Sharp CD-DVD500 (serv.man10) Service Manual ▷ View online

CD-DVD500H

– 30 –

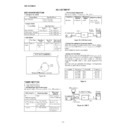

Since the pickup semiconductor laser can easily damaged by

the static electricity, handle the mechanism unit with care.

To prevent damage by the static electricity during

transportation, the LD terminals are short-circuited at 2 points

on the PWB. Unsolder them by a soldering iron after

completing the connection. When you return the mechanism

unit, solder the terminals again.

the static electricity, handle the mechanism unit with care.

To prevent damage by the static electricity during

transportation, the LD terminals are short-circuited at 2 points

on the PWB. Unsolder them by a soldering iron after

completing the connection. When you return the mechanism

unit, solder the terminals again.

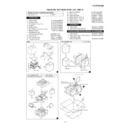

Notes for handling the mechanism unit

4X

Soldering on the

mechanism PWB (two points)

mechanism PWB (two points)

Flexible PWB

DVD Motor PWB

Figure 30

CD-DVD500H

– 30 –

Since the pickup semiconductor laser can easily damaged by

the static electricity, handle the mechanism unit with care.

To prevent damage by the static electricity during

transportation, the LD terminals are short-circuited at 2 points

on the PWB. Unsolder them by a soldering iron after

completing the connection. When you return the mechanism

unit, solder the terminals again.

the static electricity, handle the mechanism unit with care.

To prevent damage by the static electricity during

transportation, the LD terminals are short-circuited at 2 points

on the PWB. Unsolder them by a soldering iron after

completing the connection. When you return the mechanism

unit, solder the terminals again.

Notes for handling the mechanism unit

4X

Soldering on the

mechanism PWB (two points)

mechanism PWB (two points)

Flexible PWB

DVD Motor PWB

Figure 30

CD-DVD500H

– 30 –

Since the pickup semiconductor laser can easily damaged by

the static electricity, handle the mechanism unit with care.

To prevent damage by the static electricity during

transportation, the LD terminals are short-circuited at 2 points

on the PWB. Unsolder them by a soldering iron after

completing the connection. When you return the mechanism

unit, solder the terminals again.

the static electricity, handle the mechanism unit with care.

To prevent damage by the static electricity during

transportation, the LD terminals are short-circuited at 2 points

on the PWB. Unsolder them by a soldering iron after

completing the connection. When you return the mechanism

unit, solder the terminals again.

Notes for handling the mechanism unit

4X

Soldering on the

mechanism PWB (two points)

mechanism PWB (two points)

Flexible PWB

DVD Motor PWB

Figure 30

CD-DVD500H

– 30 –

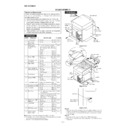

Since the pickup semiconductor laser can easily damaged by

the static electricity, handle the mechanism unit with care.

To prevent damage by the static electricity during

transportation, the LD terminals are short-circuited at 2 points

on the PWB. Unsolder them by a soldering iron after

completing the connection. When you return the mechanism

unit, solder the terminals again.

the static electricity, handle the mechanism unit with care.

To prevent damage by the static electricity during

transportation, the LD terminals are short-circuited at 2 points

on the PWB. Unsolder them by a soldering iron after

completing the connection. When you return the mechanism

unit, solder the terminals again.

Notes for handling the mechanism unit

4X

Soldering on the

mechanism PWB (two points)

mechanism PWB (two points)

Flexible PWB

DVD Motor PWB

Figure 30