Sharp SD-CX1 (serv.man5) Service Manual ▷ View online

SD-CX1H

– 32 –

Rotating the loading motor forcibly

The loading motor can be rotated forcibly by rotating the VOL

UP/DOWN button while STOP or EJECT in the test mode

appears on the display.

UP/DOWN button while STOP or EJECT in the test mode

appears on the display.

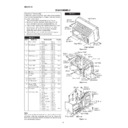

Check of the magnetic head fixing position

• Be sure to check the fixing position of the magnetic head

when replacing the magnetic head and the optical pickup.

• Move the optical pickup to the center in order to make the

fixing position adjustment easy.

1. Secure the magnetic head to the optical pickup with

screw (B1) x 1 pc.

2. Set the transparent disc for checking the head.

3. Lower the magnetic head up shift arm manually to lower

3. Lower the magnetic head up shift arm manually to lower

the magnetic head.

4. Check whether the magnetic head aligns with the optical

pickup objective, seeing the set from above.

5. Check that the magnetic head goes up and down

smoothly. (See Fig. 32-2.)

Figure 32-2

Figure 32-3 Optical Pickup Grating Deviation

Measuring Method

Mechanism Adjustment

1. Optical pickup grating inspecting method

After auto adjustment (COMPLETE appears) in the test mode

(auto) using the high reflection MD disc TGYS1, adjust the

Lissajou's waveform (x-y) of EOUT to FOUT.

1. Slightly loosen the 3 screws of the spindle motor, adjust

(auto) using the high reflection MD disc TGYS1, adjust the

Lissajou's waveform (x-y) of EOUT to FOUT.

1. Slightly loosen the 3 screws of the spindle motor, adjust

while observing the Lissajou's waveform.

2. After adjustment, tighten screws 1, 2, and 3 in numerical

order. (See Fig. 32-4)

Figure 32-4

It is lowered

by hand.

by hand.

(B1)x1

ø1.7x 5mm

ø1.7x 5mm

Magnetic head up shift arm

Down

Magnetic head

Objective

lens

Radiai

Tangential

direction

Optical Pickup

GND CH1

CH2

X

Y

100K

470p

470p

a

b

100K

Osilloscope

Lissajous's waveform

4 Pin of IC1201

GND (TP1202)

11 Pin of IC1201

EIN (TP1253)

12 Pin of IC1201

FIN (TP1254)

Less then a:b = 4:1

2

3

1

2

3

1

adjusting

hole

hole

Check the Lissajou's waveform,

shifting the mounting position with

a screwdriver (to be fitted into the

spindle motor adjusting hole).

shifting the mounting position with

a screwdriver (to be fitted into the

spindle motor adjusting hole).

Spindle Motor

Spindle Motor

Figure 32-1

2. Confirmation

Check that the display shows "_COMPLETE_" instead of

"#COMPLETE_" in step 4 of the AUTO adjustment mode.

"#COMPLETE_" in step 4 of the AUTO adjustment mode.

(A1) X1

A

B

MD Mechanism

Switch PWB

Switch PWB

Lead In Switch

1. Adjustment

Load a high-reflective TYGS1 test disc.

Note:

Adjust the position of the lead-in switch between FF85 to

FFD2.

1. Loosen the screw (A1) x 1 pc., fixing the mechanism

Note:

Adjust the position of the lead-in switch between FF85 to

FFD2.

1. Loosen the screw (A1) x 1 pc., fixing the mechanism

switch PWB.

2. Retighten the screw while pushing the PWB in the

direction of arrow A if the switch position is at FF85 or

lower, or in the direction of arrow B if it is at FFD2 or

higher, and measure its position again.

After adjusting the position, fix it with the screw (A1) x 1

pc. (See Fig. 32-1)

lower, or in the direction of arrow B if it is at FFD2 or

higher, and measure its position again.

After adjusting the position, fix it with the screw (A1) x 1

pc. (See Fig. 32-1)

– 33 –

SD-CX1H

Can't REC

• Errors occurred 10 times continuously in the REC-PLAY

• Check for scratch, dust, fingerprints, or black spots on

mode.

the disc. Check that the disc is not eccentric or largely

• In the REC-PLAY mode, recording enable cluster became

deflected.

0 due to errors.

• Cannot read the address. The unit cannot enter the REC

mode for 20 seconds regardless of repetitive tries.

Can't COPY

• During the REC-PAUSE or REC-PLAY mode, the disc was

• Check if it is the copy-prohibited disc (Example: CD-R

judged as follows according to the channel status of the

etc.).

digital signal input at D-IN:

1 It is not an audio disc.

2 It is not for public use.

3 Due to the inversion of COPY bit on the CD, the

1 It is not an audio disc.

2 It is not for public use.

3 Due to the inversion of COPY bit on the CD, the

contents cannot be copied.

NO SIG.

