Sharp AR-161 (serv.man8) Service Manual ▷ View online

Makes the laser scanning speeds at both ends of the drum same as

each other.

each other.

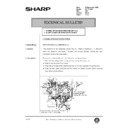

B. Laser beam path

a

≠

b

≠

c

a

b

c

d = e = f

d e

f

5. Paper feed section

A. Basic structure

1

No. 1 cassette paper feed roller (Semi-circular roller)

Picks up paper from No. 1 cassette.

2

Main motor

Drives the process section and the paper transport section.

3

No. 1 cassette paper feed solenoid

Rotates and controls No. 1 cassette paper feed roller.

4

No. 1 cassette paper feed roller clutch

Drives No. 1 cassette paper feed roller.

5

Manual paper feed roller

Picks up paper from the manual paper feed tray.

6

Manual paper transport roller

Transport paper which was picked up from the manual paper feed tray.

7

Manual paper feed roller clutch

Drives the manual paper feed roller.

8

Manual paper transport roller clutch

Drives the manual paper transport roller.

9

Manual paper feed roller solenoid

Rotates and controls the manual paper feed roller.

10

Manual paper transport roller solenoid

Rotates and controls the manual paper transport roller.

11

Resist roller

Takes synchronization between the paper lead edge and the image lead edge.

12

Resist roller clutch

Drives the resist roller.

13

Resist roller solenoid

Rotates and controls the resist roller.

B. Brief descriptions of operations

This machine allows two ways of paper feed system: cassette paper

feed and manual paper feed.

The cassette of universal type is employed to hold 250 sheets. The

front loading system allows to attach or detach the cassette from the

front of the machine.

Paper size can be selected by the user.

feed and manual paper feed.

The cassette of universal type is employed to hold 250 sheets. The

front loading system allows to attach or detach the cassette from the

front of the machine.

Paper size can be selected by the user.

Paper size detection is set by the software. (User setting is allowed.)

By installing the optional 1-step paper feed unit or the multi-step

paper feed unit, the capacity of paper can be increased.

By installing the optional 1-step paper feed unit or the multi-step

paper feed unit, the capacity of paper can be increased.

(1) Cassette paper feed operation

Select the cassette and press the START button, and the paper feed

roller solenoid will be turned on and the paper feed clutch will be

released.

The drive power of the main motor is transmitted through the paper

feed roller clutch to the paper feed roller, rotating the paper feed roller

and feeding paper.

roller solenoid will be turned on and the paper feed clutch will be

released.

The drive power of the main motor is transmitted through the paper

feed roller clutch to the paper feed roller, rotating the paper feed roller

and feeding paper.

AR-160/161 FM/E [6] OPERATIONAL DESCRIPTIONS 11/27/1998

AR-161

6 – 6

(2) Manual paper feed tray operation

(3) Resist roller

6. Fusing section

A. Basic composition

(Top view)

1

Before-fusing

paper guide

paper guide

Guides the paper transported from

the process section to the fusing unit.

the process section to the fusing unit.

2

Upper heat roller

Applies heat and pressure to the

paper to fuse.

paper to fuse.

3

Thermistor

Detects the surface temperature of

the upper heat roller.

the upper heat roller.

4

Thermostat

Stops power supply to the heat roller

in case of an abnormally high

temperature of the heat roller.

in case of an abnormally high

temperature of the heat roller.

5

Separation pawl

Separates the print paper from the

upper heat roller.

upper heat roller.

6

POD1

Detects that the paper has been

transported from the fusing section.

transported from the fusing section.

7

Heater lamp

Heats the heat roller.

8

Lower heat roller

Applies a pressure to the paper

together with the upper heat roller.

together with the upper heat roller.

B. Heat roller

A pressure roller is used for the heat roller and a silicone rubber roller

is used for the lower heat roller for better toner fusing performance

and paper separation.

is used for the lower heat roller for better toner fusing performance

and paper separation.

