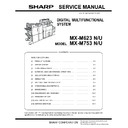

Sharp MX-M623U / MX-M753U (serv.man10) Service Manual ▷ View online

MX-M753N SIMULATION 6 – 13

7

7-1

Purpose

Setting

Function (Purpose) Used to set the operating conditions of

aging.

Section

Other

Operation/Procedure

1)

1)

Select the target to be set with the touch panel key.

2)

Press [EXECUTE] key.

The machine is rebooted in the aging mode.

The machine is rebooted in the aging mode.

The aging operation condition set by this mode is maintained here-

after unless the power is turned off or the setting is changed.

after unless the power is turned off or the setting is changed.

7-6

Purpose

Setting

Function (Purpose) Used to set the operating intermittent aging

cycle.

Section

Operation/Procedure

1)

1)

Enter the intermittent aging operation cycle (unit: sec) with 10-

key.

key.

2)

Press [OK] key.

The time entered in procedure 1) is set.

* The interval time that can be set is 1 to 900 (sec).

The time entered in procedure 1) is set.

* The interval time that can be set is 1 to 900 (sec).

The aging operation condition set by this mode is maintained here-

after unless the power is turned off or the setting is changed.

after unless the power is turned off or the setting is changed.

7-8

Purpose

Operation display

Function (Purpose) Used to display the warm-up time.

Section

Section

Operation/Procedure

Press [EXECUTE] key.

Counting of the warm-up time is started and the time required for

warm-up is displayed

* Interruption of counting by pressing [EXECUTE] key is inhibited.

Press [EXECUTE] key.

Counting of the warm-up time is started and the time required for

warm-up is displayed

* Interruption of counting by pressing [EXECUTE] key is inhibited.

7-12

Purpose

Operation test/check

Function (Purpose) The document reading number of sheets

setting (for aging operation)

Section

Automatic document feeder

Operation/Procedure

1)

1)

Set document reading quantity with 10-key.

(Setting range: 0 - 255)

(Setting range: 0 - 255)

2)

Press [OK] key. The set value is saved.

The aging operation condition set by this mode is maintained here-

after unless the power is turned off or the setting is changed.

after unless the power is turned off or the setting is changed.

8

8-1

Purpose

Operation test/Check/Adjustment

Function (Purpose) Used to check and adjust the operations of

the developing voltage in each print mode

and the control circuit.

and the control circuit.

Section

Process (Developing)

Operation/Procedure

1)

1)

Enter the setting value with 10-key.

2)

Press [EXECUTE] key.

The entered voltage is outputted for 30 sec and the set value is

saved.

When [EXECUTE] key is pressed during outputting, the opera-

tion is terminated.

The entered voltage is outputted for 30 sec and the set value is

saved.

When [EXECUTE] key is pressed during outputting, the opera-

tion is terminated.

8-2

Purpose

Operation test/Check/Adjustment

Function (Purpose) Used to check and adjust the operation of

the main charger grid voltage in each

printer mode and the control circuit.

printer mode and the control circuit.

Section

Process (Charging)

Operation/Procedure

1)

1)

Enter the setting value with 10-key.

2)

Press [EXECUTE] key.

The entered voltage is outputted for 30 sec and the set value is

saved.

When [EXECUTE] key is pressed during outputting, the opera-

tion is terminated.

The entered voltage is outputted for 30 sec and the set value is

saved.

When [EXECUTE] key is pressed during outputting, the opera-

tion is terminated.

8-6

Purpose

Operation test/Check/Adjustment

Function (Purpose) Used to check and adjust the operation of

the transport voltage and the control circuit.

Section

Process (Transfer)

Operation/Procedure

1)

1)

Select a target item to be adjusted with [

] [] key.

2)

Enter the set value with 10-key.

Enter the default value specified on the following list.

Enter the default value specified on the following list.

3)

Press [EXECUTE] key.

The set value is saved and the voltage corresponding to the

set value is output for 30 sec.

When [EXECUTE] key is pressed during outputting, the opera-

tion is terminated.

The set value is saved and the voltage corresponding to the

set value is output for 30 sec.

When [EXECUTE] key is pressed during outputting, the opera-

tion is terminated.

AGING

Aging operation setup

INTERVAL

Intermittent setup

MISFEED DISABLE

JAM detection enable/disable setup

FUSING DISABLE

Fusing operation enable/disable setup

WARMUP DISABLE

Warm-up skip setup

DV CHECK DISABLE

DV unit detection enable/disable setup

SHADING DISABLE

Shading disable setup

CCD GAIN FREE

No setting of the CCD gain adjustment

Item/

Display

Content

Setting

range

Default

value

MIDDLE

K color developing bias set value at the

middle speed

middle speed

0 - 700

395

LOW

K color developing bias set value at the

low speed

low speed

0 - 700

395

Item/

Display

Content

Setting

range

Default value

62 CPM

model

75 CPM

model

MIDDLE

K color charging/grid bias set

value at the middle speed

value at the middle speed

230 - 850

525

535

LOW

K color charging/grid bias set

value at the low speed

value at the low speed

230 - 850

525

525

MX-M753N SIMULATION 6 – 14

8-17

Purpose

Adjustment

Function (Purpose) Used to check and adjust the transfer elec-

tric cleaning output and the control circuit

operations.

operations.

