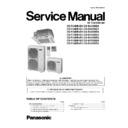

Panasonic CS-F24DB4E5 / CU-B24DBE5 / CS-F28DB4E5 / CU-B28DBE5 / CS-F28DB4E5 / CU-B28DBE8 / CS-F34DB4E5 / CU-B34DBE5 / CS-F34DB4E5 / CU-B34DBE8 / CS-F43DB4E5 / CU-B43DBE8 / CS-F50DB4E5 / CU-B50DBE8 Service Manual ▷ View online

45

9.7.10.

High Temperature Protection

• During heating operation, when outdoor temperature is more than 35°C for 15 minutes, compressor stops in order to protect the

compressor.

• After 3 minutes (restart delay control) of waiting, if thermostat is ON, outdoor unit restart.

9.7.11.

Pump-down Control

• To enable pump down operation, at outdoor PCB, set the DS1and DS2 to OFF position.

• Press Test Run button for 1 second.

• During Pump Down operation, push the Test Run button again for 1 second to stop the pump down operation.

• The pump down operation run for 10 minutes.

• The pump down operation run for 10 minutes.

9.7.12.

Thermostat Control

• Depending on differences between room temperature and setting temperature, compressor operation is decided and starts

operation.

• If temperature difference matches values shown below, thermostat switches off or on accordingly.

9.8.

Protection Control

9.8.1.

Outdoor Low-pressure Protection Control

• The purpose of low-pressure protection control is gas leakage detection control.

• The low-pressure protection control starts when low-pressure switch is activated less than 15 minutes after compressor startup.

• The low-pressure protection control starts when low-pressure switch is activated less than 15 minutes after compressor startup.

During heating operation or defrost control low-pressure detection does not start.

• During this protection control, compressor is shut down, indoor unit is set to thermo-off status.

• After 6 occasions, suction pressure error is displayed; all operation stopped except outdoor fan remaining heat removal control.

• After 6 occasions, suction pressure error is displayed; all operation stopped except outdoor fan remaining heat removal control.

Thermostat OFF

Thermostat ON

Cooling Mode

-1.5

°C

-0.5

°C

Soft Dry Mode

-2.5

°C

-2.5

°C

Heating Mode

3.5

°C

2.5

°C

46

9.8.2.

Outdoor High-pressure Protection Control

• The high-pressure protection control starts when high-pressure switch is activated less than 15 minutes after compressor

startup.

• During this protection control, compressor is shut down. And indoor unit is set to thermo-off status.

• After 6 occasions, high-pressure protection error is displayed; all operation stopped except outdoor fan remaining heat removal

• After 6 occasions, high-pressure protection error is displayed; all operation stopped except outdoor fan remaining heat removal

control.

9.8.3.

Discharge Temperature Protection Control

• The discharge temperature protection control starts when abnormal compressor temperature 115°C is detected when outdoor

unit is operating in cooling or heating operation.

• During this protection control, compressor is shut down. And indoor unit is set to thermo-off status.

• After 6 occasions, high-pressure protection error is displayed; all operation stopped except outdoor fan remaining heat removal

• After 6 occasions, high-pressure protection error is displayed; all operation stopped except outdoor fan remaining heat removal

control.

9.8.4.

Over Current Protection Control

• The purpose of over current protection control is to protect the air conditioner from over current.

• The over current protection control starts when input current from CT is maintained at 20A or more for 2 seconds when the

• The over current protection control starts when input current from CT is maintained at 20A or more for 2 seconds when the

outdoor unit is starting up or during cooling or heating operation.

• During this protection control, compressor is shut down. And indoor unit is set to thermo-off status.

• After 4 occasions, over current protection error is displayed; all operation stopped except outdoor fan remaining heat removal

• After 4 occasions, over current protection error is displayed; all operation stopped except outdoor fan remaining heat removal

control.

9.8.5.

CT Disconnection Detection Control

• CT disconnection detection control detects if the CT sensor works normally.

• The CT disconnection detection activates when:

• The CT disconnection detection activates when:

- CT input value is maintained at compressor shutdown status (1.5A or less) consecutively for 2 seconds when the compressor

is operating; except deice mode.

- During this condition, compressor is shut down and indoor unit is set to thermo-off status.

- After 4 occasions, CT sensor error is displayed; all operation stopped except outdoor fan remaining heat removal control.

- After 4 occasions, CT sensor error is displayed; all operation stopped except outdoor fan remaining heat removal control.

- CT input value is maintained at compressor operation status (5A or more) consecutively for a period of 60 seconds when the

compressor is shut down.

- During this condition, CT sensor error is displayed.

9.8.6.

Connection Capacity Protection Control

• The purpose of connection capacity protection control is to ensure the total capacity of connected indoor units is within

acceptable range.

• During this protection control, connection capacity error is displayed; all operations stopped.

9.8.7.

Sensor Disconnection Detection Control

• The sensor disconnection detection control activates when the following condition comply:

• During sensor disconnection, sensor error is displayed; all operations stops except outdoor fan remaining heat removal control.

9.8.8.

Four-way Valve Error Detection Control

• The four-way valve error detection control starts when:

- During cooling operation, when indoor heat exchanger temperature exceeds 45°C in 5 minutes after compressor starts.

- During heating operation, when indoor heat exchanger temperature is below 5°C in 5 minutes after compressor starts.

- During heating operation, when indoor heat exchanger temperature is below 5°C in 5 minutes after compressor starts.

• During four-way valve error, compressor is shut down and indoor unit is set to thermo-off status.

• After 3 occasions, four-way valve error is displayed; all operation stopped except outdoor fan remaining heat removal control.

