Sharp MX-2600N / MX-3100N / MX-2600G / MX-3100G (serv.man7) Service Manual ▷ View online

MX-3100N ADJUSTMENTS 6 – 84

(Method 2)

Use SIM67-25 to print the color balance adjustment sheet and

compare the black patch color balance of each process (CMY)

with the black patch. This procedure allows checking the color

balance adjustment result correctly.

Use SIM67-25 to print the color balance adjustment sheet and

compare the black patch color balance of each process (CMY)

with the black patch. This procedure allows checking the color

balance adjustment result correctly.

*1: In the case of the GDI printer, this section are not printed.

If the color balance of each patch of the process black (CMY

mixed color) is slightly shifted to Magenta, it means that the

adjustment is proper. If the color balance of the adjustment

pattern printed in this mode is slightly shifted to Magenta, it is

converted into the natural gray color balance by the color table

in an actual printer mode. (When the color balance target is

DEF 1.)

If a satisfactory result on the print color balance and the den-

sity is not obtained with the automatic adjustment, execute the

manual adjustment (SIM 67-25) (ADJ 21B).

If the color balance of each patch of the process black (CMY

mixed color) is slightly shifted to Magenta, it means that the

adjustment is proper. If the color balance of the adjustment

pattern printed in this mode is slightly shifted to Magenta, it is

converted into the natural gray color balance by the color table

in an actual printer mode. (When the color balance target is

DEF 1.)

If a satisfactory result on the print color balance and the den-

sity is not obtained with the automatic adjustment, execute the

manual adjustment (SIM 67-25) (ADJ 21B).

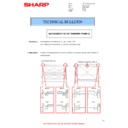

ADJ 22

Adjusting the fusing paper

guide position

guide position

This adjustment is needed in the following situations:

* When the fusing section is disassembled.

* When a paper jam occurs in the fusing section.

* When a wrinkle is made on paper in the fusing section.

* When an image deflection or image blur occurs in the paper rear

* When the fusing section is disassembled.

* When a paper jam occurs in the fusing section.

* When a wrinkle is made on paper in the fusing section.

* When an image deflection or image blur occurs in the paper rear

edge section.

1)

Loosen the fixing screw C.

2)

Shift the fusing paper guide in the arrow direction A or B (up

and down direction).

and down direction).

The standard fixing position is the center of the marking scale.

Change the position depending on the situation.

* When a wrinkle is formed on paper, change the position

Change the position depending on the situation.

* When a wrinkle is formed on paper, change the position

upward (in the arrow direction A).

* When an image deflection or image blur occurs in the paper

rear edge section, shift the position downward (in the arrow

direction A).

direction A).

ADJ 23

Document size sensor

adjustment

adjustment

This adjustment is needed in the following situations:

* When the original size sensor section has been disassembled.

* When the original size sensor section has been replaced.

* When U2 trouble has occurred.

* When the scanner control PWB is replaced.

* When the EEPROM on the scanner control PWB is replaced.

* When the original size sensor section has been disassembled.

* When the original size sensor section has been replaced.

* When U2 trouble has occurred.

* When the scanner control PWB is replaced.

* When the EEPROM on the scanner control PWB is replaced.

23-A

Document size sensor detection point

adjustment

adjustment

1)

Go through the modes specified in Simulation 41-1.

;

/

%

$M

3

/CZ

1

2

0

/

.

-

,

+

*

)

(

'

&

%

$

#

CMY

Blend

Blend

High density

Low density

Patch A of each of Y, M, C, and

BK are not copied.

BK are not copied.

2) Patch C or D of each of Y, C, M, and

BK is very slightly copied.

3) Patch for each of C, M, Y, BK

The patch density is identical between patches or not reversed.

The patch density is changed gradually.

The patch density is changed gradually.

1) The max. density section is not blurred.

*1

A

B

C

A

B

C

ǂǂǂ6,08/$7,21ǂǂ12

&/26(

7(67

3'6(1625&+(&.

