Panasonic KV-S5055C (serv.man2) Service Manual ▷ View online

33

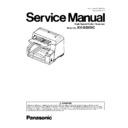

7 MAINTENANCE

7.1.

Maintenance Chart

C: Clean R:Replace (x 1000 sheets)

Caution:

*1

• The Scanning Glass (F), Scanning Glass (B), and their surroundings may be hot after scanning a lot of documents

continuously. Be sure to allow the inside of the scanner to cool down before performing any maintenance

or coming in contact with the inside of the unit.

or coming in contact with the inside of the unit.

Note

• The above roller maintenance values are stored in the maintenance counter (Refer to Sec. 9), and the PC

will notify users of the cleaning and replacing timing if the utility software for the scanner has been installed.

• The maintenance schedule was determined according to paper standards (A4: 75 g/m

2

/ Letter: 20 lb.), which can

vary greatly between users. Therefore, the values can also vary.

Description

Part Reference

Section

20

40

60

80 - 320

340 350

Paper Feed Roller

Sec. 14.4

C

C

C

Clean each part every

20,000 sheets' scanning.

20,000 sheets' scanning.

C

R

Separation Roller

Sec. 14.4

C

C

C

C

R

Double-feed Prevention Roller

Sec. 14.2

C

C

C

C

R

Drive Roller 1

Sec. 14.3

C

C

C

C

C

Drive Roller 2

Sec. 14.3

C

C

C

C

C

Drive Roller 3

Sec. 14.3

C

C

C

C

C

Exit Roller

Sec. 14.3

C

C

C

C

C

Free Roller 1

Sec. 14.4

C

C

C

C

C

Free Roller 2

Sec. 14.4

C

C

C

C

C

Free Roller 3

Sec. 14.4

C

C

C

C

C

Reference Plate (F)

Sec. 14.3

C

C

C

C

C

Reference Plate (B)

Sec. 14.5

C

C

C

C

C

*1

Scanning Glass (F)

Sec. 14.5

C

C

C

C

C

*1

Scanning Glass (B)

Sec. 14.3

C

C

C

C

C

Ionizer (Ion outlet)

Sec. 14.3

C

C

C

C

C

Reflector Sheets for sensors

Sec. 14.1, 14.2

C

C

C

C

C

Paper Sensor

Sec. 14.1

C

C

C

C

C

Waiting Sensor (on the USS / WAITING SENSOR

Board)

Board)

Sec. 14.4

C

C

C

C

C

Starting Sensor (Board)

Sec. 14.4

C

C

C

C

C

Slip Detect Sensor (Board)

Sec. 14.4

C

C

C

C

C

Exit Sensor (on the ENDING SENSOR Board)

Sec. 14.3

C

C

C

C

C

Double Feed Detector (G)

Sec. 14.4

C

C

C

C

C

Double Feed Detector (R)

Sec. 14.3

C

C

C

C

C

34

7.2.

Cleaning

7.2.1.

Preparation

1. Before cleaning, make sure to turn off the scanner.

2. Push the ADF Door Release to open the door.

35

7.2.2.

Cleaning-1 (Main)

Following the instructions in figures Fig.7.2.2-1, Fig.7.2.2-2, Fig.7.2.2-3, and Fig.7.2.2-4 below, wipe or blow off dust from

the surface of the following parts in order to maintain high scanning performance.

Note:

the surface of the following parts in order to maintain high scanning performance.

Note:

After cleaning the Paper Feed Roller, Separation Roller, and Double-feed Prevention Roller, execute

“Clear Counter for cleaning roller” with Service Utility. (See 9.3.4.)

“Clear Counter for cleaning roller” with Service Utility. (See 9.3.4.)

(Fig. 7.2.2-1) Cleaning Parts and Action

**

Action Code means cleaning methods as follows.

C: Clean each surface with the included Roller Cleaning Paper or Model KV-SS03. (Option: Roller Cleaning Paper)

B: Blow off each surface with the included Blower.

B: Blow off each surface with the included Blower.

Caution:

*1

• The Scanning Glass (F), Scanning Glass (B), and their surroundings may be hot after scanning a lot of documents

continuously. Be sure to allow the inside of the scanner to cool down before performing any maintenance

or coming in contact with the inside of the unit.

or coming in contact with the inside of the unit.

Note 1: Roller Cleaning Paper

• Open the bag on the dotted line and take out the Roller Cleaning Paper.

• If the bag is left open for a long period of time before using it, the alcohol will evaporate. Please use the Roller

Cleaning Paper immediately after opening the bag.

• The Roller Cleaning Paper (KV-SS03 Option) is available from sales channel.

Note 2:

How to clean sensors (detectors)

Remove the brush from the accessory Blower and blow off the dust with the blower.

Description

**

Action Code

Remarks

Paper Feed Roller

C

1. After cleaning these three rollers, execute “Clear

Counter for cleaning roller” with Service Utility.

(See 9.3.4.)

2. Refer to Note 1 (Roller Cleaning Paper).

Counter for cleaning roller” with Service Utility.

(See 9.3.4.)

2. Refer to Note 1 (Roller Cleaning Paper).

*2

Separation Roller

C

*2

Double-feed Prevention Roller

C

Drive Roller 1

C

Refer to Note 1 (Roller Cleaning Paper).

Drive Roller 2

C

Drive Roller 3

C

Exit Roller

C

Free Roller 1

C

Free Roller 2

C

Free Roller 3

C

*1

Scanning Glass (F)

C

*1

Scanning Glass (B)

C

Reference Plate (F)

C, B

Refer to Note 1 (Roller Cleaning Paper).

Refer to Note 2 (How to clean sensors (detectors)).

Refer to Note 2 (How to clean sensors (detectors)).

Reference Plate (B)

C, B

Ionizer (Ion outlet)

B

1. Refer to Note 2 (How to clean sensors (detectors)).

Reference Sheets for sensors

B

Paper Sensor

B

Waiting Sensor (on the USS / WAITING SENSOR

Board)

Board)

B

Starting Sensor (Board)

B

Slit Detect Sensor (Board)

B

Exit Sensor (on the ENDING SENSOR Board)

B

Double Feed Detector (G)

B

Double Feed Detector (R)

B

36

Note 3: In case that a scanning problem on the image quality (line) or on the performance of conveying

still occurs,

with a vacuum cleaner, remove any staples and paper dust inside and outside the scanning glass,

being careful not to scratch the glass surface or its surroundings.

(Don't clean the glass surface or its surroundings with the included Blower.)

being careful not to scratch the glass surface or its surroundings.

(Don't clean the glass surface or its surroundings with the included Blower.)

Note 4:

*2

Direction for wiping rollers

Click on the first or last page to see other KV-S5055C (serv.man2) service manuals if exist.