Sharp MX-M850 (serv.man19) Service Manual ▷ View online

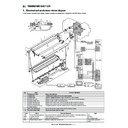

MX-M1100 IMAGE PROCESS SECTION H – 9

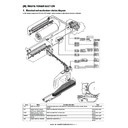

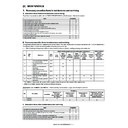

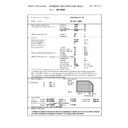

F. Process control execution conditions and timing

The process control is executed under the following conditions at the following timing.

(*1) : Setting of the process control execution conditions and timing with SIM 44-28.

The execution conditions and timing of each process control can be set with SIM 44-28.

The execution conditions and timing of each process control can be set with SIM 44-28.

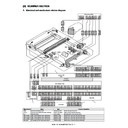

G. Process control conditions and settings

No.

Item

Forcible execution

by the simulation

Execution conditions, timing

1

Image density sensor sensitivity

adjustment

adjustment

TC44-2

Before execution of the high density image correction (High density process control)

2

OPC drum dark potential correction

TC44-3

Before execution of the high density image correction (High density process control)

3

OPC drum photo sensitivity

correction/OPC drum charging

correction

correction/OPC drum charging

correction

Before execution of the high density image correction (High density process control)

4

High density image correction (High

density process control)

density process control)

TC44-6

(TC44-2/44-3)

(TC44-2/44-3)

Depends on the set conditions of SIM 44-28. (*1)

5

Half-tone density correction (half-tone

process control)

process control)

TC-44-34

After execution of the high density image correction (High density process control)

6

Toner density correction

When there is a change in the temperature/humidity. When the developer counter

reaches the specified value. When the developing bias voltage changes more than the

specified level after execution of the high density image correction (high density

process control).

reaches the specified value. When the developing bias voltage changes more than the

specified level after execution of the high density image correction (high density

process control).

7

Transfer current correction

When the paper type or the paper size is changed. When there is a change in the

temperature/humidity.

temperature/humidity.

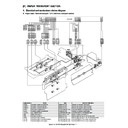

Item

Process control execution conditions

Setting

(Disable / Enable)

Default

SW ON

In previous rotation when turning on the power (canceling the sleep mode).

Disable / Enable

0 (Enable)

24H

When the machine has been left in READT (sleep setting) mode for 24 hours or more.

Disable / Enable

0 (Enable)

HUM

When a change in the temperature/humidity greater than that in execution of the previous

process control is found by monitoring the temperature/humidity at the specified time

interval (180 min).

process control is found by monitoring the temperature/humidity at the specified time

interval (180 min).

Disable / Enable

0 (Enable)

REV1

When the developing roller rotation time passes the specified level (10 min) after turning

on the power.

on the power.

Disable / Enable

0 (Enable)

REV2

When the developing rotation time reaches the specified level (30 min) from execution of

the previous density correction.

the previous density correction.

Disable / Enable

0 (Enable)

INITIAL

When warming up after clearing the counters of the OPC drum and the developing unit.

Disable / Enable

0 (Enable)

PIX

When the toner (pixel) count value accumulated from execution of the previous high

density correction exceeds the specified level.

density correction exceeds the specified level.

Disable / Enable

1 (Disable)

HUM HOUR

Setting of the temperature/humidity monitor time interval (min) in the item of HUM.

1-255

180

HUM_DIF

Specified value of the area difference in the item of HUM compared with that in execution

of the previous process control

of the previous process control

1-16

2

REV1_MINUTE

Developing rotation time (min) of the item of REV1 after turning on the power

1-255

10

REV2_MINUTE

Developing rotation time(min) of the item of REV2 after execution of the previous density

correction

correction

1-255

30

PIX_RATIO

Magnification ratio of the accumulated toner count value of the item of PIX from execution

of the previous high density correction

of the previous high density correction

1-99

10

PATCH

After passing the specified time of rotation of the developing roller from the previous high

density process control, and when the toner patch image is made and the difference

between its density and the target density level is greater than the value specified with the

PATCH CONTROL.

density process control, and when the toner patch image is made and the difference

between its density and the target density level is greater than the value specified with the

PATCH CONTROL.

Disable / Enable

1 (Disable)

PATCH MINUTE

Operation interval of item PATCH.

1-255

10

PATCH RATIO

Specified value of the difference between the toner patch image and the target density

level in the operation of item PATCH.

level in the operation of item PATCH.

1-100

100

MX-M1100 IMAGE PROCESS SECTION H – 10

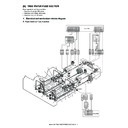

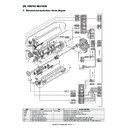

H. Process control operation flow

The process control is executed in the following flow.

Along with execution of the OPC drum dark potential correction, the high density image correction (high density process control), and the half-

tone density correction (half-tone process control), the developing bias voltage, the main charger grid voltage, and the laser power are cor-

rected and changed in the following flow.

The developing bias voltage, the main charger grid voltage, and the laser power are finally determined with Job No. 6B, 8B, and 9B.

Along with execution of the OPC drum dark potential correction, the high density image correction (high density process control), and the half-

tone density correction (half-tone process control), the developing bias voltage, the main charger grid voltage, and the laser power are cor-

rected and changed in the following flow.

The developing bias voltage, the main charger grid voltage, and the laser power are finally determined with Job No. 6B, 8B, and 9B.

Job

No.

Job

No.

