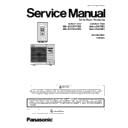

Panasonic WH-SDC07F3E5 / WH-SDC09F3E5 / WH-UD07FE5 / WH-UD09FE5 Service Manual ▷ View online

Order No: PAPAMY1406033CE

Indoor Unit

Outdoor Unit

WH-SDC07F3E5

WH-SDC09F3E5

WH-SDC09F3E5

WH-UD07FE5

WH-UD09FE5

WH-UD09FE5

Destination

Europe

PRECAUTION OF LOW TEMPERATURE

In order to avoid frostbite, be assured of no refrigerant leakage during the instation or repairing of refrigerant circuit.

WARNING

This service information is designed for experienced repair technicians only and is not designed for use by the general public.

It does not contain warnings or cautions to advise non-technical individuals of potential dangers in attempting to service a product.

service or repair the products dealt with in this service information by anyone else could result in serious injury or death.

2

TABLE OF CONTENTS

1.

Safety Precautions ............................................. 3

2.

Specifications ..................................................... 5

2.1

WH-SDC07F3E5 WH-UD07FE5 ................... 5

2.2

WH-SDC09F3E5 WH-UD09FE5 ................... 8

3.

Features ............................................................. 11

4.

Location of Controls and Components .......... 12

4.1

Indoor Unit ................................................... 12

4.2

Outdoor Unit ................................................. 20

5.

Dimensions ....................................................... 21

5.1

Indoor Unit ................................................... 21

5.2

Outdoor Unit ................................................. 22

6.

Refrigeration and Water Cycle Diagram ........ 23

7.

Block Diagram .................................................. 25

8.

Wiring Connection Diagram ............................ 26

8.1

Indoor Unit ................................................... 26

8.2

Outdoor Unit ................................................. 27

9.

Electronic Circuit Diagram .............................. 28

9.1

Indoor Unit ................................................... 28

9.2

Outdoor Unit ................................................. 29

10.

Printed Circuit Board ....................................... 30

10.1

Indoor Unit ................................................... 30

10.2

Outdoor Unit ................................................. 32

11.

Installation Instruction ..................................... 34

11.1

Select the Best Location .............................. 34

11.2

Indoor/Outdoor Unit Installation Diagram .... 34

11.3

Indoor Unit ................................................... 35

11.4

Outdoor Unit ................................................. 40

12.

Operation and Control ..................................... 44

12.1

Basic Function ............................................. 44

12.2

Water Pump ................................................. 65

12.3

Pump Down Operation [Service Mode: 01] . 67

12.4

Flow Switch .................................................. 67

12.5

Indoor Unit Safety ........................................ 68

12.6

Auto Restart Control .................................... 68

12.7

Indication Panel ........................................... 68

12.8

Indoor Back-Up Heater Control ................... 69

12.9

Tank Booster Heater Control ....................... 70

12.10

Base Pan Heater Control (Optional) ............ 70

12.11

Sterilization Mode ........................................ 71

12.12

Quiet Operation ............................................ 71

12.13

Anti Freeze Control ...................................... 72

12.14

Solar Operation (Optional) ........................... 73

12.15

External Room Thermostat Control (Optional)

.................................................................... 77

.................................................................... 77

12.16

Three Ways Valve Control ........................... 78

12.17

Two Ways Valve Control ............................. 78

12.18

External OFF/ON Control ............................ 79

12.19

Holiday Mode ............................................... 80

12.20

Dry Concrete Function ................................. 80

13.

Protection Control ............................................ 81

13.1

Protection Control for All Operations ........... 81

13.2

Protection Control for Heating Operation.....83

13.3

Protection Control for Cooling Operation .....84

14.

Servicing Guide ................................................85

14.1

How to Take Out Front Plate .......................85

14.2

How to Take Out Side Cabinet ....................85

14.3

Test Run ......................................................85

14.4

Proper Pump Down Procedure [SERVICE

MODE: 01] ...................................................85

MODE: 01] ...................................................85

14.5

How to Adjust Water Flow Rate [SERVICE

MODE: 02] ...................................................86

MODE: 02] ...................................................86

14.6

Expansion Vessel Pre Pressure Checking ..86

14.7

How to Unlock Cool Mode ...........................87

14.8

Dry Concrete [SERVICE MODE: 03] ...........87

14.9

EEPROM Factory Default Data Setup

Procedure ....................................................87

Procedure ....................................................87

15.