Section

Process (Transfer)

Operation/Procedure

1)

1)

Select a target item to be adjusted with [

] [] key.

2)

Enter the set value with 10-key.

Enter the default value specified on the following list.

Enter the default value specified on the following list.

3)

Press [EXECUTE] key.

The set value is saved and the voltage corresponding to the

set value is output for 30 sec.

When [EXECUTE] key is pressed during outputting, the opera-

tion is terminated.

The set value is saved and the voltage corresponding to the

set value is output for 30 sec.

When [EXECUTE] key is pressed during outputting, the opera-

tion is terminated.

8-18

Purpose

Adjustment

Function (Purpose) Used to check and adjust the transfer

cleaning roller output and the control circuit

operations.

operations.

Section

Process (Transfer)

Operation/Procedure

1)

1)

Select a target item to be adjusted with [

] [] key.

2)

Enter the set value with 10-key.

Enter the default value specified on the following list.

Enter the default value specified on the following list.

3)

Press [EXECUTE] key.

The set value is saved and the voltage corresponding to the

set value is output for 30 sec.

When [EXECUTE] key is pressed during outputting, the opera-

tion is terminated.

The set value is saved and the voltage corresponding to the

set value is output for 30 sec.

When [EXECUTE] key is pressed during outputting, the opera-

tion is terminated.

8-20

Purpose

Adjustment

Function (Purpose) Used to check and adjust the output

between transfer papers and the control cir-

cuit operations.

cuit operations.

Section

Process (Transfer)

Operation/Procedure

1)

1)

Enter the set value with 10-key.

2)

When [OK] key is pressed, the currently entered data are

saved in the EEPROM and the RAM.

saved in the EEPROM and the RAM.

9

9-2

Purpose

Operation test/check

Function (Purpose) Used to check the operation of the sensors

and detectors in the switchback section

(duplex section) and the control circuit.

(duplex section) and the control circuit.

Section

Duplex

Operation/Procedure

The operating conditions of the sensors and detectors are dis-

played.

The code names of the sensors and the detectors which are active

are highlighted.

The operating conditions of the sensors and detectors are dis-

played.

The code names of the sensors and the detectors which are active

are highlighted.

9-3

Purpose

Operation test/check

Function (Purpose) Used to check the operations of the load in

the paper reverse section (duplex section)

and its control circuit.

and its control circuit.

Section

Duplex

Operation/Procedure

1)

1)

Select the item to be operation checked with the touch panel

key.

key.

2)

Press [EXECUTE] key.

The selected load performs the operation.

When [EXECUTE] key is pressed during operation, the opera-

tion is terminated.

The selected load performs the operation.

When [EXECUTE] key is pressed during operation, the opera-

tion is terminated.

Item/Display

Content

Setting

range

Default value

62 CPM model

75 CPM model

A

TC PLAIN BW SPX

Transfer current

Black/White

Standard

paper mode

Front surface

0 - 255

97

129

B

TC PLAIN BW DPX

Back surface

0 - 255

97

129

C

TC HEAVY BW SPX

Heavy paper

mode

Front surface

0 - 255

113

113

D

TC HEAVY BW DPX

Back surface

0 - 255

113

113

E

TC OHP BW

OHP mode

0 - 255

97

113

F

TC INTERVAL BIAS

Current value between papers

0 - 255

97

129

G

TC ADSORPTION BIAS

Transfer current value at adsorption

0 - 255

97

129

H

TC FRONT EDGE BIAS

Current value at the paper front edge

0 - 255

97

113

Item/Display

Content

Setting

range

Default

value

A

TC CLEANING

AC

AC

Transfer cleaning output

value AC

value AC

0 - 255

191

B

TC CLEANING

DC

DC

Transfer cleaning output

value DC

value DC

0 - 255

36

Item/Display

Content

Setting

range

Default

value

A

TC CLEANING

ROLLER +

ROLLER +

Transfer

cleaning roller

output

cleaning roller

output

Print

mode

mode

0 - 255

211

B

TC CLEANING

ROLLER -

ROLLER -

Cleaning

mode

mode

0 - 255

205

Item/Display

Content

Setting

range

Default

value

A

FRONT EDGE

BIAS TERM

BIAS TERM

Paper front edge current

time adjustment value

time adjustment value

0 - 100

1

DSW_ADU

ADU transport open/close detection

AINPD

ADU paper entry detector

APPD1

ADU paper pass detector 1

APPD2

ADU paper pass detector 2

MX-M753N SIMULATION 6 – 15

10

10-1

Purpose

Operation test/check

Function (Purpose) Used to check the operations of the toner

supply mechanism (toner clutch) and the

related circuit.

related circuit.

