Panasonic PT-EZ570U / PT-EZ570E / PT-EZ570UL / PT-EZ570EL (serv.man2) Service Manual ▷ View online

-49-

Electrical Adjustments

Circuit adjustments

CAUTION: The each circuit has been made by the fine adjustment at factory. Do not attempt to adjust the following

adjustments except requiring the readjustments in servicing otherwise it may cause loss of performance

and product safety. Before adjustment, please turn on the projector for more than 10 minutes to stabilize

the operation.

and product safety. Before adjustment, please turn on the projector for more than 10 minutes to stabilize

the operation.

WARNING : USE UV RADIATION EYE AND SKIN

PROTECTION DURING SERVICING.

CAUTION:

To prevent suffer of UV radiation, those adjustments

must be completed within 25 minutes.

To prevent suffer of UV radiation, those adjustments

must be completed within 25 minutes.

[Adjustment Condition]

● Input signal

Computer signal ......................... 0.7Vp-p/75

Ω terminated (XGA)

Video signal .............................. 1.0Vp-p/75

Ω terminated (Composite video signal)

Component video signal ............ 1.0Vp-p/75

Ω terminated (Component video signal (480i)

● Input signal pattern

● Image mode ..................... Standard

● Lamp power ..................... Normal

Note:

* Please refer to "Service adjustment menu operation" for entering the service mode and adjusting the service data.

* Please refer to "Service adjustment menu operation" for entering the service mode and adjusting the service data.

White 100%

White 0%

16 steps gray scale pattern

8 color 100% full color bar

W

Y

C

G

M

R

B

BK

White 100%

White 0%

-50-

Electrical Adjustments

1. Fan voltage adjustment

Equipment

Digital voltmeter

1. Enter the service mode.

2. Adjust the voltage on each test point by changing the

2. Adjust the voltage on each test point by changing the

data values of Group-No.

Group - No. Fan

Test Points Adjustment value

250 - 0 FAN 1 TPFN11 4.5 +0.1 -0Vdc

250 - 1

FAN 1

TPFN11

13.8 -0.1Vdc

250 - 2

FAN 2

TPFN6

4.5 +0.1 -0Vdc

250 - 3

FAN 2

TPFN6

13.8 -0.1Vdc

250 - 4

FAN 3

TPFN4

4.5 +0.1 -0Vdc

250 - 5

FAN 3

TPFN4

13.8 -0.1Vdc

250 - 6

FAN 4

TPFN2

4.5 +0.1 -0Vdc

250 - 7

FAN 4

TPFN2

13.8 -0.1Vdc

250 - 8

FAN 5

TPFN1

4.5 +0.1 -0Vdc

250 - 9

FAN 5

TPFN1

13.8 -0.1Vdc

250 - 10 FAN 6

TPFN3

4.5 +0.1 -0Vdc

250 - 11 FAN 6

TPFN3

13.8 -0.1Vdc

250 - 12 FAN 7

TPFN5

4.5 +0.1 -0Vdc

250 - 13 FAN 7 TPFN5 13.8 -0.1Vdc

3. Auto calibration adjustment [PC]

Input mode

Input 1 (RGB)

Input signal

XGA computer signal

Signal pattern

16-step gray scale

1. Enter the service mode.

2. Select Group "200", No. "70" and set data value to

"0". Select Group "200", No. "72" and set data value

to "0".

3. Select Group "260", No. "0" and set data value "0"

2. Select Group "200", No. "70" and set data value to

"0". Select Group "200", No. "72" and set data value

to "0".

3. Select Group "260", No. "0" and set data value "0"

to "1".

The projector begins auto-calibration for MAIN and

then "OK" will appear on the screen.

4. Select Group "200", No. "70" and set data value

to "1".

5. Select Group "260", No. "0" and set data value "0"

then "OK" will appear on the screen.

4. Select Group "200", No. "70" and set data value

to "1".

5. Select Group "260", No. "0" and set data value "0"

to "1".

The projector begins auto-calibration for SUB and

then "OK" will appear on the screen.

6. Select Group "200", No. "70" and set data value

to "0". Select Group "200", No. "72" and set data

value to "1".

then "OK" will appear on the screen.

