Panasonic KV-S5076H / KV-S5046H Service Manual ▷ View online

113

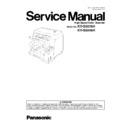

Bent Paper

Sensor

Sensor

1. Click “Bent Paper Sensor” on the main menu.

2. Place the Bend Paper Sensor Adjustment Tool(See 14.8.) on

2. Place the Bend Paper Sensor Adjustment Tool(See 14.8.) on

the Feed Tray.

Then push the Bend Paper Sensor Adjustment Tool in the

direction of the arrow untile they stop.

Note : Please select the "Auto"at the manual feed selec-

Then push the Bend Paper Sensor Adjustment Tool in the

direction of the arrow untile they stop.

Note : Please select the "Auto"at the manual feed selec-

tor.

3. Lay the Shading Sheet (See 14.8.) on the Bend Paper Sen-

sor Adjustment Tool.

4. Click “Adjust Automatically" to adjust the sensor level.

(Confirm all of the sensor status is “ON".)

5. Click "OK" to return to the main menu.

(Confirm all of the sensor status is “ON".)

5. Click "OK" to return to the main menu.

—

Item

Operation

Default

Remarks

Manual feed selector

Bend Sensor

Adjustment Tool

Adjustment Tool

Shading Paper

114

9.3.9.

Other (Save Information)

Click “Save Info” on the main menu to save the scanner and the PC information as text files.

* USB ID

1. Click “USB ID” on the main menu to enter the “USB ID”

dialog box.

2. Click “Set” on the “USB ID” dialog box to store a new ID

number for a new replaced CONTROL Board.

3. Click “Close” to return to the main menu.

dialog box.

2. Click “Set” on the “USB ID” dialog box to store a new ID

number for a new replaced CONTROL Board.

3. Click “Close” to return to the main menu.

—

*This setting is available only

for a new replaced

CONTROL Board or IC0004.

for a new replaced

CONTROL Board or IC0004.

Feed Speed

1. Click “Feed Speed” on the main menu.

2. Change the parameter (%: 10 to 100).

3. Click “OK” to renew the setting, and to return to the main

menu.

Note:

2. Change the parameter (%: 10 to 100).

3. Click “OK” to renew the setting, and to return to the main

menu.

Note:

1. Reducing the Feed Speed to slow may reduce the

number of paper-jams or double-feeds.

2. Setting this parameter to too low may cause

a paper-feed problem. After changing the

parameter, make sure to perform the scanning test,

and to confirm that paper-jams do not occur.

number of paper-jams or double-feeds.

2. Setting this parameter to too low may cause

a paper-feed problem. After changing the

parameter, make sure to perform the scanning test,

and to confirm that paper-jams do not occur.

100 %

Sensor Sensitive

Level

Level

1. Click “Sensor Sensitive Level” on the main menu.

Note:

Note:

The adjustment is done for all the sensors below at

a time.

Waiting Sensor, Slip Detect Sensor, Starting Sensor,

Ending Sensor, Skew(R) Sensor*, Skew(L) Sensor*.

*KV-S5076H only

So be sure to clean before adjusting and remove dust

thoroughly from the sensors and reflectors at the oppo-

site side with a cotton swab.

*If dust remains on them, the adjustment is not done

properly and the paper detection may not be able to

work.

a time.

Waiting Sensor, Slip Detect Sensor, Starting Sensor,

Ending Sensor, Skew(R) Sensor*, Skew(L) Sensor*.

*KV-S5076H only

So be sure to clean before adjusting and remove dust

thoroughly from the sensors and reflectors at the oppo-

site side with a cotton swab.

*If dust remains on them, the adjustment is not done

properly and the paper detection may not be able to

work.

2. Click “Adjust” on the “Sensor Sensitive Level” dialog box to adjust

the sensor Sensitive level. Check each sensor’s sensitive level

(Offset, LED Current, Slice) on the Sensor Sensitive Level dialog box.

the sensor Sensitive level. Check each sensor’s sensitive level

(Offset, LED Current, Slice) on the Sensor Sensitive Level dialog box.

3. Click “Close” to return to the main menu.

Item

Operation

Default

Remarks

115

9.4.

Scanner Self-test

Without connecting the scanner to the PC, the following scanner self-test can be performed. The following mechanical test is

generally used after replacing or reassembling rollers (Drive Rollers) and other mechanical parts related to feeding documents.

generally used after replacing or reassembling rollers (Drive Rollers) and other mechanical parts related to feeding documents.

Test Item

Operation

LED or Indicator Status

Remarks

*8

Indicators

(Control Panel)

*8

LED (Back)

1. Paper Feed

Motor rotation

Motor rotation

1 While pushing the “START/STOP Key” on the Control

Panel, turn on the scanner.