2&6:

3'

3'

3'

3'

3'

3'

3'

MX-3100N ADJUSTMENTS 6 – 85

Loosen the original cover switch actuator adjustment screw

and slide the actuator position so that the display OCSW is

returned to the normal display when the height of the arm unit

top from the table glass is 32

and slide the actuator position so that the display OCSW is

returned to the normal display when the height of the arm unit

top from the table glass is 32

±0.5mm by slowly tilting the doc-

ument detection arm unit in the arrow direction and adjust.

(If the ON timing of the original cover switch is shifted, the doc-

ument detection function may malfunction.)

(If the ON timing of the original cover switch is shifted, the doc-

ument detection function may malfunction.)

23-B

Adjust the sensitivity of the original size

sensor

sensor

1)

Enter the SIM41-2 mode.

2)

Execute the sensor adjustment without document.

With the document cover open, without placing a document on

the table glass, press [EXECUTE] key.

With the document cover open, without placing a document on

the table glass, press [EXECUTE] key.

3)

Place A3 (11" x 17") paper on the document table and press

[EXECUTE] key.

If the adjustment is completed normally, "DOCUMENT PHOTO

SENSOR LEVEL IS ADJUESTED" is displayed.

[EXECUTE] key.

If the adjustment is completed normally, "DOCUMENT PHOTO

SENSOR LEVEL IS ADJUESTED" is displayed.

32 0.5mm

+-

Adjustment completed

EXECUTE

Adjustment

failed

failed

EXECUTE

ǂǂǂ6,08/$7,21ǂǂ12

&/26(

7(67

'2&80(176,=(3+2726(16256(783

(;(&87(

ේⓂᬌ⍮ࡦ ࠨߩࡌ࡞ࠍ⺞ᢛߒ߹ߒߚޕ

ǂǂǂ6,08/$7,21ǂǂ12

&/26(

7(67

'2&80(176,=(3+2726(16256(783

(;(&87(

ࠝࠫ࠽ ࡞ࠞࡃࠍ㐿ߚ⁁ᘒߢࠟࠬ㕙ߦේⓂࠍ࠶࠻ߒߥߢ

=':'%76'?ࡏ࠲ࡦࠍߒߡߊߛߐޕ

ǂǂǂ6,08/$7,21ǂǂ12

&/26(

7(67

'2&80(176,=(3+2726(16256(783

(;(&87(

ࠟࠬ㕙 ߦ#

ࠨࠗ࠭ߩ↪⚕ࠍ࠶࠻ߒߡޔ

=':'%76'?ࡏ࠲ࡦࠍߒߡߊߛߐޕ

ǂǂǂ6,08/$7,21ǂǂ12

&/26(

7(67

'2&80(176,=(3+2726(16256(783

(;(&87(

ਅ⸥ߩේⓂ ᬌ⍮ࡦࠨߢ⺞ᢛਇ⦟߇⊒↢ߒ߹ߒߚޕ

2&

MX-3100N ADJUSTMENTS 6 – 86

ADJ 24

Manual paper feed tray paper

size (width) sensor adjustment

size (width) sensor adjustment

This adjustment is needed in the following situations:

* The manual paper feed tray section has been disassembled.

* The manual paper feed tray unit has been replaced.

* U2 trouble has occurred.

* The PCU PWB has been replaced.

* The EEPROM of the PCU PWB has been replaced.

1)

* The manual paper feed tray section has been disassembled.

* The manual paper feed tray unit has been replaced.

* U2 trouble has occurred.

* The PCU PWB has been replaced.

* The EEPROM of the PCU PWB has been replaced.

1)

Go through the modes specified in Simulation 40-2.

2)

Open the manual paper feed guide to the maximum width posi-

tion.

tion.

3)

Press [EXECUTE] key.

[EXECUTE] key is highlighted. Then it returns to the normal

display.

The maximum width position detection level of the manual

paper feed guide is recognized.

[EXECUTE] key is highlighted. Then it returns to the normal

display.

The maximum width position detection level of the manual

paper feed guide is recognized.

4)

Set the manual paper feed guide to the A4 size.

5)

Press [EXECUTE] key.

[EXECUTE] key is highlighted. Then it returns to the normal

display.

The A4 size width position detection level of the manual paper

feed guide is recognized.

[EXECUTE] key is highlighted. Then it returns to the normal

display.

The A4 size width position detection level of the manual paper

feed guide is recognized.

