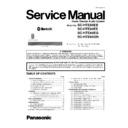

Panasonic SC-HTE80EB / SC-HTE80EE / SC-HTE80EG / SC-HTE80GN Service Manual ▷ View online

5

1.3.

Before Repair and Adjustment

Disconnect AC power to discharge unit AC Capacitors (C5701, C5702, C5703, C5704, C5705 and C5706) through a 10W, 1W

resistor to ground.

Caution :

DO NOT SHORT-CIRCUIT DIRECTLY (with a screwdriver blade, for instance), as this may destroy solid state devices.

After repairs are completed, restore power gradually using a variac, to avoid overcurrent.

resistor to ground.

Caution :

DO NOT SHORT-CIRCUIT DIRECTLY (with a screwdriver blade, for instance), as this may destroy solid state devices.

After repairs are completed, restore power gradually using a variac, to avoid overcurrent.

• Current consumption at AC 220V - 240V, at 50Hz during power on, (Selector : Standby mode) should be ~150 mA.

1.4.

Protection Circuitry

The protection circuitry may have operated if either of the following conditions are noticed:

• No sound is heard when the power is turned on.

• Sound stops during a performance.

• Sound stops during a performance.

The function of this circuitry is to prevent circuitry damage if, for example, the positive and negative speaker connection wires are

"shorted", or if speaker systems with an impedance less than the indicated rated impedance of the amplifier are used.

If this occurs, follow the procedure outlines below:

"shorted", or if speaker systems with an impedance less than the indicated rated impedance of the amplifier are used.

If this occurs, follow the procedure outlines below:

1. Turn off the power.

2. Determine the cause of the problem and correct it.

3. Turn on the power once again after one minute.

2. Determine the cause of the problem and correct it.

3. Turn on the power once again after one minute.

Note:

When the protection circuitry functions, the unit will not operate unless the power is first turned off and then on again.

When the protection circuitry functions, the unit will not operate unless the power is first turned off and then on again.

1.5.

Caution For Fuse Replacement

6

1.6.

Safety Part Information

Safety Parts List:

There are special components used in this equipment which are important for safety.

These parts are marked by in the Schematic Diagrams, Exploded View & Replacement Parts List. It is essential that these

critical parts should be replaced with manufacturer’s specified parts to prevent shock, fire or other hazards. Do not modify the

original design without permission of manufacturer.

critical parts should be replaced with manufacturer’s specified parts to prevent shock, fire or other hazards. Do not modify the

original design without permission of manufacturer.

Safety

Ref. No.

Part No.

Part Name & Description

Remarks

4

REX1657

1P RED WIRE (AC INLT - SMPS)

5

REX1658

1P BLACK WIRE (AC INLET - SMPS)

17

RGN3400-K

NAME PLATE

EB/EG-K

17

RGN3401-S

NAME PLATE

EB/EG-S

17

RGN3402-S

NAME PLATE

GN-S

17

RGN3403-K

NAME PLATE

GN-K

17

RGN3404-S

NAME PLATE

EE-S

38

RMZ1415

SMPS PCB BOTTOM INSULATOR

A1

N2QAYC000098

REMOTE CONTROL

A2

K2CJ2YY00093

AC CORD

GN

A2

K2CQ2YY00119

AC CORD

EE,EG

A2

K2CT2YY00097

AC CORD

EB

A3

RQT9861-B

O/I BOOK (EN)

EB,GN

A3

RQT9862-D

O/I BOOK (Ge/Fr/It/Du/Fi)

EG

A3

RQT9865-Z

O/I BOOK (En/Po/Cz/Sp/Sw/Da)

EG

A3

RQT9866-R

O/I BOOK (Ru/Ur)

EE

C5701

F0CAF104A105

0.1uF

C5702

F0CAF104A105

0.1uF

C5703

F0CAF104A105

0.1uF

C5704

F1BAF471A013

470pF

C5705

F1BAF471A013

470pF

C5706

F1BAF1020020

1000pF

DZ5701

ERZV10V511CS

ZNR

(E.S.D)

F1

K5G312Y00007

FUSE

L5702

G0B922G00004

LINE FILTER

L5703

G0B922G00004

LINE FILTER

P5701

K2AA2B000011

AC INLET

PC5720

B3PBA0000579

PHOTO COUPLER

PC5760

B3PBA0000579

PHOTO COUPLER

PCB1

REP4860T

SMPS P.C.B.

(RTL)

R5700

ERJ8GEYJ105V

1M 1/4W

R5701

ERJ8GEYJ105V

1M 1/4W

R5710

ERJ8GEYJ105V

1M 1/4W

T5701

G4DYA0000486

TRANSFORMER

7

2 Warning

2.1.

