Panasonic PT-DZ13KU / PT-DZ13KE / PT-DZ13KT / PT-DS12KU / PT-DS12KE / PT-DW11KU / PT-DW11KE / PT-DZ10KU / PT-DZ10KE (serv.man2) Service Manual ▷ View online

DIS-19

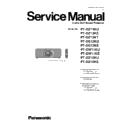

3. 6. RL-P.C.Board

3. 7. R-P.C.Board/RM-P.C.Board

RL13

RL5

RL12

RL10 RL6

*Clamp

・RL3-Intake2 fan lead wire

・RL5-Lamp2 fan lead wire

・RL6-Composition mirror fan lead wire

・RL8-F1 lead wire

・RL9-M21(Air flow sensor) lead wire

・RL10-M11(Intake temperature sensor) lead wire

・RL12-L21(Lamp2 memory) lead wire

・RL13-H1/MR1(Iris) lead wire

・RL14-M31(Luminance sensor) lead wire

・RL5-Lamp2 fan lead wire

・RL6-Composition mirror fan lead wire

・RL8-F1 lead wire

・RL9-M21(Air flow sensor) lead wire

・RL10-M11(Intake temperature sensor) lead wire

・RL12-L21(Lamp2 memory) lead wire

・RL13-H1/MR1(Iris) lead wire

・RL14-M31(Luminance sensor) lead wire

*The lead wires lets the inside of the line

processing sheet go through.

RL9

RL8

RL14

RL3

*RL14-M31(Luminance sensor) lead wire

*Hook

・RM1-G12 lead wire

・RM2-MV lead wire

・RM2-MV lead wire

*Hook

・RM3-MF lead wire

・RM6-Position SW lead wire

・RM7-MH lead wire

・RM6-Position SW lead wire

・RM7-MH lead wire

RM7

RM3

RM6

RM2

RM1

R2

R1

R3

*Under R1 lead wire, intersect

R2 lead wire in R3 lead wire.

*The lead wires is not good through the rectangles

hole of the line processing sheet.

1. Adjustment items and procedure

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

ADJ-2

1. 1. Lighting area adjustment

1. 2. Electrical convergence adjustment

1. 3. Lens calibration

1. 4. EEPROM Data transfer

1. 5. Model information setup

1. 6. Clog sensor calibration

1. 7. Contrast adjustment

2. Software Update procedure

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

ADJ-9

2. 1. Update by LAN Terminal connection (Main, Sub, Network Microprocessor)

2. 2. Update by Serial Terminal Cnnection (Main, Sub Microprocessor)

CONTENTS

SECTION 3

Adjustments

Model No.

PT-DZ13KU / DZ13KE

PT-DS12KU / DS12KE

PT-DW11KU / DW11KE

PT-DZ10KU / DZ10KE

PT-DS12KU / DS12KE

PT-DW11KU / DW11KE

PT-DZ10KU / DZ10KE

ADJ - 2

1. Adjustment item and a procedure

1.1. Lighting Area Adjustment

1. 1. 1. Lighting area confirmation

1. After replacing the DMD block, check if any shade is visible

in the DMD effective display area.

2. When the Lighting area interferes with the effective area,

adjust the Relay Lens Holder.

1. 1. 2. Lighting area adjustment

1. Projection "All White" in internal test pattern. (Lamp select "DUAL" and Lamp power "HIGH")

2. Loosen the 2 fixed screw, with a hexagon wrench (2.5mm).

3. Make quantity of prominence of adjustment

screw ① and ② about 9mm beforehand.

4. Adjustment screw ① coordinates the vertical direction of

the Lighting area.

・The Lighting area moves to the rightward when turn

a screw in the right direction.

5. Adjustment screw ② coordinates the vertical direction of

the Lighting area.

・The Lighting area moves to an upper direction when

turn a screw in the right direction.

6.When adjustment is completed, tighten two fixation screws.

Stepper motor (H/V/F)

When a power supply was cut during

shift/focus movement, carry it out.

1.3. Lens Calibration

Replaced Component

Remarks

Adjustment Item

1.1. Lighting Area Adjustment

1.2. Electrical Convergence Adjustment

DMD Block / Each Analysis Block part

DMD Block

Only DW11K* is effective.

* Make the projection environment as dark as possible and project an

all-white and all-black pattern (internal test pattern) for this check.

* Change lamp select to "DUAL" "LAMP1" "LAMP2", and please confirm it.

1.4. EEPRPM Data transmission

1.6. Clog Sensor Calibration

A-P.C.Board

Save data to a PC before A-P.C.B exchange once

and write in the data which saved at a new A-P.C.B

G-P.C.Board / M2-P.C.Board

1.5. Model Information Setup

A-P.C.Board

When data transmission was finished, it is

not necessary.

1.7. Contrast Adjustment

DMD Block / Iris unit

When the following components in this projector are replaced, adjustments are required.

Adjust each item according to the table below.

Adjust each item according to the table below.

Lighting area

Effective area

Adjustment screw ①

Adjustment screw ②

Fixed screw

9mm

Effective area

Lighting area

Adjustment Screw ②

Adjustment

Screw ①

Screw ①

ADJ - 3

1. 2. Electrical Convergence Adjustment

It is a function to correct a convergence by a pixel unit every R/G/B ingredient.

・When adjust the DZ/DS models, because it uses the entire pixel of DMD, the edge pixel of the projection

screen is missing.

1. Projected cross-hatch pattern, confirm a position gap of R/G/B.

2. Setting to service mode, and select sub menu "CONVERGENCE" of main menu "EXTRA OPTION".

3. Select a color to be adjusted.

4. Press " ▲ " " ▼ " button to adjust the vertical direction, press " ◀ " " ▶ " button to adjust the horizontal direction.

5. After adjustment completion, resetting to user mode.

1. 3. Lens calibration

1. Select sub menu "LENS CALIBRATION" of main menu "PROJECTOR SETUP".

2. Because a confirmation message is displayed, select "OK".

3. The lens will move vertically and horizontally, and the limit value of the lens shift and home position are set automatically.

4. When the lens has been completely stopped, calibration is complete.

・If the calibration has not been correctly executed, a message [INCOMPLETE] will appear.

In this case, please start again from 1.

Note

* Default : 0

* Variable range of adjustment

[DW11K]

V : -64 ~ 64, H : -16 ~ 16

[DZ13K/DS12K/DZ10K]

V : -64 ~ 0, H : 0 ~ 16

* Variable range of adjustment

[DW11K]

V : -64 ~ 64, H : -16 ~ 16

[DZ13K/DS12K/DZ10K]

V : -64 ~ 0, H : 0 ~ 16

Click on the first or last page to see other PT-DZ13KU / PT-DZ13KE / PT-DZ13KT / PT-DS12KU / PT-DS12KE / PT-DW11KU / PT-DW11KE / PT-DZ10KU / PT-DZ10KE (serv.man2) service manuals if exist.