Section

Process (Developing)

Operation/Procedure

1)

1)

Press [EXECUTE] key.

The selected load operation is performed for 10 sec.

When [EXECUTE] key is pressed during operation, the opera-

tion is terminated.

The selected load operation is performed for 10 sec.

When [EXECUTE] key is pressed during operation, the opera-

tion is terminated.

NOTE: This simulation must be executed without installing the

toner cartridge and the toner hopper.

If this simulation is executed with the toner cartridge and

the toner hopper installed, toner will be forcibly supplied to

the developing unit, resulting in over toner.

If this simulation is erroneously executed with the toner car-

tridge installed, the over toner state may be canceled by

making several background copies.

If this simulation is executed with the toner cartridge and

the toner hopper installed, toner will be forcibly supplied to

the developing unit, resulting in over toner.

If this simulation is erroneously executed with the toner car-

tridge installed, the over toner state may be canceled by

making several background copies.

10-2

Purpose

Operation test/check

Function (Purpose) Used to check the operations of the toner

remaining quantity sensor and the related

circuits.

circuits.

Section

Process (Developing)

Operation/Procedure

1)

1)

Press [EXECUTE] key, and the toner motor 1 is driven for 10

sec.

* During execution of the simulation, each sensor name is

sec.

* During execution of the simulation, each sensor name is

highlighted. Only at the moment when a sensor is turned

ON, the sensor name is highlighted.

ON, the sensor name is highlighted.

NOTE: The TNFS check must be performed with the toner car-

tridge installed.

When this simulation is executed, toner is forcibly supplied

to the developer unit, resulting in an overtoner. Therefore,

do not execute this simulation continuously.

When this simulation is executed, toner is forcibly supplied

to the developer unit, resulting in an overtoner. Therefore,

do not execute this simulation continuously.

13

13--

Purpose

Cancel (Trouble etc.)

Function (Purpose) Used to cancel the self-diag "U1" trouble.

Section

Section

Operation/Procedure

1)

1)

Press [EXECUTE] key.

2)

Press [YES] key to execute cancellation of the trouble.

14

14--

Purpose

Cancel (Trouble etc.)

Function (Purpose) Used to cancel the self-diag "H3, H4, H5"

trouble.

Section

Operation/Procedure

1)

1)

Press [EXECUTE] key.

2)

Press [YES] key to execute cancellation of the trouble.

15

15--

Purpose

Cancel

Function (Purpose) Used to cancel the self-diag "F3-12, F3-22,

U6-09" trouble.

Section

LCC

Operation/Procedure

1)

1)

Press [EXECUTE] key.

2)

Press [YES] key to execute cancellation of the trouble.

16

16--

Purpose

Cancel (Trouble etc.)

Function (Purpose) Used to cancel the self-diag "U2" trouble.

Section

Section

MFP PWB / PCU PWB / SCU PWB

Operation/Procedure

1)

1)

Press [EXECUTE] key.

2)

Press [YES] key to execute cancellation of the trouble.

17

17--

Purpose

Cancel (Trouble etc.)

Function (Purpose) Used to cancel the self-diag "PF" trouble.

Section

Section

Operation/Procedure

1)

1)

Press [EXECUTE] key.

2)

Press [YES] key to execute cancellation of the trouble.

21

21-1

Purpose

Setting

Function (Purpose) Used to set the maintenance cycle.

Section

Section

Operation/Procedure

1)

1)

Select a target item of setting with [

] [] key on the touch

panel.

ADM1

ADU motor 1

ADM2

ADU motor 2

DGS

ADU gate solenoid

TNM1

Toner motor 1

TNM2

Toner motor 2

TFSD

Toner remaining quantity sensor

TNFS

Waste toner full sensor

MX-M753N SIMULATION 6 – 16

2)

Enter the set value with 10-key.

3)

Press [OK] key. (The set value is saved.)

22

22-1

Purpose

Adjustment/Setting/Operation data output/

Check

Check

Function (Purpose) Used to display the print count value of

each section and the operation mode.

Section

Operation/Procedure

22-2

Purpose

Adjustment/Setting/Operation data check

Function (Purpose) Used to display the number of total mis-

feed and the number of troubles.

Section

Operation/Procedure

The paper jam, trouble counter value is displayed.

The paper jam, trouble counter value is displayed.