C. Separator pawl

Four separator pawls are used on the upper heat roller. The

separator pawls are teflon coated to reduce friction with the roller and

prevent a smear on the paper caused by the separator pawl.

separator pawls are teflon coated to reduce friction with the roller and

prevent a smear on the paper caused by the separator pawl.

D. Thermal control

1) The heater lamp, thermistor, main PWB, DC power supply PWB,

and triac within the power supply unit are used to control the

temperature in the fuser unit.To prevent against abnormally high

temperature in the fuser unit, a thermostat is used for safety pur-

poses.

temperature in the fuser unit.To prevent against abnormally high

temperature in the fuser unit, a thermostat is used for safety pur-

poses.

2) The surface temperature of the upper heat roller is set to 180˚C ~

195˚C. The surface temperature during the power save mode is

set to 100˚C.

set to 100˚C.

3) The self-check function comes active when one of the following

malfunctions occurs, and an "H" is displayed on the copy quantity

display.

display.

Fusing temperature error value

H4 (Low temperature error)

•

During machine operation

The case where the fusing temperature (thermistor output

value) does not reach 155˚C within 55 sec from lighting of the

heater lamp. (If the toner motor rotates for 10 sec or more

continuously when starting the machine, the case where the

fusing temperature does not reach 155˚C within 60 sec.)

The case where the fusing temperature (thermistor output

value) does not reach 155˚C within 55 sec from lighting of the

heater lamp. (If the toner motor rotates for 10 sec or more

continuously when starting the machine, the case where the

fusing temperature does not reach 155˚C within 60 sec.)

•

During printing

When the fusing temperature (thermistor output value) falls

below 145˚C.

When the fusing temperature (thermistor output value) falls

below 145˚C.

H3 (High temperature error)

Fusing temperature (thermistor output value) of about 220 to

240˚C (varies depending on the resistance.)

240˚C (varies depending on the resistance.)

E. Fusing resistor

(1) Fusing resistor

Since the upper heat roller is conductive when copy paper is highly

moistured and the distance between the transfer unit and the fusing

unit is short, the transfer current leaks through the copy paper, the

upper heat roller and the discharging brush.

To prevent against this, a resistor of 150MOhm is provided between

the frame and the discharge brush to minimize leak current and

improve transfer efficiency.

moistured and the distance between the transfer unit and the fusing

unit is short, the transfer current leaks through the copy paper, the

upper heat roller and the discharging brush.

To prevent against this, a resistor of 150MOhm is provided between

the frame and the discharge brush to minimize leak current and

improve transfer efficiency.

Safety device

(thermal breaker, thermal

fuse)

Triac (in the

power supply unit)

power supply unit)

Heated by the

heater lamp.

(950W )

The surface temperature

of the upper hea t roller

is sensed by the thermistor.

Level of the thermistor is

controlled by the main PWB.

controlled by the main PWB.

With the signal from the

main PWB, the triac is

main PWB, the triac is

controlled on and off.

(power supply PWB )

AR-160/161 FM/E [6] OPERATIONAL DESCRIPTIONS 11/27/1998

AR-161

6 – 7

(2) Manual paper feed tray operation

(3) Resist roller

6. Fusing section

A. Basic composition

(Top view)

1

Before-fusing

paper guide

paper guide

Guides the paper transported from

the process section to the fusing unit.

the process section to the fusing unit.

2

Upper heat roller

Applies heat and pressure to the

paper to fuse.

paper to fuse.

3

Thermistor

Detects the surface temperature of

the upper heat roller.

the upper heat roller.

4

Thermostat

Stops power supply to the heat roller

in case of an abnormally high

temperature of the heat roller.

in case of an abnormally high

temperature of the heat roller.

5

Separation pawl

Separates the print paper from the

upper heat roller.

upper heat roller.

6

POD1

Detects that the paper has been

transported from the fusing section.

transported from the fusing section.