6. Select Group "200", No. "70" and set data value

to "0". Select Group "200", No. "72" and set data

value to "1".

Adjustments item no. [3] and [5] are carried out

at the spare parts shipment in the factory, there-

fore they are not required when the main board is

replaced with new one.

fore they are not required when the main board is

replaced with new one.

2. Panel type check and setting

* Before setting, you need to check which type of LCD

panel is placed on the projector according to the item

"LCD panel/prism assy removal" in the chapter "Optical

Parts Disassembly".

"LCD panel/prism assy removal" in the chapter "Optical

Parts Disassembly".

1. Enter the service mode.

2. Panel Type Check

Select Group “290”, No. “0”. Check the data value as

2. Panel Type Check

Select Group “290”, No. “0”. Check the data value as

follows;

Data value “0” : For L-Type of LCD Panel

Data value “20” : For R-Type of LCD panel

If the mounted LCD panel type and set Panel mode

Data value “20” : For R-Type of LCD panel

If the mounted LCD panel type and set Panel mode

are differ, take the step below.

3. Panel Type Mode Setting

Select Group “290”, No. “1” and change the data value

Select Group “290”, No. “1” and change the data value

from 10 to 0 or 20 depending on your LCD panel type.

When the data value reaches 0 or 20, it returns to 10

quickly. The gamma-characteristics changes accord-

ing to your selection.

When the data value reaches 0 or 20, it returns to 10

quickly. The gamma-characteristics changes accord-

ing to your selection.

4. Auto calibration adjustment [Component]

Input mode

Input 2 (Component)

Input signal

100% color bar signal (480i)

100% color bar signal (480p)

100% color bar signal (720p)

100% color bar signal (1080i)

1. Enter the service mode.

2. At first, input the 100% color bar signal (480i).

3. Select Group "200", No. "72" and set data value

to "0". Select Group "200", No. "71" and set data

value to "1".

4. Select Group "260", No. "0" and set data value "0" to

2. At first, input the 100% color bar signal (480i).

3. Select Group "200", No. "72" and set data value

to "0". Select Group "200", No. "71" and set data

value to "1".

4. Select Group "260", No. "0" and set data value "0" to

"1".

The projector begins auto-calibration and then "OK"

will appear on the screen.

5. Select Group "200", No. "71" and set data value

to "0".

6. Select Group "260", No. "0" and set data value "0"

to "1".

The projector begins auto-calibration and then "OK"

will appear on the screen.

7. Change another input signal and take steps 3 - 6 again.

8. Select Group "200", No. "71" and set data value to

"1". Select Group "200", No. "72" and set data value

to "1".

to "0".

6. Select Group "260", No. "0" and set data value "0"

to "1".

The projector begins auto-calibration and then "OK"

will appear on the screen.

7. Change another input signal and take steps 3 - 6 again.

8. Select Group "200", No. "71" and set data value to

"1". Select Group "200", No. "72" and set data value

to "1".

5. Auto calibration adjustment [Video]

Input mode

Input 3 (Video)

Input signal

100% color bar composite video signal

1. Enter the service mode.

2. To start the auto-calibration for composite-video

adjustment, select Group "260", No. "0", and then

change data value "0" to "1".

2. To start the auto-calibration for composite-video

adjustment, select Group "260", No. "0", and then

change data value "0" to "1".

After the auto-calibration completed, "OK" will appear

on the screen.

-51-

Electrical Adjustments

9. Color shading correction adjustment

Software PROJECTOR SERVICE TOOL v4.20

Signal pattern

Signal pattern

5%, 10%, 15%, 20%, 30%, 50%,

75%, 95% whole gray

Use the software to correct the color shading of the

screen. See the further information of the software in-

struction manual.

The color shading correction adjustment for this model

should be performed with the whole-gray patterns speci-

fied as above.

screen. See the further information of the software in-

struction manual.

The color shading correction adjustment for this model

should be performed with the whole-gray patterns speci-

fied as above.

Corresponding to the pull-down menu of the gray level

selector on the software.

selector on the software.

