Sharp AR-651 (serv.man58) Service Manual / Technical Bulletin ▷ View online

ARE543

Sharp Electronics (UK) Ltd., Technical Services Group

Additions and Changes in [Service Handbook] (Changes related to this upgrade)

1. Codes 309 and 370 were added.

2. The default for the codes 365 and 366 was changed from [50] to [60].

2. The default for the codes 365 and 366 was changed from [50] to [60].

05 Code

Code

Items adjusted

Target

Functions

Default

Toleranc

e

Description

Operating

Procedure

309

Carriage

packagingpositi

on

packagingpositi

on

ALL

---

---

If this code is executed, the

carriage for scanner moves

to the packaging area and

the power is automatically

turned off

carriage for scanner moves

to the packaging area and

the power is automatically

turned off

6

370

RADF scanned

position

position

ALL

2

0^10

0: Reference Position

1^10: The position where

the original data is scanned

moves to the paper

delivery side by x 0.5mm.

1^10: The position where

the original data is scanned

moves to the paper

delivery side by x 0.5mm.

365

RADF leading

edge position

(In simplex

mode)

edge position

(In simplex

mode)

ALL

60

0^100

366

RADF leading

edge

position(In

duplex mode)

edge

position(In

duplex mode)

ALL

60

0^100

1

Note) When the RADF original data scanned position is changed in 05-370, please be sure to do [05-365] and [05-

366] to adjust the ADF leading edge position at the same time. Also, please be sure to use the Ver.07 or later

for the scanner ROM in combination with other ROMs.

3. Codes 219, 304, 502, 635, 681were added.

4. The default for the code 300 was changed from [0^3] to [0^4].

08 Code

4. The default for the code 300 was changed from [0^3] to [0^4].

08 Code

Code

Items adjusted

Target

Functions

Default

Toleranc

e

Description

Operating

Procedure

219

ON/OFF

switching of

Control Panel

LCD in power

save mode.

switching of

Control Panel

LCD in power

save mode.

ALL

0

0^1

Enabled on the machine only for

JapanThis code can change the

state of the LCD back light

(On/Off) in power save mode.

0: LCD ON

1: LCD OFF

JapanThis code can change the

state of the LCD back light

(On/Off) in power save mode.

0: LCD ON

1: LCD OFF

300

MAX9

ALL

0

0^4

The numbers of digit for the

maximum numbers of copies can

be selected.

0: 9999

1: 999

2: 99

3: 9

4:Limited according to the value in

maximum numbers of copies can

be selected.

0: 9999

1: 999

2: 99

3: 9

4:Limited according to the value in

08-304

304

Setting for the

maximum

numbers of

copies

maximum

numbers of

copies

PPC

9999

0^9999

In case the value in 08-300 is [4],

this code is enabled.

If any value is set in this code, this

is the maximum limit of numbers

of copies.

this code is enabled.

If any value is set in this code, this

is the maximum limit of numbers

of copies.

502

Setting for

switching the

image process

system in photo

mode

switching the

image process

system in photo

mode

ALL

1

0^1

Switching Setting for the image

process system in photo mode

0: Error Diffusion

1: Dithering

process system in photo mode

0: Error Diffusion

1: Dithering

635

Numbers of

Audit Account

ControlSelectio

n for 150 / 500

Audit Account

ControlSelectio

n for 150 / 500

ALL

1

0^1

Switching Setting for the numbers

of Audit Account Control

0: 150

1: 500

of Audit Account Control

0: 150

1: 500

681

AR-P15:Setting

for switching the

compressionme

thod of

scanneddata

for switching the

compressionme

thod of

scanneddata

PRT

0

0^1

AR-P15:Switching Setting for the

compressionmethod of scanned

data

0: Judged/Controlled via Controller

1: Fixed in JBIG

compressionmethod of scanned

data

0: Judged/Controlled via Controller

1: Fixed in JBIG

1

Note) - In [08-219], it is possible to turn the LCD backlight off in power save mode in order to efficiently save the

energy consumption on 55/65 cpm model.