7

Heater lamp

Heats the heat roller.

8

Lower heat roller

Applies a pressure to the paper

together with the upper heat roller.

together with the upper heat roller.

B. Heat roller

A pressure roller is used for the heat roller and a silicone rubber roller

is used for the lower heat roller for better toner fusing performance

and paper separation.

is used for the lower heat roller for better toner fusing performance

and paper separation.

C. Separator pawl

Four separator pawls are used on the upper heat roller. The

separator pawls are teflon coated to reduce friction with the roller and

prevent a smear on the paper caused by the separator pawl.

separator pawls are teflon coated to reduce friction with the roller and

prevent a smear on the paper caused by the separator pawl.

D. Thermal control

1) The heater lamp, thermistor, main PWB, DC power supply PWB,

and triac within the power supply unit are used to control the

temperature in the fuser unit.To prevent against abnormally high

temperature in the fuser unit, a thermostat is used for safety pur-

poses.

temperature in the fuser unit.To prevent against abnormally high

temperature in the fuser unit, a thermostat is used for safety pur-

poses.

2) The surface temperature of the upper heat roller is set to 180˚C ~

195˚C. The surface temperature during the power save mode is

set to 100˚C.

set to 100˚C.

3) The self-check function comes active when one of the following

malfunctions occurs, and an "H" is displayed on the copy quantity

display.

display.

Fusing temperature error value

H4 (Low temperature error)

•

During machine operation

The case where the fusing temperature (thermistor output

value) does not reach 155˚C within 55 sec from lighting of the

heater lamp. (If the toner motor rotates for 10 sec or more

continuously when starting the machine, the case where the

fusing temperature does not reach 155˚C within 60 sec.)

The case where the fusing temperature (thermistor output

value) does not reach 155˚C within 55 sec from lighting of the

heater lamp. (If the toner motor rotates for 10 sec or more

continuously when starting the machine, the case where the

fusing temperature does not reach 155˚C within 60 sec.)

•

During printing

When the fusing temperature (thermistor output value) falls

below 145˚C.

When the fusing temperature (thermistor output value) falls

below 145˚C.

H3 (High temperature error)

Fusing temperature (thermistor output value) of about 220 to

240˚C (varies depending on the resistance.)

240˚C (varies depending on the resistance.)

E. Fusing resistor

(1) Fusing resistor

Since the upper heat roller is conductive when copy paper is highly

moistured and the distance between the transfer unit and the fusing

unit is short, the transfer current leaks through the copy paper, the

upper heat roller and the discharging brush.

To prevent against this, a resistor of 150MOhm is provided between

the frame and the discharge brush to minimize leak current and

improve transfer efficiency.

moistured and the distance between the transfer unit and the fusing

unit is short, the transfer current leaks through the copy paper, the

upper heat roller and the discharging brush.

To prevent against this, a resistor of 150MOhm is provided between

the frame and the discharge brush to minimize leak current and

improve transfer efficiency.

Safety device

(thermal breaker, thermal

fuse)

Triac (in the

power supply unit)

power supply unit)

Heated by the

heater lamp.

(950W )

The surface temperature

of the upper hea t roller

is sensed by the thermistor.

Level of the thermistor is

controlled by the main PWB.

controlled by the main PWB.

With the signal from the

main PWB, the triac is

main PWB, the triac is

controlled on and off.

(power supply PWB )

AR-160/161 FM/E [6] OPERATIONAL DESCRIPTIONS 11/27/1998

AR-161

6 – 7

(2) Manual paper feed tray operation

(3) Resist roller

6. Fusing section

A. Basic composition

(Top view)

1

Before-fusing

paper guide

paper guide

Guides the paper transported from

the process section to the fusing unit.

the process section to the fusing unit.

2

Upper heat roller

Applies heat and pressure to the

paper to fuse.

paper to fuse.