Maintenance Guide...........................................88

16.

Troubleshooting Guide ....................................90

16.1

Refrigeration Cycle System .........................90

16.2

Relationship between the Condition of the Air-

to-Water Heatpump Indoor and Outdoor Units

and Pressure and Electric Current ...............91

to-Water Heatpump Indoor and Outdoor Units

and Pressure and Electric Current ...............91

16.3

Breakdown Self Diagnosis Function ............92

16.4

Error Codes Table ........................................93

16.5

Self-diagnosis Method .................................95

17.

Disassembly and Assembly Instructions ... 132

17.1

To Remove Front Plate ............................. 132

17.2

To Remove Cabinet .................................. 132

17.3

To Remove Pressure Gauge .................... 133

17.4

To Remove Control Panel ........................ 133

17.5

To Remove RCCB .................................... 134

17.6

To Remove Transformer and Electronic

Controller Board ........................................ 135

Controller Board ........................................ 135

17.7

To Remove Pressure Relief Valve, Flow

Switch and Air Purge Valve ...................... 135

Switch and Air Purge Valve ...................... 135

17.8

To Remove Water Pump and Bottle Complete

................................................................. 136

................................................................. 136

18.

Technical Data ............................................... 138

18.1

Operation Characteristics ......................... 138

18.2

Heating Capacity Table............................. 150

18.3

Cooling Capacity Table ............................. 150

19.

Exploded View and Replacement Parts List 151

19.1

Indoor Unit ................................................ 151

19.2

Outdoor Unit .............................................. 153

3

CAUTION

WARNING

WARNING

1. Safety Precautions

Read the following “SAFETY PRECAUTIONS” carefully before perform any servicing.

Electrical work must be installed or serviced by a licensed electrician. Be sure to use the correct rating and main

circuit for the model installed.

The caution items stated here must be followed because these important contents are related to safety. The

meaning of each indication used is as below. Incorrect installation or servicing due to ignoring of the instruction

will cause harm or damage, and the seriousness is classified by the following indications.

will cause harm or damage, and the seriousness is classified by the following indications.

This indication shows the possibility of causing death or serious injury.

This indication shows the possibility of causing injury or damage to properties.

The items to be followed are classified by the symbols:

Carry out test run to confirm that no abnormality occurs after the servicing. Then, explain to user the operation,

care and maintenance as stated in instructions. Please remind the customer to keep the operating instructions for

future reference.

future reference.

1. Do not modify the machine, part, material during repairing service.

2. If wiring unit is supplied as repairing part, do not repair or connect the wire even only partial wire break. Exchange the whole wiring unit.

3. Do not wrench the fasten terminal. Pull it out or insert it straightly.

4. Engage dealer or specialist for installation and servicing. If installation of servicing done by the user is defective, it will cause water leakage,

electrical shock or fire.

electrical shock or fire.

5. Install according to this installation instructions strictly. If installation is defective, it will cause water leakage, electric shock or fire.

6. Use the attached accessories parts and specified parts for installation and servicing. Otherwise, it will cause the set to fall, water leakage,

refrigerant leakage, fire or electrical shock.

refrigerant leakage, fire or electrical shock.

7. Install at a strong and firm location which is able to withstand the set’s weight. If the strength is not enough or installation is not properly done,

the set will drop and cause injury.

8. Do not install outdoor unit near handrail of veranda. When installing outdoor unit at veranda of high rise building, child may climb up

to outdoor unit and cross over the handrail and causing accident.

the set will drop and cause injury.

8. Do not install outdoor unit near handrail of veranda. When installing outdoor unit at veranda of high rise building, child may climb up

to outdoor unit and cross over the handrail and causing accident.

9. For electrical work, follow the local national wiring standard, regulation and the installation instruction. An independent circuit and single outlet

must be used. If electrical circuit capacity is not enough or defect found in electrical work, it will cause electrical shock or fire.

must be used. If electrical circuit capacity is not enough or defect found in electrical work, it will cause electrical shock or fire.

10. This equipment must be properly earthed. Earth line must not be connected to gas pipe, water pipe, earth of lightning rod and telephone.