Originally, the LCD backlight was turned off on 55/65 cpm model but turned on for 81 cpm model, however,

from now on the control system was changed so that this was able to be set in this code. For the factory

setting, [OFF] is set for the LCD backlight of the model for local market in Japan in power save mode.

(Please note that this is disabled on the models for overseas market although it is possible to operate this code.)

from now on the control system was changed so that this was able to be set in this code. For the factory

setting, [OFF] is set for the LCD backlight of the model for local market in Japan in power save mode.

(Please note that this is disabled on the models for overseas market although it is possible to operate this code.)

ARE543

Sharp Electronics (UK) Ltd., Technical Services Group

- In case that [1] is set for the code [08-502], please be sure to use the Scanner ROM (Ver.07 or later) for

combination.

5.Change of Default in All Clear

1) PM Support Mode related code (08) * Default is mentioned for e-STUDIO

550/650/810 in order.

Standards for Change (Tolerance: 0~99999999)

Code<Procedure>

Default (×1000)

Tandem LCF Pickup Roller

2302<1>

300/300/300

400/400/400

Tandem LCF Paper

Feed Roller

Feed Roller

2322<1>

300/300/300

400/400/400

Tandem LCF Separation

Roller

Roller

2342<1>

300/300/300

400/400/400

2) Adjustment Mode (05)

Code

Item Adjusted

Target Function

Default

Tolerance

676-4

PRT

10

7

0~10

677-4

Printer Image

Density

Adjustment

Toner Save

PRT

10

7

0~10

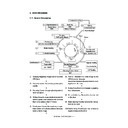

6. Addition of Check function for Middle Transfer Sensor Input Data

Input Data Check (Test Mode 03)

[OFF] in [Power Save] Key (LED for [Power Save] is turned off.)

Numeric keypad

Icon

Items

Conditions in highlighted display

[6]

A

Middle Transfer

Sensor

No Paper

ARE543

Sharp Electronics (UK) Ltd., Technical Services Group

ROM Upgrade (1)

From September 2002 Production

ROM

System ROM

UI ROM

Main ROM

Laser

ROM

Scanner

ROM

PFC ROM

RADF ROM

Version

005

005

005

08

06

06

06

02

Corrected Problems

1) Under the setting of 4in1 (simplex/simplex original)/saddle stitch (left side) using 4-page original (Letter) and 4

Letter size sheets, if the width of saddle stitch was set from 11mm to 15mm, the lower side of the original data

for the first and the second pages was not copied. This was corrected. (The same symptom experienced

when the width of saddle stitch is 5mm was also corrected.)

for the first and the second pages was not copied. This was corrected. (The same symptom experienced

when the width of saddle stitch is 5mm was also corrected.)

2) The accuracy was improved for time monitoring process when the mode is switched to sleep mode and off-

mode.

3) After the printing operation stopped because the temperature is lowered during copying and when the copying

process was started, E09 Jam may be experienced. This was corrected.

4) Problem when input data for APS sensor was checked. (Only for LT series)

5) When the original data on the glass was scanned with the scaling 270% ~ 290% for B5 size and 285% ~ 290%

5) When the original data on the glass was scanned with the scaling 270% ~ 290% for B5 size and 285% ~ 290%

for 16K size, the carriage was not properly operated. This was corrected.

6) The error code [C85] was indicated as [C81]. This was corrected.

7) When the finisher was used, if the 8K size data is printed in duplex mode, the paper jam may be experienced.

7) When the finisher was used, if the 8K size data is printed in duplex mode, the paper jam may be experienced.

This was corrected.

8) The scanned speed is improved for scaled down data printing, so the situation was improved so that the data

can be read more than 65 pages / mins regardless of any resolution if the network scan mode is used.

Note) To correct the following problem, the OS related section has to be corrected. Therefore, in order to

incorporate the corrections on the previous SYS-ROM version, it is necessary to download it using the jig.

It is impossible to incorporate the corrections even using the PC downloading method. When downloaded

with PC, if #5 is selected in 39 mode, 10, 11, 12, 13(Printer, PFC, Laser, Scanner) should be serially

updated, however, only the items from 10 to 12 were serially updated. This was corrected.