• During the REC-PAUSE, REC-PLAY, or CD FUNC playback

• Check for an abnormality with the D-IN signal line.

mode, the following occurred responding to the digital signal

input at D-IN:

1 Digital IN PLL is unlocked.

2 PLL is locked even if FS is not 44.1 kHz.

input at D-IN:

1 Digital IN PLL is unlocked.

2 PLL is locked even if FS is not 44.1 kHz.

TOC FULL

• There is no space left for track numbers or character

• Replace the disc with the one on which the space for

information (track names, disc name, etc.).

recording UTOC is left.

• No recordable space was found when entering the REC-

PAUSE mode.

Can't u READ

• FTNO > LTNO has been recognized.

• There is an error with UTOC data. Replace the disc.

• FTNO is not 0 or 1.

• Cannot read UTOC recorded on the disc.

• Cannot read UTOC recorded on the disc.

TOC FROM a

• The start address > end address has been recognized.

• There is an error with UTOC data. Replace the disc.

TOC FROM L0-4

• One of UTOC 0-4 data is looping.

• There is an error with UTOC data. Replace the disc.

NOT AUDIO

• Non-audio data is recorded in the track mode of currently

• Select another track number or replace the disc.

selected track number.

? DISC

• The ASCII codes data "MINI" of the system ID written in

• This is a non-standard disc. Replace the disc and

TOC is not correct.

check.

• The disc type written in TOC does not belong to either of

the pre-master MD, recording MD or hybrid MD.

DISC FULL

• No recordable space was found when entering the REC-

• Replace the disc with the one on which the recording

PAUSE mode.

space for UTOC is left.

PROTECT

• You tried recording or editing on a disc with the erase-

• Move the tab back to its original position and try

prevention tab moved.

recording or editing again.

• You tried editing the track that is write-protected due to the

* Try editing other tracks that are not write-protected.

information written in UTOC.

Can't EDIT

• Conditions in each editing function have not been satisfied. • The unit is not operated properly. Try again in right

procedures.

TEMP OVER

• The temperature inside of the set (MD unit) becomes too

• Check the remedy on the troubleshooting chart.

high due to an error.

• Is the unit used in a place of high temperature?

Can't READ

• The read data is not correct, or data has not been

• There may be an error in TOC or UTOC data or

( : Number or

read properly.

scratches on the disc. Replace the disc.

symbol)

• An error occurred while recording sound data, and

the recording could not be completed.

Can't s READ

• The read data is not correct.

• TOC information on the disc does not comply with the

r READ

• TOC information cannot be read.

MD standard. Replace the disc.

• There may be scratches on the disc. Replace the disc.

Can't WRITE

• An error occurred while overwriting UTOC, and it could not

• There may be scratches on the disc. Replace the disc.

be overwritten properly.

BLANK MD

• Although UTOC is read, total number of letters of TNO and

• Check that the disc is a recordable disc by recording on it.

NAME is 0.

Er-MD41

• UTOC can be read but cannot be overwritten.

• Is the recording head positioned properly? Check the

connection between the PWB and recording head.

Er-MD80

• EEPROM data is not correct.

• Reset the unit and try again. If it does not restore the

unit, replace EEPROM.

MD P ERR

• Due to the abnormality with the power supply, MD unit

• Reset the unit and try again. If it does not restore the

cannot be operated properly.

unit, the power supply circuit is defective. Check the

DC voltage of Q570 E , Q550 E , and Q853 E .

DC voltage of Q570 E , Q550 E , and Q853 E .

MD error messages

ERROR MESSAGE LIST

Error Display

Error Message

Remarks

SD-CX1H

– 34 –

S P G

1 1

H

S P G — i n

6 0

H

S P G — m i d

4 B

H

S P G — o u t

3 B

H

S P G M

9 6

H

S P 1

1 0

H

S P 2

9 3

H

S P 2 2

9 3

H

S P 3

E D

H

S P 4

E E

H

S P 5

2 0

H

S P 5 2

2 0

H

S P D L I M

6 2

H

S P K L E V m

1 6

H

F G

9 B

H

F G 2

B 1

H

F F 0

1 0

H

F F 1

7 0

H

F F 2

E 0

H

F Z H L E V

E D

H

F O K L E V h

0 7

H

F O K L E V L

0 9

H

F O S T n

2 C

H

D S C J G

0 D

H

The details description of mechanism error

Error Display

Error Message

E r - M D 1

Cannot eject the disc.

E r - M D 2

The head does not ascend.

E r - M D 3

The head does not descend.

HINF

(93 Pin of IC1401)

= E

EJECT complete position

< 1.0V

= M

LOAD/EJECT halfway position

> 3V

= L

LOAD complete position

1.31 ~ 2.35V

= D

HEAD DOWN position

1.01 ~ 1.3V

EEPROM WRITING PROCEDURE

EEPROM (IC1402) writing procedure

1. Method for setting the reference temperature value

(This setting should be performed quickly at a room

temperature, between 21

temperature, between 21

°

C to 29

°

C when the PWB is not

hot.)