22-3

Purpose

Adjustment/Setting/Operation data check

Function (Purpose) Used to display the mis-feed position and

the number of mis-feed at the position.

Section

Operation/Procedure

The paper jam and mis-feed history is displayed from the latest one

up to 50 items. (The old ones are deleted sequentially.)

The paper jam and mis-feed history is displayed from the latest one

up to 50 items. (The old ones are deleted sequentially.)

22-4

Purpose

Adjustment/Setting/Operation data check

Function (Purpose) Used to display the trouble (self diag) his-

tory.

Section

Operation/Procedure

The trouble history is displayed from the latest one up to 30 items.

(The old ones are deleted sequentially.)

The trouble history is displayed from the latest one up to 30 items.

(The old ones are deleted sequentially.)

22-5

Purpose

Other

Function (Purpose) Used to display the ROM version of each

unit (section).

Section

Firmware

Operation/Procedure

The ROM version of the installed unit in each section is displayed.

When there is any trouble in the software, use this simulation to

check the ROM version, and upgrade the version if necessary.

The ROM version of the installed unit in each section is displayed.

When there is any trouble in the software, use this simulation to

check the ROM version, and upgrade the version if necessary.

Item/Display

Content

Setting range

Default

value

A

MAINTENANCE

COUNTER

(TOTAL)

COUNTER

(TOTAL)

Maintenance

counter

(Total)

counter

(Total)

0 : Default

1 - 300: 1K - 300K

999 : Free

1 - 300: 1K - 300K

999 : Free

300K

Target

counter

Display

Content

Default

value

Display

range/

No. of

digits

Total output

quantity

TOTAL OUT

(BW)

Total output

quantity of black

and white

quantity of black

and white

0

Max. 8

Total use

quantity

TOTAL (BW)

Total use

quantity of black

and white

quantity of black

and white

0

Max. 8

TOTAL (COL)

Total use

quantity of full

color

quantity of full

color

0

Max. 8

Copy

COPY (BW)

Black and white

copy counter

copy counter

0

Max. 8

Print

PRINT (BW)

Black and white

print counter

print counter

0

Max. 8

Document

filing

DOC FIL (BW)

Black and white

document filing

print counter

document filing

print counter

0

Max. 8

Other

OTHER (BW)

Black and white

other counter

other counter

0

Max. 8

Maintenance

counter

MAINTENANCE

ALL

Maintenance

counter (Total)

counter (Total)

0

Max. 8

Fuser unit

FUSER UNIT

(U)

Fusing unit print

counter (Heat

roller upper)

counter (Heat

roller upper)

0

Max. 8

FUSER UNIT(L)

Fusing unit print

counter (Heat

roller lower)

counter (Heat

roller lower)

0

Max. 8

FUSER DAY(U)

Use day of

fusing unit (Heat

roller upper)

fusing unit (Heat

roller upper)

0

0 - 740

FUSER DAY(L)

Use day of

fusing unit (Heat

roller lower)

fusing unit (Heat

roller lower)

0

0 - 740

FUSER WEB

SEND (U)

Fuser web

cleaning send

counter

cleaning send

counter

0

Max. 8

FUSER WEB

UNIT (U)

Fuser web print

counter

counter

0

Max. 8

FUSER WEB

DAY (U)

Use day of fuser

web unit

web unit

0

0 - 740

FUSER WEB

SEND (L)

Fuser lower web

cleaning feed

counter

cleaning feed

counter

0

Max. 8

FUSER WEB

UNIT (L)

Fuser lower web

print counter

print counter

0

Max. 8

FUSER WEB

DAY (L)

Use day of fuser

lower web unit

lower web unit

0

0 - 740

Drum life

meter

DRUM LIFE (K)

Accumulated

number of drum

rotations (K)

number of drum

rotations (K)

0

0 - 100

(%) (

1%

unit)

Developer

life meter

DEVE LIFE (K)

Accumulated

number of

developer

rotations (K)

number of

developer

rotations (K)

0

0 - 100

(%) (

1%

unit)

Item/Display

Content

MACHINE JAM

Machine JAM counter

RSPF/DSPF JAM

SPFJAM counter

TROUBLE

Trouble counter

Item/Display

Content

S/N

Serial No. (The codes for November and December

are "X" and "Y" respectively.)

are "X" and "Y" respectively.)

ICU (MAIN)

ICU (Main section)

ICU (BOOT)

ICU (Boot section)

LANGUAGE

Language support data version

GRAPHIC

Graphic data for LCD

IMG DATA ROM

ImageASIC ROM data

PCU

PCU

Target

counter

Display

Content

Default

value

Display

range/

No. of

digits

Click on the first or last page to see other MX-M623U / MX-M753U (serv.man10) service manuals if exist.