Sharp R-8740 (serv.man8) Service Manual ▷ View online

R-8740M - 18

J

FUSE F1 20A

CARRY OUT 3D CHECKS

If the fuse F1 20A is blown, there is a shorts or grounds in electrical parts or wire harness. Check them

and replace the defective parts or repair the wire harness.

and replace the defective parts or repair the wire harness.

CARRY OUT 4R CHECKS

CAUTION: Only replace fuse with the correct value replacement.

K

BLOWN FUSE F2 F8A

CARRY OUT 3D CHECKS

1. If the fuse F2 F8A is blown when the door is opened, check the monitored latch switch and monitor

1. If the fuse F2 F8A is blown when the door is opened, check the monitored latch switch and monitor

switch.

2. If the fuse F2 F8A is blown by incorrect door switching replace the defective switch(es) and the fuse

F2 F8A.

3. If the fuse F2 F8A is blown, there could be shorts in the asymmetric rectifier or there is a ground in

wire harness. A short in the asymmetric rectifier may be occurred due to short or ground in H.V.

rectifier, magnetron, high voltage transformer or H.V. wire. Check them and replace the defective

parts or repair the wire harness.

rectifier, magnetron, high voltage transformer or H.V. wire. Check them and replace the defective

parts or repair the wire harness.

CARRY OUT 4R CHECKS

CAUTION: Only replace fuse F2 F8A with the correct value replacement.

M

TOP AND BOTTOM GRILL HEATING ELEMENT TEST

CARRY OUT 3D CHECKS

Before carrying out the following tests make sure the heating element is cool completely.

1. Resistance of heating element.

1. Resistance of heating element.

Disconnect the wire leads to the heating element to be tested. Using ohmmeter with low resistance

range. Check the resistance across the terminals of the heating element as described in the following

table.

range. Check the resistance across the terminals of the heating element as described in the following

table.

Table: Resistance of heating element

Part name

Resistance

Bottom grill heating element

Approximately 66 Ω

Top grill heating element

Approximately 22 Ω x 2 = 44 Ω

2. Insulation resistance.

Disconnect the wire leads to the heating element to be tested. Check the insulation resistance

between the element terminal and cavity using a 500V - 100MΩ insulation tester. The insulation

resistance should be more than 10M&ohm in the cold start.

between the element terminal and cavity using a 500V - 100MΩ insulation tester. The insulation

resistance should be more than 10M&ohm in the cold start.

If the results of above test 1 and/or 2 are out of above specifications, the heating element is probably

faulty and should be replaced.

faulty and should be replaced.

CARRY OUT 4R CHECKS

CARRY OUT 3D CHECKS.

Disconnect connector B from CPU unit. Measure the resistance of thermistor with an ohmmeter. Connect

the ohmmeter leads to Pin No's C1 and C3 of the thermistor harness.

the ohmmeter leads to Pin No's C1 and C3 of the thermistor harness.

Room Temperature

Resistance

20˚C - 30˚C

Approximately 326 kΩ - 175 kΩ

If the merter does not indicate above resistance, replace the thermistor.

CARRY OUT 4R CHECKS.

N

THERMOSTAT TEST

TEST PROCEDURES

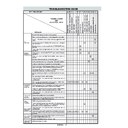

PROCEDURE

LETTER

COMPONENT TEST

R-8740M - 19

TEST PROCEDURES

O TOUCH CONTROL PANEL ASSEMBLY TEST

The touch control panel consists of circuits including semiconductors such as LSI, ICs, etc. Therefore,

unlike conventional microwave ovens, proper maintenance can not be performed with only a voltmeter and

ohmmeter.

In this service manual, the touch control panel assembly is divided into two units, Control Unit and Key Unit,

and troubleshooting by unit replacement is described according to the symptoms indicated.

1. Key Unit Note : Check key unit ribbon connection before replacement.

unlike conventional microwave ovens, proper maintenance can not be performed with only a voltmeter and

ohmmeter.

In this service manual, the touch control panel assembly is divided into two units, Control Unit and Key Unit,

and troubleshooting by unit replacement is described according to the symptoms indicated.

1. Key Unit Note : Check key unit ribbon connection before replacement.

The following symptoms indicate a defective key unit. Replace the key unit.

a) When touching the pads, a certain pad produces no signal at all.

b) When touching a number pad, two figures or more are displayed.

c) When touching the pads, sometimes a pad produces no signal.

b) When touching a number pad, two figures or more are displayed.

c) When touching the pads, sometimes a pad produces no signal.

2. Control Panel

The following symptoms indicate a defective control unit. Before replacing the control unit.

perform the key unit test (Procedure M) to determine if control unit is faulty.

perform the key unit test (Procedure M) to determine if control unit is faulty.