1. When replacing the EEPROM, wait until it has cooled

down.

2. Connect the main unit using the single MD main PWB.

3. Enter the test mode as shown on page 26.

3. Enter the test mode as shown on page 26.

"EJECT"

4. Press the TUNER (BAND) button.

"TEMP

"

: Measured temperature,

: Temperature setting

5. Find the temperature correction value for the current

ambient temperature on the following table. Adjust the

temperature correction value using the VOLUME UP/

DOWN button.

temperature correction value using the VOLUME UP/

DOWN button.

Ambient Temperature

Correction

+ 21.0

°

C ~ + 23.2

°

C

-1

H

+ 23.3

°

C ~ + 26.8

°

C

±

0

H

+ 26.9

°

C ~ + 29.0

°

C

+1

H

EEPROM DATA LIST (Version : 01)

Focus setting

Item indication

Setting

Spin setting

Item indication

Setting

An example: When ambient temperature is 22

°

C and

measured temperature is 7AH

Temperature setting = 7A H - 01 H

Temperature setting = 7A H - 01 H

= 79 H

* When the measured temperature fluctuates

between two values, take lower one (if

temperature fluctuates between 7AH and

79H, take 79H).

temperature fluctuates between 7AH and

79H, take 79H).

6. Press the POWER button and write the temperature

setting into the EEPROM.

2. Method for making settings other than the reference

temperature

1. Install the MD main PWB in the mechanism, and connect

it to the main unit.

2. Enter the test mode as shown on page 26, and insert a

disc.

"AUTO AJST"

3. Press the CD PLAY button seven times.

"EEPROM SET"

4. Set the value according to the EEPROM DATA LIST

using the VOLUME UP/DOWN button.

5. Press the POWER button, and the settings will be written

into the EEPROM.

6. Enter the test mode again, perform an "AUTO YOBI

adjustment", and write the results into the EEPROM.

– 35 –

SD-CX1H

Tracking setting

Item indication

Setting

T G

4 9

H

T G 2

6 B

H

T F 0

1 0

H

T F 1

6 B

H

T F 2

F 0

H

T F 3

0 8

H

S V C N T 4

0 1

H

T R B L V o

6 2

H

T R B L V t

4 C

H

T R K L V o

5 B

H

T R K L V t

2 B

H

T D P W o

6 7

H

T D P W t

2 1

H

S L C T o

0 0

H

S L C T t

5 0

H

S L C T m

5 3

H

T C R S C I P

1 6

H

T C R S C 0 h

0 0

H

T C R S C 0 L

F A

H

T C R S C H h

0 2

H

T C R S C H L

0 2

H

C O T L V P

0 A

H

C O T L V r

2 8

H

J P i n t

0 0

H

K I K 1 0

6 4

H

Sled setting

Item indication

Setting

S L G

4 6

H

S L 2

1 0

H

S L D L I M

7 F

H

S L D L E V

1 4

H

S L K L V k

6 0

H

S L K L V t

3 4

H

S L K L V m

6 0

H

S L B K m

0 8

H

S L K r i o

6 4

H

S L K r o i

6 2

H

S L K l i o

6 4

H

S L K l o i

6 0

H

I N N E R 1

8 6

H

I N N E R u

D 0

H

E J _ W A I T

7 8

H

C O K

5 8

H

F A T

C 0

H

T A T

3 E

H

C A T

4 0

H

F A B

6 4

H

S T R

0 B

H

S F S

0 D

H

S T C

0 D

H

Control setting

Item indication

Setting

C O N T R L 1

0 8

H

C O N T R L 2

0 2

H

A D J T T M

1 4

H

H D E Q A D

9 2

H

L D E Q A D

8 E

H

G D E Q A D

9 1

H

G D E Q A D 2

9 1

H

M D E Q B C

8 C

H

L D E Q B C

8 F

H

G D E Q B C

8 A

H

G D E Q B C 2

8 A

H

H A L S G

1 1

H

L A L S G

1 1

H

G A L S G

1 1

H

H A L S O F S

F F

H

L A L S O F S

0 0

H

G A L S O F S

0 0

H

A J S T

0 0

H

ADJUST setting

Item indication

Setting

REC bit setting

Item indication

Setting

S P_WR50

C 0

H

S P_WR56

F E

H

S P_WR44

0 0

H

S P_WR53

1 6

H

L P2 WR50

8 0

H

L P2 WR56

2 0

H

L P2 WR44

8 0

H

L P2 WR53

0 0

H

L P4 WR50

B F

H

L P4 WR56

0 2

H

L P4 WR44

8 0

H

L P4 WR53

0 0

H

R V D

0 0

H

Click on the first or last page to see other SD-CX1 (serv.man5) service manuals if exist.