Otherwise, it may cause electric shock in case equipment breakdown or insulation breakdown.

11. Do not use joint cable for indoor/outdoor connection cable. Use specified indoor/outdoor connection cable, refer to Installation Instructions

CONNECT THE CABLE TO THE INDOOR UNIT and connect tightly for indoor/outdoor connection. Clamp the cable so that no external force

will be acted on the terminal. If connection or fixing is not perfect, it will cause heat up or fire at the connection.

12. When install or relocate Air to Water Heatpump indoor/outdoor unit, do not let any substance other than the specified refrigerant, eg. air etc.

mix into refrigerant cycle (piping). Mixing of air etc. will cause abnormal high pressure in refrigeration cycle and result in explosion, injury etc.

13. This is a R410A model, when connecting the piping, do not use any existing (R22) pipes and flare nuts. Using such same may cause

abnormally high pressure in the refrigeration cycle (piping), and possibly result in explosion and injury. Use only R410A refrigerant.

Thickness of copper pipes used with R410A must be more than 0.8 mm. Never use copper pipes thinner than 0.8 mm.

It is desirable that the amount of residual oil is less than 40 mg/10 m.

14. During installation, install the refrigerant piping properly before run the compressor. Operation of compressor without fixing refrigeration piping

and valves at opened condition will cause suck-in of air, abnormal high pressure in refrigeration cycle and result in explosion, injury etc.

15. During pump down operation, stop the compressor before remove the refrigeration piping. Removal of refrigeration piping while compressor is

operating and valves are opened condition will cause suck-in of air, abnormal high pressure in refrigeration cycle and result in explosion,

injury etc.

16. After completion of the installation servicing confirm there is no leakage of refrigerant gas. It may generate toxic gas when the refrigerant

contacts with fire.

Otherwise, it may cause electric shock in case equipment breakdown or insulation breakdown.

11. Do not use joint cable for indoor/outdoor connection cable. Use specified indoor/outdoor connection cable, refer to Installation Instructions

CONNECT THE CABLE TO THE INDOOR UNIT and connect tightly for indoor/outdoor connection. Clamp the cable so that no external force

will be acted on the terminal. If connection or fixing is not perfect, it will cause heat up or fire at the connection.

12. When install or relocate Air to Water Heatpump indoor/outdoor unit, do not let any substance other than the specified refrigerant, eg. air etc.

mix into refrigerant cycle (piping). Mixing of air etc. will cause abnormal high pressure in refrigeration cycle and result in explosion, injury etc.

13. This is a R410A model, when connecting the piping, do not use any existing (R22) pipes and flare nuts. Using such same may cause

abnormally high pressure in the refrigeration cycle (piping), and possibly result in explosion and injury. Use only R410A refrigerant.

Thickness of copper pipes used with R410A must be more than 0.8 mm. Never use copper pipes thinner than 0.8 mm.

It is desirable that the amount of residual oil is less than 40 mg/10 m.

14. During installation, install the refrigerant piping properly before run the compressor. Operation of compressor without fixing refrigeration piping

and valves at opened condition will cause suck-in of air, abnormal high pressure in refrigeration cycle and result in explosion, injury etc.

15. During pump down operation, stop the compressor before remove the refrigeration piping. Removal of refrigeration piping while compressor is

operating and valves are opened condition will cause suck-in of air, abnormal high pressure in refrigeration cycle and result in explosion,

injury etc.

16. After completion of the installation servicing confirm there is no leakage of refrigerant gas. It may generate toxic gas when the refrigerant

contacts with fire.

17. Ventilate the room if there is refrigerant gas leakage during operation. Extinguish all fire sources if present. It may cause toxic gas when the

refrigerant contacts with fire.

refrigerant contacts with fire.

18. Only use the supplied or specified installation parts, else, it may cause unit vibrate loose, water/refrigerant leakage, electrical shock or fire.

This symbol denotes item that is PROHIBITED from doing.

4

CAUTION

WARNING

19. The unit is only for use in a closed portable water system. Utilization in an open water circuit or non-portable water circuit, may lead to

excessive corrosion of the water piping and risk of incubating bacteria colonies, particularly Legionella, in water.

excessive corrosion of the water piping and risk of incubating bacteria colonies, particularly Legionella, in water.

