Panasonic CF-Y5LWVYZBM Service Manual ▷ View online

45

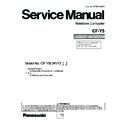

9.3.3.6. Assembly of the Wireless LAN Module / MODEM

Board externals

MDC EMI

Sheet

Sheet

<MODEM preparation 2>

<W-LAN Module preparation>

Antenna Board (MAIN)

Connection

<MODEM preparation 3>

Cable is processed

to the board side

to the board side

PET Tape

(19mmx25mm)

(19mmx25mm)

0-2

1-2

Connection

<MODEM preparation 1>

MODEM

The film is

wrapped

wrapped

The PET Tape (19mmx25mm)

is wrapped

is wrapped

From the tube edge

2-5mm

2-5mm

MODEM Cable

34-36

2.0

2.0

2.0

2.0

Safety work

Safety work

Safety work

Safety work

Safety work

The remainder is affixed

on an opposite side

on an opposite side

Fit Board’s hole to

Conductive Cloth’s hole.

Conductive Cloth’s hole.

EMI Sheet’s for MDC

tape externals

tape externals

The position is decided with a

treatment device.

treatment device.

Antenna Board (SUB)

Processes to board’s just beside.

W-LAN Module

Connection

-Work in midair prohibition when module is connected with antenna board.

-Connects applying the board to the receiving stand.

(For the distortion prevention of the board)

-Connects applying the board to the receiving stand.

(For the distortion prevention of the board)

Put out the position with the tube

drawn to the Jack side

drawn to the Jack side

46

9.3.3.7. Insert the Main Board

1-3mm

2-4mm

Tape

Coin Battery

Edge side central distribution

Affixation

within this range

within this range

Safety Work

Safety Work

Safety Work

Screw

(DXQT2+D25FNL)

(DXQT2+D25FNL)

Screw

(DXQT2+D25FNL)

(DXQT2+D25FNL)

MODEM Preparation goods

W-LAN Module Preparation goods

Screw

(DXQT2+D25FNL)

(DXQT2+D25FNL)

Memory Spreader

Screw

(DXQT2+E6FNL)

(DXQT2+E6FNL)

Affixes to the sheet..Does not get on the board.

Valley case

Bend with 0.5 or more

(Use the treatment device)

Bend with 0.5 or more

(Use the treatment device)

The adsorption sheet of the

axis for fixation is peeled off

before installs. (2 places)

axis for fixation is peeled off

before installs. (2 places)

Safety Work

The adsorption sheet of the

axis for fixation is peeled off

before installs. (2 places)

axis for fixation is peeled off

before installs. (2 places)

After the pin by which the

position is decided is inserted, a

fixed screw is tightened.

After the screw is tightened, the

pin is detached.

position is decided is inserted, a

fixed screw is tightened.

After the screw is tightened, the

pin is detached.

Slit externals match

0-1.5mm

*Does not overlap in the slit

0 2mm

0 2mm

AL Sheet externals standard

Board Label

Character

direction (Upper)

direction (Upper)

MODEM LAN Holder

MODEM CN installation

LAN CN installation

Installs so that the cable should not cross.

Pressurizes with the battery the finger is

put in the PCMCIA slot.

put in the PCMCIA slot.

(Attention)

-The board is set in the receiving treatment device and works.

-When carrying to the following process, a special palette is used.

(The FPC bend in YB respect is prohibited)

-The board is set in the receiving treatment device and works.

-When carrying to the following process, a special palette is used.

(The FPC bend in YB respect is prohibited)

The cable is processed to this part remaining. Does

not get on a top side in the main body of the battery.

not get on a top side in the main body of the battery.

Fit to

connector

affixation

connector

affixation

9.3.3.8. Note of Wireless LAN module is inserted

<Notes when Wireless LAN Module is inserted>

Please do Board’s insertion and extraction correctly according to the direction and the procedure shown in the figure below

Please go from parallel respect to mounting Board in Board’s insertion and extraction within the range of 5 -10

Please insert in the interior completely when you insert Board.

Please insert in the interior completely when you insert Board.

47

9.3.4. Assembly knowhow of the Top Case

9.3.4.1. Assembly of the Disk Cover

48

9.3.4.2. Putting Disk Angle Cushion

9.4.3.3. Assembly of the Top Case

Disk Angle

Disk Angle Cushion

Disk Angle Cushion

Disk Angle Cushion

Affixes according to the

ruled line.

ruled line.

Affixes according to the

ruled line.

ruled line.

Affixes according to the

ruled line.

ruled line.

Affixes at the right of the ruled line.

<Position where LED Cushion is Affixed>

PAD Lenz Tape affixation

Top Case

LED Cushion Affixation

Lan Sw Blank Installation

Hole for

LENZ (4 places)

LENZ (4 places)

Tape posi-

tioning pin

tioning pin

The pin is inserted through

the top case hole.

Thing not diagonal insert-

ed.(crack measures)

the top case hole.

Thing not diagonal insert-

ed.(crack measures)

LCD LENS PAD installation

(The pin after installs is welded)

(The pin after installs is welded)

The length hole (2 places) is

matched to the positioning pin,

and so as not to over on the top

case hole (4 places), affixes.

matched to the positioning pin,

and so as not to over on the top

case hole (4 places), affixes.

The pin 2 places (outside) of a

top case are welded with a

treatment device.

top case are welded with a

treatment device.

2 places on the inside are the re-

serves for the second fixation.

serves for the second fixation.

Pin shape standard after welds

Thing without

floatage

floatage

<Position where LED LENS PAD is installed>

LED LENZ BATT installation

(The pin after installs is

welded)

(The pin after installs is

welded)

Safety work

W-LAN ON /OFF

SW Knob Sheet

SW Knob Sheet

Power SW

knob Sheet

knob Sheet

Click on the first or last page to see other CF-Y5LWVYZBM service manuals if exist.