Prevention of Electrostatic Discharge (ESD) to Electrostatically Sensi-

tive (ES) Devices

tive (ES) Devices

Some semiconductor (solid state) devices can be damaged easily by static electricity. Such components commonly are called Elec-

trostatically Sensitive (ES) Devices.

trostatically Sensitive (ES) Devices.

The following techniques should be used to help reduce the incidence of component damage caused by electrostatic discharge

(ESD).

(ESD).

1. Immediately before handling any semiconductor component or semiconductor-equipped assembly, drain off any ESD on your

body by touching a known earth ground. Alternatively, obtain and wear a commercially available discharging ESD wrist strap,

which should be removed for potential shock reasons prior to applying power to the unit under test.

which should be removed for potential shock reasons prior to applying power to the unit under test.

2. After removing an electrical assembly equipped with ES devices, place the assembly on a conductive surface such as alumi-

num foil, to prevent electrostatic charge buildup or exposure of the assembly.

3. Use only a grounded-tip soldering iron to solder or unsolder ES devices.

4. Use only an anti-static solder removal device. Some solder removal devices not classified as “anti-static (ESD protected)” can

4. Use only an anti-static solder removal device. Some solder removal devices not classified as “anti-static (ESD protected)” can

generate electrical charge sufficient to damage ES devices.

5. Do not use freon-propelled chemicals. These can generate electrical charges sufficient to damage ES devices.

6. Do not remove a replacement ES device from its protective package until immediately before you are ready to install it. (Most

6. Do not remove a replacement ES device from its protective package until immediately before you are ready to install it. (Most

replacement ES devices are packaged with leads electrically shorted together by conductive foam, aluminum foil or compara-

ble conductive material).

ble conductive material).

7. Immediately before removing the protective material from the leads of a replacement ES device, touch the protective material

to the chassis or circuit assembly into which the device will be installed.

CAUTION:

CAUTION:

Be sure no power is applied to the chassis or circuit, and observe all other safety precautions.

8. Minimize bodily motions when handling unpackaged replacement ES devices. (Otherwise harmless motion such as the

brushing together of your clothes fabric or the lifting of your foot from a carpeted floor can generate static electricity (ESD) suf-

ficient to damage an ES device).

ficient to damage an ES device).

8

2.2.

Service caution based on Legal restrictions

2.2.1.

General description about Lead Free Solder (PbF)

The lead free solder has been used in the mounting process of all electrical components on the printed circuit boards used for this

equipment in considering the globally environmental conservation.

equipment in considering the globally environmental conservation.

The normal solder is the alloy of tin (Sn) and lead (Pb). On the other hand, the lead free solder is the alloy mainly consists of tin

(Sn), silver (Ag) and Copper (Cu), and the melting point of the lead free solder is higher approx.30 degrees C (86

(Sn), silver (Ag) and Copper (Cu), and the melting point of the lead free solder is higher approx.30 degrees C (86

°F) more than that

of the normal solder.

Definition of PCB Lead Free Solder being used

Service caution for repair work using Lead Free Solder (PbF)

• The lead free solder has to be used when repairing the equipment for which the lead free solder is used.

(Definition: The letter of “PbF” is printed on the PCB using the lead free solder.)

• To put lead free solder, it should be well molten and mixed with the original lead free solder.

• Remove the remaining lead free solder on the PCB cleanly for soldering of the new IC.

• Since the melting point of the lead free solder is higher than that of the normal lead solder, it takes the longer time to melt the

• Remove the remaining lead free solder on the PCB cleanly for soldering of the new IC.

• Since the melting point of the lead free solder is higher than that of the normal lead solder, it takes the longer time to melt the

lead free solder.

• Use the soldering iron (more than 70W) equipped with the temperature control after setting the temperature at 350±30 degrees

C (662±86

°F).

Recommended Lead Free Solder (Service Parts Route.)

• The following 3 types of lead free solder are available through the service parts route.

RFKZ03D01K-----------(0.3mm 100g Reel)

RFKZ06D01K-----------(0.6mm 100g Reel)

RFKZ10D01K-----------(1.0mm 100g Reel)

RFKZ06D01K-----------(0.6mm 100g Reel)

RFKZ10D01K-----------(1.0mm 100g Reel)

Note

* Ingredient: Tin (Sn), 96.5%, Silver (Ag) 3.0%, Copper (Cu) 0.5%, Cobalt (Co) / Germanium (Ge) 0.1 to 0.3%

The letter of “PbF” is printed either foil side or components side on the PCB using the lead free solder.

(See right figure)

(See right figure)

Click on the first or last page to see other SC-HTE80EB / SC-HTE80EE / SC-HTE80EG / SC-HTE80GN service manuals if exist.