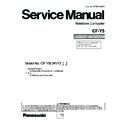

Panasonic CF-Y5LWVYZBM Service Manual ▷ View online

65

A

Cutting lack part central distribution pasting

Putting standard

Put along the case shape

Side WP Sheet 2

Wall reliance

attachment

attachment

attachment

Wall reliance

attachment

attachment

Wall reliance

attachment

attachment

Wall reliance

attachment

attachment

Side WP Sheet 2

(1.0)

Side WP Sheet 2 <part A chart>

Cutting lack part top side

Outer wall bottom corner

The right and left : between ribs.

Sheet must not get rolled up,

and not bend within this range.

and not bend within this range.

Safety Work

DVD Knob Sheet

66

9.3.5.4. Putting Foot Rubber

<FIG1>

Foot Rubber

Foot Rubber Support

Foot Rubber Support

<Notes and procedures when rubber foot / rubber foot (center) putting>

1) Wipe rubber foot/ rubber foot (center) pasting side

with the dry cloth (3 places)

1) Wipe rubber foot/ rubber foot (center) pasting side

with the dry cloth (3 places)

(Cautions) - Exchange the cloth (rag)

wiped off regularly (twice / day)

wiped off regularly (twice / day)

2) A rubber foot/rubber foot(center) pasting

(Cautions) - Put on the Bottom Case with tweezers etc.

- Paste so as not to touch the sticking side.

- Paste so as not to touch the sticking side.

3) Pressurizing (treatment device use) condition:

Pressurizing power : 2.5kgf or more,

Time : 3 seconds or more

Time : 3 seconds or more

Adjust the inclination of the direction of

the length hand to 0.2 or less

the length hand to 0.2 or less

Do not pressurize the concave

Bottom Case part

(Sheet concave measures).

Bottom Case part

(Sheet concave measures).

Do not go out of the rib

heaven side

heaven side

Bottom BATT Sheet

Put on the rib side

Ref to FIG 1

Put on the rib side

Ref to FIG 1

Affixes to the concave part.

Pressurizing treatment device use

Pressurizing treatment device use

Affixes to the concave part.

Pressurizing treatment device use

Pressurizing treatment device use

Affixes to the concave part.

Pressurizing treatment device use

Pressurizing treatment device use

Bottom BATT Sheet

Work with a specified treatment device when you pressurize Foot Rubber and Bottom BATT Sheet .

Safety Work

Safety Work

Safety Work

Safety Work

Safety Work

Screw

(XSB2+4FNL)

Installation

-Please work after installs in the treatment

device when you tighten the screw.

device when you tighten the screw.

(Attention)

67

9.3.6. Assembly knowhow of the Body

9.3.6.1. Keyboard preparation

9.3.6.2. Installation of Main Board

Affixes between

square holes

square holes

Affixes between

square holes

square holes

both sides tape

both sides tape

Boss central standard

0 1mm

0 1mm

From a square hole extemals

0-2mm

0-2mm

KBD Tape

Keyboard

Square hole extemals standard

0 1mm

0 1mm

Affixes between

square holes

square holes

MAIN PWB A'SSY

DIMM COVER

FIG1

It is confirmed that W-LAN SW

is turning off(Left) before building

in of BOTTOM CASE.

(OFF:Left ON:Right)

is turning off(Left) before building

in of BOTTOM CASE.

(OFF:Left ON:Right)

Main PWB A'ssy

is installed

is installed

Attention when Main

Pwb A'ssy is installed

Pwb A'ssy is installed

FIG 1

BOTTOM CAB A'SSY:

Attention of using properly

Attention of using properly

The ANT PWB connection

cable passes the FCC under

cable passes the FCC under

There is BT and for the model

The flaking off paper of the cushion is

peeled off, installs in the cabinet in the

under, and affixes .

peeled off, installs in the cabinet in the

under, and affixes .

FIG1

Attention of using properly

MK1=Only Dimm Cover

Excluding MK1=

There is heat radiation part affixation

There is heat radiation part affixation

Attention of using properly of BOTTOM CAB A'SSY

(Confirms by the hinge fixation boss in the cabi in the under)

(Confirms by the hinge fixation boss in the cabi in the under)

YA-0=It is penetration and a hole of about 2.0.

68

9.3.6.3. Assembly of the HDD Slot Guard

Line Hold Sheet

Pet Tape

Screw

(DXQT2+E6FNL)

Screw (DXQT2+D25FNL)

A B C

0-3

7-11

0 1

A

B

C

Affixes Line Hold Sheet

FIG2

0-0.5

0-1

FIG1

The flaking off paper on the

other side is peeled off and

affixes in the cabi in the under

other side is peeled off and

affixes in the cabi in the under

FIG2

White line

Corner part

Pet Tape is affixed at the white

line of FPC and the position set

to corner part Hdd Slot Guard

line of FPC and the position set

to corner part Hdd Slot Guard

Affixes Pet Tape

after fixing Hdd

Slot Guard A'ssy

FIG2

FIG1

Conductive fabric from

MDC is affixed in the

cabinet in the under

The width of the flaking off paper

peels off short one and Hdd Slot

Guard A'ssy affixes

peels off short one and Hdd Slot

Guard A'ssy affixes

It is confirmed that the substrate

does not run aground in the boss

and concludes

does not run aground in the boss

and concludes

Tighten Screw

Installation Hdd

Slot Guard A'ssy

Slot Guard A'ssy

Click on the first or last page to see other CF-Y5LWVYZBM service manuals if exist.