—

—

2 Release the key after LED (Back) status changes to

blinking.

OFF

Blinking

3 Push the “START/STOP Key” once to enter the test

selection mode.

Blinking

Count

4 Push the “START/STOP Key” once at the timing when

LED (Back) status is 1 (h)

*1

.

5 Push the “START/STOP Key” to start rotating the

Paper Feed Motor and Separation Motor.

6 Push the “START/STOP Key” to stop the rotating.

7 Turn off the scanner to finish this test.

—

—

2. Conveyor

Motor rotation

Motor rotation

1 While pushing the “START/STOP Key” on the Control

Panel, turn on the scanner.

—

—

2 Release the key after LED (Back) status changes to

blinking.

OFF

Blinking

3 Push the “START/STOP Key” once to enter the test

selection mode.

Blinking

Count

4 Push the “START/STOP Key” once at the timing when

LED (Back) status is 2 (h)

*2

.

5 Push the “START/STOP Key” to start rotating the

Conveyor Motor.

6 Push the “START/STOP Key” to stop the rotating.

7 Turn off the scanner to finish this test.

—

—

3. DFP Pressure

Motor rotation

Motor rotation

1 While pushing the “START/STOP Key” on the Control

Panel, turn on the scanner.

—

—

2 Release the key after LED (Back) status changes to

blinking.

OFF

Blinking

3 Push the “START/STOP Key” once to enter the test

selection mode.

Blinking

Count

4 Push the “START/STOP Key” once at the timing when

LED (Back) status is 3 (h)

*3

.

5 Push the “START/STOP Key” to start rotating the

DFP Pressure Motor.

6 Push the “START/STOP Key” to stop the rotating.

7 Turn off the scanner to finish this test.

—

—

4. Hopper Drive

1 While pushing the “START/STOP Key” on the Control

Panel, turn on the scanner.

—

—

2 Release the key after LED (Back) status changes to

blinking.

OFF

Blinking

3 Push the “START/STOP Key” once to enter the test

selection mode.

Blinking

Count

4 Push the “START/STOP Key” once at the timing when

LED (Back) status is 4 (h)

*4

.

5 Push the “START/STOP Key” to start to execute the

open/close operation of the gate.

6 Push the “START/STOP Key” to stop the rotating.

7 Turn off the scanner to finish this test.

—

—

116

5. Feed

1 While pushing the “START/STOP Key” on the Control

Panel, turn on the scanner.

—

—

2 Release the key after LED (Back) status changes to

blinking.

OFF

Blinking

3 Push the “START/STOP Key” once to enter the test

selection mode.

Blinking

Count

4 Push the “START/STOP Key” once at the timing when

LED (Back) status is 5 (h)

*5

.

5 Set documents on the Feed Tray.

6 Push the “START/STOP Key” to feed documents.

7 Turn off the scanner to finish this test.

—

—

6. Shading

1 While pushing the “START/STOP Key” on the Control

Panel, turn on the scanner.

—

—

Before executing the

shading function, be

sure to clean the

Scanning Glass (F),

Scanning Glass (B),

Reference Plate (F),

Reference Plate (B),

rollers, and

conveyors related to

conveying

documents.

shading function, be

sure to clean the

Scanning Glass (F),

Scanning Glass (B),

Reference Plate (F),

Reference Plate (B),

rollers, and

conveyors related to

conveying

documents.

Until this process

is completed,

don’t stop the

process by

opening any doors

or turning off the

scanner.

is completed,

don’t stop the

process by

opening any doors

or turning off the

scanner.

2 Release the key after LED (Back) status changes to

blinking.

OFF

Blinking

3 Set the Shading Sheet (Part No.: See 14.8.) on the

Hopper in landscape orientation.

OFF

Blinking

4 Push the “START/STOP Key” once to enter the test

selection mode.

Blinking

Count

5 Push the “START/STOP Key” once at the timing when

LED (Back) status is 6 (h)

*6

.

6 Push the “START/STOP Key” for 5 seconds or more to

start shading.

7 When the Ready and Error Indicators start to blink,

reverse Reference Plates to white after opening the

ADF Door. And then close the ADF Door.

ADF Door. And then close the ADF Door.

8 Paper feeding starts to execute the shading.

(At this time, the Error Indicator status changes from

blinking to OFF.)

blinking to OFF.)

9 When the Ready and Error Indicators start to blink

again, reverse Reference Plates to black after opening

the ADF Door. And then close the ADF Door.

the ADF Door. And then close the ADF Door.

10 After confirming the Ready Indicator turns ON and the

Error Indicator turn OFF, turn off the scanner to finish

this test.

this test.

—

Click on the first or last page to see other KV-S5076H / KV-S5046H service manuals if exist.