1

OPC drum dark potential correction

(DVB + Cleaning filed)

(DVB + Cleaning filed)

Vg/Vo

2A

DVB

3

EDV

Effective developing bias voltage check

4A

EDV

Effective developing bias voltage securing

5A

150V

6A

LDP

Half-tone density correction (Half-tone process control)

7

EDV

Effective developing bias voltage check

8A

EDV

Effective developing bias voltage securing

9A

150V

Proper cleaning field securing

4B

DVB

Developing bias voltage change

5B

Vg/Vo

OPC drum dark potential correction

2B

VL

OPC drum dark potential detection

8B

DVB

Developing bias voltage change

9B

Vg/Vo

OPC drum dark potential correction

6B

HVL/VL

High density image correction (High density process

control) (Developing bias voltage correction)

control) (Developing bias voltage correction)

Laser power change/ OPC drum light potential

change (OPC drum light potential VL detection)

change (OPC drum light potential VL detection)

Proper cleaning field securing (keep the diffrence in

potential between DV bias and Drum serface.)

potential between DV bias and Drum serface.)

: Main charger grid voltage

: OPC drum dark potential

: Developing bias voltage

: Effective developing bias voltage (DVB - VL)

: Vo - DVB

: Half-tone potential

: Light potential

: Laser power

Vg

Vo

DVB

EDV

Cleaning filed

HVL

VL

LDP

MX-M1100 IMAGE PROCESS SECTION H – 10

H. Process control operation flow

The process control is executed in the following flow.

Along with execution of the OPC drum dark potential correction, the high density image correction (high density process control), and the half-

tone density correction (half-tone process control), the developing bias voltage, the main charger grid voltage, and the laser power are cor-

rected and changed in the following flow.

The developing bias voltage, the main charger grid voltage, and the laser power are finally determined with Job No. 6B, 8B, and 9B.

Along with execution of the OPC drum dark potential correction, the high density image correction (high density process control), and the half-

tone density correction (half-tone process control), the developing bias voltage, the main charger grid voltage, and the laser power are cor-

rected and changed in the following flow.

The developing bias voltage, the main charger grid voltage, and the laser power are finally determined with Job No. 6B, 8B, and 9B.

Job

No.

Job

No.

1

OPC drum dark potential correction

(DVB + Cleaning filed)

(DVB + Cleaning filed)

Vg/Vo

2A

DVB

3

EDV

Effective developing bias voltage check

4A

EDV

Effective developing bias voltage securing

5A

150V

6A

LDP

Half-tone density correction (Half-tone process control)

7

EDV

Effective developing bias voltage check

8A

EDV

Effective developing bias voltage securing

9A

150V

Proper cleaning field securing

4B

DVB

Developing bias voltage change

5B

Vg/Vo

OPC drum dark potential correction

2B

VL

OPC drum dark potential detection

8B

DVB

Developing bias voltage change

9B

Vg/Vo

OPC drum dark potential correction

6B

HVL/VL

High density image correction (High density process

control) (Developing bias voltage correction)

control) (Developing bias voltage correction)

Laser power change/ OPC drum light potential

change (OPC drum light potential VL detection)

change (OPC drum light potential VL detection)

Proper cleaning field securing (keep the diffrence in

potential between DV bias and Drum serface.)

potential between DV bias and Drum serface.)

: Main charger grid voltage

: OPC drum dark potential

: Developing bias voltage

: Effective developing bias voltage (DVB - VL)

: Vo - DVB

: Half-tone potential

: Light potential

: Laser power

Vg

Vo

DVB

EDV

Cleaning filed

HVL

VL

LDP

MX-M1100 IMAGE PROCESS SECTION H – 10

H. Process control operation flow

The process control is executed in the following flow.

Along with execution of the OPC drum dark potential correction, the high density image correction (high density process control), and the half-

tone density correction (half-tone process control), the developing bias voltage, the main charger grid voltage, and the laser power are cor-

rected and changed in the following flow.

The developing bias voltage, the main charger grid voltage, and the laser power are finally determined with Job No. 6B, 8B, and 9B.

Along with execution of the OPC drum dark potential correction, the high density image correction (high density process control), and the half-

tone density correction (half-tone process control), the developing bias voltage, the main charger grid voltage, and the laser power are cor-

rected and changed in the following flow.

The developing bias voltage, the main charger grid voltage, and the laser power are finally determined with Job No. 6B, 8B, and 9B.

Job

No.

Job

No.

1

OPC drum dark potential correction

(DVB + Cleaning filed)

(DVB + Cleaning filed)

Vg/Vo

2A

DVB

3

EDV

Effective developing bias voltage check

4A

EDV

Effective developing bias voltage securing

5A

150V

6A

LDP

Half-tone density correction (Half-tone process control)

7

EDV

Effective developing bias voltage check

8A

EDV

Effective developing bias voltage securing

9A

150V

Proper cleaning field securing

4B

DVB

Developing bias voltage change

5B

Vg/Vo

OPC drum dark potential correction

2B

VL

OPC drum dark potential detection

8B

DVB

Developing bias voltage change

9B

Vg/Vo

OPC drum dark potential correction

6B

HVL/VL

High density image correction (High density process

control) (Developing bias voltage correction)

control) (Developing bias voltage correction)

Laser power change/ OPC drum light potential

change (OPC drum light potential VL detection)

change (OPC drum light potential VL detection)

Proper cleaning field securing (keep the diffrence in

potential between DV bias and Drum serface.)

potential between DV bias and Drum serface.)

: Main charger grid voltage

: OPC drum dark potential

: Developing bias voltage

: Effective developing bias voltage (DVB - VL)

: Vo - DVB

: Half-tone potential

: Light potential

: Laser power

Vg

Vo

DVB

EDV

Cleaning filed

HVL

VL

LDP