Sharp AR-M351U / AR-M451U (serv.man11) Service Manual ▷ View online

AR-M351U/M451U, AR-M355U/M455U MAINTENANCE AND DETAILS OF EACH SECTION 7 - 6

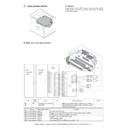

[OPC drum section]

A. General

In this section, laser beams are radiated to the OPC drum surface

which was negatively charged, making electrostatic latent images.

which was negatively charged, making electrostatic latent images.

B. Major parts and signal functions

DM

PSPS

+24V1

PSPS\

1

1

2

2

PHNR-02-H+BU02P-TR-P-H

8FE-BT-VK-N

DSW-L

DM-T

DM\

5

6

DSW-L

GND1

3

2

1

4

GND1

DMCLK\

(NC)

8

7

PCU PWB

1

2

3

4

5

6

7

8

DM-T

GND2

DM\

CN6

GND2

DSW-F

DSW-F

DMCLK\

9604S-08C

(NC)

1

2

3

4

5

6

7

8

CN5

+24V1

CRUCLK

+5VCRU

GND2

CRUSDA

PSPS\

(NC)

B8B-PH-K-S

+24V1

1

DVREM\

DHVREM

MHVREM\

THV+PWM\

6

4

13

14

12

GND2

3

7

8

9

10

5

GBPWM\

11

CN15

DSW-F

THin

DHVPWM\

THV-PWM\

THVREM\

2

DVPWM\

9604S-14F

GND2

MHV-T

RD

GR

BL

YL

WH

HV

1

DVREM\

DHVREM

MHVREM\

THV+PWM\

6

4

13

14

12

GND2

3

7

8

9

10

5

GBPWM\

11

DSW-F

THin

DHVPWM\

THV-PWM\

THVREM\

2

DVPWM\

1-84432-4(AMP)

GND2

MHV-T

PS-187

SRA-21T-4L

BIAS

PS-187

PS-187

PS-187

WH

WH

MHV

THV

GB

DHV

DV

RD

PS-187

SRA-21T-3

SRA-21T-4L

RD

SRA-21T-3

8

3

1

2

2

5

4

9

7

6

Code

Signal

name

Name

Function/Operation

Type

Note

DM

DM

OPC drum motor

Drives the OPC drum and the transfer section.

DC brushless motor

PSPS

PSPS

Drum separation pawl solenoid

Drives the OPC drum separation pawl

Solenoid

No.

Name

Operation

1

OPC drum

Forms electrostatic latent images by laser beams.

2

Drum separation pawl

Separates paper from the drum.

3

Sub blade (Cleaning seal)

Prevents against toner leakage from the cleaner section.

4

Screen grid

Helps to charge the OPC drum evenly with electric charges provided from the main charger.

5

Saw-teeth charger

Applies a high voltage to charge the OPC drum.

6

Separation pawl oscillation shaft

Moves in the front and rear frame direction to install the separation pawl.

7

Cleaning blade

Cleans remaining toner on the OPC drum.

8

Waste toner transport pipe

Transports toner from the cleaner unit to the waste toner box in the toner cartridge front section.

9

Cleaning unit

Saw teeth charger is cleaned.

AR-M351U/M451U, AR-M355U/M455U MAINTENANCE AND DETAILS OF EACH SECTION 7 - 7

C. Operational descriptions

The OPC drum surface is negatively charged by the main charger.

The laser beam images are radiated to the OPC drum surface by

the laser unit to form latent electrostatic images.

The laser beam images are radiated to the OPC drum surface by

the laser unit to form latent electrostatic images.

1) The OPC drum surface is negatively charged by the main

charger.

The main charger grid is provided with the screen grid. The

OPC drum is charged at a voltage virtually same as the volt-

age applied to the screen grid.

OPC drum is charged at a voltage virtually same as the volt-

age applied to the screen grid.

2) LED lights are radiated to the OPC drum surface by the laser

unit to form latent electrostatic images.

When LED lights are radiated to the OPC drum CGL, negative

and positive charges are generated.

and positive charges are generated.

Positive charges generated in CGL are attracted to the nega-

tive charges on the OPC drum surface. On the other hand,

negative charges are attracted to the positive charges in the

OPC drum aluminum layer.

tive charges on the OPC drum surface. On the other hand,

negative charges are attracted to the positive charges in the

OPC drum aluminum layer.

Therefore, positive charges and negative charges are bal-

anced out on the OPC drum and in the aluminum layer, reduc-

ing positive and negative charges to decrease the OPC drum

surface voltage.

anced out on the OPC drum and in the aluminum layer, reduc-

ing positive and negative charges to decrease the OPC drum

surface voltage.

Electric charges remain at a position where LED lights are not

radiated.

radiated.

As a result, latent electrostatic images are formed on the OPC

drum surface.

drum surface.

3) After transfer operation, remaining toner is removed by the

cleaning blade.

Residual toner removed from the OPC drum surface is trans-

ported to the recycle toner collection section in the toner car-

tridge by the waste toner transport screw.

ported to the recycle toner collection section in the toner car-

tridge by the waste toner transport screw.

4) All the surface of the OPC drum is discharged by laser beams.

After completion of the job, laser beams are radiated onto al

the surface of the OPC drum.

