Panasonic KX-MB263RU / KX-MB263UA Service Manual ▷ View online

53

KX-MB263RU/KX-MB263UA

wave form

54

KX-MB263RU/KX-MB263UA

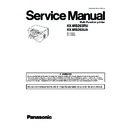

6.16. POWER SUPPLY BOARD SECTION

The power supply board circuit generates +7V and +24Vdc. It also supplies

AC voltage to the halogen heat lamp in the fuser unit.

The power supply board uses the switching regulator method.

AC voltage to the halogen heat lamp in the fuser unit.

The power supply board uses the switching regulator method.

[Input Circuit]

The input current goes into the input rectifier circuit through the filter circuit.

The filter circuit decreases the noise voltage and the noise electric field strength.

The filter circuit decreases the noise voltage and the noise electric field strength.

[Rectifier Circuit]

The input circuit is rectified by D10 to D13 and charge C5 to make DC voltage.

Then it supplies power to the converter circuit.

Then it supplies power to the converter circuit.

[Kick-on Voltage Circuit]

Bias is applied to the Q1 gate via this circuit when the AC power is turned on and Q1 begins operating.

[Over Current Limiter (O.C.L)]

The highest drain current of Q1 is limited by a limit current circuit. The 24V output is limited by this circuit.

[Over Voltage Circuit]

If the 24V output increases because the error detecting circuit or control circuit is broken, Control circuit will recognize this signal

and output becomes 0V. D104 and D503 also prevent over voltage.

and output becomes 0V. D104 and D503 also prevent over voltage.

Dummy load method (to quickly check the power supply output)

Refer to POWER SUPPLY BOARD SECTION (P.124).

Input

Circuit

Circuit

AC

Input

Input

C5

G

H

24V

Kick-on

Voltage

Circuit

Voltage

Circuit

E

F

7V

HTRCTL

GND

Control

Circuit

Circuit

R4

R3

R2

Converter

Circuit

Circuit

C

D

Rectifier

Circuit

Circuit

A

B

+

Error Detecting

Circuit

Circuit

O.C.L

Q1

A-B Voltage Wave Form

C-D Voltage Wave Form

E-F

G-H Voltage Wave Form

0

0

0

T1

PC1

Triac

SCR51

SCR51

Heat Lamp

Photo Triac

Coupler PC2

Coupler PC2

Block Diagram

+

+

55

KX-MB263RU/KX-MB263UA

6.17. Mechanical Operation

6.17.1. PRINTING

The main motor gear rotates as shown in figure.

GEAR DRIVE OPC drives each part of fixing and developing.

When paper is fed from the standard cassette, the plunger of solenoid is pulled to drive PICK UP ROLLER (STANDARD), then

the roller starts feeding paper.

When paper is fed manually, first the plunger of solenoid is pulled to stop RESISTANT ROLLER. After a few moments turn off

the solenoid to drive RESISTANT ROLLER, then the roller starts feeding paper.

GEAR DRIVE OPC drives each part of fixing and developing.

When paper is fed from the standard cassette, the plunger of solenoid is pulled to drive PICK UP ROLLER (STANDARD), then

the roller starts feeding paper.

When paper is fed manually, first the plunger of solenoid is pulled to stop RESISTANT ROLLER. After a few moments turn off

the solenoid to drive RESISTANT ROLLER, then the roller starts feeding paper.

56

KX-MB263RU/KX-MB263UA

7 Location of Controls and Components

7.1.

OVERVIEW

7.1.1.

Front view

(1) Top cover

(2) Document cover

(3) Output cover

(4) Top cover release lever

(5) Paper input tray

(6) Recording paper exit

(2) Document cover

(3) Output cover

(4) Top cover release lever

(5) Paper input tray

(6) Recording paper exit

7.1.2.

Rear view

(1) Recording paper guides

(2) Power inlet

(3) Manual input tray (Rear cover)

(4) USB interface connector

(2) Power inlet

(3) Manual input tray (Rear cover)

(4) USB interface connector

Click on the first or last page to see other KX-MB263RU / KX-MB263UA service manuals if exist.