• After 3 occasions, four-way valve error is displayed; all operation stopped except outdoor fan remaining heat removal control.

Model Number

Min. Capacity (kW)

Max. Capacity (kW)

Model Number

Min. Capacity (kW)

Max. Capacity (kW)

CU-B14DBE5

5.3

6.9

CU-B28DBE8

6.3

9.8

CU-B18DBE5

5.3

6.9

CU-B34DBE8

7.3

12.3

CU-B24DBE5

6.3

9.8

CU-B43DBE8

10.2

13.8

CU-B28DBE5

7.3

12.3

CU-B50DBE8

12.7

15.8

Sensor

Detection Threshold

Duration (Sec.)

Detection Condition

Discharge Temperature

< -4.5

°C or 201.8°C

5

Other than compressor start control

and compressor ON

Outdoor Heat Exchanger

< -50.5

°C or 103.7°C

5

Regularly

47

9.8.9.

Valve Error Detection Control

• This control is to protect the compressor.

• Valve error is detected if comply with condition below:

• Valve error is detected if comply with condition below:

- Power is on for the first time and within 5 minutes from compressor starts (However, the unit is considered power on for first

time when compressor starts operating continuously for 7 minutes).

- Indoor heat exchanger temperature at compressor start -3°C < current heat exchanger temperature for 1 minutes.

• During this error, four-way valve error is displayed; compressor is shutdown.

9.8.10.

High-pressure Switch Disconnection Error Detection Control

• High-pressure switch disconnection is detected when high-pressure switch input continuously open for 1 minutes while the

compressor shutdown.

• During this error, high-pressure switch error is displayed.

9.8.11.

Low-pressure Switch Disconnection Error Detection Control

• Low-pressure switch disconnection is detected when low-pressure switch input continuously open for 1 minutes while

compressor shutdown.

• During this error, low-pressure switch error is displayed.

9.9.

Test Run

• Test run is necessary after installation is completed.

• To enable forced cooling test run, at outdoor PCB, set the DS1 to ON position and DS2 to OFF position.

• To enable forced cooling test run, at outdoor PCB, set the DS1 to ON position and DS2 to OFF position.

• To enable forced heating test run, at outdoor PCB, set the DS1 to ON position and DS2 to ON position.

• Press Test Run button at outdoor pcb for 1 second.

48

10 Installation Instruction

10.1. Pipe length

• CORRECTION OF CAPACITIES

1. Correction of capacities according to the connecting pipe length.

The data of rated capacities (marked on the name plate) are based on 7.5 meters connecting pipe and horizontal installation.

2. For other pipe length of other installation multiply by the following correction factor to determine the revised cooling capacity.

Note:

Piping elevation B = outdoor unit installed at top

Piping elevation C = outdoor unit installed at bottom

Piping elevation B = outdoor unit installed at top

Piping elevation C = outdoor unit installed at bottom

• Calculation 1

In case of CU-B28DBE5, CU-B28DBE8, CU-B34DBE5, CU-B34DBE8

When pipe length exceed 30m calculated by formula 1, adding refrigerant amount should be calculated by formula 2. If

calculation result is less than 30m, it is not necessary to add refrigerant.

Pipe length = main pipe + (branch pipe La + branch pipe Lb)/2.78...formula 1

Add refrigerant = (main pipe + (branch pipe La + branch pipe Lb)/2.78-30) * 50...formula 2

When pipe length exceed 30m calculated by formula 1, adding refrigerant amount should be calculated by formula 2. If

calculation result is less than 30m, it is not necessary to add refrigerant.

Pipe length = main pipe + (branch pipe La + branch pipe Lb)/2.78...formula 1

Add refrigerant = (main pipe + (branch pipe La + branch pipe Lb)/2.78-30) * 50...formula 2

• Calculation 2

In case of CU-B43DBE8, CU-B50DBE8

When pipe length exceed 30m calculated by formula 3, adding refrigerant amount should be calculated by formula 4. If

calculation result is less than 30m, it is not necessary to add refrigerant.

Pipe length = main pipe + branch pipe La + branch pipe Lb... formula 3

Add refrigerant = (main pipe + branch pipe La + branch pipe Lb-30) * 50...formula 4

When pipe length exceed 30m calculated by formula 3, adding refrigerant amount should be calculated by formula 4. If

calculation result is less than 30m, it is not necessary to add refrigerant.

Pipe length = main pipe + branch pipe La + branch pipe Lb... formula 3

Add refrigerant = (main pipe + branch pipe La + branch pipe Lb-30) * 50...formula 4

Piping Size / Length & Elevation

Model No.

Piping size

Piping

length

length

(A)

Piping

elevation

(B)

Piping

elevation

(C)

Piping

Chargeless

Add

Refrigerant

Liquid /

High

Valve

Gas /

Low

Valve

Max(m)

Max(m)

Max(m)

Max(m)

(g/m)

R

CS-F24DB4E5

Cassette

4

CS-F28DB4E5

type

1

CS-F34DB4E5

9.52

3-ways

15.88

3-ways

50

30

20

30

50

0

CS-F43DB4E5

A

CS-F50DB4E5

Click on the first or last page to see other CS-F24DB4E5 / CU-B24DBE5 / CS-F28DB4E5 / CU-B28DBE5 / CS-F28DB4E5 / CU-B28DBE8 / CS-F34DB4E5 / CU-B34DBE5 / CS-F34DB4E5 / CU-B34DBE8 / CS-F43DB4E5 / CU-B43DBE8 / CS-F50DB4E5 / CU-B50DBE8 service manuals if exist.