When laser beams are radiated onto the CGL of the OPC

drum, positive and negative charges are generated.

the surface of the OPC drum.

When laser beams are radiated onto the CGL of the OPC

drum, positive and negative charges are generated.

Positive charges generated in CGL are attracted to the nega-

tive charges on the OPC drum surface. On the other hand,

negative charges are attracted to positive charges in the alu-

minum layer of the OPC drum.

tive charges on the OPC drum surface. On the other hand,

negative charges are attracted to positive charges in the alu-

minum layer of the OPC drum.

Therefore, positive and negative charges are balanced out on

the OPC drum surface and in the aluminum layer, reducing

positive and negative charged to decrease the surface voltage

of the OPC drum.

the OPC drum surface and in the aluminum layer, reducing

positive and negative charged to decrease the surface voltage

of the OPC drum.

Aluminum

layer

OPC drum

CTL

CGL

High voltage unit

Main corona unit

Screen grid

OPC drum

LED lights

Aluminum

layer

OPC drum

CGL

CTL

Drum

LED lights

CLT

CGL

Aluminum

layer

Aluminum

layer

CLT

CGL

CGL

AR-M351U/M451U, AR-M355U/M455U MAINTENANCE AND DETAILS OF EACH SECTION 7 - 8

D. Maintenance and parts replacement

(1) Maintenance list

(2) Maintenance and parts replacement

a. Drum cartridge

1) Release the lock, and pull out the left door.

2) Open the front door.

3) Put down the DV guide handle. Loosen the screw, and remove

the drum cartridge.

Unit name

No.

Part name

When

calling

100K 200K 300K 400K 500K 600K 700K 800K

Remark

Drum

peripheral

peripheral

1

Drum

✕

▲

✕

▲

✕

▲

✕

▲

Replace at 200K or 1 year.

2

DSD collar

❍

❍

❍

❍

❍

❍

❍

❍

3

Cleaner blade

✕

▲

✕

▲

✕

▲

✕

▲

4

Toner reception seal

✕

▲

✕

▲

✕

▲

✕

▲

5

Side molt F

✕

▲

✕

▲

✕

▲

✕

▲

Apply side seal powder.

6

Side molt R

✕

▲

✕

▲

✕

▲

✕

▲

Apply side seal powder.

7

Drum separation pawl unit

✕

▲

✕

▲

✕

▲

✕

▲

8

MC unit

✕

❍

▲

❍

▲

❍

▲

❍

▲

Includes the screen grid, the

charging plate, and the MC

cleaner.

charging plate, and the MC

cleaner.

❍

: Charging plate cleaning by

the MC cleaner

1

7

2

4

6

2

5

3

8

No.

Unit

Parts

a

Drum cartridge

1

MC unit

×

❍

2

Drum

▲

3

DSD collar

❍

4

Drum separation pawl unit

×

5

Toner reception seal

×

6

Cleaner blade

×

7

Side molt F

×

8

Side molt R

×

b

1

Separation solenoid

a-2

a-4

a-3

a-7

a-6

a

a-1

a-3

b-1

a-5

a-8

AR-M351U/M451U, AR-M355U/M455U MAINTENANCE AND DETAILS OF EACH SECTION 7 - 9

a-1. MC unit

1) Remove the drum cartridge.

2) Check to confirm that the cleaning unit is inserted fully to the

bottom.

3) Remove the pawl, and remove the MC unit.

∗

For cleaning the MC unit (charging plate), reciprocate the clean-

ing unit back and forth 3 times or more.

ing unit back and forth 3 times or more.

a-2. Drum

a-3. DSD collar

1) Remove the drum cartridge.

2) Loosen the screw, and remove the drum boss mounting plate.

3) Remove the drum, and remove the DSD collar.

∗

When removing the drum, place the drum cartridge as shown in

the figure and remove the drum.

the figure and remove the drum.

∗

When replacing the OPC drum, clear the following counters.

• Drum rotating time

• Drum counter

∗

When installing a new drum, apply starting powder.

∗

When installing, install the DSD collar R to the drum frame, then

install the drum and the DSD collar F. When installing the DSD

collar, engage the DSD collar boss with the drum frame hole.

install the drum and the DSD collar F. When installing the DSD

collar, engage the DSD collar boss with the drum frame hole.

a-4. Drum separation pawl unit

1) Remove the drum cartridge.

2) Remove the screw, and remove the drum separation pawl

unit.

∗

When handling the separation pawl, be careful not to break or

scratch the tip of the separation pawl and keep it away from dirt.

scratch the tip of the separation pawl and keep it away from dirt.

After installing the drum separation pawl unit, push the separation

lever and check to confirm that the separation pawl operates nor-

mally.

lever and check to confirm that the separation pawl operates nor-

mally.

a-5. Toner reception seal

1) Remove the drum cartridge.

2) Remove the drum and the DSD collar.

3) Remove the drum separation pawl unit.

4) Remove the screw, and remove the toner reception seal.

∗

When installing the toner reception seal, tighten the screw (a)

on the positioning side for the first time. Check to confirm that

the process earth plate and the toner reception seal are conduc-

tive. (10

on the positioning side for the first time. Check to confirm that

the process earth plate and the toner reception seal are conduc-

tive. (10

Ω

or less)

(a)