It is impossible to incorporate the corrections even using the PC downloading method. When downloaded

with PC, if #5 is selected in 39 mode, 10, 11, 12, 13(Printer, PFC, Laser, Scanner) should be serially

updated, however, only the items from 10 to 12 were serially updated. This was corrected.

(Regarding the PC downloading method, please see the Service Handbook 6-1 page or later.)

Spec Change

1) The operation was suspended while the data was input; the message [Press Start] was indicated. This was

corrected.

2) The spec was changed so that the user can input the selection even when the mode was being recovered

(during warm-up) from sleep mode.

3) The spec was changed so that the combination with [Page serial printing] and [Booklet] was prohibited.

4) In the [HELP] screen indicated when the jam is experienced, the display for [HELP] was changed depending on

4) In the [HELP] screen indicated when the jam is experienced, the display for [HELP] was changed depending on

the situation where the option LCF is installed or not.

5) The spec was changed so that the paper size placed in the Inserter is automatically recognized when the paper

size for Inserter is set.

6) The highlighted indication for tab section for [QUICK] menu selection was changed.The situation was changed

so that the [QUICK] tab is indicated in black in white, and other tabs such as [BASIC][EDIT] are indicated in

white in black when the [QUICK] tab is selected (Currently, the color for black and white is reversed.)

white in black when the [QUICK] tab is selected (Currently, the color for black and white is reversed.)

7) The control system for the model for Taiwan/Saudi Arabia was added.

For TWD,SAD: 08-849 = 1. Except TWD,SA: 08-849 = 0

8) Default Change: Adjustment mode (05)

9) The spec was changed so that the machine indicates the message “Service recommended for SPC” when the

power is turned on again after the V0 sensor failure is experienced.

10) The adjustment method of the printing start position for front side was changed.1. Please take in the setting

value for [05-410] and [05-411] on Laser ROM Ver. 05 2. After the version for Laser ROM is updated to Ver.

06, please add [70] to the value taken in the step (1) above for setting.

06, please add [70] to the value taken in the step (1) above for setting.

11) The performance for the switching operation to each cassette was improved if the copy mode is selected.

[Note] These have been included from the version combination above-mentioned or later.

[Note] These have been included from the version combination above-mentioned or later.

ARE543

Sharp Electronics (UK) Ltd., Technical Services Group

Addition and Change on [Service Handbook] (Change related to this upgrade)

1. Deleted codes for 03:

03-238 System Fan ON/OFF

03-219 Exit Fan ON/OFF

03-219 Exit Fan ON/OFF

2. Additional codes for 03

Code

Function

Procedure

236

Paper Delivery Fan Motor: High Speed ON/OFF

3

237

Paper Delivery Fan Motor: Low Speed ON/OFF

3

241

System Fan Motor: High Speed ON/OFF

3

242

System Fan Motor: Low Speed ON/OFF

3

3. Additional codes for 08

Code

Name

Function

Default

Acceptable

Value

Value

Contents

Operation

Procedure

Procedure

331

Selection of

preferential screen

after the auto clear

period is

completed

preferential screen

after the auto clear

period is

completed

ALL

0

0,2

The screen indicated

after the auto clear

period is finished, or

after the mode is

recovered from the

power save mode or

the sleep mode is

selected.

(This is supported

when GA1140 is

installed)

0: Copy

2: Printer/Network

after the auto clear

period is finished, or

after the mode is

recovered from the

power save mode or

the sleep mode is

selected.

(This is supported

when GA1140 is

installed)

0: Copy

2: Printer/Network

1

849

Switching of fuser

control method for

TWD, SAD

control method for

TWD, SAD

ALL

0

0^1

This is the code for

switching the model

to the A series 115V

model. Please set [0]

for this setting.

0: Disabled

1: Enabled

switching the model

to the A series 115V

model. Please set [0]

for this setting.

0: Disabled

1: Enabled

1

4. Changed code for 08

08-206: Auto Off Time Setting

Initial value was changed from 9(60mins) to 12(90mins).

Initial value was changed from 9(60mins) to 12(90mins).

Display