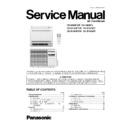

Panasonic CS-E9GFEW / CU-E9GFE / CS-E12GFEW / CU-E12GFE / CS-E18GFEW / CU-E18GFE Service Manual ▷ View online

57

11.3. Indoor Unit

11.3.1.

Selecting the Installation Location

• Indoor unit

Before choosing the installation site, obtain user approval.

- There should not be any heat source or steam near the unit.

- There should not be any obstacles blocking the air circulation.

- A place where air circulation in the room is good.

- A place where drainage can be easily done.

- A place where noise prevention is taken into consideration.

- Do not install the unit near the door way.

- Locate the indoor unit at least 1m or more from TV, radio, wireless equipment, antenna cables and fluorenscent light, and 2m

- There should not be any obstacles blocking the air circulation.

- A place where air circulation in the room is good.

- A place where drainage can be easily done.

- A place where noise prevention is taken into consideration.

- Do not install the unit near the door way.

- Locate the indoor unit at least 1m or more from TV, radio, wireless equipment, antenna cables and fluorenscent light, and 2m

or more away from a telephone.

- Ensure the spaces indicated by arrows from the wall, ceiling, fence or other obstacles.

58

• Remote controller

- Signals may not be transmitted and received correctly when the remote controller is operated while in the holder. Take the

remote controller in your hand to operate the unit.

- Mount the holder in a location that is not subject to the effects of heat (direct sunlight and stoves, etc.).

11.3.2.

Selection of Pipe and Heat Insulation Materials

• When using commercial copper pipes and fittings, observe the following:

1. Insulation material:Polyethylene form

Heat transfer rate: 0.041 to 0.052 W/mk (0.035 to 0.045kal/mh°C)

Refrigerant gas pipe's surface temperature reaches 110°C max.

Choose heat insulation materials that will withstand this temperature.

Refrigerant gas pipe's surface temperature reaches 110°C max.

Choose heat insulation materials that will withstand this temperature.

2. Be sure to insulate both the gas and liquid piping and to provide insulation dimension as below.

3. Use separate heat insulation pipes for gas and liquid refrigerant pipes.

11.3.3.

Installing the Indoor Unit

11.3.3.1. Exposed installation

Refrigerant piping

1. Drill a hole (70mm in diameter) in the spot indicated by the

symbol in the illustration as below.

2. The location of the hole is different depending on which side of the pipe is taken out.

3. For piping, see 5. Connecting the refrigerant piping.

4. Allow space around the pipe for a easier indoor unit pipe connection.

3. For piping, see 5. Connecting the refrigerant piping.

4. Allow space around the pipe for a easier indoor unit pipe connection.

Model

Pipe Dimension

Thermal Insulation Dimension

E9GF

Gas side

3/8” (O. D. 9.5mm 10.8mm)

I. D. 12.15mm t10mm Min

E12GF

Liquid side

1/4” (O. D. 6.4mm 10.8mm)

I. D. 8.10mm t10mm Min

E18GF

Gas side

1/2” (O. D. 12.7mm 10.8mm)

I. D. 14.16mm t10mm Min

Liquid side

1/4” (O. D. 6.4mm 10.8mm)

I. D. 8-10mm t10mm Min

Caution

Min. allowable length

• The suggested shortest pipe length is 2.5m, in order to avoid noise from the outdoor unit and vibration.

(Mechanical noise and vibration may occur depending on how the unit is installed and the environment in which

it is used.)

it is used.)

• See the installation manual for the outdoor unit for the maximum pipe length.

• For multi-connections, see the installation manual for the multi-outdoor unit.

• For multi-connections, see the installation manual for the multi-outdoor unit.

59

To drill a hole in the wall and install a sleeve of piping

1. Insert the piping sleeve to the hole.

2. Fix the bushing to the sleeve.

3. Cut the sleeve until it extrudes about 15 mm from the

2. Fix the bushing to the sleeve.

3. Cut the sleeve until it extrudes about 15 mm from the

wall.

4. Finish by sealing the sleeve with putty or caulking

compound at the final stage.

Drain piping

1. Use commercial rigid polyvinyl chloride pipe (general VP 20 pipe, outer diameter 26mm, inner diameter 20mm) for the drain

pipe.

2. The drain hose (outer diameter 18mm at connecting end, 220mm long) is supplied with the indoor unit. Prepare the drain pipe

picture below position.

3. The drain pipe should be inclined downward so that water will flow smoothly without any accumulation. (Should not be trap.)

4. Insert the drain hose to this depth so it won’t be pulled out of the drain pipe.

5. Insulate the indoor drain pipe with 10mm or more of insulation material to prevent condensation.

6. Remove the air filters and pour some water into the drain pan to check the water flows smoothly.

4. Insert the drain hose to this depth so it won’t be pulled out of the drain pipe.

5. Insulate the indoor drain pipe with 10mm or more of insulation material to prevent condensation.

6. Remove the air filters and pour some water into the drain pan to check the water flows smoothly.

Indoor unit preparation

• Open the front panel, remove the 4 screws and dismount the

front grille.

• Follow the procedure below when removing the slit portions.

• For Moldings

- Remove the pillars. (Remove the slit portions on the bot-

tom frame using nippers.)

• For Side Piping

- Remove the pillars.

1. Remove the 7 screws.

2. Remove the upper casing (2 tabs).

3. Remove the left and right casings (2 tabs on each

2. Remove the upper casing (2 tabs).

3. Remove the left and right casings (2 tabs on each

side).

4. Remove the slit portions on the bottom frame and

casings using nippers.

5. Return by following the steps in reverse order

(3 > 2 > 1).

Caution

When the wall is hollow, please be sure to use the

sleeve for tube ass’y to prevent dangers caused by

mice biting the connecting cable.

sleeve for tube ass’y to prevent dangers caused by

mice biting the connecting cable.

Caution

Use polyvinyl chloride adhesive agent for gluing. Failure to do so may cause water leakage.

60

• Connecting the Drain Hose

See 4. Connecting the Drain Hose

Indoor unit installation

• Secure using 6 screws for floor installations. (Do not forget to secure to the rear wall.)

• For wall installations, secure the mounting plate

using 5 screws and the indoor unit using 4 screws.

• The mounting plate should be installed on a wall which can support the weight of the indoor unit.

1. Temporarily secure the mounting plate to the wall, make sure that the panel is completely level, and mark the boring points

on the wall.

2. Secure the mounting plate to the wall with screws.

3. Once refrigerant piping and drain piping connections are complete, fill in the gap of the through hole with putty.

A gap can lead to condensation on the refrigerant pipe, and drain pipe, and the entry of insects into the pipes

4. Attach the front panel and front grille in their original positions once all connections are complete.

11.3.3.2. Half concealed installation

• Only item peculiar to this installation method are given here. See Exposed installation for additional instructions.

Wall hole

• Drill a wall hole of the size shown in the illustration on the

right.

Click on the first or last page to see other CS-E9GFEW / CU-E9GFE / CS-E12GFEW / CU-E12GFE / CS-E18GFEW / CU-E18GFE service manuals if exist.