Panasonic KV-S2048C Service Manual ▷ View online

13

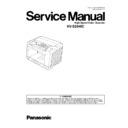

5.3.

Circuit Boards

LED Board

RELAY (BACK) Board

RELAY (FRONT) Board

CONTROL Board

POWER Board

POWER SW Board

(Power Switch)

(Power Switch)

DOUBLE FEED

DETECTOR (R) Board

DETECTOR (R) Board

DOUBLE FEED

DETECTOR (G) Board

DETECTOR (G) Board

14

5.4.

Sensor Boards and Switch

Note:

Compared to the previous scanner KV-S2025C / S2045C / S2026C / S2046C Series, “Double-feed Detection

by Double Feed Detector (Ultrasonic Sensor)” is introduced to this product.

by Double Feed Detector (Ultrasonic Sensor)” is introduced to this product.

ENDING SENSOR Board

(Ending Sensor)

(Ending Sensor)

STARTING POSITION

SENSOR Board

(Starting Position Sensor)

SENSOR Board

(Starting Position Sensor)

Door Switch

WAITING SENSOR Board

(Waiting Sensor)

(Waiting Sensor)

Paper Detector

Double Feed Detector (G)

Double Feed Detector (R)

15

6 MECHANICAL FUNCTION

6.1.

Feed Mechanism

1. Scanning command is issued from PC, Paper detector checks whether documents exist on the Feed Tray.

2. Conveyor Motor is driven to rotate Drive Rollers.

3. Paper Feed Motor is driven to rotate Paper Feed Roller and Separation Roller.

2. Conveyor Motor is driven to rotate Drive Rollers.

3. Paper Feed Motor is driven to rotate Paper Feed Roller and Separation Roller.

Double-feed Prevention Roller (Retard Roller) is supported by a shaft fixed via torque limiter, and it is pressed

against the Separation Roller.

When documents enter into the separation section, the Double-feed Prevention Roller (Retard Roller) exerts

a manipulation force onto the document with the torque which has been already set.

This Manipulation force enables to separate the documents, and to feed a piece of document to scanning section.

against the Separation Roller.

When documents enter into the separation section, the Double-feed Prevention Roller (Retard Roller) exerts

a manipulation force onto the document with the torque which has been already set.

This Manipulation force enables to separate the documents, and to feed a piece of document to scanning section.

4. When the leading edge of the document advances at about 10mm from the 1

st

Drive Roller after passing through the

separation section and Waiting Sensor, the Paper Feed Motor stops and Paper Feed Roller and Separation Roller turn

together.

together.

5. When the leading edge of the document passes through Starting Position Sensor, scanning the image starts after the defined

period. (Time to be required to conveyor the documents from the Starting Position Sensor to the scanning start point)

6. When the heeling edge of the document comes to about +5mm forward from the Double-feed Prevention Roller

(Retard Roller) whose length is equivalent to the distance between the Starting Position Sensor and the scanning

start point, the Paper Feed Motor is driven again to feed the 2

start point, the Paper Feed Motor is driven again to feed the 2

nd

document. If the data size of a document is within

the amount of the memory in the scanner, the Paper Feed Motor is driven to feed the 2

nd

document after finishing

the 1

st

document scanning.

7. Repeat the sequence "3." to "6.".

Note

When the scanner’s buffer becomes full, the scanner stops to prevent buffer overflow, while allowing the data

to be transferred to the PC continuously. When enough free buffer area is secured again, the scanner

resumes the scanning process.

to be transferred to the PC continuously. When enough free buffer area is secured again, the scanner

resumes the scanning process.

16

7 MAINTENANCE

7.1.

Maintenance Chart

C: Clean R:Replace (x 1000 sheets)

Note

• The above roller maintenance values are registered in the maintenance counter (Refer to Sec. 9), and the PC

will inform users the cleaning or replacing timing if the utility software in this scanner has been already installed.

• The maintenance schedule was determined according to paper standards (A4: 80 g/m

2

/ Letter: 20 lb.), which can

vary greatly between users. Therefore, the values can also vary

7.2.

Cleaning

When cleaning rollers and CIS Sec. 7.2.1. mentions, the accessory Roller Cleaning Paper or KV-SS03 Option (Roller Cleaning

Paper) is needed.

Note

Paper) is needed.

Note

1. Roller Cleaning Paper

• Open the bag on the dotted line and take out the Roller Cleaning Paper.

• If the opened bag is left open for a long period of time before using it, the alcohol will evaporate. Please use the

Roller Cleaning Paper immediately after opening the bag.

• The Roller Cleaning Paper (KV-SS03 Option) is available via sales route.

2. If the ADF Door does not open even with ADF Door Release pushed repeatedly, there is a possibility that the door is

not latched. In this case, try to close the ADF Door until it clicks into place.

Description

Part Reference

Section

20

40

60

80 - 260

280 300

Paper Feed Roller

Sec.14.3

C

C

C

Clean each part every 20 (x

1000) sheets'

scanning.

1000) sheets'

scanning.

C

R

Separation Roller

Sec.14.3

C

C

C

C

R

Double-feed Prevention Roller (Retard Roller)

Sec.14.1

C

C

C

C

R

Drive Roller 1

Sec.14.2

C

C

C

C

C

Drive Roller 2

Sec.14.2

C

C

C

C

C

Drive Roller 3

Sec.14.2

C

C

C

C

C

Exit Roller

Sec.14.2

C

C

C

C

C

CIS

For front side Sec.14.3

C

C

C

C

C

For back side Sec.14.2

C

C

C

C

C

Sensor Roller

For front side Sec.14.2

C

C

C

C

R

For back side Sec.14.3

C

C

C

C

R

Paper Release Roller

Sec.14.1

C

C

C

C

C

Free Roller

Sec.14.3

C

C

C

C

C

Paper Detector (Sensor)

Sec.14.1

C

C

C

C

C

Waiting Sensor (Board)

Sec.14.3

C

C

C

C

C

Starting Position Sensor (Board)

Sec.14.3

C

C

C

C

C

Ending Sensor (Board)

Sec.14.2

C

C

C

C

C

Reflector (Mirror) Sheet for Waiting Position

Sensor

Sensor

Sec.14.2

C

C

C

C

C

Reflector (Mirror) Sheet for Starting Position

Sensor

Sensor

Sec.14.2

C

C

C

C

C

Reflector (Mirror) Sheet for Ending Sensor

Sec.14.1

C

C

C

C

C

Double Feed Detector (G) (Board)

Sec.14.2

C

C

C

C

C

Double Feed Detector (R) (Board)

Sec.14.3

C

C

C

C

C

Click on the first or last page to see other KV-S2048C service manuals if exist.