Sharp R-8740 (serv.man8) Service Manual ▷ View online

R-8740M - 15

A

B

C

D2

D1

ASYMMETRIC

RECTIFIER

RECTIFIER

HIGH VOLTAGE RECTIFIER

C

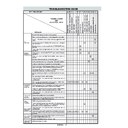

HIGH VOLTAGE RECTIFIER ASSEMBLY TEST

HIGH VOLTAGE RECTIFIER TEST

CARRY OUT 3D CHECKS.

Isolate the high voltage rectifier assembly from the HV circuit. The high voltage rectifier can be tested

using an ohmmeter set to its highest range. Connect the ohmmeter across the terminal B+C of the high

voltage rectifier and note the reading obtained. Reverse the meter leads and note this second reading.

The normal resistance is infinite in one direction and more than 100 kΩ in the other direction.

using an ohmmeter set to its highest range. Connect the ohmmeter across the terminal B+C of the high

voltage rectifier and note the reading obtained. Reverse the meter leads and note this second reading.

The normal resistance is infinite in one direction and more than 100 kΩ in the other direction.

CARRY OUT 4R CHECKS

ASYMMETRIC RECTIFIER TEST

CARRY OUT 3D CHECKS.

CARRY OUT 3D CHECKS

Disconnect the leads to the primary winding of the high voltage transformer. Disconnect the filament and

secondary winding connections from the rest of the HV circuitry. Using an ohmmeter, set on a low range,

it is possible to check the continuity of all three windings. The following readings should be obtained:-

secondary winding connections from the rest of the HV circuitry. Using an ohmmeter, set on a low range,

it is possible to check the continuity of all three windings. The following readings should be obtained:-

If the reading obtained are not stated above, then the high voltage transformer is probably faulty and

should be replaced.

should be replaced.

CARRY OUT 4R CHECKS

a. Primary winding

1.9 ohms approximately

b. Secondary winding

122 ohms approximately

c. Filament winding

less than 1 ohm

WARNING: High voltages and large currents are present at the secondary winding and

filament winding transformer. It is very dangerous to work near this part when

the oven is on. NEVER make any voltage measurements of the high-voltage

circuits, including the magnetron filament.

the oven is on. NEVER make any voltage measurements of the high-voltage

circuits, including the magnetron filament.

B

HIGH VOLTAGE TRANSFORMER TEST

TEST PROCEDURES

PROCEDURE

LETTER

COMPONENT TEST

R-8740M - 16

Isolate the high voltage rectifier assembly from the HV circuit. The asymmetric can be tested using an

ohmmeter set to its highest range across the terminals A+B of the asymmetric rectifier and note the

reading obtained. Reverse the meter leads and note this second reading. If an open circuit is indicated

in both direction then the asymmetric rectifier is good. If an asymmetric rectifier is shorted in either

direction, then the asymmetric rectifier is probably faulty and must be replaced with high voltage rectifier.

When the asymmetric rectifier is defective, check whether magnetron, high voltage rectifier, high voltage

wire or filament winding of the power transformer is shorted.

ohmmeter set to its highest range across the terminals A+B of the asymmetric rectifier and note the

reading obtained. Reverse the meter leads and note this second reading. If an open circuit is indicated

in both direction then the asymmetric rectifier is good. If an asymmetric rectifier is shorted in either

direction, then the asymmetric rectifier is probably faulty and must be replaced with high voltage rectifier.

When the asymmetric rectifier is defective, check whether magnetron, high voltage rectifier, high voltage

wire or filament winding of the power transformer is shorted.

CARRY OUT 4R CHECKS

NOTE: FOR MEASUREMENT OF THE RESISTANCE OF THE RECTIFIER, THE BATTERIES OF

THE MEASURING INSTRUMENT MUST HAVE A VOLTAGE OF AT LEAST 6 VOLTS,

BECAUSE OTHERWISE AN INFINITE RESISTANCE MIGHT BE SHOWN IN BOTH

DIRECTIONS.