6)

Set the manual paper feed guide to the width for the A4R size.

7)

Press [EXECUTE] key.

[EXECUTE] key is highlighted. Then it returns to the normal

display.

Set the manual paper feed guide to the width for the A4R size.

[EXECUTE] key is highlighted. Then it returns to the normal

display.

Set the manual paper feed guide to the width for the A4R size.

8)

Open the manual paper feed guide to the minimum width posi-

tion.

tion.

9)

Press [EXECUTE] key.

[EXECUTE] key is highlighted. Then it returns to the normal

display.

The minimum width position detection level of the manual

paper feed guide is recognized.

If the above operation is not completed normally, "ERROR" is

displayed.

When the operation is completed normally, the above data are

saved to the memory and "COMPLETE" is displayed.

[EXECUTE] key is highlighted. Then it returns to the normal

display.

The minimum width position detection level of the manual

paper feed guide is recognized.

If the above operation is not completed normally, "ERROR" is

displayed.

When the operation is completed normally, the above data are

saved to the memory and "COMPLETE" is displayed.

EXECUTE

EXECUTE

Repeat the above procedure to adjust

the A4R width MIN POSITION.

the A4R width MIN POSITION.

ǂǂǂ6,08/$7,21ǂǂ12

&/26(

7(67

%<3$6675$<$'-8670(17

(;(&87(

0$;326,7,21$'-8670(17

35(66>(;(&87(@7267$57

ǂǂǂ6,08/$7,21ǂǂ12

&/26(

7(67

%<3$6675$<$'-8670(17

(;(&87(

0$;326,7,21$'-8670(17

(;(&87,1*

ǂǂǂ6,08/$7,21ǂǂ12

&/26(

7(67

%<3$6675$<$'-8670(17

(;(&87(

3$326,7,21$'-8670(17

35(66>(;(&87(@7267$57

ǂǂǂ6,08/$7,21ǂǂ12

&/26(

7(67

%<3$6675$<$'-8670(17

(;(&87(

&203/(7(

MX-3100N ADJUSTMENTS 6 – 87

ADJ 25

RSPF tray paper size (width)

sensor adjustment (RSPF

mode)

sensor adjustment (RSPF

mode)

1)

Enter the SIM 53-6 mode.

2)

Set the tray document guide to the max. width position, and

press [EXECUTE] key. The button is highlighted and the tray

size volume maximum value adjustment is started.

* During the adjustment, "EXECUTING..." is displayed.

* After completion of the tray size volume maximum value

press [EXECUTE] key. The button is highlighted and the tray

size volume maximum value adjustment is started.

* During the adjustment, "EXECUTING..." is displayed.

* After completion of the tray size volume maximum value

adjustment, the set value is saved to EEPROM and RAM

and the display is shifted to the tray volume A4R size adjust-

ment value start screen. (Each set value is saved to

EEPROM and RAM at each setting.)

and the display is shifted to the tray volume A4R size adjust-

ment value start screen. (Each set value is saved to

EEPROM and RAM at each setting.)

3)

Set the tray document guide to A4R width position and press

[EXECUTE] button. The pressed button is highlighted and the

tray A4R size adjustment is started.

[EXECUTE] button. The pressed button is highlighted and the

tray A4R size adjustment is started.

4)

Adjust the tray volume A5R size and the tray size volume min-

imum value according to the above procedures.

imum value according to the above procedures.

5)

Completion of the adjustment, "COMPLETE" is displayed. If

the adjustment is not completed normally for any reason,

"ERROR" is displayed. In that case, the adjustment must be

executed again.

the adjustment is not completed normally for any reason,

"ERROR" is displayed. In that case, the adjustment must be

executed again.

<Adjustment item and content>

When one of 1-4 in the above table is selected, the guide plate is

shifted to each position of the four widths of the guide plate shown

in the table below. The value of the document width sensor

(RSPF_WIDTH) A/D value is saved to EEPROM.

<Guide plate positions and widths on the mechanism and A/D val-

ues to be saved>

shifted to each position of the four widths of the guide plate shown

in the table below. The value of the document width sensor

(RSPF_WIDTH) A/D value is saved to EEPROM.

