Panasonic CS-YW7MKD / CS-YW9MKD / CS-YW12MKD / CS-YW7MKD-1 / CS-YW9MKD-1 / CS-YW12MKD-1 / CU-YW7MKD / CU-YW9MKD / CU-YW12MKD / CU-YW7MKD-1 / CU-YW9MKD-1 / CU-YW12MKD-1 Service Manual ▷ View online

29

z

During Heating operation:-

f the compressor has been continuously running for 5 minutes or longer, and the difference of temperature between

intake air and evaporator is continuously lower than 5 ℃ or below for 2 minutes, the compressor will stop, and then

restart 3 minutes later. (Time Delay Safety Control is effective.)

intake air and evaporator is continuously lower than 5 ℃ or below for 2 minutes, the compressor will stop, and then

restart 3 minutes later. (Time Delay Safety Control is effective.)

△ T= Intake air temperature – Indoor heat exchanger temperature

11.7 Dew Prevention Control

z

To prevent dew formation at indoor unit discharge area, the horizontal air vane is automatically set at position 2

(refer to 9.6).

(refer to 9.6).

z

This control is activated when:-

*Compressor runs continuously for 60 minutes.

*Horizontal air vane is at position 4 or 5 (refer to 10.6).

*Actual fan speed is lower than Lo level.

*Intake air temperature is lower than 29℃

*Intake air temperature changes within 2℃ for more than 30 minutes.

*Horizontal air vane is at position 4 or 5 (refer to 10.6).

*Actual fan speed is lower than Lo level.

*Intake air temperature is lower than 29℃

*Intake air temperature changes within 2℃ for more than 30 minutes.

z

Dew prevention stops when:-

z

Any of the above condition is out of the range described above.

z

Operation stops.

z

Power OFF.

11.8 Overload Protection Control

During Heating operation:-

When temperature of indoor heat exchanger rise to 51’C, outdoor fan will stop.

When Temperature of indoor heat exchanger falls to 49’C, outdoor fan will restart.

When Temperature of indoor heat exchanger rises to 65’C or above, compressor stops, and will restart 4 minutes

later.

When temperature of indoor heat exchanger rise to 51’C, outdoor fan will stop.

When Temperature of indoor heat exchanger falls to 49’C, outdoor fan will restart.

When Temperature of indoor heat exchanger rises to 65’C or above, compressor stops, and will restart 4 minutes

later.

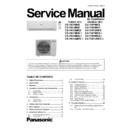

Compressor runs ≥ 5 min

△T≤ 5℃ last for 2 min

△T≤ 5℃ last for 2 min

Compressor stops

Compressor restarts 3 minutes later

Indoor Heat Exchanger ≥ 65’C

Compressor stops

Compressor restarts 4 minutes later

30

12. Servicing

Mode

12.1 Auto Off/On Button

1

AUTO OPERATION MODE

Auto Operation will be activated immediately once the Auto OFF/ON button is pressed. This operation can be

used to operate air conditioner with limited function if remote control is misplaced or malfunction.

Auto Operation will be activated immediately once the Auto OFF/ON button is pressed. This operation can be

used to operate air conditioner with limited function if remote control is misplaced or malfunction.

2

TEST RUN OPERATION (FOR PUMP DOWN/SERVICING PURPOSE)

The Test Run Operation will be activated if the Auto OFF/ON button is pressed continuously for more than 5

seconds. A “beep” sound will be heard at the fifth seconds, in order to identify the starting of this operation.

The Test Run Operation will be activated if the Auto OFF/ON button is pressed continuously for more than 5

seconds. A “beep” sound will be heard at the fifth seconds, in order to identify the starting of this operation.

3

REMOTE CONTROL RECEIVING SOUND OFF/ON MODE

z

To switch OFF the remote control receiving sound, press and hold "AUTO OFF/ON"

button for approximately 10 seconds until you hear 2 “beep” sounds. Release you hand.

Within 1 minutes, press this button again for approximately 10 seconds until you hear 2

“beep” sounds again, setting complete.

button for approximately 10 seconds until you hear 2 “beep” sounds. Release you hand.

Within 1 minutes, press this button again for approximately 10 seconds until you hear 2

“beep” sounds again, setting complete.

z

To switch ON the sounds, repeat above operation.

4

Random Auto Restart Function OFF/ON

z

Factory setting is ON.

z

To close this function, press and hold “AUTO OFF/ON” button for approximately 15

seconds until you hear 3 “beep” sounds. Release your hand and then press this button

again for 15 seconds until you hear 3 “beep” sounds again, setting complete. The step

should be completed within 1 minute.

seconds until you hear 3 “beep” sounds. Release your hand and then press this button

again for 15 seconds until you hear 3 “beep” sounds again, setting complete. The step

should be completed within 1 minute.

z

To recover this function, repeat above operation.