2-1 In connection with pads

a) When touching the pads, a certain group of pads do not produce a signal.

b) When touching the pads, no pads produce a signal.

b) When touching the pads, no pads produce a signal.

2-2 In connection with indicators

a) At a certain digit, all or some segments do not light up.

b) At a certain digit, brightness is low.

c) Only one indicator does not light up.

d) The corresponding segments of all digits do not light up; or they continue to light up.

e) Wrong figure appears.

f) A certain group of indicators do not light up.

g) The figure of all digits flicker.

b) At a certain digit, brightness is low.

c) Only one indicator does not light up.

d) The corresponding segments of all digits do not light up; or they continue to light up.

e) Wrong figure appears.

f) A certain group of indicators do not light up.

g) The figure of all digits flicker.

2-3 Other possible troubles caused by defective control unit.

a) Buzzer does not sound or continues to sound.

b) Clock does not operate properly.

c) Cooking is not possible.

d) Proper temperature measurement is not obtained.

b) Clock does not operate properly.

c) Cooking is not possible.

d) Proper temperature measurement is not obtained.

PROCEDURE

LETTER

COMPONENT TEST

P RELAY TEST

CARRY OUT 3D CHECKS.

Remove the outer case and check voltage between Pin Nos. 11 and 9 of the 6 pin connector (A) on the

control unit with an A.C. voltmeter.

The meter should indicate rated voltage, if not check oven circuit.

Remove the outer case and check voltage between Pin Nos. 11 and 9 of the 6 pin connector (A) on the

control unit with an A.C. voltmeter.

The meter should indicate rated voltage, if not check oven circuit.

RY1, RY2, RY3, RY4, RY5 and RY7 Relay Test

These relays are operated by D.C. voltage

Check voltage at the relay coil with a D.C. voltmeter during the microwave cooking operation, grill cooking,

convection cooking or dual cooking.

These relays are operated by D.C. voltage

Check voltage at the relay coil with a D.C. voltmeter during the microwave cooking operation, grill cooking,

convection cooking or dual cooking.

DC. voltage indicated ............. Defective relay.

DC. voltage not indicated ....... Check diode which is connected to the relay coil. If diode is good, control

DC. voltage not indicated ....... Check diode which is connected to the relay coil. If diode is good, control

unit is defective.

RELAY SYMBOL

OPERATIONAL VOLTAGE

CONNECTED COMPONENTS

RY1

Approx. 24.0V D.C.

Oven lamp / Turntable motor

RY2

Approx. 18.0V D.C.

High voltage transformer

RY3

Approx. 23.0V D.C.

Top heating element

RY4

Approx. 23.0V D.C.

Bottom heating element

RY5

Approx. 23.0V D.C.

Fan motor

RY7

Approx. 23.0V D.C.

Convection motor

CARRY OUT 4R CHECKS.

R-8740M - 20

CARRY OUT 3D CHECKS.

STEPS

OCCURRENCE

CAUSE OR CORRECTION

1

The rated AC voltage is not present at

Check supply voltage and oven power cord.

power terminal of CPU connector (CN-A).

2

The rated AC voltage is present at primary

Low voltage transformer or secondary circuit defective.

side of low voltage transformer.

Check and repair.

3

Only pattern at "a" is broken.

*Insert jumper wire J1 and solder.

(CARRY OUT 3D CHECKS BEFORE REPAIR)

4

Pattern at "a" and "b" are broken.

*Insert the coil RCILF2003YAZZ between "c" and "d".

(CARRY OUT 3D CHECKS BEFORE REPAIR)

Q

PROCEDURES TO BE TAKEN WHEN THE FOIL PATTERN ON THE PRINTED WIRING BOARD

(PWB) IS OPEN

NOTE: *At the time of these repairs, make a

visual inspection of the varistor for burn-

ing damage and examine the trans-

former with tester for the presence of

layer short circuit (check primary coil

resistance). If any abnormal condition

is detected, replace the defective parts.

ing damage and examine the trans-

former with tester for the presence of

layer short circuit (check primary coil

resistance). If any abnormal condition

is detected, replace the defective parts.

CARRY OUT 3D CHECKS

Q20

a

b

c

d

RY5

FM

(J1)

B

PWR

CN - A

VRS1

T1

P

4

1

RY6

AC

D25

TEST PROCEDURES

PROCEDURE

LETTER

COMPONENT TEST

R

KEY UNIT TEST

If the display fails to clear when the STOP pad is depressed, first verify the flat ribbon cable is

marking good contact, verify that the door sensing switch (stop switch) operates properly; that is

the contacts are closed when the door is closed and open when the door is open. If the door

sensing switch (stop switch) is good, disconnect the flat ribbon cable that connects the key unit to

the control unit and make sure the door sensing switch is closed (either close the door or short

the door sensing switch connecter). Use the Key unit matrix indicated on the control panel

schematic and place a jumper wire between the pins that correspond to the STOP pad marking

momentary contact. If the control unit responds by clearing with a beep the key unit is faulty and

must be replaced. If the control unit does not respond, it is a faulty and must be replaced. If a

specific pad does not respond, the above method may be used (after clearing the control unit) to

determine if the control unit or key pad is at fault.