<Guide plate positions and widths on the mechanism and A/D val-

ues to be saved>

ADJ 26

Touch panel coordinate setting

This adjustment is needed in the following situations:

* The operation panel has been replaced.

* U2 trouble has occurred.

* The scanner control PWB has been replaced.

* The EEPROM on the scanner control PWB has been replaced.

1)

* The operation panel has been replaced.

* U2 trouble has occurred.

* The scanner control PWB has been replaced.

* The EEPROM on the scanner control PWB has been replaced.

1)

Enter the SIM 65-1 mode.

2)

Precisely press the cross mark points (4 positions).

When the cross mark is pressed precisely, a buzzer sounds

and the display is reversed. When all the four points are

pressed and the touch panel adjustment is completed, the dis-

play returns to the simulation sub number entry screen.

In case of an error, the display returns to the entry screen

again.

Check to confirm that there is no shift between the display

frame and the detection position when the touch panel is

pressed.

* When pressing the touch panel, never use a sharp tip (such

When the cross mark is pressed precisely, a buzzer sounds

and the display is reversed. When all the four points are

pressed and the touch panel adjustment is completed, the dis-

play returns to the simulation sub number entry screen.

In case of an error, the display returns to the entry screen

again.

Check to confirm that there is no shift between the display

frame and the detection position when the touch panel is

pressed.

* When pressing the touch panel, never use a sharp tip (such

as a needle or a pin).

ADJ 27

Image loss, void area, image

off-center, image magnification

ratio auto adjustment with

SIM50-28

off-center, image magnification

ratio auto adjustment with

SIM50-28

The following adjustment items can be executed automatically with

SIM50-28.

* ADJ 8 Print image magnification ratio adjustment

SIM50-28.

* ADJ 8 Print image magnification ratio adjustment

(Main scanning direction) (Print engine section)

* ADJ 9 Image off-center adjustment (Print engine section)

* ADJ 14/15 Scan image magnification ratio adjustment

* ADJ 16 Scan image off-center adjustment

* ADJ 17 Print area (void area) adjustment (Print engine section)

* ADJ 18 Copy image position, image loss adjustment

(Menu in SIM50-28 mode)

* ADJ 14/15 Scan image magnification ratio adjustment

* ADJ 16 Scan image off-center adjustment

* ADJ 17 Print area (void area) adjustment (Print engine section)

* ADJ 18 Copy image position, image loss adjustment

(Menu in SIM50-28 mode)

NO.

Display

Content

1

TRAYVOLMAX

Tray size volume maximum value

2

TRAYVOLA4R

Tray volume A4R size adjustment value

3

TRAYVOLA5R

Tray volume A5R size adjustment

4

TRAYVOLMIN

Tray size volume minimum value

NO

Guide

plate

position

Widths on the mechanism

A/D

value,

code in

the figure

below

Remark

AB

series

INCH

series

Code in

the figure

below

1

Maximum

position

position

299

299

WIDTH

_MAX

_MAX

AD_MAX

2

Middle

position (L)

position (L)

210

215.9

WITH_P1

AD_P1

A4R OR

LTR

LTR

3

Middle

position (S)

position (S)

148.5

139.7

WITH_P2

AD_P2

A5R OR

INVR

INVR

4

Minimum

position

position

118

118

WITH_MIN

AD_MIN

ǂǂǂ6,08/$7,21ǂǂ12

&/26(

7(67

63)75$<$'-8670(17

(;(&87(

75$<92/0$;75$<$'-8670(17

35(66>(;(&87(@7267$57

Display/Item

Content

OC ADJ

Image loss off-center sub scanning direction

image magnification ratio adjustment

(Document table mode)

image magnification ratio adjustment

(Document table mode)

BK-MAG ADJ

Main scanning direction image magnification

ratio adjustment

ratio adjustment

SPF ADJ

Image loss off-center sub scanning direction

image magnification ratio adjustment

(RSPF mode)

image magnification ratio adjustment

(RSPF mode)

SETUP/PRINT ADJ

Print lead edge adjustment, image off-center

(each paper feed tray, duplex mode)

adjustment

(each paper feed tray, duplex mode)

adjustment

RESULT

Adjustment result display

DATA

Display of data used when an adjustment is

executed

executed