Sharp CD-DVD500 (serv.man10) Service Manual ▷ View online

CD-DVD500H

– 18 –

fL: Low-range frequency

fH: High-range frequency

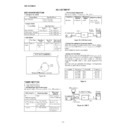

• AM adjustment and confirmation

fH: High-range frequency

• AM adjustment and confirmation

Figure 18-3 AM IF

TUNER SECTION

• Setting the Test Mode

While holding down the MEMORY/SET button and the X-

BASS button, press the ON/STAND-BY button. Frequencies

are rewritten in memory as shown in table 18. Call them

using the VOLUME knob of tuner circuit adjustment and

check.

Note that once you reinitialize the settings, the frequencies

recorded by users will be changed.

While holding down the MEMORY/SET button and the X-

BASS button, press the ON/STAND-BY button. Frequencies

are rewritten in memory as shown in table 18. Call them

using the VOLUME knob of tuner circuit adjustment and

check.

Note that once you reinitialize the settings, the frequencies

recorded by users will be changed.

Preset No.

Frequency

P01

87.50 MHz

P06

522 kHz

P02

108.00 MHz

P07

1,620 kHz

P03

90.00 MHz

P08

603 kHz

P04

106.00 MHz

P09

1,404 kHz

P05

98.00 MHz

P10

990 kHz

Adjusting item

Adjusting object

Adjusting

method

IF

T351

Set IF waveform

Adjust the indication

450 kHz to maximum.

of set to 1,620 kHz.

Frequency cover

fL: T306 (522 kHz)

fL: 1.1

±

0.1 V

(VT line voltage of

Adjust the indication

fH: 8.0

±

1.3 V

TP301)

of set to 522 kHz.

(Only confirmation)

fH: (1,620 kHz)

Tracking

fL: T302 (990 kHz)

Set the output of

speaker terminal

to maximum.

speaker terminal

to maximum.

AM signal oscillator Frequency 400 Hz, 30 %, AM modulation

• FM mute level adjustment

Frequency

Adjusting

object

Adjusting

method

98.0 MHz

25 dB(EMF)

VR351

Input: SO301

Output: Speaker

Terminal

Output: Speaker

Terminal

FM signal oscillator Frequency 1 kHz, 40 kHz

Adjusting object

Preset No.

Frequency

Figure 18-2 FM Mute Level

Table 18

Electronic

Voltmeter

Voltmeter

GND

AM Loop Antenna

AM signal oscillator

Loop Antenna

UNIT

IF : Speaker Terminal

Frequency cover: TP301

Frequency cover: TP301

Electronic

Voltmeter

Voltmeter

UNIT

FM signal oscillator

SO301

Speaker

Terminal

Terminal

• Erasing the registered broadcast station

When the power is off, press and hold the TUNER (BAND)

button and the X-BASS button, and then press the POWER

button.

All the registered stations are erased.

When the power is off, press and hold the TUNER (BAND)

button and the X-BASS button, and then press the POWER

button.

All the registered stations are erased.

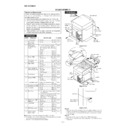

ADJUSTMENT

MECHANISM SECTION

•

Driving Force Check

Torque Meter

Specified Value

Play: TW-2111

Tape 1: Over 80 g

Tape 2: Over 80 g

Tape 2: Over 80 g

•

Torque Check

Torque Meter

Tape 2

Play: TW-2111

30 to 80 g.cm

30 to 80 g.cm

Fast forward: TW-2231

—

70 to 180 g.cm

Rewind: TW-2231

—

70 to 180 g.cm

Specified Value

Tape 1

Specified

Value

Adjusting

Point

Instrument

Connection

Test Tape

Normal

MTT-111

Variable

3,000

±

30 Hz

Speaker

speed

Resistor in

Terminal

motor.

(Load

resistance:

6 ohms)

resistance:

6 ohms)

•

Tape Speed

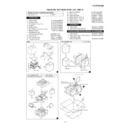

Figure 18-1

TAPE MECHANISM

Tape

Motor

Motor

Variable Resistor in motor

– 19 –

CD-DVD500H

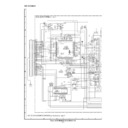

DVD/CD SECTION

• Adjustment

Since this DVD/CD system incorporates the following

automatic adjustment functions, readjustment is not needed

when replacing the pickup. Therefore, different PWBs and

pickups can be combined freely.

