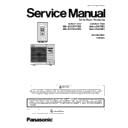

Panasonic WH-SDC07F3E5 / WH-SDC09F3E5 / WH-UD07FE5 / WH-UD09FE5 Service Manual ▷ View online

93

16.4 Error Codes Table

Diagnosis display

Abnormality/Protection control

Abnormality judgement

Primary location to verify

H00

No abnormality detected

—

—

H12

Indoor/Outdoor capacity unmatched

90s after power supply

Indoor/outdoor connection wire

Indoor/outdoor PCB

Specification and combination table in

Specification and combination table in

catalogue

H15

Outdoor compressor temperature sensor

abnormality

abnormality

Continue for 5 sec.

Compressor temperature sensor

(defective or disconnected)

H20

Water pump abnormality

Continue for 10 sec.

Indoor PCB

Water pump (malfunction)

H23

Indoor refrigerant liquid temperature

sensor abnormality

sensor abnormality

Continue for 5 sec.

Refrigerant liquid temperature sensor

(defective or disconnected)

H27

Service valve error

Continue for 5 minutes

High pressure sensor (defective or

disconnected)

H42

Compressor low pressure abnormality

—

Outdoor pipe temperature sensor

Clogged expansion valve or strainer

Insufficient refrigerant

Outdoor PCB

Compressor

Compressor

H62

Water flow switch abnormality

Continue for 1 min.

Water flow switch

H64

Refrigerant high pressure abnormality

Continue for 5 sec.

Outdoor high pressure sensor

(defective or disconnected)

H65

Deice circulation error

Continue for 10 sec.

Water flow switch sensor (defective or

disconnected)

Water pump malfunction

Buffer tank (is used)

H70

Back-up heater OLP abnormality

Continue for 60 sec.

Back-up heater OLP

(Disconnection or activated)

H72

Tank sensor abnormal

Continue for 5 sec.

Tank sensor

H76

Indoor - control panel communication

abnormality

abnormality

—

Indoor - control panel

(defective or disconnected)

H90

Indoor/outdoor abnormal communication

> 1 min after starting operation

Internal/external cable connections

Indoor/Outdoor PCB

H91

Tank heater OLP abnormality

Continue for 60 sec.

Tank heater OLP

(Disconnection or activated)

H95

Indoor/Outdoor wrong connection

—

Indoor/Outdoor supply voltage

H98

Outdoor high pressure overload

protection

protection

—

Outdoor high pressure sensor

Water pump or water leakage

Clogged expansion valve or strainer

Excess refrigerant

Excess refrigerant

Outdoor PCB

H99

Indoor heat exchanger freeze prevention

—

Indoor heat exchanger

Refrigerant shortage

Refrigerant shortage

F12

Pressure switch activate

4 times occurrence within 20

minutes

minutes

Pressure switch

F14

Outdoor compressor abnormal revolution

4 times occurrence within 20

minutes

minutes

Outdoor compressor

F15

Outdoor fan motor lock abnormality

2 times occurrence within 30

minutes

minutes

Outdoor PCB

Outdoor fan motor

Outdoor fan motor

F16

Total running current protection

3 times occurrence within 20

minutes

minutes

Excess refrigerant

Outdoor PCB

Outdoor PCB

F20

Outdoor compressor overheating

protection

protection

4 times occurrence within 30

minutes

minutes

Compressor tank temperature sensor

Clogged expansion valve or strainer

Clogged expansion valve or strainer

Insufficient refrigerant

Outdoor PCB

Compressor

F22

IPM (power transistor) overheating

protection

protection

3 times occurrence within 30

minutes

minutes

Improper heat exchange

IPM (Power transistor)

F23

Outdoor Direct Current (DC) peak

detection

detection

7 times occurrence

continuously

continuously

Outdoor PCB

Compressor

F24

Refrigeration cycle abnormality

2 times occurrence within 20

minutes

minutes

Insufficient refrigerant

Outdoor PCB

Compressor low compression

Compressor low compression

F25

Cooling/Heating cycle changeover

abnormality

abnormality

4 times occurrence within 30

minutes

minutes

4-way valve

V-coil

V-coil

F27

Pressure switch abnormality

Continue for 1 min.

Pressure switch

F30

Water outlet sensor 2 abnormality

Continue for 5 sec.

Water outlet sensor 2 (defective or

disconnected)

94

Diagnosis display

Abnormality/Protection control

Abnormality judgement

Primary location to verify

F36

Outdoor air temperature sensor

abnormality

abnormality

Continue for 5 sec.

Outdoor air temperature sensor

(defective or disconnected)

F37

Indoor water inlet temperature sensor

abnormality

abnormality

Continue for 5 sec.

Water inlet temperature sensor

(defective or disconnected)

F40

Outdoor discharge pipe temperature

sensor abnormality

sensor abnormality

Continue for 5 sec.

Outdoor discharge pipe temperature

sensor (defective or disconnected)

F41

PFC control

4 times occurrence within 10

minutes

minutes

Voltage at PFC

F42

Outdoor heat exchanger temperature

sensor abnormality

sensor abnormality

Continue for 5 sec.

Outdoor heat exchanger temperature

sensor (defective or disconnected)

F43

Outdoor defrost sensor abnormality

Continue for 5 sec.

Outdoor defrost sensor (defective or

disconnected)

F45

Indoor water outlet temperature sensor

abnormality

abnormality

Continue for 5 sec.

Water outlet temperature sensor

(defective or disconnected)

F46

Outdoor Current Transformer open

circuit

circuit

—

Insufficient refrigerant

Outdoor PCB

Outdoor PCB

Compressor low

F48

Outdoor EVA outlet temperature sensor

abnormality

abnormality

Continue for 5 sec.

Outdoor EVA outlet temperature sensor

(defective or disconnected)

F49

Outdoor bypass outlet temperature

sensor abnormality

sensor abnormality

Continue for 5 sec.

Outdoor bypass outlet temperature

sensor (defective or disconnected)

F95

Cooling high pressure overload

protection

protection

—

Outdoor high pressure sensor

Water pump or water leakage

Water pump or water leakage

Clogged expansion valve or strainer

Excess refrigerant

Outdoor PCB

Outdoor PCB

95

16.5 Self-diagnosis

Method

16.5.1 Connection Capability Rank Abnormality (H12)

Malfunction Decision Conditions:

During startup operation of cooling and heating, the capability rank of indoor checked by the outdoor is used to

determine connection capability rank abnormality.

determine connection capability rank abnormality.

Malfunction Caused:

1 Wrong model interconnected.

2 Wrong indoor unit or outdoor unit PCB (main) used.

3 Faulty indoor unit or outdoor unit PCB (main).

2 Wrong indoor unit or outdoor unit PCB (main) used.

3 Faulty indoor unit or outdoor unit PCB (main).

Abnormality Judgment:

Continue for 90 seconds.

96

16.5.2 Compressor Tank Temperature Sensor Abnormality (H15)

Malfunction Decision Conditions:

During startup and operation of cooling and heating, the temperatures detected by the compressor tank

temperature sensor are used to determine sensor error.

temperature sensor are used to determine sensor error.

Malfunction Caused:

1 Faulty connector connection.

2 Faulty sensor.

3 Faulty outdoor unit PCB (main).

2 Faulty sensor.

3 Faulty outdoor unit PCB (main).

Abnormality Judgment:

Continue for 5 seconds.

Click on the first or last page to see other WH-SDC07F3E5 / WH-SDC09F3E5 / WH-UD07FE5 / WH-UD09FE5 service manuals if exist.