BECAUSE OTHERWISE AN INFINITE RESISTANCE MIGHT BE SHOWN IN BOTH

DIRECTIONS.

D

HIGH VOLTAGE CAPACITOR TEST

CARRY OUT 3D CHECKS

A. Isolate the high voltage capacitor from the circuit.

B. Continuity check must be carried out with measuring instrument which is set to the highest resistance

B. Continuity check must be carried out with measuring instrument which is set to the highest resistance

range.

C. A normal capacitor shows continuity for a short time (kick) and then a resistance of about 10MΩ after

it has been charged.

D. A short-circuited capacitor shows continuity all the time.

E. An open capacitor constantly shows a resistance about 10 MΩ because of its internal 10MΩ

E. An open capacitor constantly shows a resistance about 10 MΩ because of its internal 10MΩ

resistance.

F. When the internal wire is opened in the high voltage capacitor shows an infinite resistance.

G. The resistance across all the terminals and the chassis must be infinite when the capacitor is normal.

If incorrect reading are obtained, the high voltage capacitor must be replaced.

G. The resistance across all the terminals and the chassis must be infinite when the capacitor is normal.

If incorrect reading are obtained, the high voltage capacitor must be replaced.

CARRY OUT 4R CHECKS

E

SWITCH TEST

CARRY OUT 3D CHECKS

Isolate the switch to be tested and using an ohmmeter check between the terminals as described in the

following table.

following table.

COM; Common terminal, NO; Normally open terminal NC; Normally close terminal

S.C.; Short, O.C.; Open circuit

S.C.; Short, O.C.; Open circuit

Table: Terminal Connection of Switch

Plunger Operation

COM to NO

COM to NC

Released

O.C.

S.C.

Depressed

S.C.

O.C.

If incorrect readings are obtained, replace the switch.

CARRY OUT 4R CHECKS.

TEST PROCEDURES

PROCEDURE

LETTER

COMPONENT TEST

R-8740M - 17

G

THERMAL CUT-OUT TEST

CARRY OUT 3D CHECKS

Disconnect the leads from the terminals of the thermal cut-out. Then using an ohmmeter, make a

continuity test across the two terminals as described in the below.

continuity test across the two terminals as described in the below.

CARRY OUT 4R CHECKS

Table: Thermal Cut-out Test

Temperature of

Temperature of

Indication of

"ON" condition

"OFF" condition

ohmmeter

Parts Name

(closed circuit).

(open circuit).

(When room

(˚C)

(˚C)

temperature is

approx. 20˚C.)

Thermal cut-out

Below 130˚C

Above 150˚C

Closed circuit

150˚C TC1

Thermal cut-out

This is not resetable

Above 125˚C

Closed circuit

125˚C TC2

type

H

MOTOR WINDING TEST

CARRY OUT 3D CHECKS

Disconnect the leads from the motor. Using an ohmmeter, check the

resistance between the two terminals as described in the table below.

resistance between the two terminals as described in the table below.

I

NOISE FILTER TEST

CARRY OUT 3D CHECKS

Disconnect the leads from the terminals of

noise filter.

Using an ohmmeter, check between the ter-

minals as described in the following table.

noise filter.

Using an ohmmeter, check between the ter-

minals as described in the following table.

MEASURING POINTS

INDICATION OF OHMMETER

Between N and L

Approx. 680 kΩ

Between terminal N and WHITE

Short circuit

Between terminal L and RED

Short circuit

L (min)

Cx ± 20%

Cy ± 20%

1.0mH

0.22µF

4700pF

Table: Resistance of Motor

Motors

Resistance

Fan motor

Approximately 216 Ω

Turntable motor

Approximately 16 kΩ

Convection fan motor

Approximately 410 Ω

If incorrect readings are obtained, replace the thermal cut-out.

An open circuit thermal cut-out (MG) TC2 indicates that the magnetron has overheated, this may be due

to resistricted ventilation, cooling fan failure.

An open circuit thermal cut-out (OVEN) TC1 indicates that the oven cavity has overheated, this may be

due to no load operation.