Each time a disc is changed, these adjustments are

performed automatically. Therefore, playback of each disc

can be performed under optimum conditions.

automatic adjustment functions, readjustment is not needed

when replacing the pickup. Therefore, different PWBs and

pickups can be combined freely.

Each time a disc is changed, these adjustments are

performed automatically. Therefore, playback of each disc

can be performed under optimum conditions.

Figure 19 ADJUSTMENT POINTS

FE301

AM IF

T302

T306

T351

AM

TRACKING fL

AM BAND

COVERAGE fL

FM MUTE

LEVEL

MAIN PWB

CNP301

AM LOOP

ANTENNA

SO301

FM ANTENNA

TERMINAL

VR351

TP302

R350

R345

TP301

CD-DVD500H

– 20 –

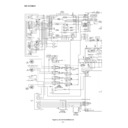

TEST MODE

During POWER off mode, push below each 2 keys and [POWER] key.

Then go to each TEST MODE.

Then go to each TEST MODE.

KEY

TEST MODE

CONTENTS

[POWER] [TUN] + [X-BASS]

TEST 1

TUNER PRESET MEMORY CLEAR

[POWER] [MEMORY/SET] + [X-BASS]

TEST 2

TUNER PRESET FOR PRODUCTION

Test mode for the production and display

TEST 3

Test mode for the production

[POWER] [CD] + [X-BASS]

TEST 4

Ver. No Display (DVD Microcomputer)

Test mode for the production and display

TEST 5

Test mode for the production

[POWER] [>] + [X-BASS]

TEST 6

ALL CLEAR (RESET)

Test mode for the production and display

TEST 7

Test mode for the production

[POWER] [TUN DOWN] + [X-BASS]

TEST 8

PRODUCTION INITIALIZE FOR CHANGER

Test mode for the production and display

TEST 11

Test mode for the production

[POWER] [<<] + [X-BASS]

TEST 12

Ver. No DISPLAY (SYSTEM MICROCOMPUTER)

[POWER] [CD] + [G.EQ]

TEST 15

DVD MICROCOMPUTER (ROM Renewal Mode)

TEST MODE 1 (Write in, operation manual, open to user)

Work:

Clear all TUNER PRESET MEMORY.

Function: - TUNER

- BAND: FM ST

- FREQUENCY RECEIVE: F.L. (MINIMUM FREQUENCY)

- FREQUENCY RECEIVE: F.L. (MINIMUM FREQUENCY)

Figure:

The above figure: Displayed for about 1.0 sec

Other conditions: - Same as TEST MEMORY.

After Action: - Normal operation.

MEMORY

TUNER CL

RUN TEST 1

Clear all TUNER PRESET MEMORY.

Bring BAND SETTING FREQUENCY into operation .

POWER ON

NORMAL OPERATION

"TUNER CLEAR " is displayd for 1sec.

MEMORY

– 21 –

CD-DVD500H

TEST MODE 2

Set TUNER PRESET MEMORY according to the following conditions for each destination.

Conditions

Function

Function

: TUNER

Band

: FM MONO

Frequency

: LOW FREQUENCY

Preset last channel

: FM - 1 channel, AM - 6 channels

Volume

: LAST MEMORY

Balance

: CENTER (A

µ

-com only)

Preset G-EQ

: FLAT

X-Bass

: OFF

PRESET LIST

1

2

3

4

5

6

7

8

9

10

FM

FM

FM

FM

FM

AM

AM

AM

AM

AM

87.50 MHz

108.00 MHz 90.00 MHz

106.00 MHz 98.00 MHz

522 kHz

1620 kHz

603 kHz

1404 kHz

990 kHz

TEST MODE 3 (FUNCTION: KEY AND LAST DISPLAY) (Test mode for the production)

TEST 3

ODD

GRID LIGHT UP.

EVEN

GRID LIGHT UP.

1. 0sec TIMER (WAIT)

1. 0sec TIMER (WAIT)

LIGHT OFF

KEY INPUT

KEY INPUT =

"POWER"?

While each KEY INPUT is performed,

the display allocated to the key appears.

the display allocated to the key appears.

POWER OFF.

TEST CANCEL.

NOTES: 1. REMOCON input in test mode is invalid.

2. Volume "0"

• This is a test mode for producing CD-DVD500H. Do not use except when servicing.

FUNCTION: KEY AND LAST DISPLAY

After the odd grids, even grids and FL pipe segment light up according to each KEY, turn the power off to cancel TEST MODE.