Sharp AR-M351U / AR-M451U (serv.man13) Service Manual ▷ View online

AR-M351U/M451U, AR-M355U/M455U MAINTENANCE AND DETAILS OF EACH SECTION 7 - 33

3) Remove the E-ring, the gear, and the spring.

4) Remove the screw, and remove the lift-up motor.

4. Transport section/Paper exit reverse

section

A. General

In this paper transport section, paper fed from each paper feed

port is transported to the resist roller section, where the lead edge

of the paper is aligned with the lead edge of images on the OPC

drum. Images are transferred onto paper in the transfer section,

and the paper is discharged face-up or face-down through the fus-

ing section.

port is transported to the resist roller section, where the lead edge

of the paper is aligned with the lead edge of images on the OPC

drum. Images are transferred onto paper in the transfer section,

and the paper is discharged face-up or face-down through the fus-

ing section.

AR-M351U/M451U, AR-M355U/M455U MAINTENANCE AND DETAILS OF EACH SECTION 7 - 34

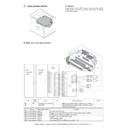

B. Major parts and signal functions

DSW-F

MM-T

GND2

+5V1

GND2

MM\

9604S-08C

1

2

3

4

5

6

7

8

CN9

DSW-F

GND2

SMR-06V+SMP-06V-NC

/POMB

4

/POMXB

/POMA

/POMXA

+24V1

3

1

1

6

5

2

3

2

5

4

+24V1

6

BR

BR

BR

BR

RD

RD

HVR

PWB

GY

HVR

PWB

GY

SFPS-41T-187

RD

RD

PHNR-03-H+BU03P-TR-P-H

+24V1

3

1

3

VFM2\

2

GND2

1

2

RD

GY

BR

PHNR-03-H+BU03P-TR-P-H

BR

PHR-3

CFM1\

BR

DRAWER

PWB

+24V1

1

2

3

RD

3

3

+24V1

1

4

GY

1

2

2

TSR-04V-K

CFM1\

+24V1

3

RD

CFM1\

GND2

GND2

GY

2

GND2

1

GND2

BR

GY

GY

RD

+24V1

RRC\

1

1

2

2

PHNR-02-H+BU02P-TR-P-H

RD

BR

+24V1

TRC1\

1

1

2

2

(NC)

3

3

PHNR-03-H+BU03P-TR-P-H

RD

BR

GND2

+5V2

GND2

GND2

PED

+5V2

+5V2

LUD

PPD1

1

2

3

4

5

6

7

8

9

1

2

3

4

5

6

7

8

9

PHNR-09-H+BU09P-TR-P-H

BL

GY

BR

2

+5V2

PPD1

1

GND2

2

PPD1

1

3

3

1

GND2

+5V2

3

179228-3(AMP)

2

PHNR-03-H+BU03P-TR-P-H

GY

BL

BR

BL

BR

GY

POD1

GND2

1

2

3

179228-3

+5V2

3

2

179228-3

POD2

1

GND2

+5V2

3

POD3

179228-3

GND2

2

1

POD1

+5V2

GND2

2

1

2

SMP-03V-BC+SMR-03V-B

3

1

3

BL

GY

BR

GY

GY

GY

GY

BL

BL

BL

BL

BR

BR

BR

BR

+5V2

DSW-L

MM-T

GND2

+5V2

GND1

MM\

8

7

6

5

4

3

2

1

DSW-L

GND1

8FE-ST-VK-N

MM

POM

POD3

POD2

POD1

DSW-L

RRC

VFM2

PPD1

TRC

CFM1

POD3

POD1

POD2

/POMA

/POMXA

GND2

/POMXB

+5V2

/POMB

2

3

4

5

6

7

8

9

10

11

12

13

14

CN4

CFM2\

1

+24V1

+24V1

DSW-L

15

16

17

18

+5V2

GND2

+5V2

19

20

21

22

GND2

+24V1

+24V1

TRC\

LUMA

PED

CPFC\

PPD1

CSS

LUMB

LUD

RRC\

GND2

+5V2

GND2

+24V1

18

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

GND

19

20

GND2

+5V2

+5V2

GND2

21

22

23

24

+24V1

CFM1\

GND2

GND2

+24V1

GND2

+24V1

23

24

25

26

27

28

29

30

32

31

+24V1

VFM2\

+24V1

GND2

(NC)

GND2

(NC)

DSW-L

(NC)

(NC)