20. Do not insert your fingers or other objects into the unit, high speed rotating fan may cause injury.

21. Do not dismantle refrigerant piping using pipe wrench. It might deform the piping and cause the unit to malfunction.

22. Select a location where in case of water leakage, the leakage will not cause damage to other properties.

23. Do not locally purchase electrical parts of the product for the purpose of installation, service, maintenance and etc. They might cause

electrical shock or fire.

electrical shock or fire.

24. Do not branch the power from terminal block to heater tape. Overloaded terminal block will cause electrical shock or fire.

25. Installation or servicing work. It may need two people to carry out the installation or servicing work.

26. Do not use unspecified cord, modified cord, joint cord or extension cord for power supply cord. Do not share the single outlet with other

electrical appliances. Poor contact, poor insulation or over current will cause electrical shock or fire.

electrical appliances. Poor contact, poor insulation or over current will cause electrical shock or fire.

27. Tighten the flare nut with torque wrench according to specified method. If the flare nut is over-tightened, after a long period, the flare may

break and cause refrigerant gas leakage.

break and cause refrigerant gas leakage.

1. Do not install the air-to-water heatpump indoor unit and outdoor unit at place where leakage of flammable gas may occur. In case

gas leaks and accumulates at surrounding of the unit, it may cause fire.

gas leaks and accumulates at surrounding of the unit, it may cause fire.

2. Carry out drainage piping as mentioned in installation instructions. If drainage is not perfect, water may enter the room and damage the

furniture.

furniture.

3. It may need two persons to carry out the installation work. The weight of indoor/outdoor unit might cause injury if carried by one person.

4. Do not touch outdoor unit air inlet and aluminium fin. It may cause injury.

5. Select an installation location which is easy for maintenance.

6. Pb free solder has a higher melting point than standard solder; typically the melting point is 50°F - 70°F (30°C - 40°C) higher. Please use a

high temperature solder iron. In case of the soldering iron with temperature control, please set it to 700 ± 20°F (370 ± 10°C).

Pb free solder will tend to splash when heated too high (about 1100°F/600°C).

high temperature solder iron. In case of the soldering iron with temperature control, please set it to 700 ± 20°F (370 ± 10°C).

Pb free solder will tend to splash when heated too high (about 1100°F/600°C).

7. Power supply connection to indoor unit.

Power supply point should be in easily accessible place for power disconnection in case of emergency.

Must follow local national wiring standard, regulation and this installation instruction.

Must follow local national wiring standard, regulation and this installation instruction.

Strongly recommended to make permanent connection to a circuit breaker.

- Power Supply 1: Use approved 30A 2-poles circuit breaker with a minimum contact gap of 3.0 mm.

- Power Supply 2: Use approved 15/16A 2-poles circuit breaker with a minimum contact gap of 3.0 mm.

8. Do not release refrigerant during piping work for installation, servicing, re-installation and during repairing a refrigeration parts. Take

care of the liquid refrigerant, it may cause frostbite.

- Power Supply 2: Use approved 15/16A 2-poles circuit breaker with a minimum contact gap of 3.0 mm.

8. Do not release refrigerant during piping work for installation, servicing, re-installation and during repairing a refrigeration parts. Take

care of the liquid refrigerant, it may cause frostbite.

9. Do not install this appliance in a laundry room or other high humidity location. This condition will cause rust and damage to the unit.

10. Make sure the insulation of power supply cord does not contact to hot part (i.e. refrigerant piping, water piping) to prevent from

insulation failure (melt).

insulation failure (melt).

11. Do not sit, step or place anything on the unit, you may fall down accidentally.

12. Do not touch the sharp aluminum fins or edges of metal parts.

If you are required to handle sharp parts during installation or servicing, please wear hand glove.

Sharp parts may cause injury.

13. After installation, check the water leakage condition in connection area during test run. If leakage occur, it will cause damage to other

properties.

14. The unit described in this manual is designed for use in a closed water system only. Utilization in an open water circuit may lead to

excessive corrosion of the water piping.

If you are required to handle sharp parts during installation or servicing, please wear hand glove.

Sharp parts may cause injury.

13. After installation, check the water leakage condition in connection area during test run. If leakage occur, it will cause damage to other

properties.

14. The unit described in this manual is designed for use in a closed water system only. Utilization in an open water circuit may lead to

excessive corrosion of the water piping.