3

Thermistor

Detects the surface temperature of

the upper heat roller.

the upper heat roller.

4

Thermostat

Stops power supply to the heat roller

in case of an abnormally high

temperature of the heat roller.

in case of an abnormally high

temperature of the heat roller.

5

Separation pawl

Separates the print paper from the

upper heat roller.

upper heat roller.

6

POD1

Detects that the paper has been

transported from the fusing section.

transported from the fusing section.

7

Heater lamp

Heats the heat roller.

8

Lower heat roller

Applies a pressure to the paper

together with the upper heat roller.

together with the upper heat roller.

B. Heat roller

A pressure roller is used for the heat roller and a silicone rubber roller

is used for the lower heat roller for better toner fusing performance

and paper separation.

is used for the lower heat roller for better toner fusing performance

and paper separation.

C. Separator pawl

Four separator pawls are used on the upper heat roller. The

separator pawls are teflon coated to reduce friction with the roller and

prevent a smear on the paper caused by the separator pawl.

separator pawls are teflon coated to reduce friction with the roller and

prevent a smear on the paper caused by the separator pawl.

D. Thermal control

1) The heater lamp, thermistor, main PWB, DC power supply PWB,

and triac within the power supply unit are used to control the

temperature in the fuser unit.To prevent against abnormally high

temperature in the fuser unit, a thermostat is used for safety pur-

poses.

temperature in the fuser unit.To prevent against abnormally high

temperature in the fuser unit, a thermostat is used for safety pur-

poses.

2) The surface temperature of the upper heat roller is set to 180˚C ~

195˚C. The surface temperature during the power save mode is

set to 100˚C.

set to 100˚C.

3) The self-check function comes active when one of the following

malfunctions occurs, and an "H" is displayed on the copy quantity

display.

display.

Fusing temperature error value

H4 (Low temperature error)

•

During machine operation

The case where the fusing temperature (thermistor output

value) does not reach 155˚C within 55 sec from lighting of the

heater lamp. (If the toner motor rotates for 10 sec or more

continuously when starting the machine, the case where the

fusing temperature does not reach 155˚C within 60 sec.)

The case where the fusing temperature (thermistor output

value) does not reach 155˚C within 55 sec from lighting of the

heater lamp. (If the toner motor rotates for 10 sec or more

continuously when starting the machine, the case where the

fusing temperature does not reach 155˚C within 60 sec.)

•

During printing

When the fusing temperature (thermistor output value) falls

below 145˚C.

When the fusing temperature (thermistor output value) falls

below 145˚C.

H3 (High temperature error)

Fusing temperature (thermistor output value) of about 220 to

240˚C (varies depending on the resistance.)

240˚C (varies depending on the resistance.)

E. Fusing resistor

(1) Fusing resistor

Since the upper heat roller is conductive when copy paper is highly

moistured and the distance between the transfer unit and the fusing

unit is short, the transfer current leaks through the copy paper, the

upper heat roller and the discharging brush.

To prevent against this, a resistor of 150MOhm is provided between

the frame and the discharge brush to minimize leak current and

improve transfer efficiency.

moistured and the distance between the transfer unit and the fusing

unit is short, the transfer current leaks through the copy paper, the

upper heat roller and the discharging brush.

To prevent against this, a resistor of 150MOhm is provided between

the frame and the discharge brush to minimize leak current and

improve transfer efficiency.

Safety device

(thermal breaker, thermal

fuse)

Triac (in the

power supply unit)

power supply unit)

Heated by the

heater lamp.

(950W )

The surface temperature

of the upper hea t roller

is sensed by the thermistor.

Level of the thermistor is

controlled by the main PWB.

controlled by the main PWB.

With the signal from the

main PWB, the triac is

main PWB, the triac is

controlled on and off.

(power supply PWB )

AR-160/161 FM/E [6] OPERATIONAL DESCRIPTIONS 11/27/1998

AR-161

6 – 7