Panasonic CF-T4HWETZBM Service Manual ▷ View online

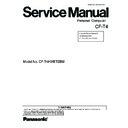

6.3.4.

Assembly of Touch Pad

The hooks are hooked

The hooks are inserted

Pad Cover

Putting of pad cover

It is confirmed that all

LED lenses fit in the

hole of the pad cover

LED lenses fit in the

hole of the pad cover

Pin for positioning

Touch Pad

The touch pad

is put

is put

Putting of Touch Pad

Touch Pad

PAD FFC

Insertion of PAD FFC

PAD FFC is

inserted in the

connector.

(Direction where

the reinforcement

version is seen)

inserted in the

connector.

(Direction where

the reinforcement

version is seen)

Sets in the dent

PAD sheet

Putting of PAD sheet

This line must

become vertical

become vertical

After putting of the

PAD sheet, the

Flaking off paper is

peeled off

PAD sheet, the

Flaking off paper is

peeled off

Pad button

Latch is inserted in the top case(4 places)

Installation of Pad button

Puted in the gasket

ditch

ditch

Inserted in the

positioning pin

positioning pin

Putting of PAD cover tape

0.5mm

1mm

1mm

1mm

2mm

PAD cover

PAD cover tape

6.3.5.

Processing of DC-IN Cable and Coaxial Cable

The cable is processed to

the ditch of the bottom case

the ditch of the bottom case

The cable is processed with

the boss between ribs

the boss between ribs

Confirm the terminal is vertical

Coaxial cable

6.3.6.

Obtaining of Side Cover (L)

DC Jack Holder

the under hooks is hooked

the bottom case

the bottom case

the under hooks is hooked

the bottom case

the bottom case

Side Cover(L)

The upper part is shut with

lower hooks put on the

bottom case.

lower hooks put on the

bottom case.

39

6.3.7.

Processing of MODEM Cable and LAN Cable

LAN Cable

MODEM Cable

PET Tape

Insert LAN cable

previously

previously

The cable is

processed with the

boss between ribs

processed with the

boss between ribs

USB Sheet

The USB sheet

is put and the

cable is held

is put and the

cable is held

Standard

The cable

must enter

in the set of

3-5mm

must enter

in the set of

3-5mm

The state that the tension hangs is NG

Give slack

to the drawing

out part

to the drawing

out part

6.3.8.

Processing of USB Cable

Do not run aground in the boss

USB Board

PET Tape

PET Tape

0

2mm

0

2mm

The Cable must not enter under the

HDD unit

Do not run aground in the boss

HDD Unit

Boss

Process the line to 3 cables in parallel based on

the difference of the concave part of the bottom

case

Order is USB, modem, and LAN cable from this

side

the difference of the concave part of the bottom

case

Order is USB, modem, and LAN cable from this

side

6.3.9.

Screw tightening procedure of Each Unit

When serving, the screw tightening is executed according to the undermentioned procedure.

1. Screw tightening of top case

1-1. DXQT2+E6FNL(K:N12) is tightened. No.1 to No.3

1-2. DXQT26+D8FCL(L:N15) is tightened. No.4 ,No.5

1-3. DXHM0056ZA(J:N6) is tightened. No.6

Screw(L)

Screw(J)

Screw(K)

Screw(K)

Screw(J)

Screw(K)

40

2. Attachment preparation of Key Board

2-1. Putting of Heat Sheet KB Large

Touch the KB hole

Touch the KB hole

Inclination is set

to 0.5mm or less.

to 0.5mm or less.

Inclination is set

to 0.5mm or less.

to 0.5mm or less.

2-2. Putting of tape

0

1mm

0

1mm

8

1mm

0.5

1.5mm

0.5

1.5mm

Tape(KBD)

KeyBoard exterior and FPC are parallel.

(KBD)

0

0.5mm

3. Screw tightening of bottom case (1)

The keyboard is inserted, and after the keyboard hooks are inserted in order of a and b while holding the keyboard, the screw

tightening is done in the following order.

tightening is done in the following order.

Note:The sheet metal must not run aground on the rib (Refer to the figure below).

2-1. DXHM0039ZA(D:N5) is tightened. No.1 to No.7

2-2. DXHM0057ZA(G:N7) is tightened. No.8 to No.12

Keyboard

Hook

Hook

Top Case

Top Case Rib

OK

NG

Assembly reference chart

Screw(G)

Screw(G)

Screw(D)

Screw(D)

Screw(D)

Screw(D)

Screw(G)

Screw(G)

Screw(G)

Screw(D)

Screw(D)

Screw(D)

Keyboard Hook a

Keyboard Hook b

41

4. Screw tightening of bottom case (2)

The keyboard is inserted, and after tightening of the screw, the keyboard hooks are inserted in order of the following.

3-1. DXQT2+E12FNL(B:N11) is tightened. No.1 to No.4

3-2. DXQT2+D4FNL(F:N9) is tightened. No.5

3-3. DXQT2+E10FNL(E:N10) is tightened. No.6

3-4. DFHE5035ZA(H:N2) is tightened. No.7

3-5. DFHE5025XA(C:N501) is tightened. No.8

3-5. KIYE50000022(I:N500) is tightened. No.9

Screw(E)

Screw(F)

Screw(H)

Screw(I)

Screw(B)

Screw(C)

Screw(B)

Screw(B)

Screw(B)

6.3.10. Affixation of Win Logo Label (XP), CENTRINO Label and Energy Star Label

2

5mm

2

5mm

2

5mm

5

7mm

Win Logo Label(XP)

CENTRINO Label

Energy Star Label

Top Case

In the inclination at the time of putting the win logo label,

the CENTRINO label and energy star label the both ends

difference is within 0.2mm

the CENTRINO label and energy star label the both ends

difference is within 0.2mm

<Attention>

Confirm whether the paste of the label has overflowed

after the win logo label and putting of the CENTRINO label

and energy star label.

Confirm whether the paste of the label has overflowed

after the win logo label and putting of the CENTRINO label

and energy star label.

42

Click on the first or last page to see other CF-T4HWETZBM service manuals if exist.