Panasonic CS-TZ20TKEW / CS-TZ25TKEW / CS-TZ35TKEW / CS-TZ42TKEW / CS-MTZ16TKE / CU-TZ20TKE / CU-TZ25TKE / CU-TZ35TKE / CU-TZ42TKE Service Manual ▷ View online

113

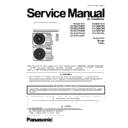

18.4.16 H97 (Outdoor Fan Motor – DC Motor Mechanism Locked)

Malfunction Decision Conditions

The rotation speed detected by the Hall IC during fan motor operation is used to determine abnormal fan motor.

Malfunction Caused

Malfunction Caused

Operation stops due to short circuit inside the fan motor winding.

Operation stops due to breaking of wire inside the fan motor.

Operation stops due to breaking of fan motor lead wires.

Operation stops due to Hall IC malfunction.

Operation error due to faulty outdoor unit PCB.

Troubleshooting

YES

NO

When abnormality indication starts again

Turn power supply on and operate fan.

Replace fan motor.

For safety reason and to prevent

component breakdown, always switch

off the power before remove and

connect the component.

component breakdown, always switch

off the power before remove and

connect the component.

Caution

Does fan rotate smoothly?

Turn off power supply and rotate fan by

hand.

hand.

Does it rotate?

CN-MTR2

(WHT)

IC19

3

5

1

10

14

16

W

U

V

FAN MOTOR

MS

CN-MTR1

PCB BOARD

5

4

3

2

1

C173

5V

R105

1k

C176

0.01μ

50V

G5

R111

1k

C177

0.01μ

50V

G5

R120

1k

C175

0.01μ

50V

G5

G5

+

YES

NO

YES

Turn off power supply and

disconnect fan motor CN-MRT2

disconnect fan motor CN-MRT2

Check resistance of the motor.

Measure at fan motor connector

CN-MRT1 (1-2, 1-3, 2-3).

Measure at fan motor connector

CN-MRT1 (1-2, 1-3, 2-3).

Replace outdoor PCB.

NO

Replace fan motor.

YES

NO

U

W

V

Replace fan motor.

Replace fan motor.

NO

Replace outdoor PCB.

Stop the fan motor

YES

Is the resistance normal?

Check the rotation feedback output from

fan motor’s CN-MTR1 output.

Rotate the fan motor manually (by hand)

while measure the voltage at PCB’s

CN-MRT1

-

fan motor’s CN-MTR1 output.

Rotate the fan motor manually (by hand)

while measure the voltage at PCB’s

CN-MRT1

-

Between 1(+) and 5(-)

-

Between 2(+) and 5(-)

-

Between 3(+) and 5(-)

Use an inverter check to check on

the power transistor on board.

the power transistor on board.

Do all 6 LED light turn ON and turn

OFF periodically?

OFF periodically?

Does the voltage at each terminal

becomes 5 and 0Vdc repeatedly?

becomes 5 and 0Vdc repeatedly?

Connect it to PCB’s CN-MRT2 port.

Turn power ON and run the unit.

Turn power ON and run the unit.

connector.

114

18.4.17 H98 (Error Code Stored in Memory and no alarm is triggered / no TIMER LED

flashing)

Malfunction Decision Conditions

Indoor high pressure is detected when indoor heat exchanger is detecting very high temperature when the unit is

operating in heating operation.

Phenomena: unit is stopping and re-starting very often in heating mode

Malfunction Caused

Malfunction Caused

Indoor heat exchanger thermistor

Clogged air filter or heat exchanger

Over-bent pipe (liquid side)

Troubleshooting

Troubleshooting

115

18.4.18 H99 (Indoor Freeze Prevention Protection: Cooling or Soft Dry)

Error Code will not display (no Timer LED blinking) but store in EEPROM

Malfunction Decision Conditions

Malfunction Decision Conditions

Freeze prevention control takes place (when indoor pipe temperature is lower than 2°C)

Malfunction Caused

Malfunction Caused

Air short circuit at indoor unit

Clogged indoor unit air filter

Dust accumulation on the indoor unit heat exchanger

2/3 way valve closed

Faulty indoor unit fan motor

Refrigerant

shortage

(refrigerant leakage)

Clogged expansion valve or strainer

Faulty indoor pipe temperature sensor

Faulty indoor unit PCB

Troubleshooting

Troubleshooting

116

18.4.19 F11 (4-way Valve Switching Failure)

Malfunction Decision Conditions

When indoor heat exchanger is cold during heating (except deice) or when indoor heat exchanger is hot during

cooling and compressor operating, the 4-way valve is detected as malfunction.

Malfunction Caused

Indoor heat exchanger (pipe) thermistor

4-way valve malfunction

Troubleshooting

Troubleshooting

* Check gas side pipe – for hot gas flow in cooling mode

Click on the first or last page to see other CS-TZ20TKEW / CS-TZ25TKEW / CS-TZ35TKEW / CS-TZ42TKEW / CS-MTZ16TKE / CU-TZ20TKE / CU-TZ25TKE / CU-TZ35TKE / CU-TZ42TKE service manuals if exist.