12.2 Remote Control Button

12.2.1 Mode selecting button

z

AUTO,HEAT, COOL, DRY, can be selected by pressing “MODE” button.

12.2.2 Temperature adjusting button

Temperature adjusting range is between 16 ℃~30 ℃

12.2.3 Fan speed button

There are 3 speed levels other than AUTO can be selected. The display on the remote controller changes as follows by pressing

the AIR SWING button.

the AIR SWING button.

12.2.4 AIR SWING button

To adjust vertical airflow directions by pressing AIR SWING button (5 options and AUTO)

Auto Operation

Test Run Operation

(Forced Cooling Operation)

Remote Control

Receiving Sound

OFF/ON

Random Auto Restart

OFF/ON

5 sec

10 sec

15 sec

ON

Beep

Beep x 2

Beep x 3

31

13. Troubleshooting

Guide

13.1 Refrigeration cycle system

In order to diagnose malfunctions, make sure that there are no

electrical problems before inspecting the refrigeration cycle. Such

problems include insufficient insulation, problem with the power

source, malfunction of a compressor and a fan. The normal outlet

air temperature and pressure of the refrigeration cycle depends on

various conditions, the standard values for them are shown in the

table on the right.

electrical problems before inspecting the refrigeration cycle. Such

problems include insufficient insulation, problem with the power

source, malfunction of a compressor and a fan. The normal outlet

air temperature and pressure of the refrigeration cycle depends on

various conditions, the standard values for them are shown in the

table on the right.

13.1.1

Normal Pressure and Outlet Air Temperature (Standard)

Gas Pressure

Mpa

(kg/cm

2

G)

Outlet air

Temperature

(°C)

Cooling Mode

0.6~0.96 ( 6~9.6)

12~16

Heating Mode 2.25~3.36(22.5~33.6)

36~45

Condition: Indoor fan speed = High

Outdoor temperature = 35°C at cooling mode

Outdoor temperature = 35°C at cooling mode

and 7°C at heating mode.

Different in the intake

and outlet

air temperatures

Normal

Value of electric current

during operation

Dusty condenser

preventing heat radiation

Excessive amount

of refrigerant

• Measuring the air

temperature different

• Measuring electric

current during operation

• Measuring gas side

pressure

More than 8°C

(15 minutes after an operation

is started) at cooling mode.

Above 14°C (15 minutes after

an operation is started.) at

heating mode

Less than 8°C at the cooling mode

Less than 14°C at the heating mode

Higher than specified

Lower than

specified

specified

Gas side

pressure

Inefficient compressor

Insufficient refrigerant

Clogged strainer or

capillary cube

Cooling

Mode

High

Low

Low

Inefficient compressor

Insufficient refrigerant

Clogged strainer or

capillary cube

Heating

Mode

Low

Low

Low

32

13.2 Relationship between the condition of the air conditioner and pressure

and electric current

Cooling Mode

Condition of the

air conditioner

Low Pressure

High Pressure

Electric current during operation

Insufficient refrigerant

(gas leakage)

Ô

Ô

Ô

Clogged capillary tube or

strainer

Ô

Ô

Ô

Short circuit in the indoor unit

Ô

Ô

Ô

Heat radiation deficiency

of the outdoor unit

Ò

Ò

Ò

Inefficient compression

Ò

Ô

Ô

• Carry out the measurement of pressure, electric current, and temperature fifteen minutes after an operation is started.

13.3 Diagnosis methods of a malfunction of a compressor

Nature of fault

Symptom

Insufficient compressing

of a compressor

z

Electric current during operation becomes approximately 20% lower thank the normal value.

z

The discharge tube of the compressor becomes abnormally hot (normally 70℃ to 90℃ )

z

The different between high pressure and low pressure becomes almost zero.

Locked compressor

z

Electric current reaches a high level abnormally, and the value exceeds the limit of an ammeter. In

some cases, a breaker turns off.

some cases, a breaker turns off.

z

Then compressor has a humming sound.

Click on the first or last page to see other CS-YW7MKD / CS-YW9MKD / CS-YW12MKD / CS-YW7MKD-1 / CS-YW9MKD-1 / CS-YW12MKD-1 / CU-YW7MKD / CU-YW9MKD / CU-YW12MKD / CU-YW7MKD-1 / CU-YW9MKD-1 / CU-YW12MKD-1 service manuals if exist.