserves for the second

fixation.

Safety work

Pin 2 place (outside) weld-

ing of top case

ing of top case

Welds so that there is no

floatage from the top

case side.

floatage from the top

case side.

Lan Sw Blank welds the

floatage which not is from

cabi application rib side.

floatage which not is from

cabi application rib side.

Lan Sw Blank

Led Lenz Batt

Pin shape

standard after

welds

standard after

welds

LED Lenz Batt : from cabi respect.

LAN SW Blank : from the application rib side.

LAN SW Blank : from the application rib side.

There is no floatage.

50

<FIG2>

Insertion

after PAD is

pressurized

after PAD is

pressurized

"NITTO No5000"

Release coated paper

Print side

<Preparation for PAD-2>

<FIG:1Preparation for PAD-1>

Touch Pad

Pad WP Sheet

Pad Cover

PAD that has been

prepared is stuck.

prepared is stuck.

Reinforcement board side

Pad FFC is inserted

Thing that doesn’t

begin to be seen

from window of

Pad Cover

begin to be seen

from window of

Pad Cover

Affixes

Pad Cover Tape

Pad Cover Tape

It sticks it

according to

U convex part

according to

U convex part

Sticking

part externals

part externals

Pad Cover Externals

The gap is

0.2 or less

0.2 or less

After of two PAD preparation completion

It installs in the pressurizing treatment

device and it pressurizes it.

It installs in the pressurizing treatment

device and it pressurizes it.

(Range of shaded portion)

The hole of a transparent mount of

PAD WP SHEET is inserted in the

pin of the treatment device.

PAD WP SHEET is inserted in the

pin of the treatment device.

PAD position-determining pin

PAD positioning spacer

PAD positioning spacer

The hole of a transparent mount of

PAD WP SHEET is inserted in the

pin of the treatment device.

PAD WP SHEET is inserted in the

pin of the treatment device.

Sticking part externals

and externals match of

Pad Case of sticking PAD

that has been prepared.

and externals match of

Pad Case of sticking PAD

that has been prepared.

<FIG2>

1. PAD is installed on the treatment device

and it installs it between positioning

the installation three places.

and it installs it between positioning

the installation three places.

2.The yellowish brown flaking off paper side

of Pad WS Sheet is peeled off and

the positioning hole of a transparent

mount is inserted in the pin of the

treatment device.

of Pad WS Sheet is peeled off and

the positioning hole of a transparent

mount is inserted in the pin of the

treatment device.

3. The sticking part of PAD and WP Sheet is

pressurized.

pressurized.

9.3.4.5. Assembly of the Touch Pad

<preparation for PAD>

Affixes Pad Cover Tape

Pad Cover

Thing that doesn’t

begin to be seen

from window of

Pad Cover

begin to be seen

from window of

Pad Cover

Safety work

Division attention of Pad Cover

"NITTO No5000"

Release coated paper

Print side

It sticks it according

to U convex part.

to U convex part.

ZA-0 = It is about the hemicycle.

YA-0 = There is no hemicycle.

51

(3

)

(0.4)

(0.4)

Reinforcement board side

Pad FFC is inserted

It sticks it

according to

U convex part

according to

U convex part

Insertion

after PAD is

pressurized

after PAD is

pressurized

Pad WP Sheet affixation

Touch Pad affixation

Pad Cover A’ssy

Safety work

Safety work

The hole of a peel of yellowish brown of

PAD WP Sheet flaking off paper and a

transparent mount is inserted in the pin

of the treatment device and

<Touch Pad> affixes.

PAD WP Sheet flaking off paper and a

transparent mount is inserted in the pin

of the treatment device and

<Touch Pad> affixes.

Installs in the receiving

stand of the pressurizing

treatment device.

stand of the pressurizing

treatment device.

<Preparation for PAD-2>

Insertion standard

Inside diameter

of grand foil

of grand foil

Sticking part

outside diameter

outside diameter

Safety work

The sticking part

externals are set

in a grand foil of PAD.

externals are set

in a grand foil of PAD.

After affixes with the hand

temporarily, pressurizes with

the treatment device so as

not to generate the sticking

part of Pad Wp Sheet like

wrinkle etc.

temporarily, pressurizes with

the treatment device so as

not to generate the sticking

part of Pad Wp Sheet like

wrinkle etc.

Sticking part

externals

externals

Pad Cover Externals

Pad Cover

affixation

Gasket (PAD)

affixation

Cutting side

Affixes in the concave part of a top case

Thing that pad Sheet’s corner does not hang on concave

happened the top part side

happened the top part side

Suppress right above

Gasket (PAD) when you

install the Pad Cover

Gasket (PAD) when you

install the Pad Cover

Touch Pad connec-

tion FFC is passed

through the hole.

tion FFC is passed

through the hole.

Safety work

Safety work

The top part side

affixation in flaking

off paper of

transparency peel.

affixation in flaking

off paper of

transparency peel.

Peel off PAD and PAD WP Sheet and assemble again in the

procedure of the standard book when you remove PAD COVER

by the repair etc.

(For steady adhesive power of PAD COVER and PAD).

procedure of the standard book when you remove PAD COVER

by the repair etc.

(For steady adhesive power of PAD COVER and PAD).

52

Gasket(PAD)

Pad Cover

Touch Pad

Top Case

OK

NG

<Gasket (PAD) installation position>

<Pad Cover installation position>

The side is

hung

hung

Thing in which space does not exist between convex

happened the top part side and Pad Cover outside diameter

happened the top part side and Pad Cover outside diameter

Affixes with the arrow direction touch to the convex

happened top part side

(Space measures with PAD BUTTON)

happened top part side

(Space measures with PAD BUTTON)

Click on the first or last page to see other CF-Y5LWVYZBM service manuals if exist.