An open circuit thermal cut-out (MG) TC2 indicates that the magnetron has overheated, this may be due

to resistricted ventilation, cooling fan failure.

An open circuit thermal cut-out (OVEN) TC1 indicates that the oven cavity has overheated, this may be

due to no load operation.

If incorrect readings are obtained, replace the motor.

CARRY OUT 4R CHECKS

If incorrect readings are absorbed, replace the noise filter unit.

CARRY OUT 4R CHECKS

RED

WHT

L

L

R1

L

R2

N

Cx

Cy

R1: 10M ohm ± 20%

R2: 680k ohm ± 20%

R2: 680k ohm ± 20%

F2:F8A

F1:F20A

TEST PROCEDURES

PROCEDURE

LETTER

COMPONENT TEST

R-8740M - 18

J

FUSE F1 20A

CARRY OUT 3D CHECKS

If the fuse F1 20A is blown, there is a shorts or grounds in electrical parts or wire harness. Check them

and replace the defective parts or repair the wire harness.

and replace the defective parts or repair the wire harness.

CARRY OUT 4R CHECKS

CAUTION: Only replace fuse with the correct value replacement.

K

BLOWN FUSE F2 F8A

CARRY OUT 3D CHECKS

1. If the fuse F2 F8A is blown when the door is opened, check the monitored latch switch and monitor

1. If the fuse F2 F8A is blown when the door is opened, check the monitored latch switch and monitor

switch.

2. If the fuse F2 F8A is blown by incorrect door switching replace the defective switch(es) and the fuse

F2 F8A.

3. If the fuse F2 F8A is blown, there could be shorts in the asymmetric rectifier or there is a ground in

wire harness. A short in the asymmetric rectifier may be occurred due to short or ground in H.V.

rectifier, magnetron, high voltage transformer or H.V. wire. Check them and replace the defective

parts or repair the wire harness.

rectifier, magnetron, high voltage transformer or H.V. wire. Check them and replace the defective

parts or repair the wire harness.

CARRY OUT 4R CHECKS

CAUTION: Only replace fuse F2 F8A with the correct value replacement.

M

TOP AND BOTTOM GRILL HEATING ELEMENT TEST

CARRY OUT 3D CHECKS

Before carrying out the following tests make sure the heating element is cool completely.

1. Resistance of heating element.

1. Resistance of heating element.

Disconnect the wire leads to the heating element to be tested. Using ohmmeter with low resistance

range. Check the resistance across the terminals of the heating element as described in the following

table.

range. Check the resistance across the terminals of the heating element as described in the following

table.

Table: Resistance of heating element

Part name

Resistance

Bottom grill heating element

Approximately 66 Ω

Top grill heating element

Approximately 22 Ω x 2 = 44 Ω

2. Insulation resistance.

Disconnect the wire leads to the heating element to be tested. Check the insulation resistance

between the element terminal and cavity using a 500V - 100MΩ insulation tester. The insulation

resistance should be more than 10M&ohm in the cold start.

between the element terminal and cavity using a 500V - 100MΩ insulation tester. The insulation

resistance should be more than 10M&ohm in the cold start.

If the results of above test 1 and/or 2 are out of above specifications, the heating element is probably

faulty and should be replaced.

faulty and should be replaced.

CARRY OUT 4R CHECKS

CARRY OUT 3D CHECKS.

Disconnect connector B from CPU unit. Measure the resistance of thermistor with an ohmmeter. Connect

the ohmmeter leads to Pin No's C1 and C3 of the thermistor harness.

the ohmmeter leads to Pin No's C1 and C3 of the thermistor harness.

Room Temperature

Resistance

20˚C - 30˚C

Approximately 326 kΩ - 175 kΩ

If the merter does not indicate above resistance, replace the thermistor.

CARRY OUT 4R CHECKS.

N

THERMOSTAT TEST

TEST PROCEDURES

PROCEDURE

LETTER

COMPONENT TEST

Display