Level L1

:5%

Level L2

:10%

Level L3

:15%

Level L4

:20%

Level L5

:30%

Level L6

:50%

Level L7

:75%

Level L8

:95%

Relation of level (%) indication and signal pattern

0%

:Black

100%

:White

8. White balance adjustment [PC]

Input mode

Input 1 (RGB)

Input signal

XGA computer signal

Signal patterns

16-step gray signals

1. Enter the service mode.

2. Select Group "

2. Select Group "

100

", No. "

5

" (Red) or

"

4

"

(Blue), and

change Data values respectively to make a proper

white balance.

white balance.

Group - No. Adjustment

100 - 5 Color balance Red

100 - 4 Color balance Blue

100 - 4 Color balance Blue

6. Common center adjustment

Input mode

Input 1 (RGB)

Input signal

XGA computer signal

Signal patterns

50% R, G, B whole signals

1. Enter the service mode.

2. Select Group "101", No. "4" and then change data

2. Select Group "101", No. "4" and then change data

value from "2" to "0" to reduce the panel frequency.

3. Change data value to obtain the minimum flicker for

each color on screen.

Group - No.

Adjustment

100 - 11

for red flicker

100 - 9

for green flicker

100 - 10

for blue flicker

4. Select Group "101", No. "4" and then change data

value from "0" to "2".

10.

Wind sensor calibration

1. Enter the service mode.

2. Select group no. “240” and item no. “2”. Confirm the

2. Select group no. “240” and item no. “2”. Confirm the

Data value is “1”.

0: Wind sensor function Disable

1: Wind sensor function Enable

3. Select group no. “240” and item no. “0”.

4. To start the adjustment, change data value from “0” to

1: Wind sensor function Enable

3. Select group no. “240” and item no. “0”.

4. To start the adjustment, change data value from “0” to

“1”. After the auto-calibration completed, "OK" will ap-

pear on the screen.

pear on the screen.

IMPORTANT

Before taking this adjustment, you need to replace the air

filter with new one and make sure the cabinet top, filter

cover and filter cartridge are securely installed.

Before taking this adjustment, you need to replace the air

filter with new one and make sure the cabinet top, filter

cover and filter cartridge are securely installed.

11.

Lens shift centering setting

1. Set the lens to the center position (horizontal and

vertical) by using the LENS SHIFT Up / Down.

Left / Right buttons.

2. Enter the service mode, select Group No. “200” and

Item No. “15” .

3. Change Data value from “0” to “10”. The centering

position of the lens shift is memorized.

4. To check the lens shift operation correctly, move the

lens to your desired position with LENS buttons.

Then press the LENS button for more than 5

seconds. The lens moves to the memorized center

position automatically.

vertical) by using the LENS SHIFT Up / Down.

Left / Right buttons.

2. Enter the service mode, select Group No. “200” and

Item No. “15” .

3. Change Data value from “0” to “10”. The centering

position of the lens shift is memorized.

4. To check the lens shift operation correctly, move the

lens to your desired position with LENS buttons.

Then press the LENS button for more than 5

seconds. The lens moves to the memorized center

position automatically.

7.

Gamma shipment adjustment

Software

PROJECTOR SERVICE TOOL v4.20

Use the software to obtain the proper gray scale. See the

further information of the software instruction manual.

further information of the software instruction manual.

-52-

Electrical Adjustments

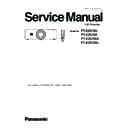

Test points and locations

VS1GB

K2551_5

K551_5

K551_7

K8B

K8C

K78A

K8E

K8F

K8G

K8I

K2551

K8J

IC1387

K8K

K78C

K8L

K7802

K8M

K551

K8P

K8R

K1551_7

K1551_5

K1151

K8802

K8803

K7801

K78F

K78G

K78H

K78J

K78K

K78L

K8S

K8H

IC401

IC2301

IC301

TPFN1

TPFN6

TPFN11

TPFN2

TPFN3

TPFN5

TPFN4

K8A

MAIN BOARD

F601

T601

K6A

T652

K6B

K6R

VR601

VR601

K6A

POWER BOARD

Click on the first or last page to see other PT-EZ570U / PT-EZ570E / PT-EZ570UL / PT-EZ570EL (serv.man2) service manuals if exist.