marking good contact, verify that the door sensing switch (stop switch) operates properly; that is

the contacts are closed when the door is closed and open when the door is open. If the door

sensing switch (stop switch) is good, disconnect the flat ribbon cable that connects the key unit to

the control unit and make sure the door sensing switch is closed (either close the door or short

the door sensing switch connecter). Use the Key unit matrix indicated on the control panel

schematic and place a jumper wire between the pins that correspond to the STOP pad marking

momentary contact. If the control unit responds by clearing with a beep the key unit is faulty and

must be replaced. If the control unit does not respond, it is a faulty and must be replaced. If a

specific pad does not respond, the above method may be used (after clearing the control unit) to

determine if the control unit or key pad is at fault.

CARRY OUT 4R CHECKS.

R-8740M

4

5

2

5

7

9

0

4

6

8

1

3

6

7

8

9

10

11

12

3

2

1

TIME

REDUCE

MEMORY

MANUAL

MICROWAVE

CONVECTION

BOTTOM

GRILL

SOUND

TOP

GRILL

STOP

START

R-8740M - 20

CARRY OUT 3D CHECKS.

STEPS

OCCURRENCE

CAUSE OR CORRECTION

1

The rated AC voltage is not present at

Check supply voltage and oven power cord.

power terminal of CPU connector (CN-A).

2

The rated AC voltage is present at primary

Low voltage transformer or secondary circuit defective.

side of low voltage transformer.

Check and repair.

3

Only pattern at "a" is broken.

*Insert jumper wire J1 and solder.

(CARRY OUT 3D CHECKS BEFORE REPAIR)

4

Pattern at "a" and "b" are broken.

*Insert the coil RCILF2003YAZZ between "c" and "d".

(CARRY OUT 3D CHECKS BEFORE REPAIR)

Q

PROCEDURES TO BE TAKEN WHEN THE FOIL PATTERN ON THE PRINTED WIRING BOARD

(PWB) IS OPEN

NOTE: *At the time of these repairs, make a

visual inspection of the varistor for burn-

ing damage and examine the trans-

former with tester for the presence of

layer short circuit (check primary coil

resistance). If any abnormal condition

is detected, replace the defective parts.

ing damage and examine the trans-

former with tester for the presence of

layer short circuit (check primary coil

resistance). If any abnormal condition

is detected, replace the defective parts.

CARRY OUT 3D CHECKS

Q20

a

b

c

d

RY5

FM

(J1)

B

PWR

CN - A

VRS1

T1

P

4

1

RY6

AC

D25

TEST PROCEDURES

PROCEDURE

LETTER

COMPONENT TEST

R

KEY UNIT TEST

If the display fails to clear when the STOP pad is depressed, first verify the flat ribbon cable is

marking good contact, verify that the door sensing switch (stop switch) operates properly; that is

the contacts are closed when the door is closed and open when the door is open. If the door

sensing switch (stop switch) is good, disconnect the flat ribbon cable that connects the key unit to

the control unit and make sure the door sensing switch is closed (either close the door or short

the door sensing switch connecter). Use the Key unit matrix indicated on the control panel

schematic and place a jumper wire between the pins that correspond to the STOP pad marking

momentary contact. If the control unit responds by clearing with a beep the key unit is faulty and

must be replaced. If the control unit does not respond, it is a faulty and must be replaced. If a

specific pad does not respond, the above method may be used (after clearing the control unit) to

determine if the control unit or key pad is at fault.

marking good contact, verify that the door sensing switch (stop switch) operates properly; that is

the contacts are closed when the door is closed and open when the door is open. If the door

sensing switch (stop switch) is good, disconnect the flat ribbon cable that connects the key unit to

the control unit and make sure the door sensing switch is closed (either close the door or short

the door sensing switch connecter). Use the Key unit matrix indicated on the control panel

schematic and place a jumper wire between the pins that correspond to the STOP pad marking

momentary contact. If the control unit responds by clearing with a beep the key unit is faulty and

must be replaced. If the control unit does not respond, it is a faulty and must be replaced. If a

specific pad does not respond, the above method may be used (after clearing the control unit) to

determine if the control unit or key pad is at fault.

CARRY OUT 4R CHECKS.

R-8740M

4

5

2

5

7

9

0

4

6

8

1

3

6

7

8

9

10

11

12

3

2

1

TIME

REDUCE

MEMORY

MANUAL

MICROWAVE

CONVECTION

BOTTOM

GRILL

SOUND

TOP

GRILL

STOP

START

Display