DSW-F

RD

GY

BL

RD

BR

BR

BR

BR

RD

GY

GY

BL

RD

RD

GY

GY

GY

BL

BL

RD

RD

RD

GY

BR

BR

BR

BR

BR

BR

BR

CFM2\

B24B-PHDSS-B

B32B-PHDSS-B

CN13

PCU PWB

5

2

4

1

5

4

3

2

1

Code

Signal

name

Name

Function/Operation

Type

Note

POD1

POD1

Paper exit detector 1

Paper exit detection from fusing

Transmission

type

type

Paper transport system sensor

POD2

POD2

Paper exit detector 2

Paper pass detection from paper exit

Transmission

type

type

Paper transport system sensor

POD3

POD3

Paper exit detector 3

Paper exit detection to upper section

paper exit tray (Full detection)

paper exit tray (Full detection)

Transmission

type

type

Paper transport system sensor

POM

POM

Paper exit motor

Drives the paper exit roller.

Stepping

motor

motor

Selection of Normal speed/

High speed/ Reverse rotation

High speed/ Reverse rotation

VFM2

VFM2

Fusing cooling fan motor

Discharges heat generated in the

fusing section.

fusing section.

DC brushless

motor

motor

PWM control

CFM1

CFM1

Fusing cooling fan motor

Discharges heat generated in the

fusing section to cool it.

fusing section to cool it.

DC brushless

motor

motor

PWM control

AR-M351U/M451U, AR-M355U/M455U MAINTENANCE AND DETAILS OF EACH SECTION 7 - 35

C. Operational descriptions

[Paper transport path and paper exit]

Paper transport path with an option installed

1.

2.

Code

Signal

name

Name

Function/Operation

Type

Note

RRC

RRC

Resist roller clutch

Resist roller ON/OFF control

Electromagnetic

clutch

clutch

TRC

TRC

Paper transport roller clutch

Paper transport roller ON/OFF control

Electromagnetic

clutch

clutch

MM

MM

Main motor

Drives the paper transport and resist roller

DC brushless

motor

motor

Paper pass

No.

Name

Function

1

Transport roller 15

Transports paper to the transport resist roller.

2

Resist roller (Drive)

Transports paper to the transfer section. / Controls the transport timing of paper to adjust the

relationship between images and paper.

relationship between images and paper.

4

Paper exit and transport roller

Transports paper from the fusing roller to the paper exit roller.

5

Paper exit roller

Discharges paper to the paper exit tray. / Switchbacks paper.

Option

Model name

Desk

AR-D27

Duplex unit

AR-DU4

Finisher

AR-FN6

Option

Model name

Desk

AR-D27

Duplex unit

AR-DU3

Finisher

AR-FN7

Male bin stacker

AR-MS1

Punch unit

AR-PN1

AR-M351U/M451U, AR-M355U/M455U MAINTENANCE AND DETAILS OF EACH SECTION 7 - 36

3.

Paper transport in duplex printing (with AR-DU3/DU4 installed)

(1) Switchback operation and paper exit to the left tray

1) Paper transported from the fusing section is sent to the paper exit section of the machine.

2) When the male bin stacker (AR-MS1) or the finisher (AR-FN5) is installed, the paper entry gate solenoid (FGS) selects the paper entry

gate to discharge paper outside the machine.

3) The paper exit sensor (POD2) detects the rear edge of paper, and the paper exit motor (POM) is rotated reversely.

4) Paper is taken into the machine again, passed over the reverse gate, and transported to the duplex unit.

5) When duplex printing is made, the ADU gate solenoid switches to the upper side of the ADU paper exit gate to switch the paper path to

the ADU.

6) When paper is discharged to the left tray or when paper is transported to the console finisher (AR-FN7), the ADU gate solenoid

switches to the upper side of the ADU paper exit gate to switch the paper path to the ADU.

(2) Paper transport speed in duplex printing

The transport speed may be doubled in duplex printing depending on the paper position.

The positions of double speed are as follows:

1) From when the rear edge of paper passes the fusing section to when switchback operation is started.

2) From switchback operation, after the lead edge of paper passes APPD1, until a certain amount is transported.

3) After that, paper is stopped at the ADU paper feed position, and fed to the laser printer again.

4.

Transport with AR-FN6 installed

The AR-FN6 is provided with the decurler to improve alignment capability of finishing.

The decurler makes decurling against curling of paper by means of the difference in rigidity of the upper roller (metal) and the lower roller

(sponge).

(sponge).

Metal

Sponge